Nailing device for packaging carton

A carton and nailing machine technology, applied in packaging, transportation and packaging, papermaking, etc., can solve problems such as reducing the quality of nailing, and achieve the effect of improving efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

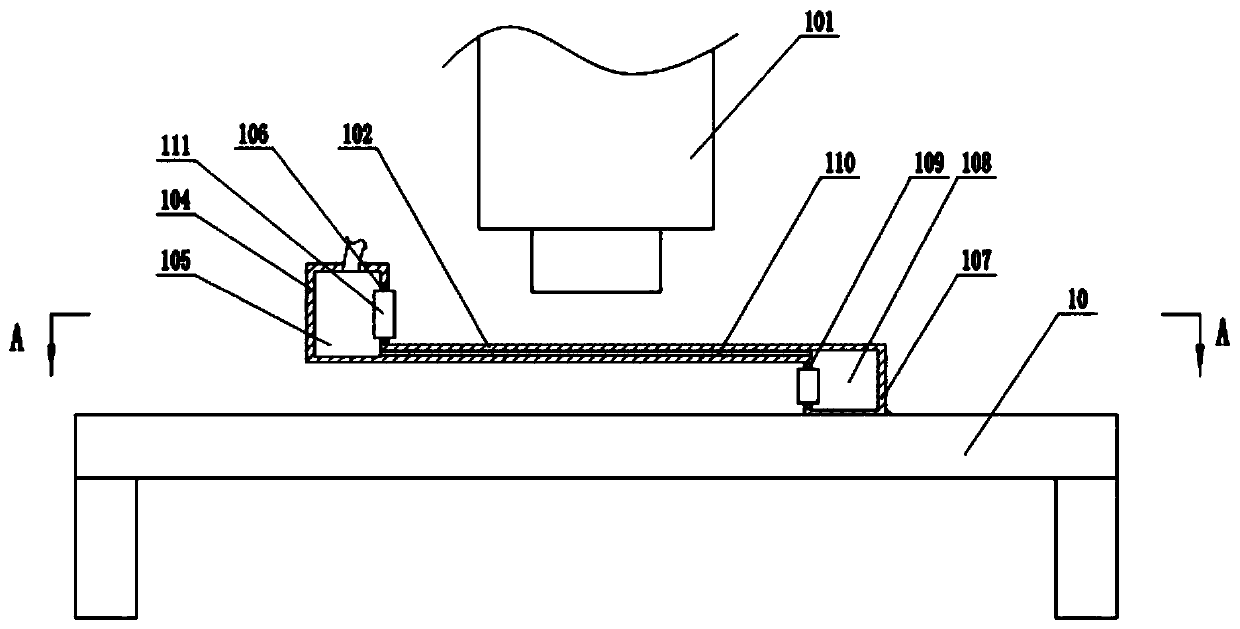

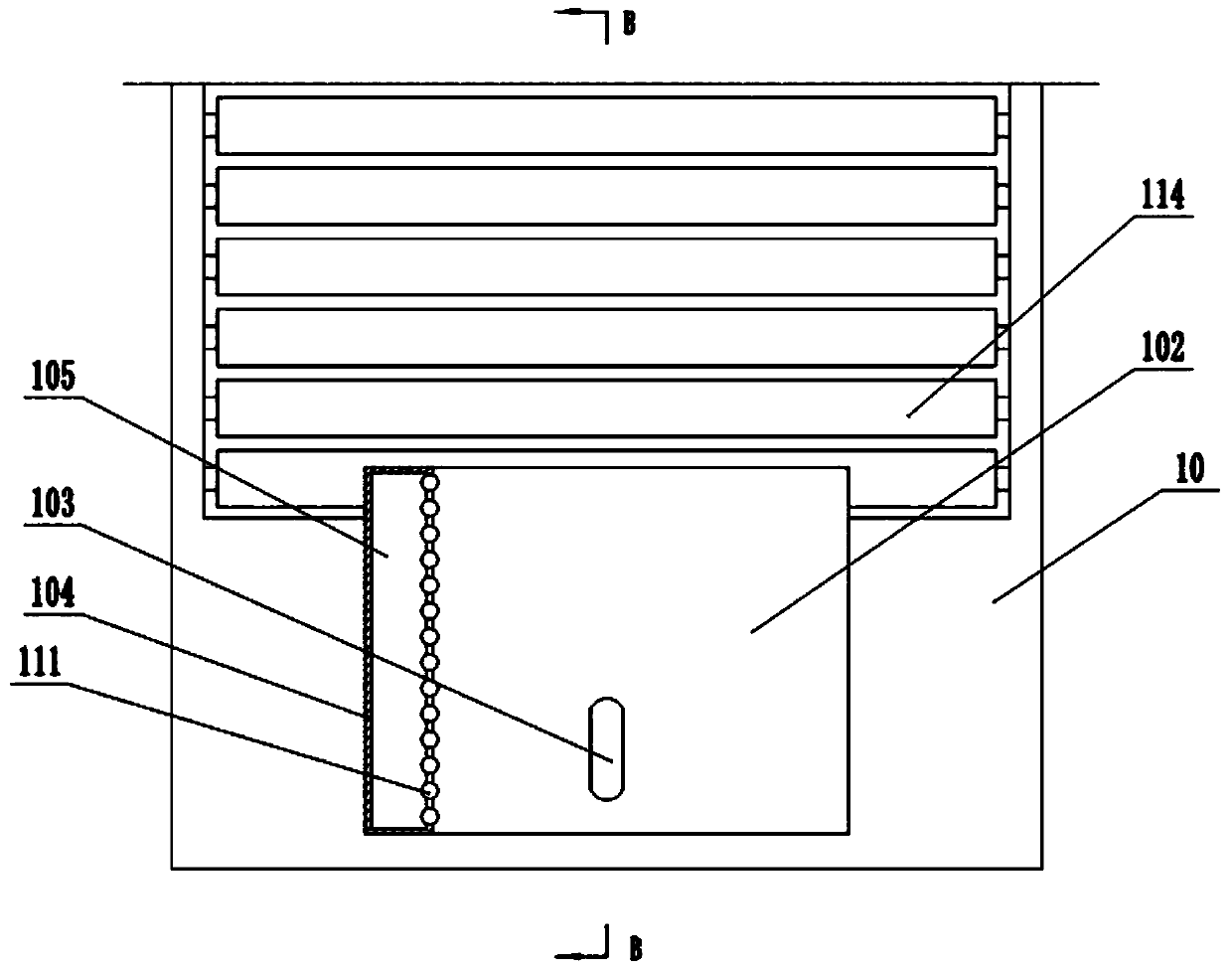

[0035] Embodiment 1 is basically as attached figure 1 with figure 2 Shown:

[0036] The nailing device for packaging cartons includes a workbench 10, a frame and a nailing machine 101, wherein the nailing machine 101 is fixed on the frame and is positioned above the workbench 10, and the nailing head of the nailing machine 101 is facing downwards. The workbench 10 is fixed with a horizontal plate 102 positioned below the nailing machine 101. The thickness of the horizontal plate 102 is no more than 1 cm. The upper left side is integrally formed with a first paper blocking box 104, and a first cavity 105 is opened in the first paper blocking box 104, and a first adsorption groove 106 communicating with the first cavity 105 is opened on the right side wall of the first paper blocking box 104 .

[0037] A second paper blocking box 107 is integrally formed under the right side of the horizontal plate 102, a second cavity 108 is opened in the second paper blocking box 107, and ...

Embodiment 2

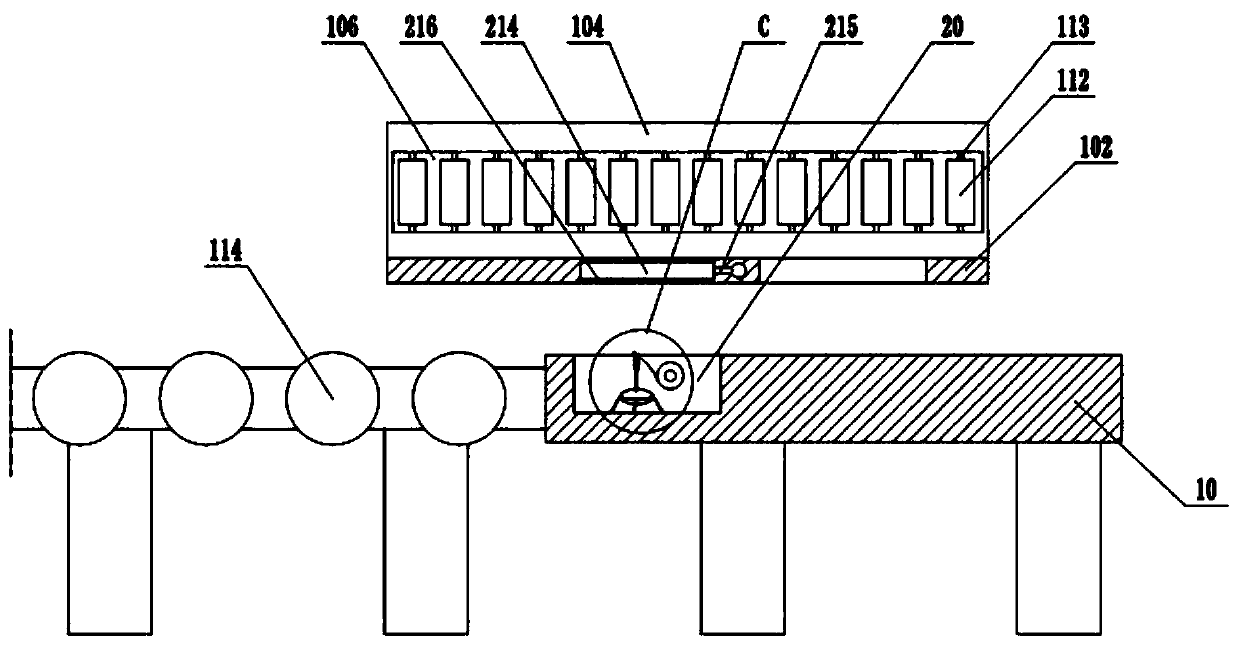

[0041] Embodiment 2 is basically as attached image 3 with Figure 4 Shown:

[0042] The difference from Embodiment 1 is that an installation groove 20 is provided on the workbench 10, and the installation groove 20 is located between the drum type transmission mechanism and the nailing machine 101, and is located below the horizontal plate 102. Adhesive mechanism, the gluing mechanism comprises the positioning bar 201 that horizontally rotates and is connected in the installation groove 20, and the adhesive cloth roll 202 is fixed on the positioning rod 201, is provided with the air bag 203 that is in the inflated state in the installation groove 20, and the air bag 203 outside sets limit The spacer ring 204 is provided with an elastic pull cord 205 fixed at the bottom of the installation groove 20 on the spacer ring 204 .

[0043] Cutting pieces are provided on the airbag 203, combined with Figure 4 As shown, the cutting member includes a vertical rod 206 bonded to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com