Miniature peanut picking machine

A peanut machine and miniature technology, applied in agricultural machinery and implements, threshing equipment, applications, etc., can solve the problems of tired work, low work efficiency, labor-intensive, labor-intensive, etc., and achieve the effect of easy operation, easy manufacture, and convenient threshing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

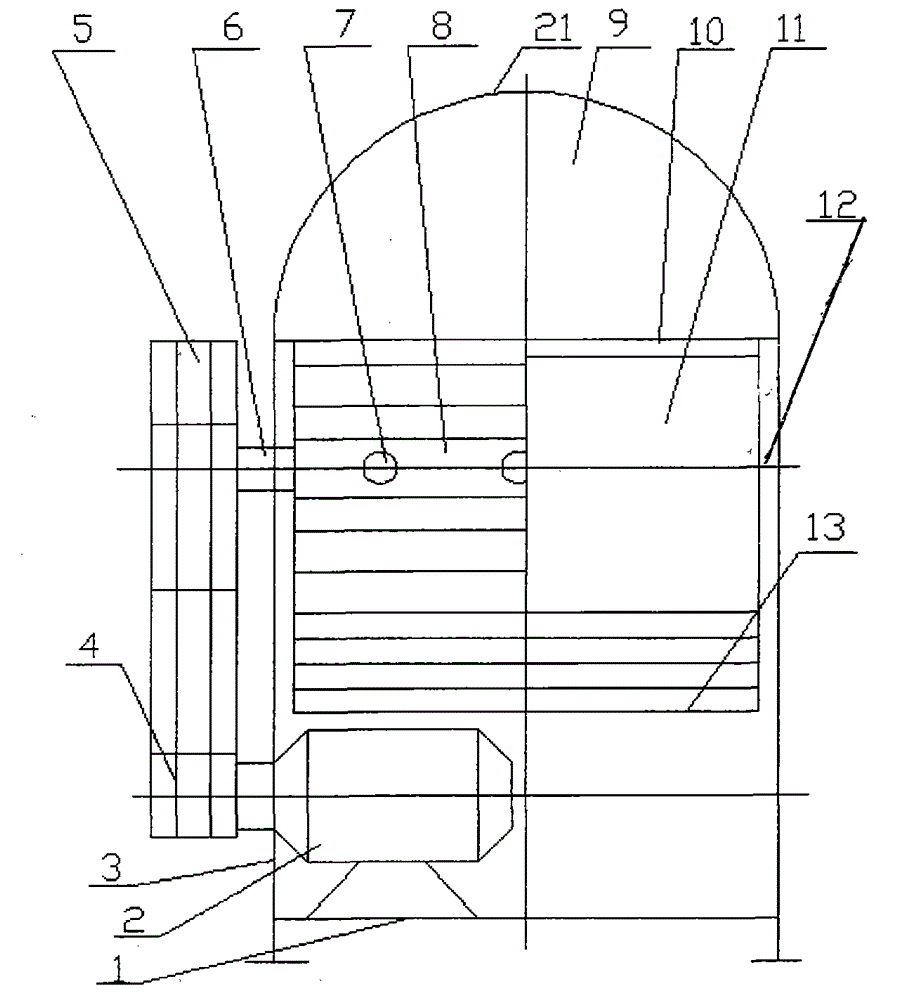

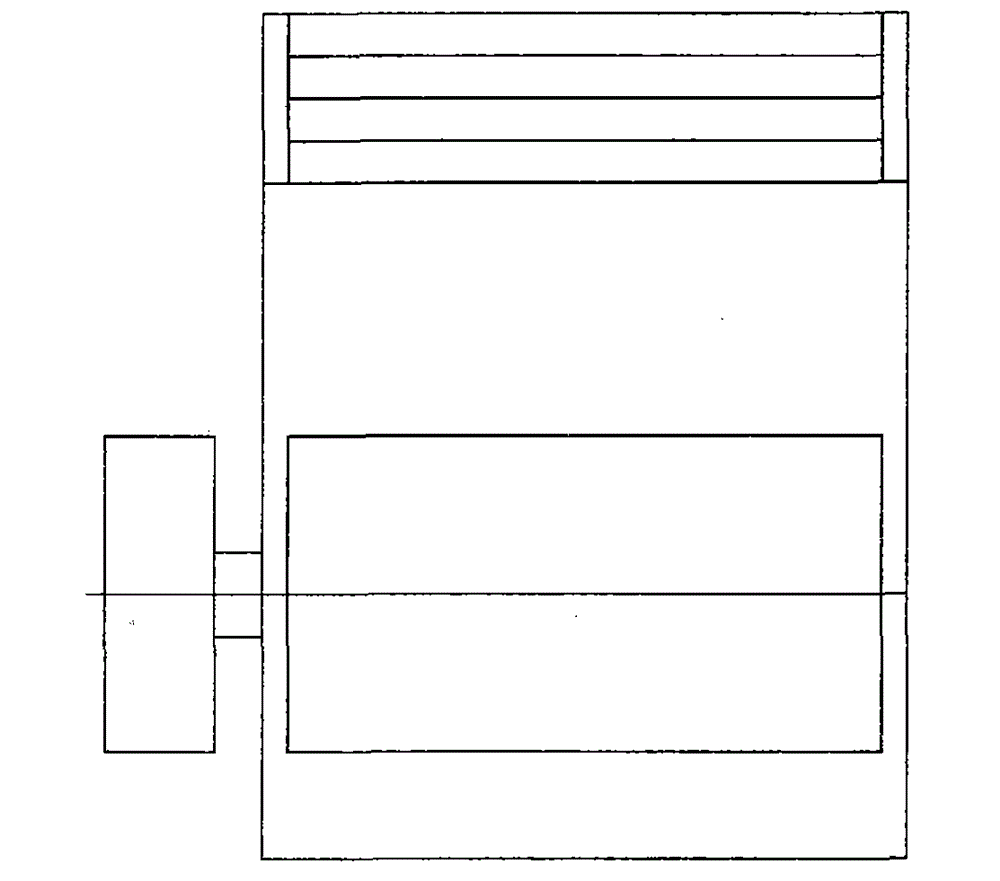

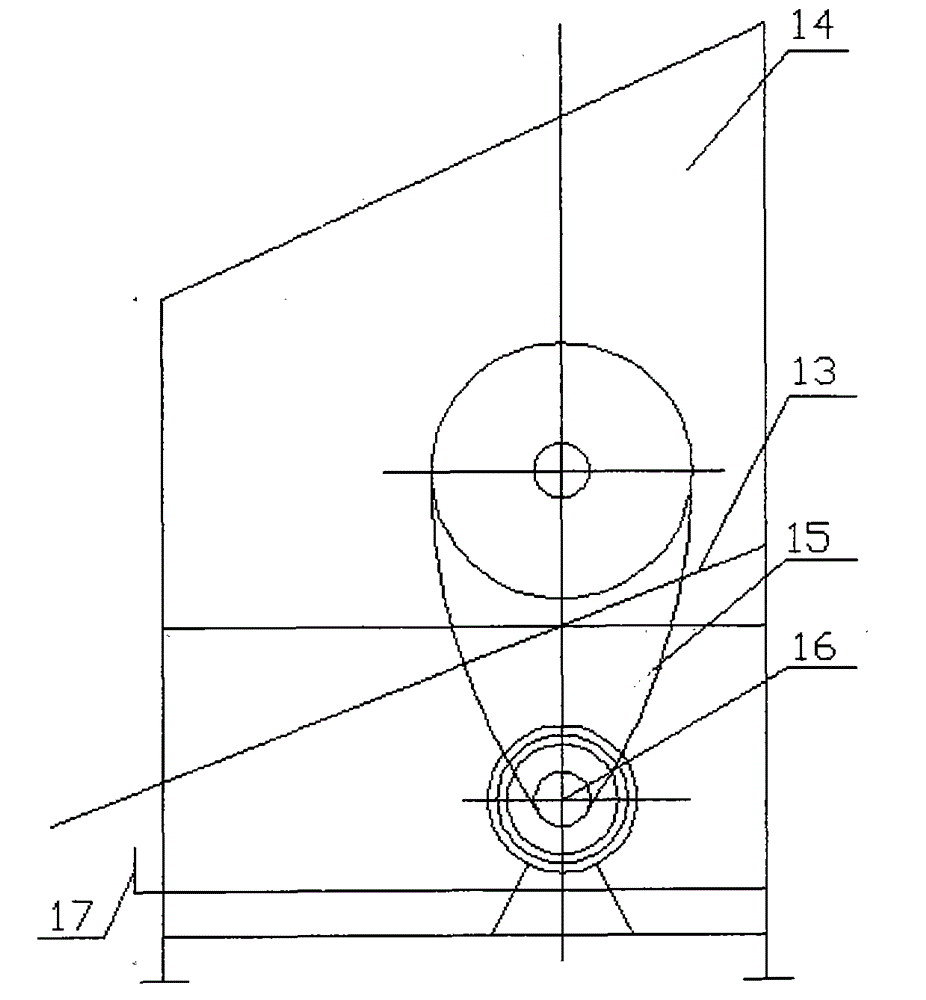

Embodiment 1

[0037] Embodiment 1, the two ends of threshing cylinder (18) are wheel rims (19), make the rim shape with iron bar, there is motor rotating shaft (16) in the middle, and motor rotating shaft (16) is supported on the cover plate (14) Between the left and right side plates, bearings (12) are installed. The outer end of motor rotating shaft (16) outer end stretches out threshing cylinder (18), and large belt pulley (5) is installed. The cylinder diameter of the threshing drum (18) is four angle irons (23) evenly distributed, and there is a space (20) between the angle irons (23), and the space (20) is the space for the peanut threshing to fall off the fender (21) , fender (21) is four correspondingly, and gap (26) is arranged between its port and the cylinder rotating shaft (6), and fender (21) top surface has angle iron installation hole (25). Rubber pad (8) has rubber pad installation hole (27). The bolt (22) passes through the rubber pad installation hole (27), the angle iro...

Embodiment 2

[0038] Embodiment 2, install the threshing gear that iron bar is made on the outer diameter tube wall of threshing cylinder (18), similar to the cylinder of threshing machine, this also plays the effect of removing peanuts equally.

Embodiment 3

[0039] Embodiment 3, a guillotine is installed under the sieve plate (13), the peanut seedlings after threshing are cut into short sections, and left in the field to allow it to be retting to make organic fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com