Automated biogas dry fermentation device

A dry fermentation device and biogas technology, which is applied in biochemical cleaning devices, special-purpose bioreactors/fermenters, enzymology/microbiology devices, etc., can solve the problem of poor sealing, waste of manpower and material resources, and impact on biogas technology Promotion and other issues, to achieve the effect of good sealing performance, convenient feeding and discharging, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

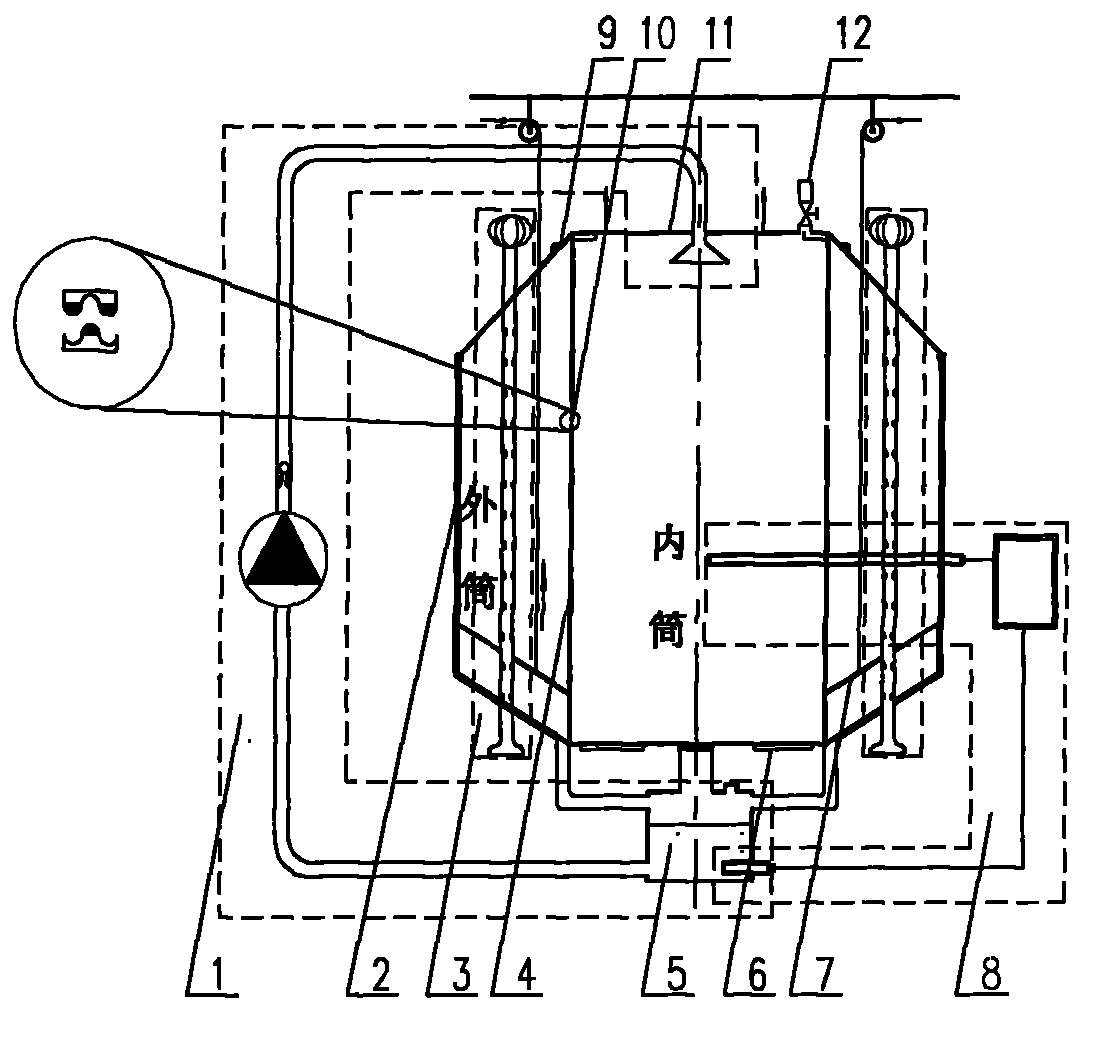

Embodiment approach 1

[0022] Embodiment 1: first crush the corn stalks to 3-5 cm, then use enzyme bacteria to treat the corn stalks, and then put them into the outer cylinder retting tank 2 through the outer cylinder feeding port 7 for retting, during which the oxygen required is determined by Natural and forced ventilation are supplied by a control system. After 5 days of retting, first the inner cylinder top cover 11 (the inner cylinder top cover 11 includes the inner cylinder cover and the inner cylinder wall part at the upper end of the inner cylinder feeding port 10) is lifted, and the inner cylinder The feed port 10 of the cylinder is exposed, and then the bottom plate 7 at the bottom of the retting tank 2 of the outer cylinder is pulled up by the rope, and the crushed corn stalks are squeezed into the anaerobic fermentation tank 4 of the inner cylinder through the feed port 10 of the inner cylinder for fermentation. After completion, the inner cylinder top cover 11 falls, and the inner cylind...

Embodiment approach 2

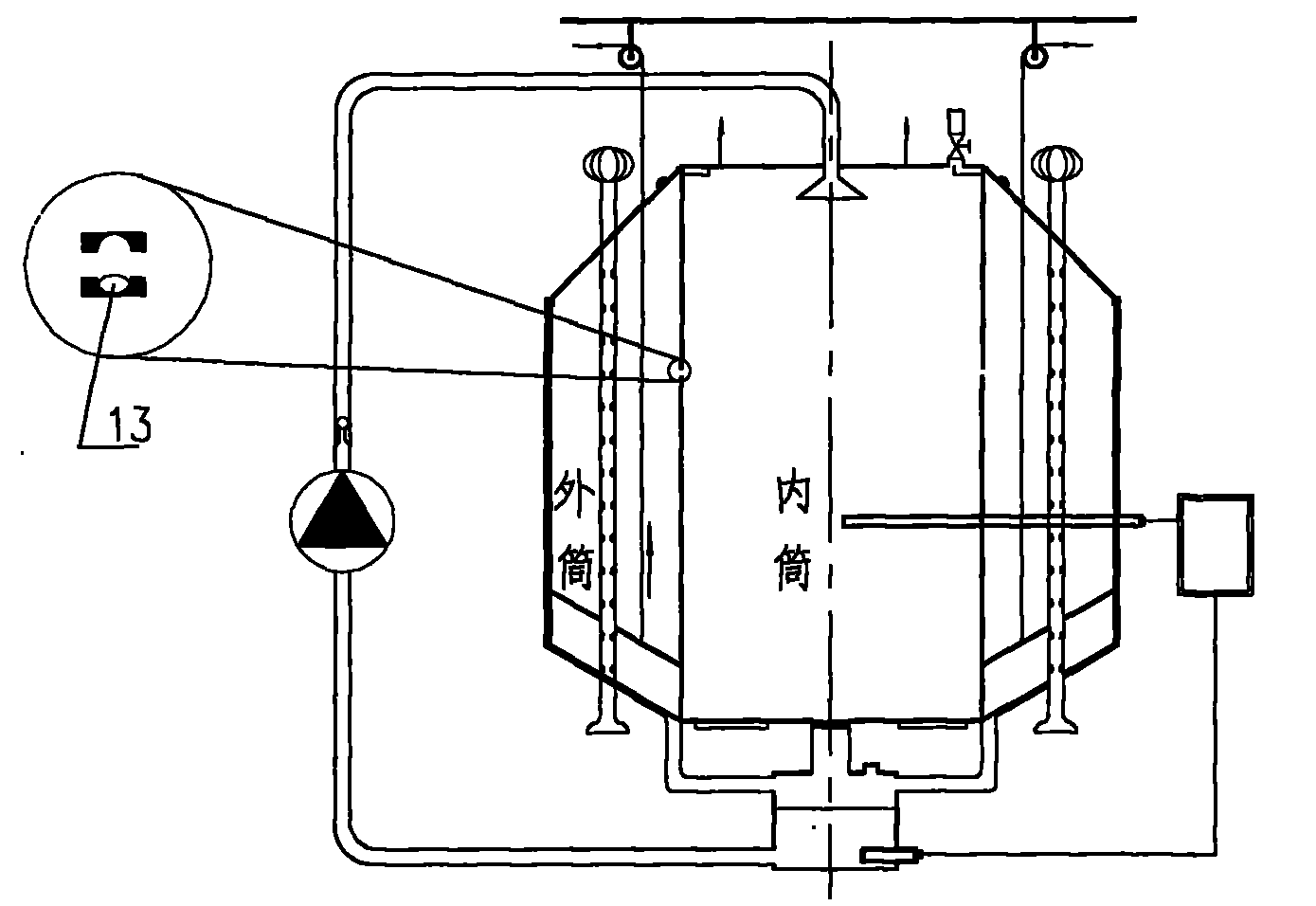

[0023] Embodiment 2: The operation mode of this program is the same as that of program 1, except that the sealing method when the inner cylinder feed port 10 is closed is an annular water ring seal, see figure 2 , there is a groove on the inner cylinder top cover 11 and the lower inner cylinder wall respectively, and an annular plastic water circle 4 is placed in the lower groove, when the inner cylinder top cover 11 is lifted, the water in the water circle 13 is drawn out, and the inner cylinder After the cylinder anaerobic fermentation tank 4 feed is completed, the inner cylinder top cover 11 falls, and this time, the water circle 13 is filled with water again.

Embodiment approach 3

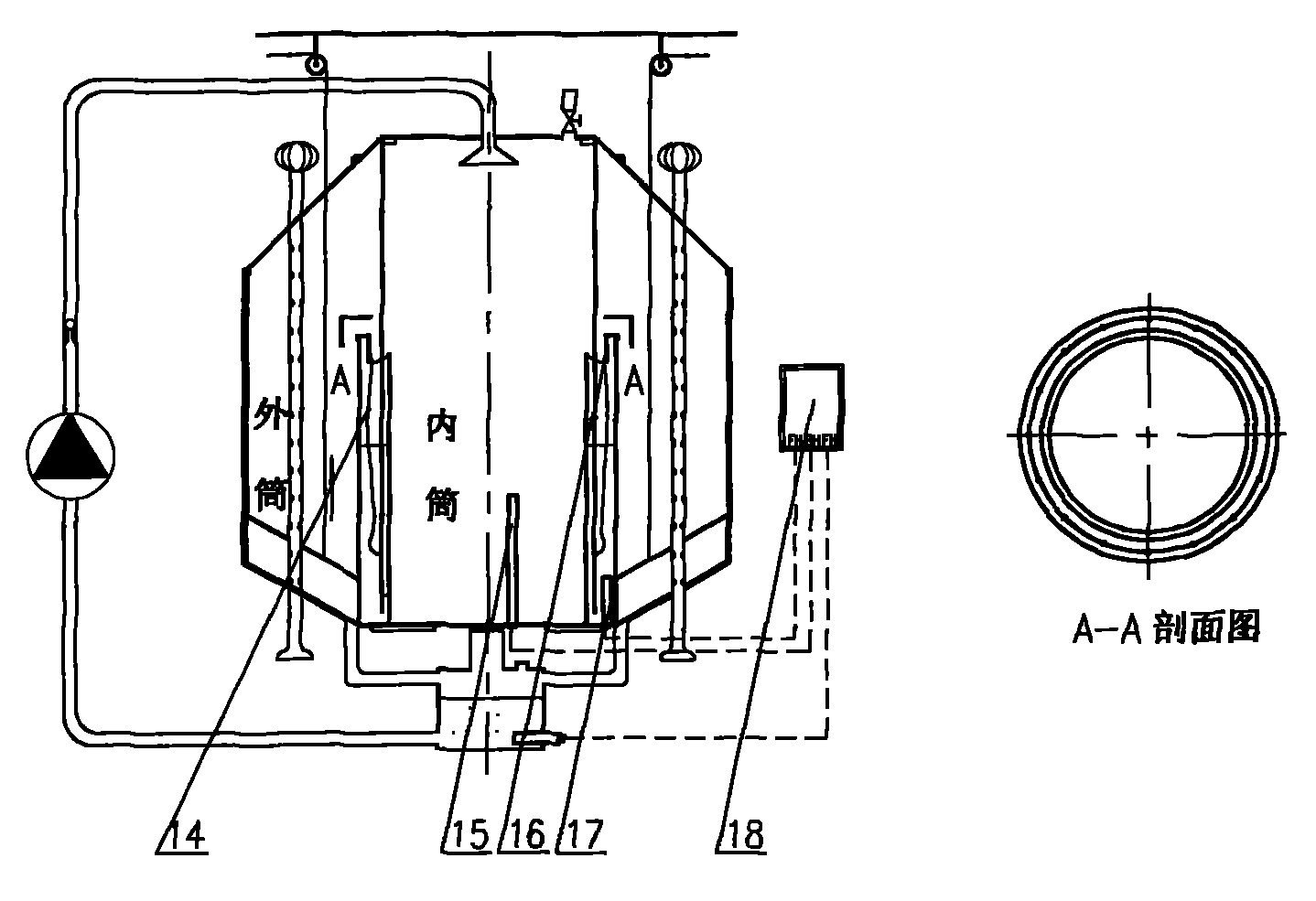

[0024] Implementation Option 3: See image 3 , the operation mode of the outer cylinder retting tank 2 of this scheme is the same as that of the scheme 1, but the feeding height of the outer cylinder retting tank 2 is lower than the height of the inner cylinder feeding port 10. The temperature sensor 15 originally inserted in the middle of the anaerobic fermentation tank 4 of the inner cylinder is now inserted into the bottom of the anaerobic fermentation tank 4 of the inner cylinder. The inner cylinder wall is surrounded by water, and an electric heater 17 is inserted in the water. 18 control, the heated water plays the role of heating and heat preservation on the material of the anaerobic fermentation tank 4 in the inner cylinder. In addition to being controlled by the original temperature control system 8, the temperature control of the inner cylinder anaerobic fermentation tank 4 is also guaranteed by the water outside the inner cylinder wall. In addition, the inner tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com