Filter for processing machines, specially extruders

A screening device and extruder technology, applied in separation methods, filtration separation, membrane technology, etc., can solve problems such as difficult to clean, complicated structural manufacturing process, etc., and achieve the effect of expansion compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

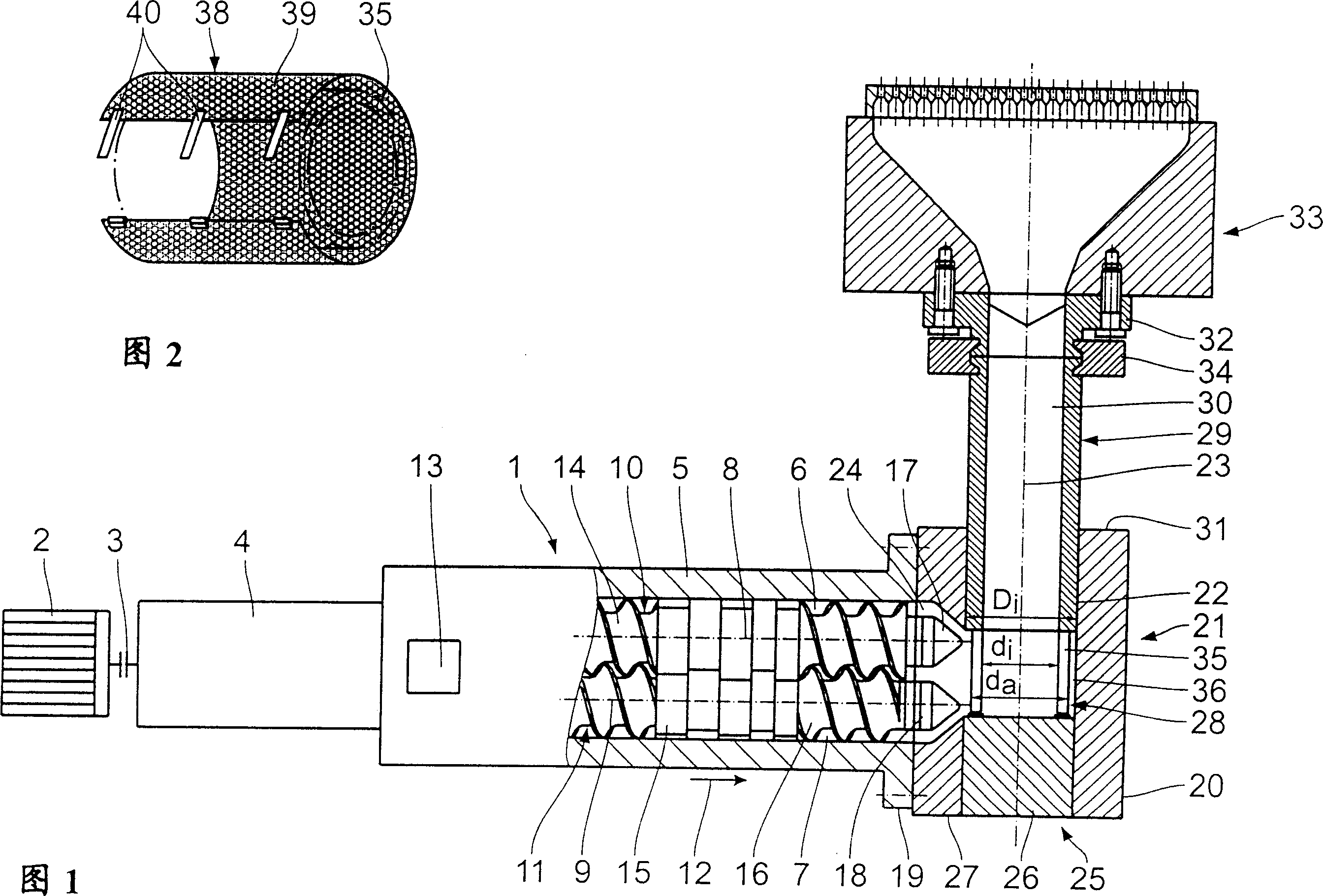

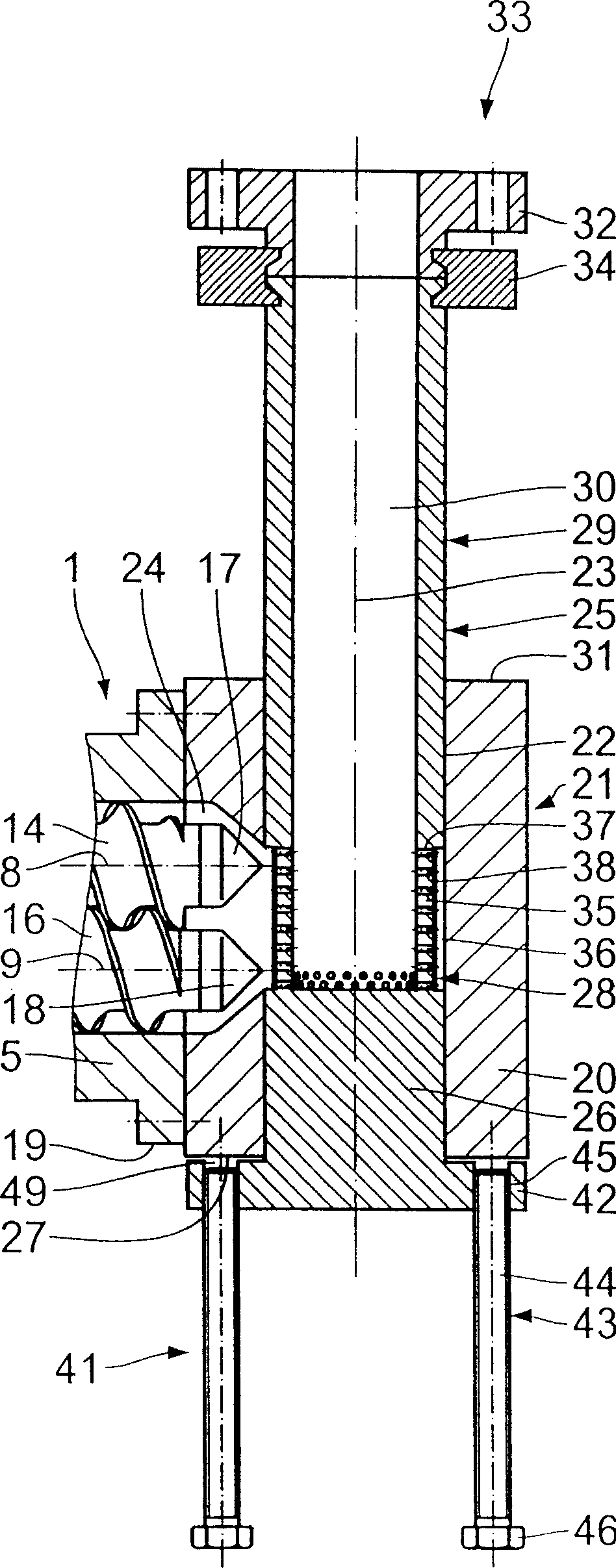

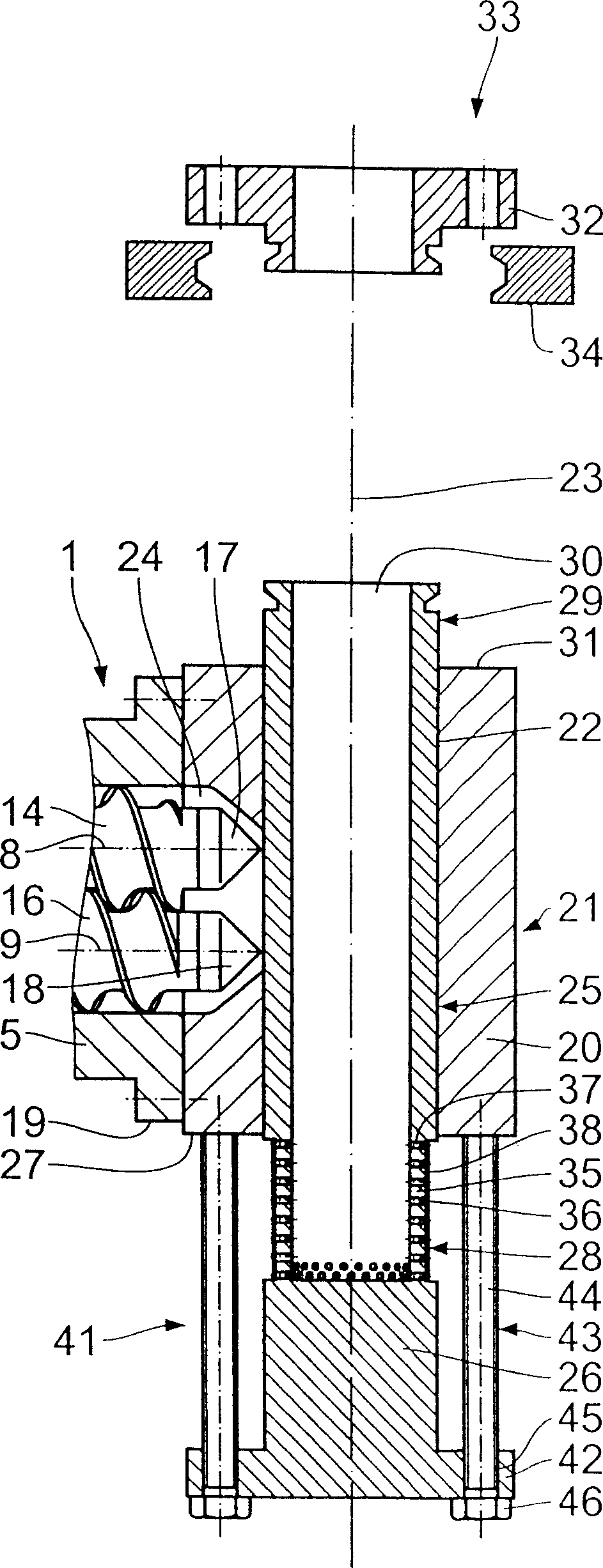

[0015] According to FIG. 1 , an extrusion device for producing, in particular, plastics has an extruder 1 . The extruder is driven by a motor 2 via a coupling 3 and transmission 4 . The extruder 1 has an extruder housing 5, two housing holes 6, 7 with mutually parallel axes 8, 9 are formed in the housing, and the housing holes are distributed parallel to each other and connected to each other to form a roughly "8". ” shape, two worm shafts 10, 11 connected to the transmission device 4 are arranged in the housing holes 6, 7. The worm shafts 10 , 11 are driven in the same direction or in opposite directions, and the extruder 1 has an inlet funnel 13 arranged downstream of the drive 4 in the conveying direction 12 , to which one or more treatment zones are connected. For this purpose, a worm part 14 , a kneading part 15 and again a worm part 16 are attached in sequence on the worm shafts 10 , 11 in the conveying direction. Worm tips 17 , 18 are formed at the rear ends of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com