High temperature alloy spring for steam turbine steam locking and its processing method and detecting installation

A technology of superalloy and inspection device, applied in the direction of springs/shock absorbers, coil springs, mechanical equipment, etc., can solve the problems of difficult steam seal retraction and deformation, affecting the overall quality of the unit, and short service life of the spring sheet, etc. The effect of easy concession and deformation, enhanced market competitiveness, and improved thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The effect of the present invention will be described in detail below in conjunction with the examples.

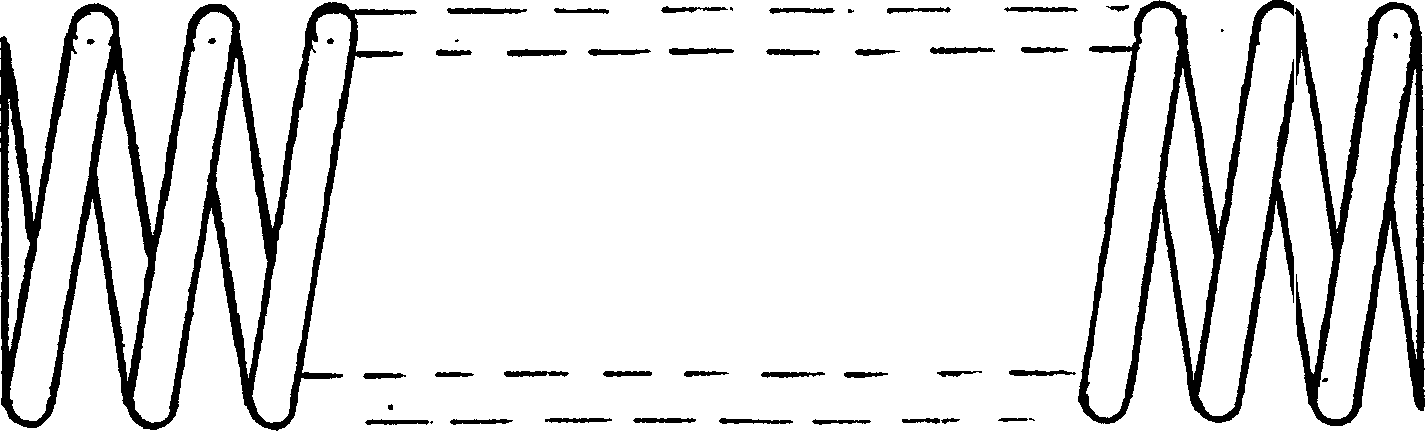

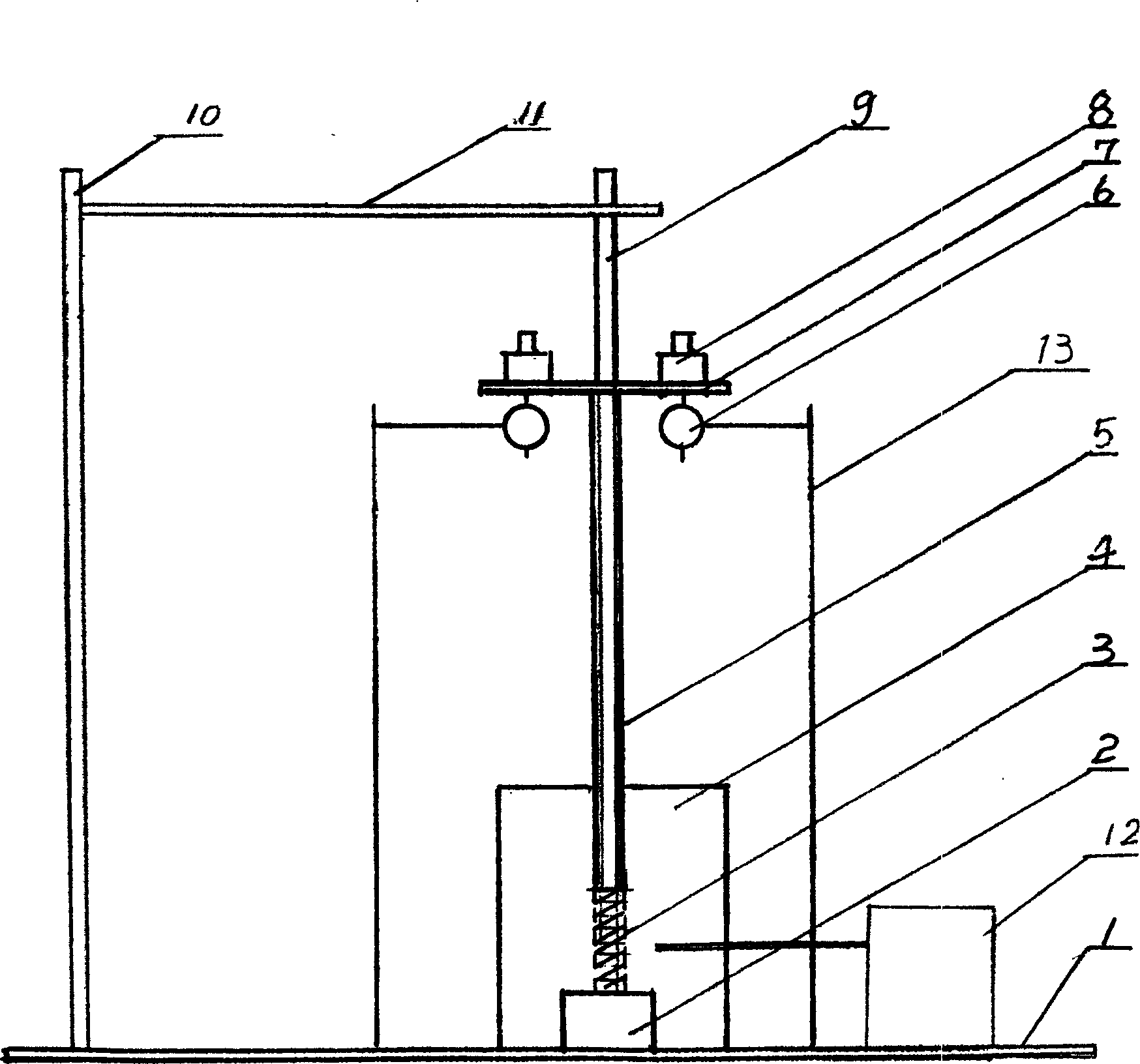

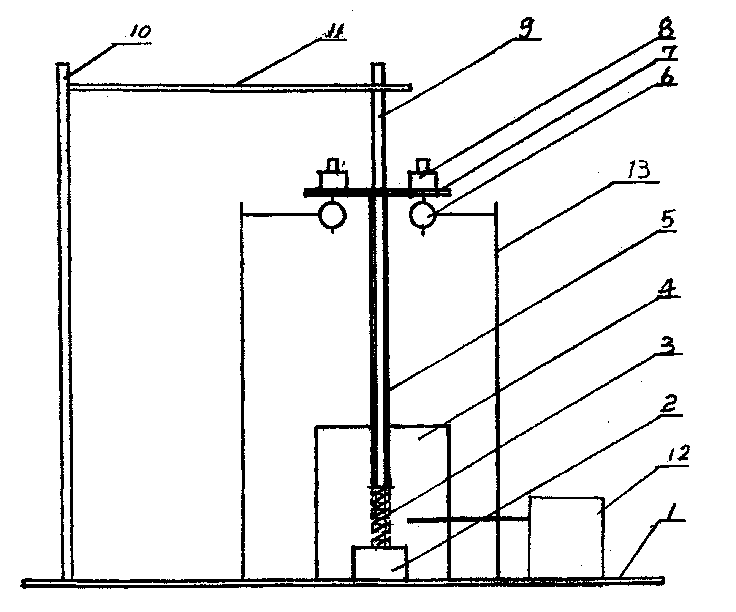

[0033] Spring structure of the present invention sees figure 1 The finished product is a cylindrical helical compression spring made of InconelX-750 (GH4145) alloy wire, and it can also be made into cylindrical helical tension springs, cylindrical helical torsion springs and other cylindrical helical springs.

[0034] figure 1 The finished product processing of the shape is completed in the following order: (1). According to the design specifications of the spring (the springs of drawing numbers Y47-171000A001, X300B-17300A001 and D300N-100000A-001, the outer diameters are 9mm, 10.5mm and 10.5mm respectively , the diameters of the spring wires are 1.2mm, 1.2mm and 1.5mm respectively, and the length of the mandrel is about 400mm). Take the alloy wire of the corresponding diameter and wind the long coil spring blank on the mandrel of the corresponding diameter; (2). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com