Composite steel wire net plate and preparation method thereof

A technology of composite steel wire and steel wire mesh, applied in screen printing machine, rotary printing machine, printing and other directions, can solve problems such as obvious gradient, and achieve the effect of reducing production and use cost, promoting development and improving quality level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The following is a further description of the technical solution of the present invention through specific embodiments in conjunction with the accompanying drawings.

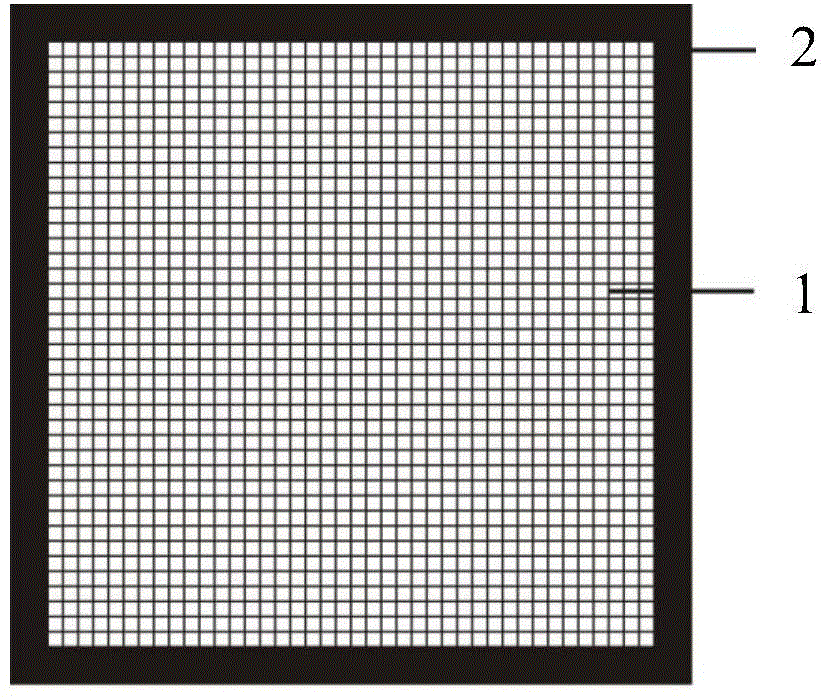

[0070] figure 1 It is a schematic diagram of the structure of the all-steel screen. After the stainless steel wire mesh cloth 1 is pulled up to a certain tension, it is bonded to the screen frame 2 as a whole to form a screen. Except for the screen frame, the entire screen surface is composed of stainless steel wire.

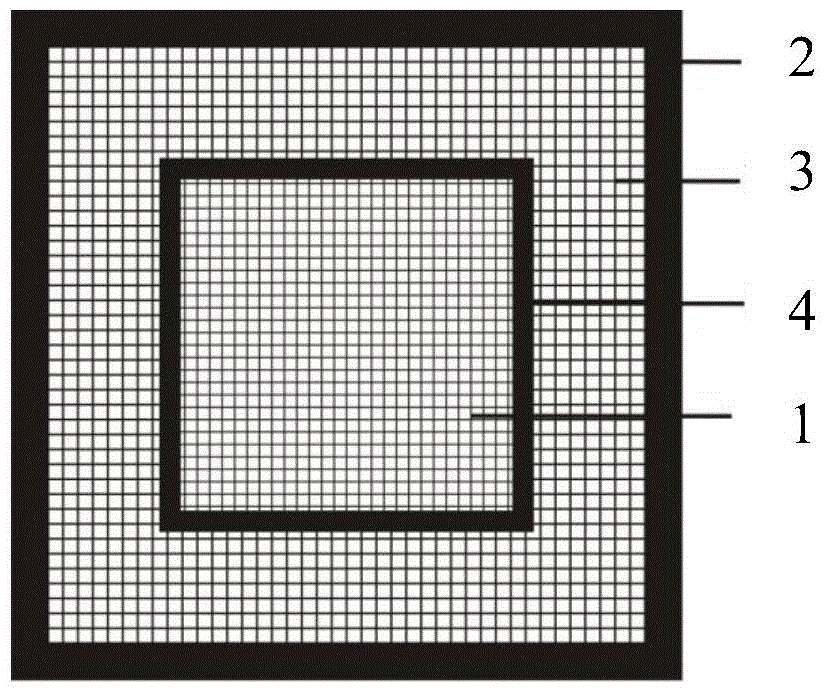

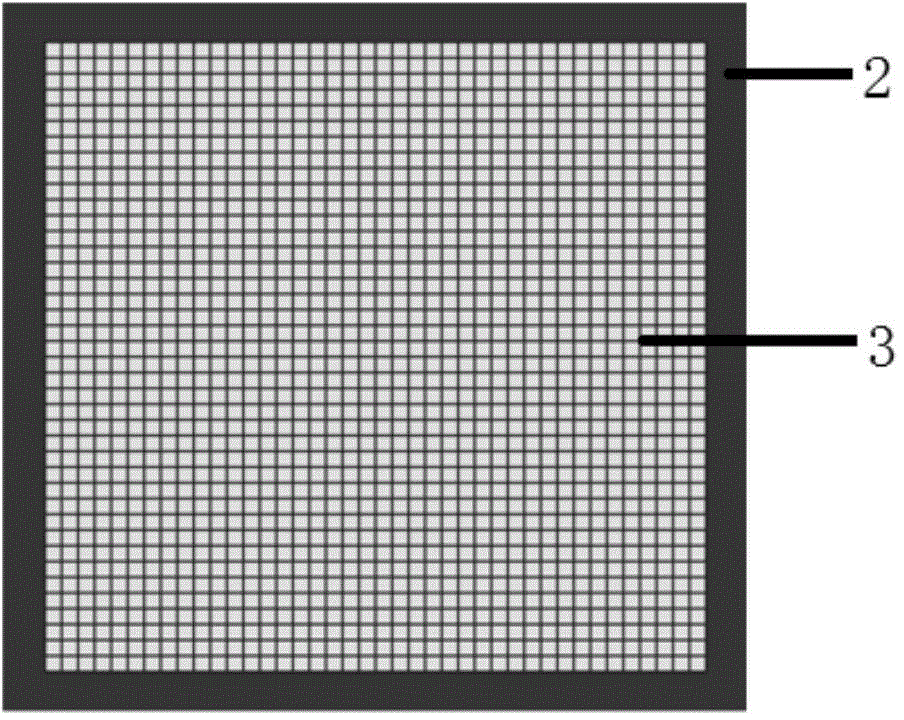

[0071] figure 2It is a schematic diagram of the structure of the composite steel mesh plate. First, the stainless steel mesh cloth 1 is cut into pieces according to the size and angle requirements; then the stainless steel mesh cloth 1 is composited in the polyester mesh cloth 3; and then the composite mesh is bonded A screen is formed on the screen frame 2. Except for the screen frame, the mesh surface is composed of polyester mesh cloth 3 and stainless steel wire mesh cloth 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com