Array substrate, display panel, methods for preparing array substrate and display panel, and display device

A technology for array substrates and display panels, which is applied in the direction of instruments, semiconductor devices, optics, etc., can solve the problems of poor sealability of the sealing glue and the bonded film layer, so as to avoid the influence of adhesion force and keep the seal performance, the effect of good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

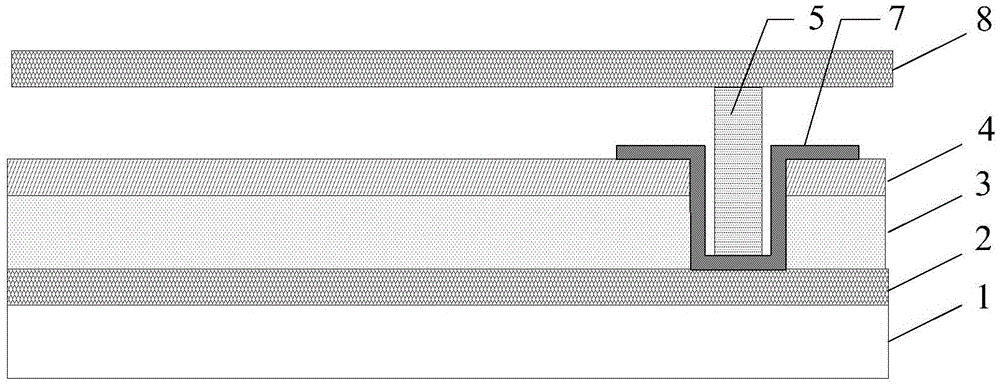

[0054] see Figure 4 , an embodiment of the present invention provides a method for preparing an array substrate, including:

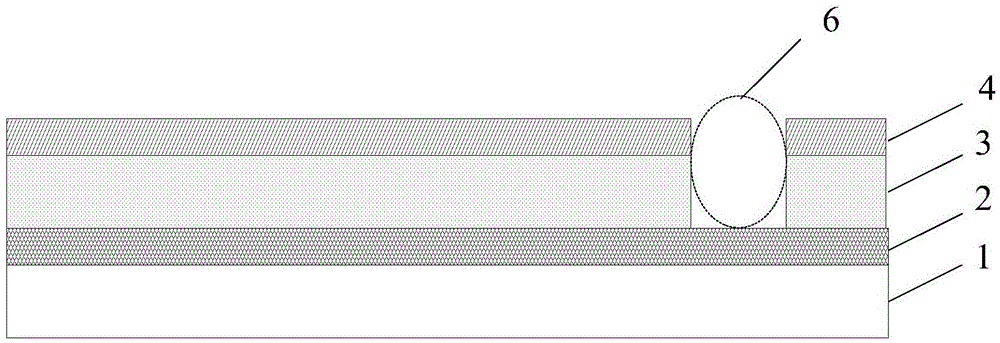

[0055] 401. Form a gate protection layer, an organic film layer, and an insulating layer in sequence on a base substrate.

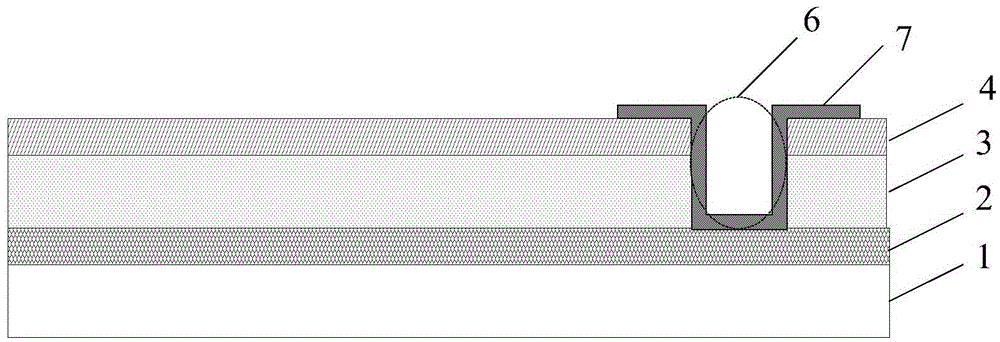

[0056] 402. Form a groove structure through a patterning process at a position for setting the sealant; wherein, the groove structure extends from the insulating layer to the gate protection layer in a direction perpendicular to the substrate, and exposes the gate protection layer.

[0057] preferred, see Figure 5 , the embodiment of the present invention provides another method for preparing an array substrate, including:

[0058] 501. Form a gate protection layer, an organic film layer, and an insulating layer in sequence on a base substrate.

[0059] 502. At the position for setting the sealant, form a groove structure through a patterning process; wherein, the groove structure extends from the insulating layer to the gate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com