Combined harvester header for partitioned harvest of millet stalks and ears and application method thereof

A technology of combine harvester and millet, applied in the direction of harvester, application, cutter, etc., can solve problems such as waste, and achieve the effect of reducing millet waste, preventing winding drum, and facilitating threshing and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

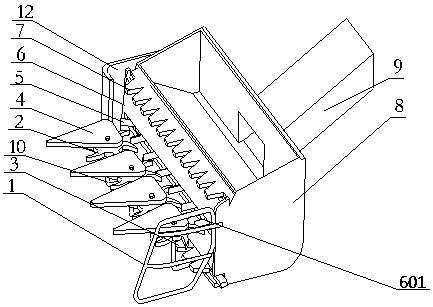

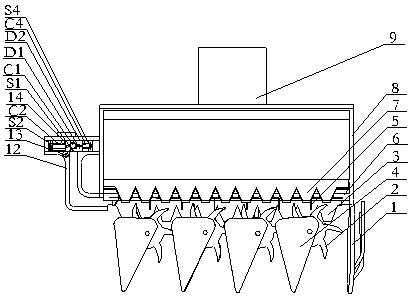

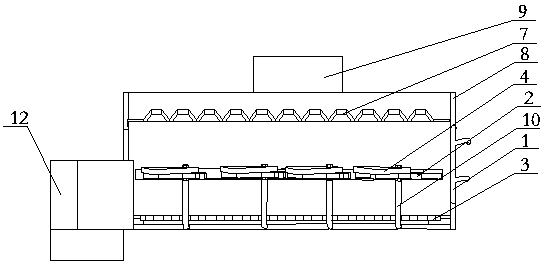

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

[0028] Such as Figure 1~3 , the combine harvester header for segmental harvesting of millet stalks and ears, comprising a harvesting device for segmental harvesting of ear heads and stalks of the millet to be harvested, and a harvesting device for beating the stalks output by the harvesting device A bundling device that collects bales and places the bundled straw on the ground. Its technical solution is that the harvesting device includes a header frame 8, a lower layer cutter 3 arranged on the side of the header frame 8 close to the ground, The upper layer cutting knife 7 that is set above the platform 8, is arranged between the lower layer cutting knife 3 and the upper layer cutting knife 7 and is used to lean on the grain holding board 6 to be harvested, and is used to collect the grain that is cut off by the upper layer cutting knife 7 The conveyer 9 of fringe, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com