Steel rolling steel plate simulation slitting quality judgment system and method

A technology for judging system and quality, applied in the field of steel rolling, can solve the problems such as the inability to guarantee the quality of the slit steel coils, the inability to meet the individual requirements of data analysis, the increase of work intensity and management costs, and to achieve advanced product quality control and quality control. The effect of inspecting, improving the quality level of the outgoing products, and improving the effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

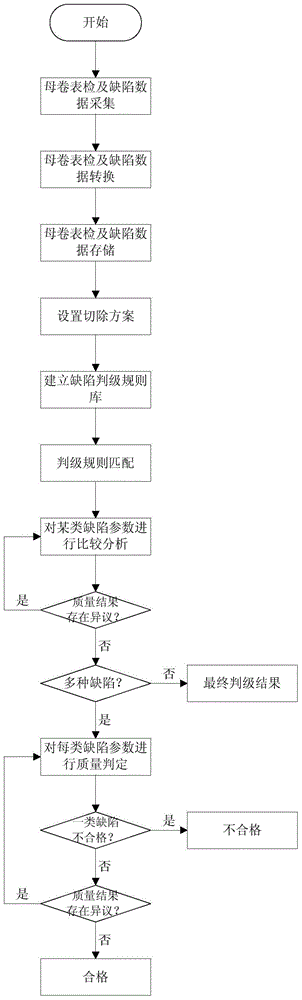

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

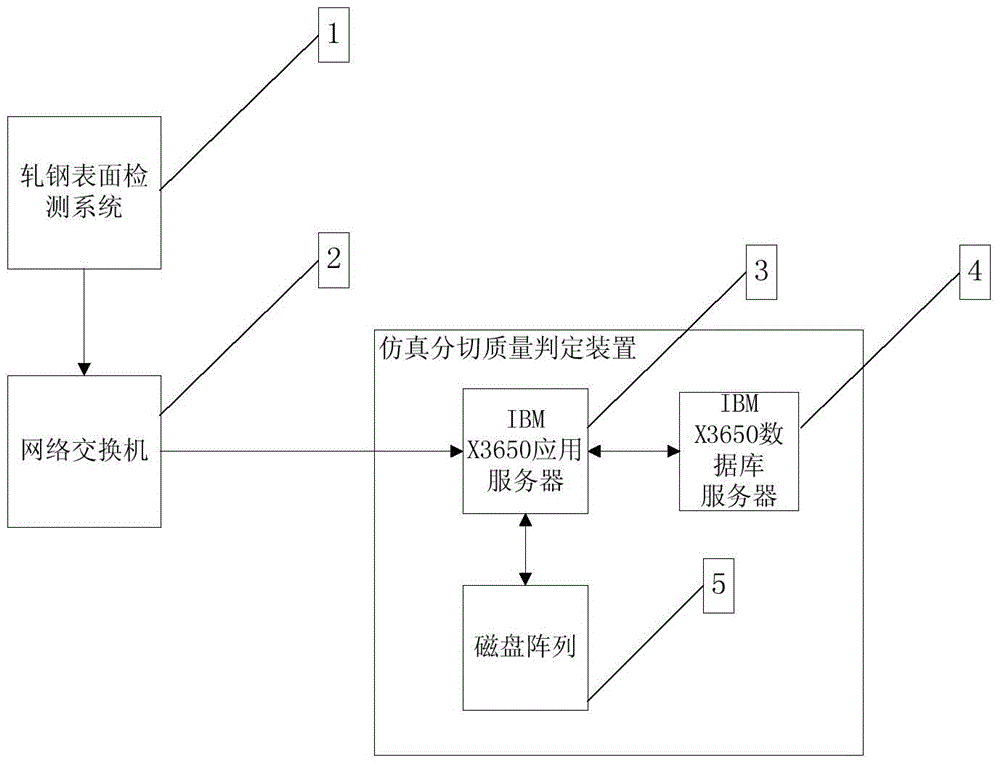

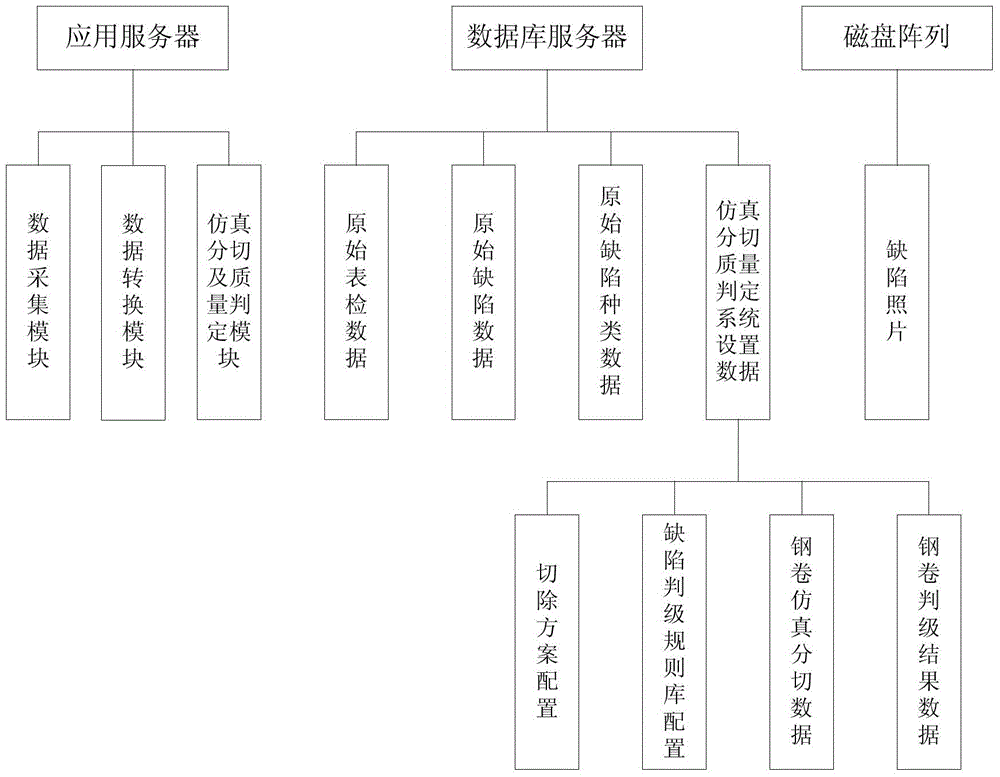

[0021] see figure 1 , the rolling steel plate emulation slitting quality judging system of the present invention comprises rolling steel surface detecting device 1, network switchboard 2, application server 3 and data storage device. The signal output end of said rolled steel surface detection device 1 (a steel coil surface defect collector has been installed on each steel rolling production line to collect steel coil surface defects) is connected to the signal input end of network switch 2, and the signal output end of said network switch 2 The signal output terminal is connected to the signal input terminal of the application server 3, and the signal input and output terminals of the application server 3 are connected to the signal input and output terminals of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com