Vertical type axial flow threshing machine specially designed for breeding soybeans

A vertical shaft and thresher technology, applied in the field of agricultural machinery, can solve the problems of large size of breeding thresher, high impurity content of grains, inability to clean quickly, etc., and achieve high social and economic benefits, good effect and reasonable structure design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

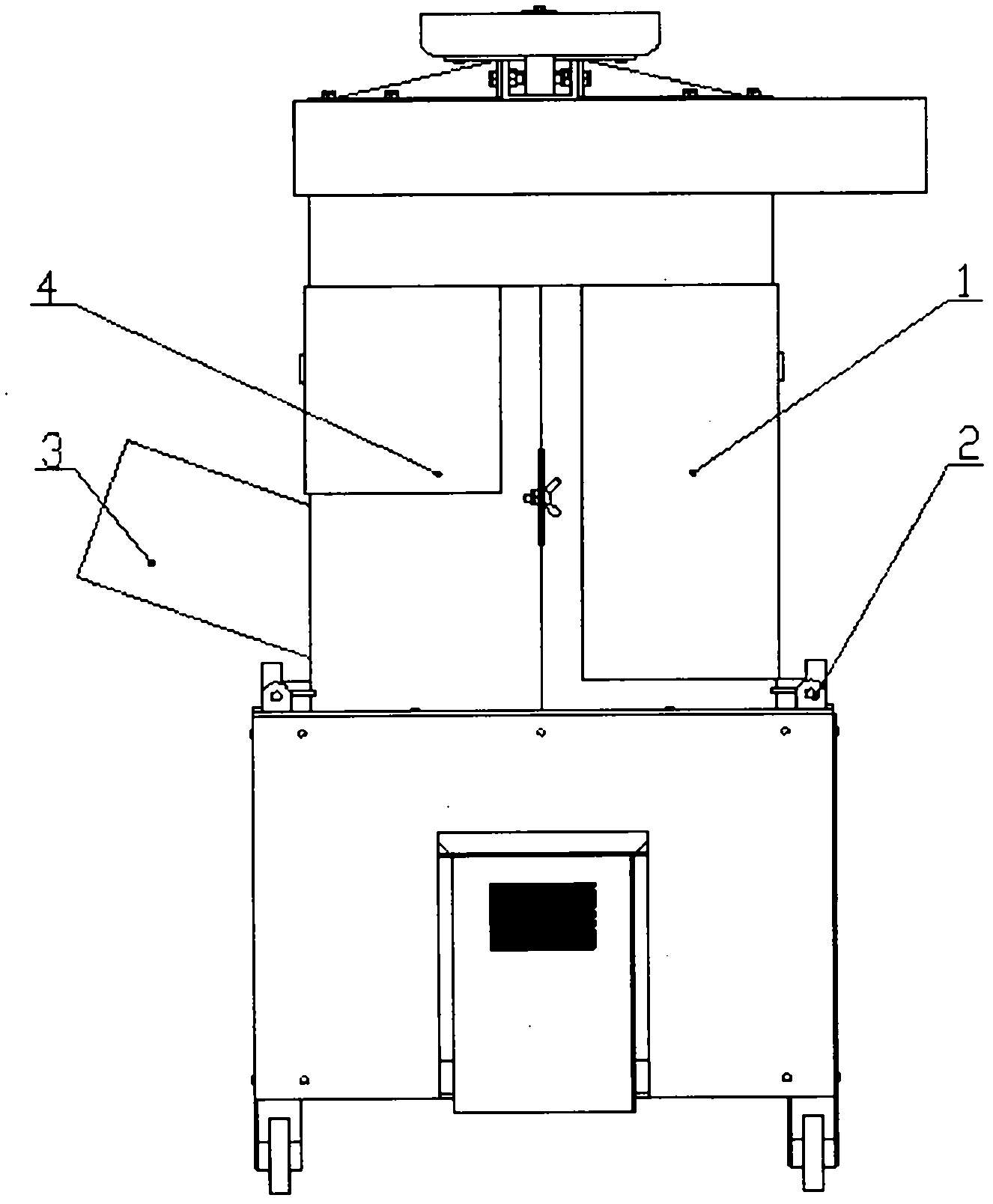

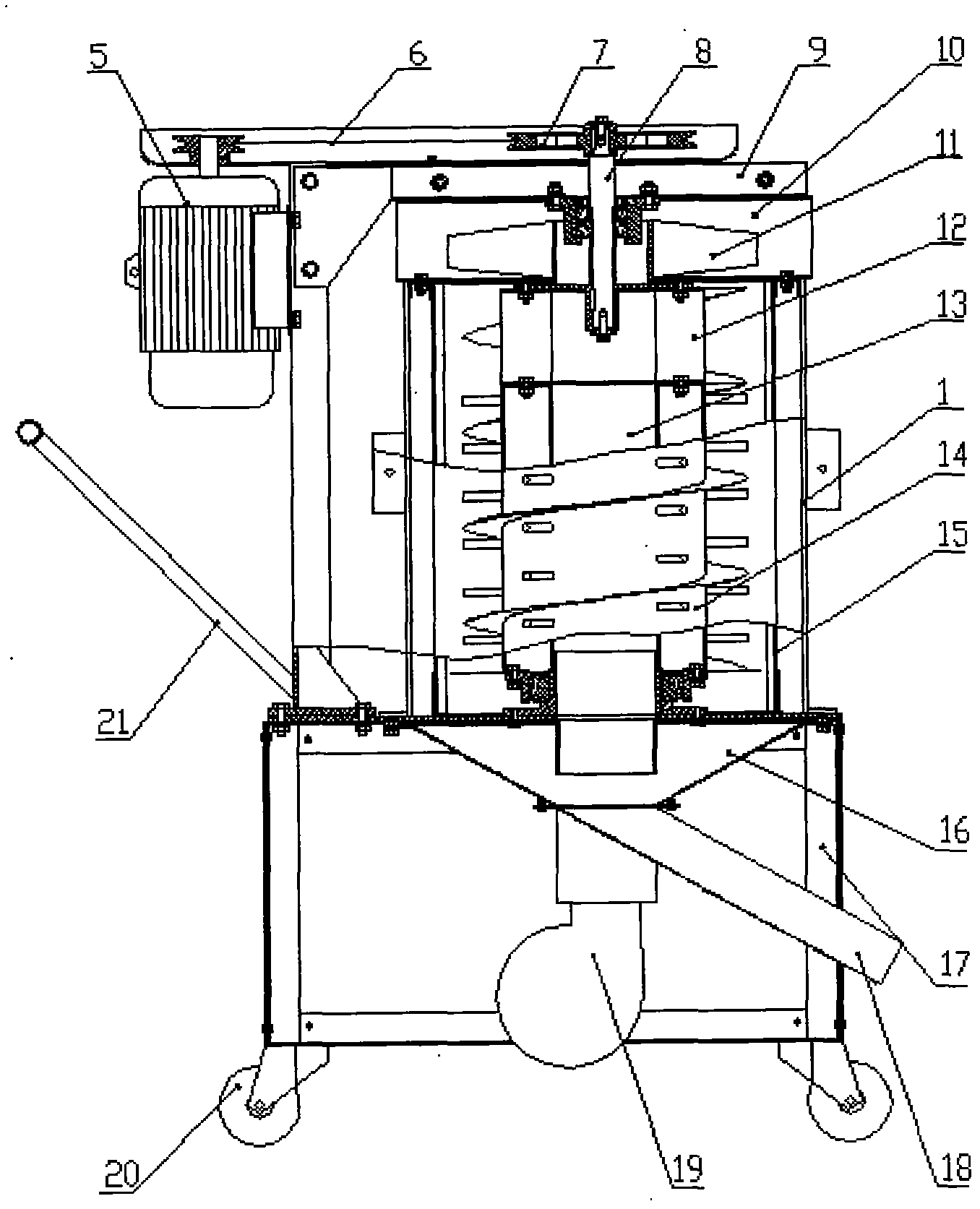

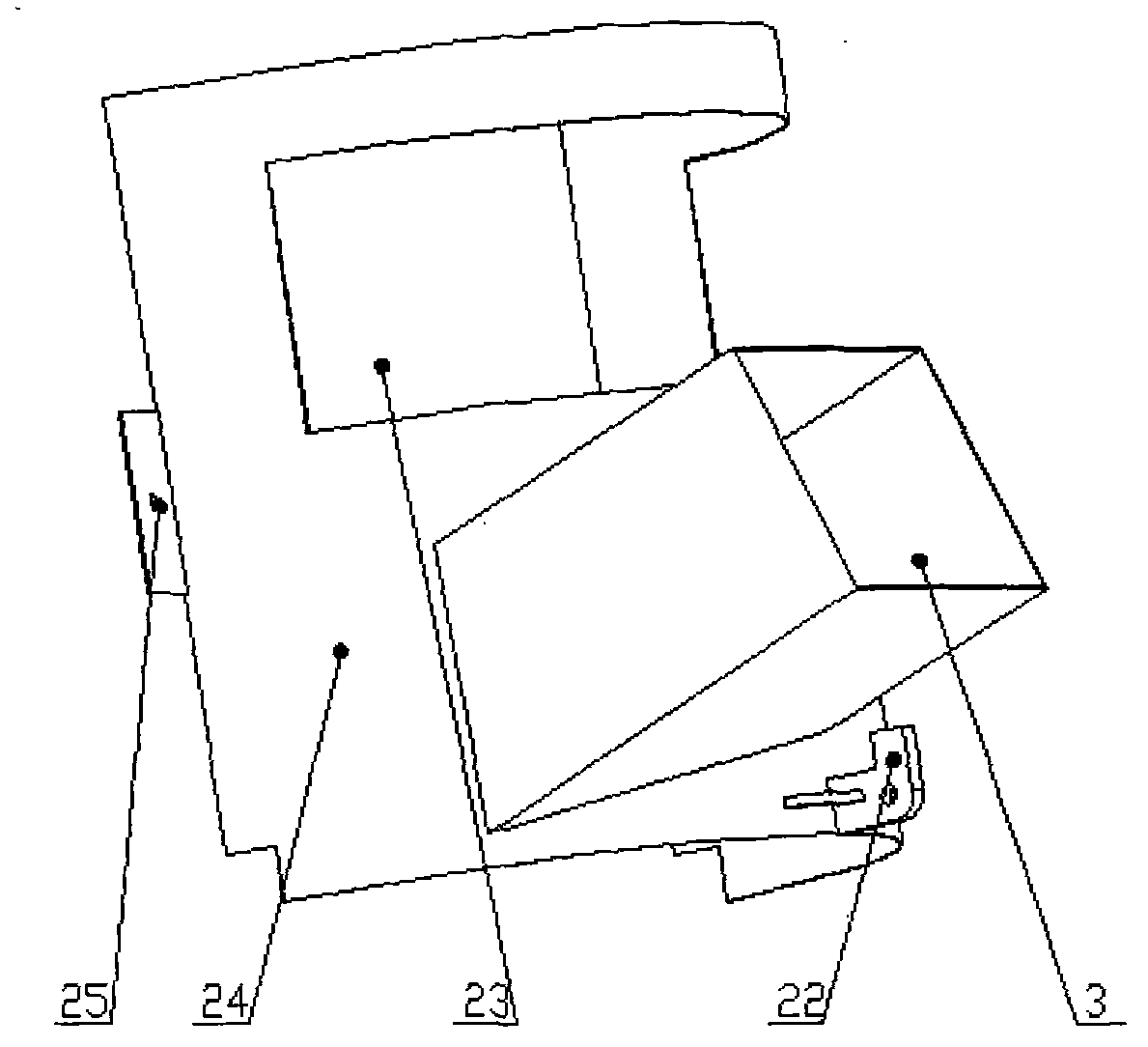

[0013] The best embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] Vertical axial-flow thresher for soybean breeding, including frame 17, traveling wheels 20 and push rods 21 mounted on frame 17; cantilever beam 9 is fixed on the upper part of frame 17, and motor 5 is fixed on On the outer side, the main shaft 8 is rotatably assembled vertically on the inner side of the cantilever beam 9, the belt pulley 7 is fixed on the upper side of the main shaft 8, the transmission belt 6 is assembled on the motor 5 and the pulley 7, and under the main shaft 8 The straw fan 11 is fixed on the side, and the straw box 10 is fixed on the lower part of the inner side of the cantilever beam 9, and is positioned outside the straw fan 11 to contain it as a whole; the blades are fixed on the lower side of the straw fan 11 type cleaning drum 12 and threshing drum 14, straw fan 11 is integrated with blade type cleaning drum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com