Novel scouring and bleaching technology for pure flax yarn

A flax yarn, boiling and bleaching technology, applied in the field of flax spinning, can solve the problems of reduced spun yarn strength, production efficiency constraints, uneven spun yarn, etc., to achieve increased strength and uniformity, high yarn quality, and good yarn quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

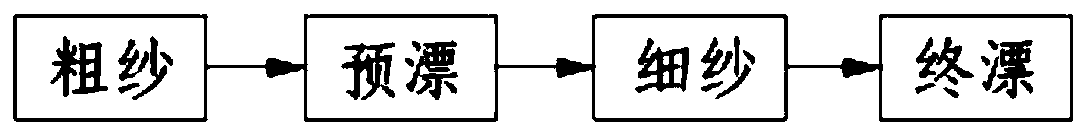

[0038] like figure 1 Shown, a kind of novel boiling and bleaching process for pure linen yarn, comprises the following steps:

[0039] (1), roving: drawing and twisting the fiber sliver after drawing and drawing to make roving, and winding the roving to form package roving;

[0040](2), pre-bleaching: the packaged roving is treated in a water bath, the pH range of the water bath is 0.5, the temperature of the water bath is set at 20°C, and the treatment time in the water bath is 45 minutes; The aqueous solution of the acidic agent is an aqueous solution of sulfuric acid. Pre-soaking the roving in an acidic environment can rapidly expand and soften the pectin on the fiber surface, and strengthen the cohesion between the fibers that make up the flax roving, thereby improving the strength of the flax roving and breaking the spun yarn when spinning The rate is reduced, and the spinning strength is improved. And because the pectin expands and softens, the pectin can be more easi...

Embodiment 2

[0052] The same part of this example and Example 1 will not be repeated, the difference is: step (2), pre-bleaching: the package roving is treated in a water bath, the pH range of the water bath is 3.5, the temperature of the water bath is set to 60 ° C, and the water bath is treated The time is 30 minutes; the water bath solution for treating the flax roving in a water bath is water or an aqueous solution containing an acidic agent. The aqueous solution containing the acidic agent is an aqueous solution of acetic acid.

[0053] (4) Final bleaching: put the spun bobbin on the creel, put it into the blanching pot, and proceed in the following order:

[0054] c. Initial bleaching, prepare the initial bleaching solution, fill another container with water, and raise the temperature to 33°C, add pectinase and penetrant with a mass concentration of 2.90g / l respectively, stir and mix thoroughly to form the initial bleaching solution, and then put the initial bleaching Pour the liqui...

Embodiment 3

[0059] The same parts of this embodiment and Embodiment 1 and 2 will not be described again, and the difference is: step (2), pre-bleaching: the package roving is treated in a water bath, the pH range of the water bath is 7, and the temperature of the water bath is set to 100 ° C. The water-bath treatment time is 15 minutes; the water-bath solution for the water-bath treatment of flax roving is water. In this embodiment, the roving is pre-soaked in a neutral environment. Compared with an acidic environment, the pectin on the surface of the fiber can also be rapidly expanded and softened, and the cohesion between the fibers forming the flax roving is enhanced, thereby improving The strength of the flax roving can reduce the breakage rate of the spun yarn and improve the strength of the spun yarn when spinning the spun yarn. And because the pectin expands and softens, the pectin can be more easily dissolved when the spun yarn is boiled and bleached, and the efficiency of the boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com