Corn threshing and silk removing device

A corn threshing and box body technology, applied in the field of agricultural machinery, can solve the problems of low production efficiency, large resistance, broken corn cobs, etc., and achieve the effects of improving production efficiency, reducing force impact and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

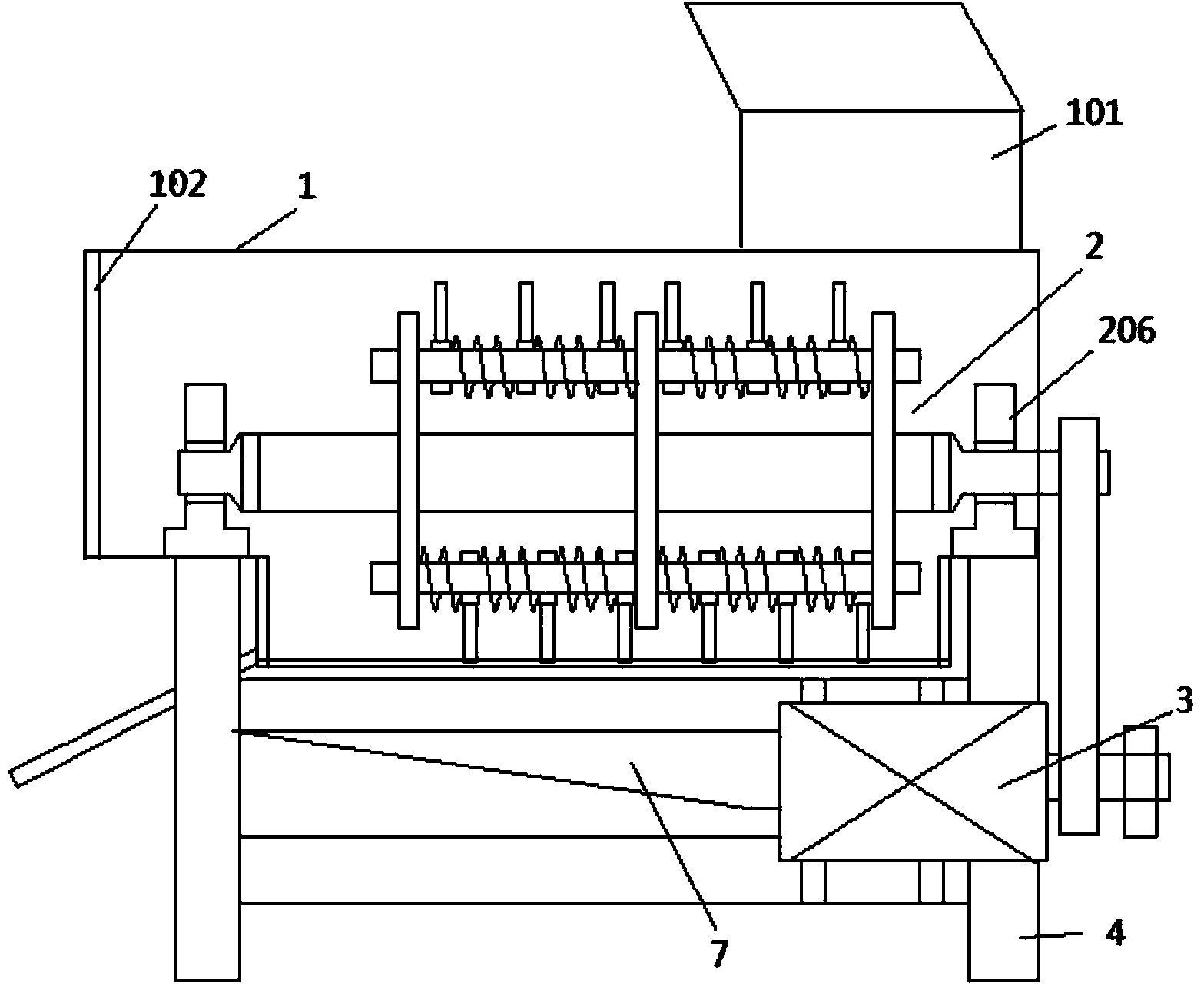

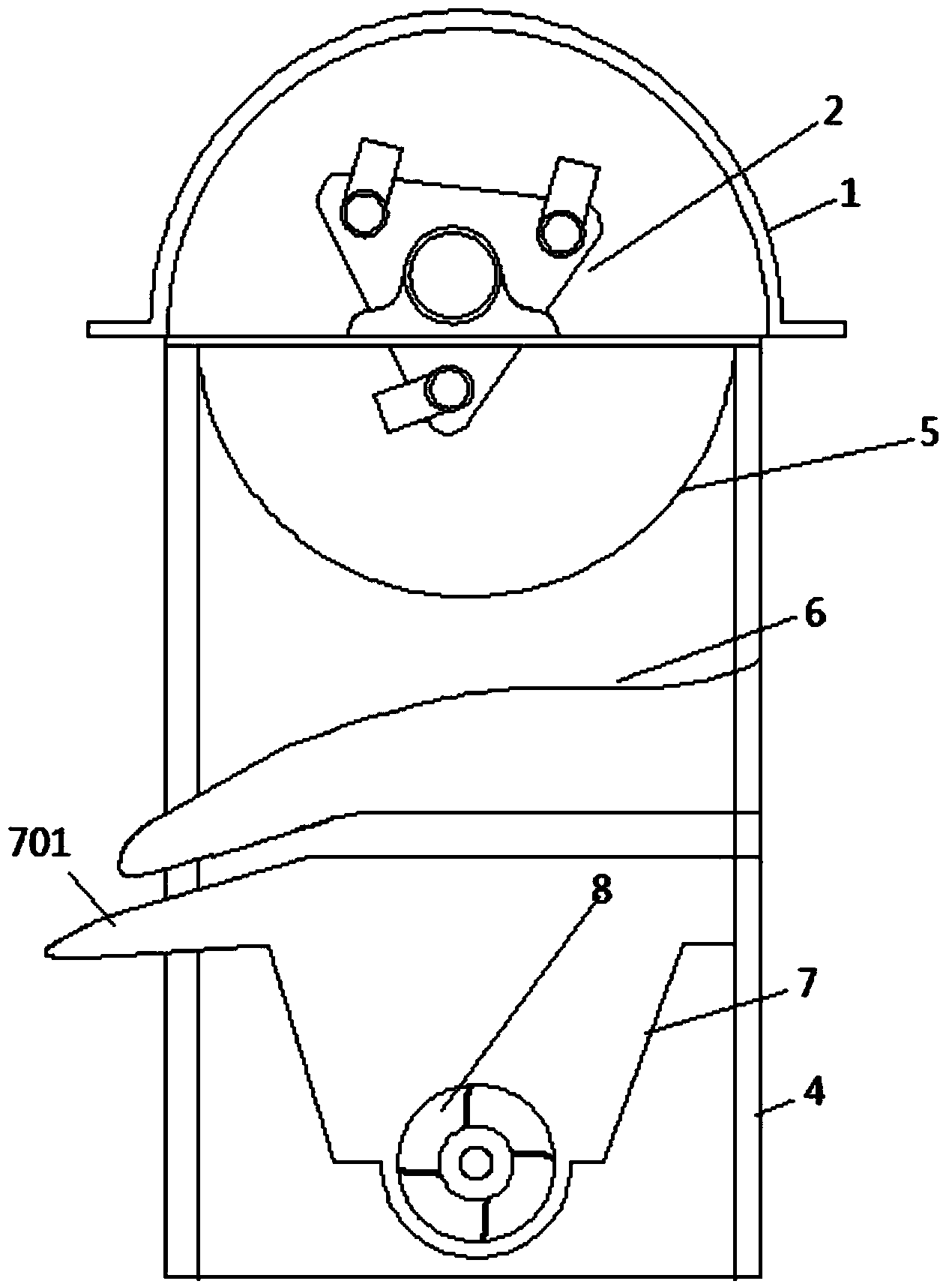

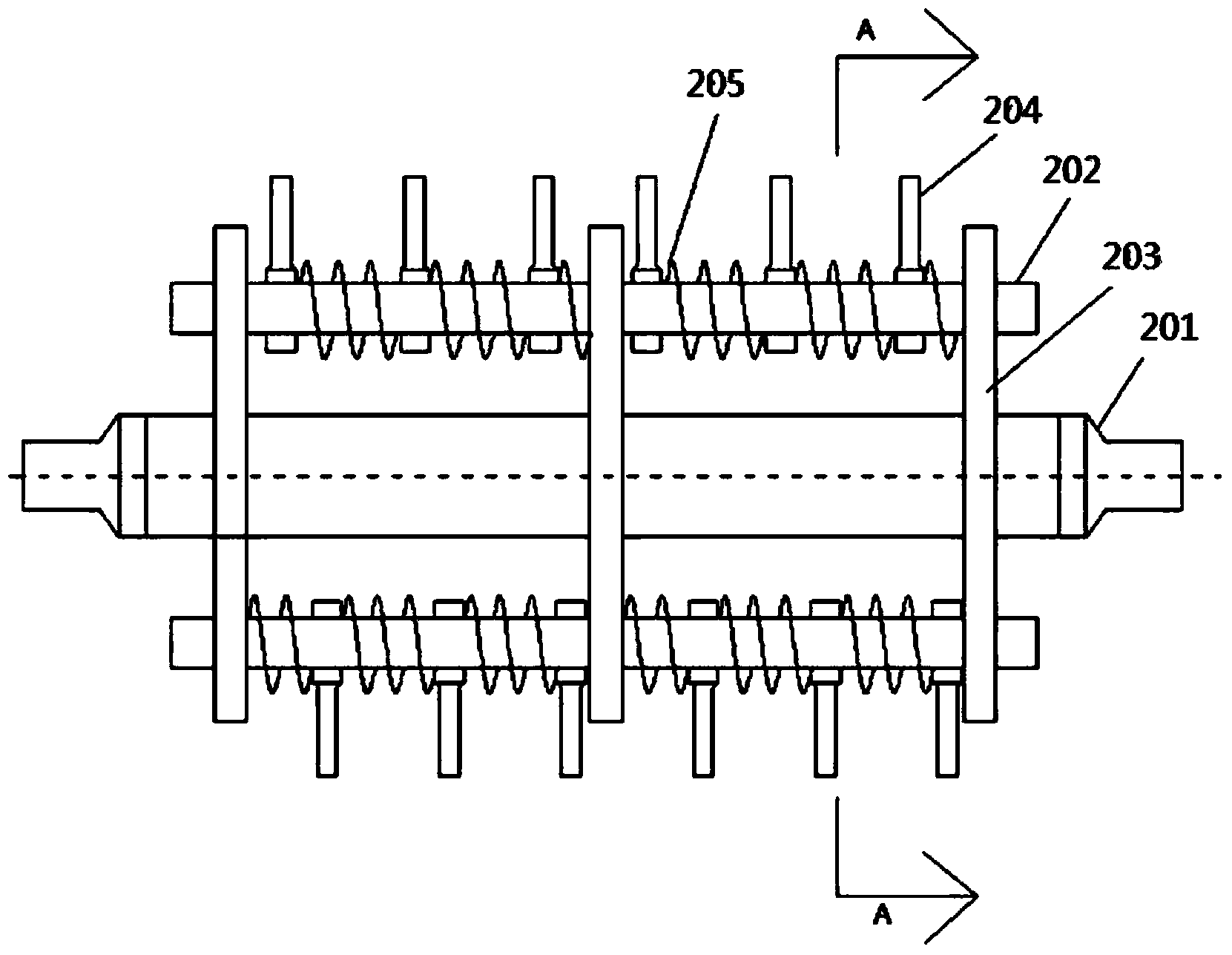

[0015] Referring to the accompanying drawings, a corn threshing and beard removal device includes a box body 1, a threshing roller 2, a drive motor 3, and a fixed frame 4 supporting the box body on the ground. The threshing roller 2 includes a rotating shaft 201 and a fixed shaft 202. and the fixed disk 203, the fixed shaft is provided with a plurality of evenly distributed around the rotating shaft into a circle, and the fixed disk 203 is arranged at the two ends and the middle of the rotating shaft 201 to fix the fixed shaft and the rotating shaft position, and the fixed shaft 202 There are multiple threshing hammers 204 on the top, and the lower end of the threshing hammer is rotatably sleeved on the fixed shaft 202. A spring sleeve 205 is arranged between adjacent threshing hammers on the same fixed shaft and a threshing hammer close to the fixed plate and the fixed plate There are spring sleeves between them, and the threshing hammers on the adjacent fixed shafts are distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com