Sunflower seed harvester

A harvester and sunflower seed technology, which can be used in harvesters, agricultural machinery, implements, cutters, etc., can solve the problem of low level of mechanized harvesting, and achieve the effects of avoiding mildew in grain storage, improving harvest quality and high harvest efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The present invention will be further explained below in conjunction with the accompanying drawings and examples, and the protection scope of the present invention cannot be limited by this. The purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

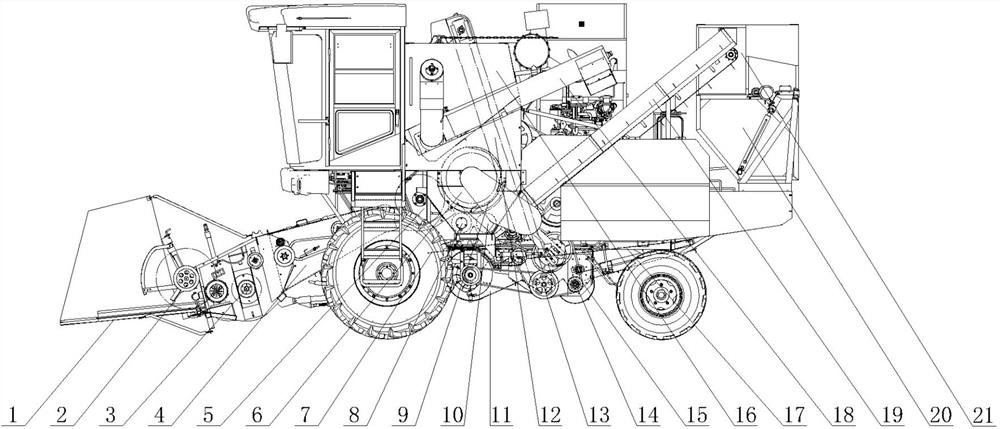

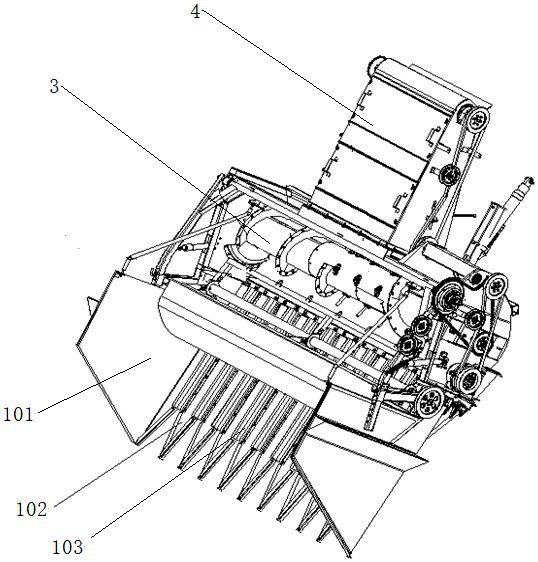

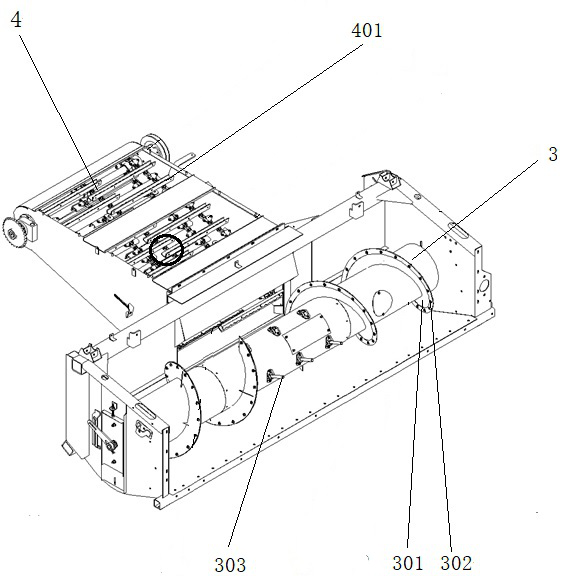

[0036] combined with Figure 1-6 A sunflower seed harvester, comprising a car body, a header mechanism, a feeding mechanism, a threshing mechanism, a cleaning mechanism, a sunflower plate collecting mechanism and a material storage device;

[0037] The car body provides walking support and power transmission for the header mechanism, feeding mechanism, threshing mechanism, cleaning mechanism, grain lifting mechanism, grain collecting mechanism, sunflower plate lifting mechanism, sunflower plate collecting mechanism and material storage device.

[0038] The header mechanism is arranged at the front end of the car body, and the header mechanism includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com