Diesel engine oil sump and casting technique

A diesel engine oil and housing technology, which is applied in the direction of engine components, engine lubrication, machine/engine, etc., can solve the problems of production capacity not meeting customer requirements, unsatisfactory sealing effect, large blank size error, etc., and achieve superior appearance , Excellent mechanical properties, good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings.

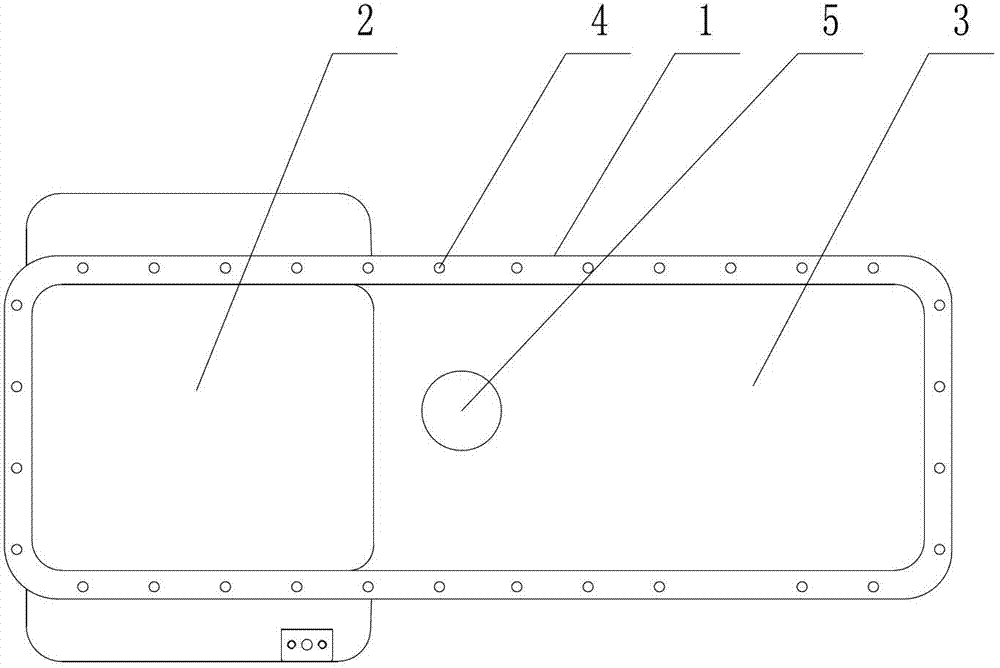

[0016] like figure 1 As shown: the diesel engine oil pan includes a housing 1, a left cavity 2, a right cavity 3, a flange 4, a gate 5, and the like.

[0017] like figure 1 As shown, the present invention includes a housing 1, and a flange 4 is provided on the periphery of the housing 1, and the flange 4 is used to be fixedly connected with the body. The inside of the housing 1 forms a left cavity 2 and a right cavity 3. The gate 5 is set in the right cavity 3; the bottom surfaces of the left cavity 2 and the right cavity 3 are smooth, and the arc transition between the left cavity 2 and the right cavity 3 makes the overall strength and rigidity of the oil pan higher, and reduces the Noise; the depth of the left cavity 2 is deeper than that of the right cavity 3, the lower part of the left cavity 2 is wider, and the upper part is narrower, forming a pocket shape, and the wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com