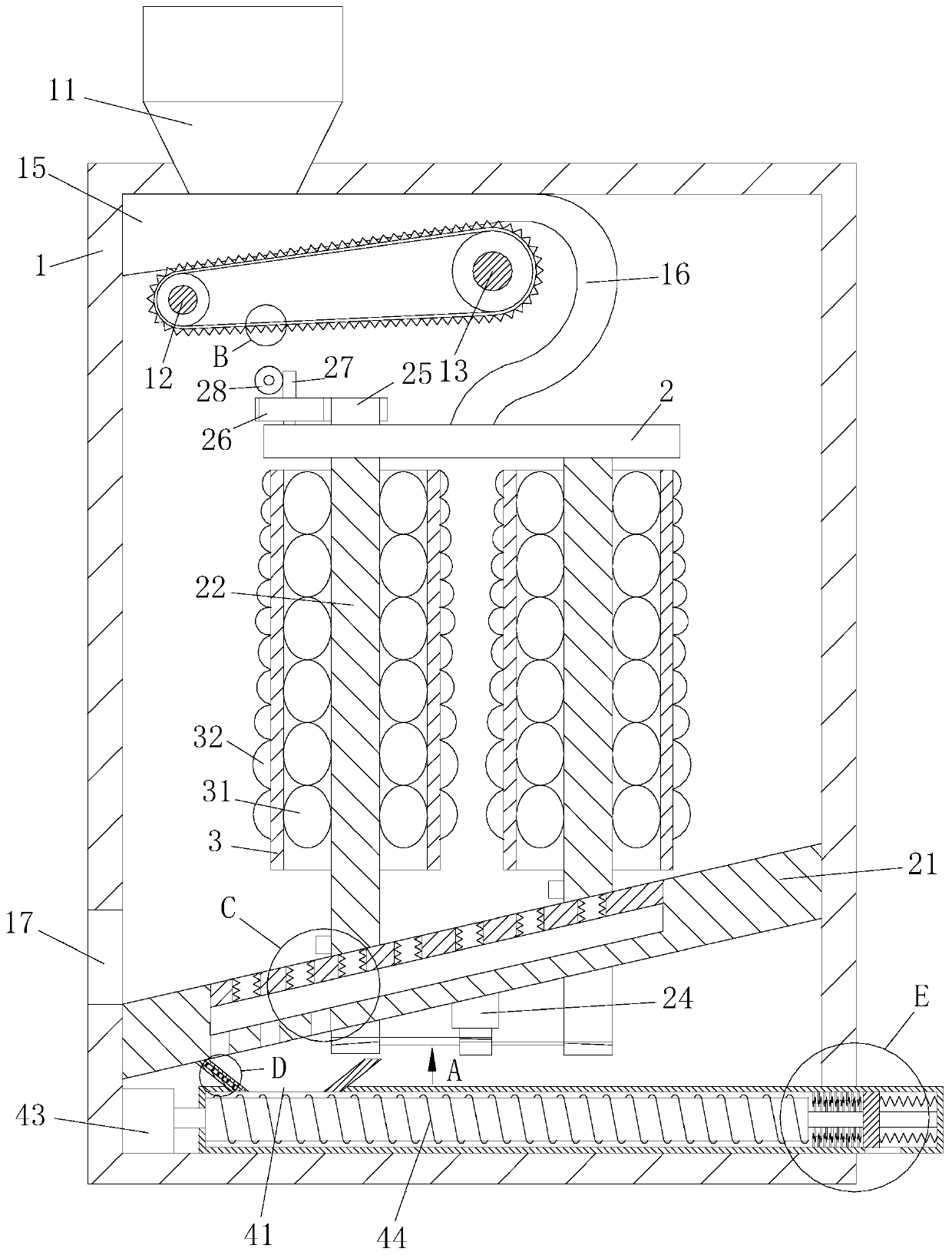

Corn flour food processing production device

A food processing and production device technology, applied in food science, threshing equipment, grain processing, etc., can solve the problems of low crushing efficiency, corn kernel blockage, inability to apply corn cob crushing, etc., and achieve the effect of thorough crushing and improved threshing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

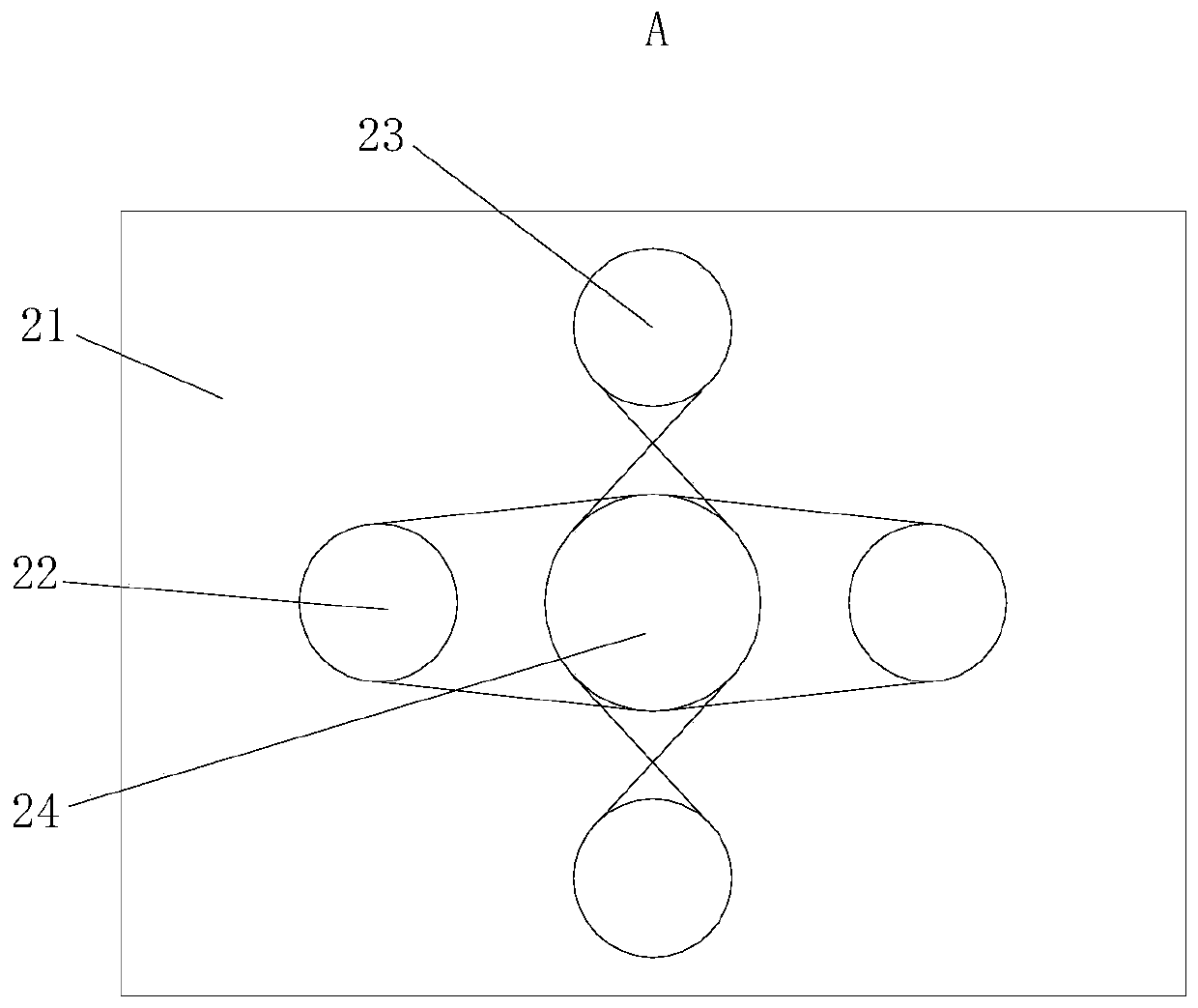

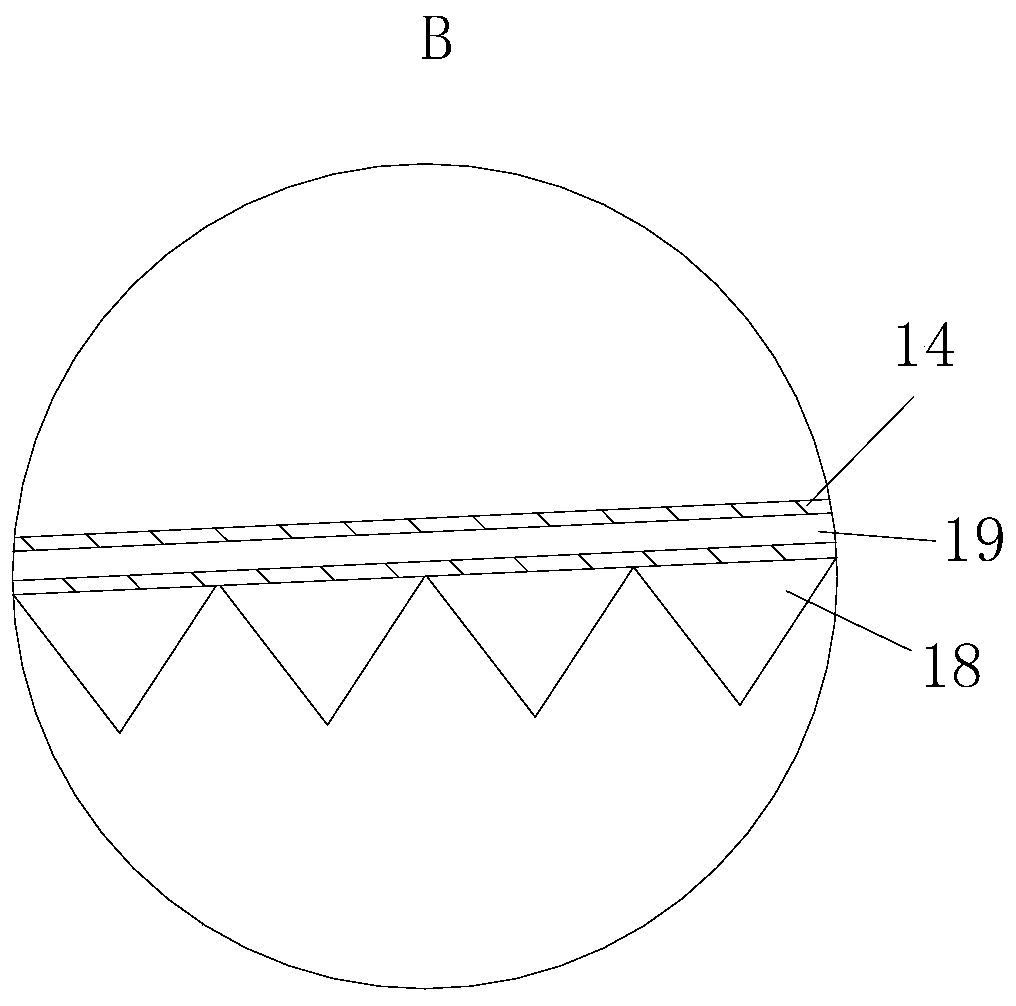

[0027] As an embodiment of the present invention, the second fixing plate 21 is designed in a "concave" shape, and a vibrating plate 5 is fixed inside the concave shape; the vibrating plate 5 is made of elastic material, and the surface of the vibrating plate 5 is provided with uniform Arranged filter holes 51; the side walls of the filter holes 51 are evenly arranged with second protruding teeth 52, and the second protruding teeth 52 are relatively staggered; the third rotating shaft 22 and the fourth rotating shaft 23 are set through the vibrating plate 5 , is connected with the vibrating plate 5 in rotation; the surface of the fourth rotating shaft 23 and the fifth rotating shaft 45 is fixedly connected with an extruding block 53; the extruding block 53 is located above the vibrating plate 5; during work, the third rotating shaft 22 and the During the rotation of the four rotating shafts 23, the extruding block 53 intermittently squeezes and relaxes the vibrating plate 5, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com