Environment-friendly installation method of metallic veneer

An installation method and veneer technology, applied in covering/lining, construction, building structure, etc., can solve the problems of high cost, poor aesthetics, environmental pollution, etc., and achieve the effect of saving cost, improving work efficiency and excellent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the utility model is further described:

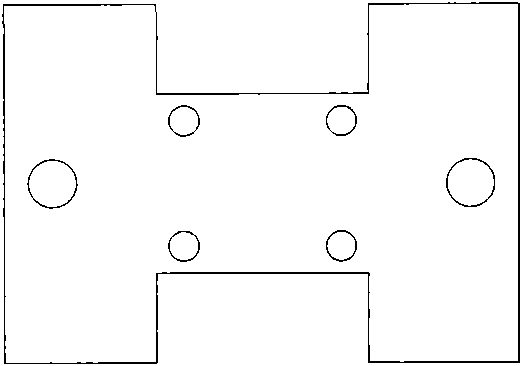

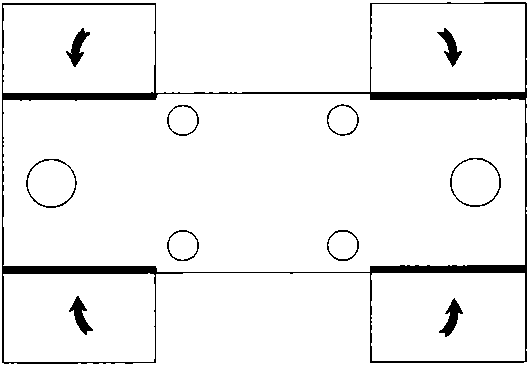

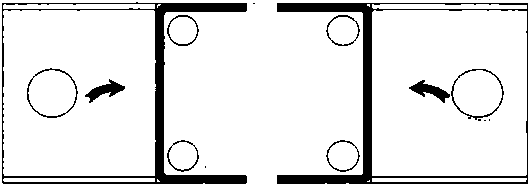

[0031] The processing technology of fixture of the present invention is as Figure 1-Figure 4 As shown, the metal veneer installation jig is made of bent steel plate, and its bending process includes: the jig is made of 1.5mm steel plate stamped, first stamping a small I-shaped steel plate on the flat steel plate such as figure 1 , and then bend the two wings as figure 2 , and finally the overall bending is as image 3 , processed into fixtures such as Figure 4 .

[0032] like Figure 5 , Image 6 As shown, the metal veneer installation fixture of the utility model includes a rectangular bottom plate 1, and vertical and transverse folds perpendicular to the four sides of the bottom plate; The horizontal folds of the horizontal folds are connected to the side faces of the longitudinal folds, there are gaps between the horizontal folds on both sides of the base plate 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com