Patents

Literature

69results about How to "Optimize production methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing copper alloy coil pipe

ActiveCN101698207AImprove yieldOptimize production methodsTemperature control deviceFurnace typesMetallurgyMethods of production

The invention relates to a method for producing a metal pipe, in particular to a method for producing a copper alloy coil pipe. According to the technical scheme provided by the invention, the method for producing the copper alloy coil pipe comprises the following steps: (a) melting, (b) horizontal and continuous casting, (c) face milling, (d) primary bright annealing, (e) planetary tube rolling, (f) stretching, (g) secondary bright annealing, (h) cleaning, and (i) third bright annealing. The method can improve the comprehensive finished product rate of a pipe material, the labor productivity and the grade of product quality.

Owner:江苏隆达超合金股份有限公司

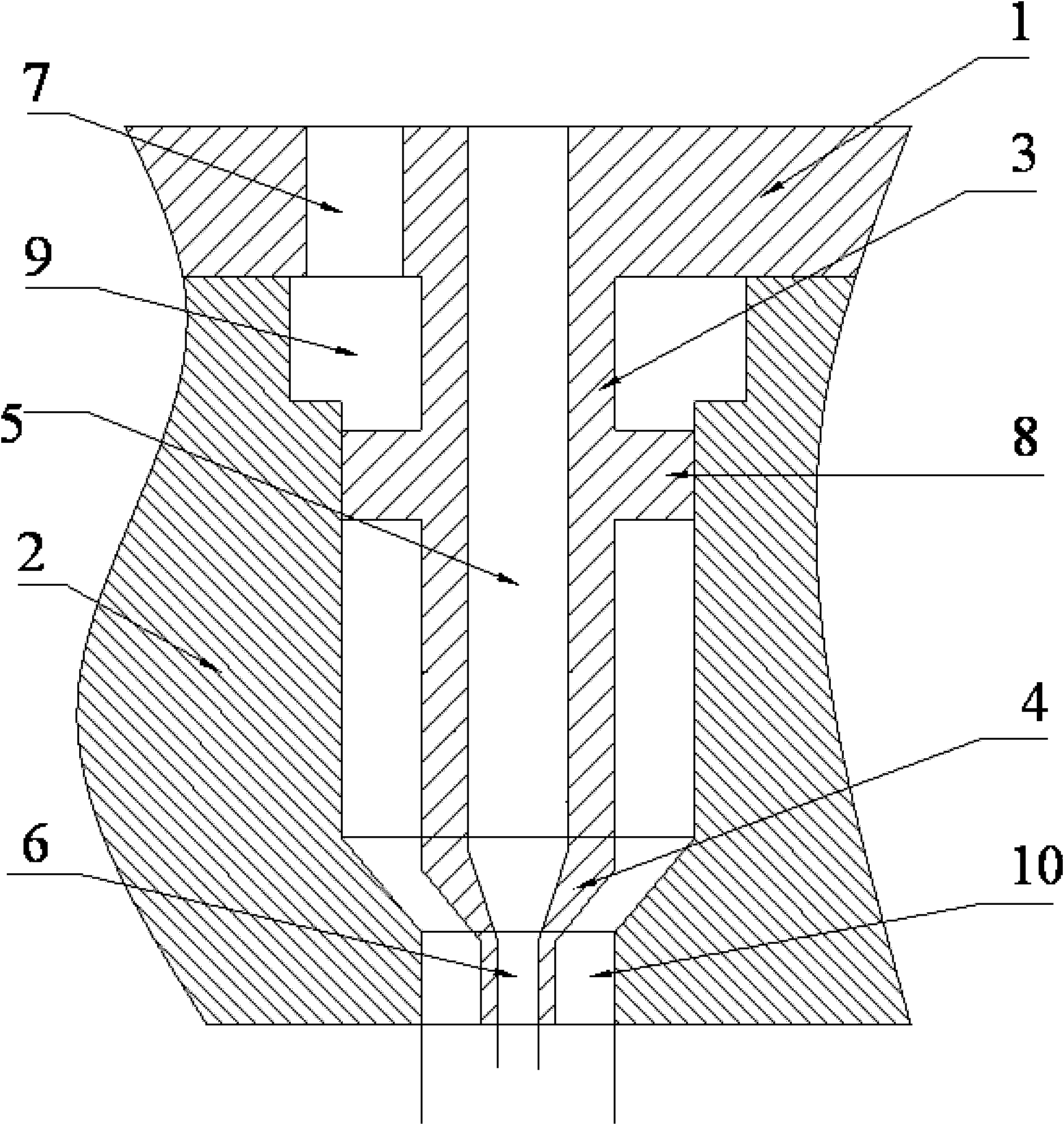

Macromolecular/ metal composite conductor and manufacture method thereof

ActiveCN102021671AMake up for the shortcomings of poor ductilityLow melting pointFilament/thread formingArtificial filament heat treatmentFiberElectrical resistance and conductance

The invention relates to a macromolecular / metal (metal alloy) composite conductor and a manufacture method thereof. The composite conductor is provided with a skin layer and a core layer, wherein the skin layer is thermoplasticity macromolecular polymer (A), the core layer is a metal alloy (B) with lowi melting point, and the cross section of fiber can be round or irregular. The manufacture method is a complex extrusion method and comprises the steps of preparing a fusant, extruding and postprocessing, wherein a complex extrusion die head is adopted. The composite conductor of the invention has excellent electric conductivity, and the volume specific resistance is 1.0*10<-6>-1.0*100 omega cm. Therefore, the composite conductor can satisfy the requirement on clothes conductors by the clothes industry and can be applied for detective textiles, such as special uniforms, textile soft keyboards, intelligent clothes, intelligent bandages and the like. Because the composite structure of the skin layer and the core layer is adopted, the composite conductor of the invention has excellence in clothes production, has soft handfeel, and can satisfy requirements on color and comfort level by clothes textile in addition to satisfying electric conductivity requirements, and meanwhile, product cost is greatly lowered.

Owner:CHINESE TEXTILE ACAD

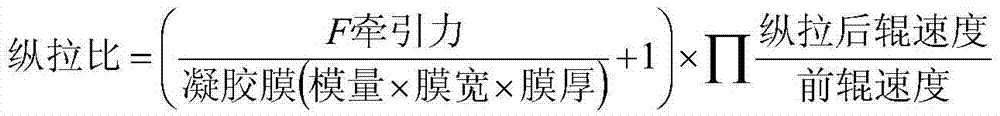

Polyimide film with high dimensional stability and preparation method of polyimide film

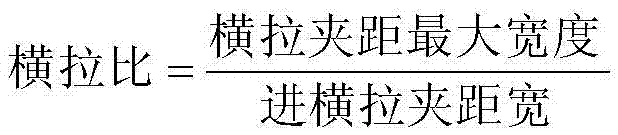

The invention discloses a polyimide film with high dimensional stability and a preparation method of the polyimide film. The polyimide film is prepared from at least one aromatic dianhydride containing a rigid structure and at least one aromatic diamine containing a rigid structure through a solution polycondensation reaction and an imidization reaction, wherein the sum of mole numbers of the aromatic dianhydride containing the rigid structure and the aromatic diamine containing the rigid structure accounts for 70-85% of the sum of mole numbers of totally reacted dianhydrides and diamines; the film thickness is 5-75 microns; the thermal shrinkage ratios of the film in the longitudinal direction and the transverse direction are respectively less than or equal to 0.1%; the coefficient of linear thermal expansion is less than or equal to 16ppm; and the operating requirements of a polyimide film base material of a flexible copper clad laminate are met. According to the preparation process of the film, a roll-to-roll production manner of performing continuous longitudinal stretching technology according to a constant speed ratio and transverse high-temperature stretching and online thermosetting treatment is adopted, the prepared polyimide film has excellent dimensional stability performance, and the production manner adopted by the film is simple, convenient, high-efficiency and reliable.

Owner:RAYITEK HI TECH FILM CO LTD

Novel environment-friendly knitted fabric rinsing process

InactiveCN104631013AReduce consumptionOptimize production methodsSucessive textile treatmentsAfter treatmentWarm water

The invention relates to a novel environment-friendly knitted fabric rinsing process. The process specially includes the steps that firstly, a continuous grey tube cloth pretreatment process procedure includes tube knitting of grey cloth, end sewing conducted by a sewing machine, untwisting and scotching, penetrating agent, degreasing agent and chelating agent padding, reaction conducted in a stacking box, warm water washing, oxygen bleaching agent padding, steaming conducted by a steaming box, hot water washing in five tanks, softening agent squeezing for whitening products, cloth delivery and dyeing; secondly, the continuous water washing after-treatment process procedure after grey tube cloth is dyed includes acquisition of the dyed grey cloth, water washing conducted a time in a dyeing machine, cloth machine delivery, cloth treatment in a continuous tube inflation open-width water washing machine, warm water washing for acid neutralization, hot water washing, soaping, fixation, softening, squeezing and drying. By the adoption of the novel environment-friendly knitted fabric rinsing process, energy is saved, environment friendliness is achieved, enterprise cost can be reduced, and enterprise benefits are provided.

Owner:QINGDAO XINYIFA IND & TRADE

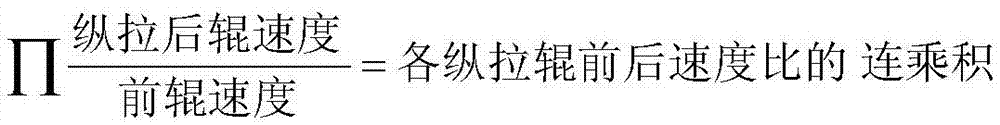

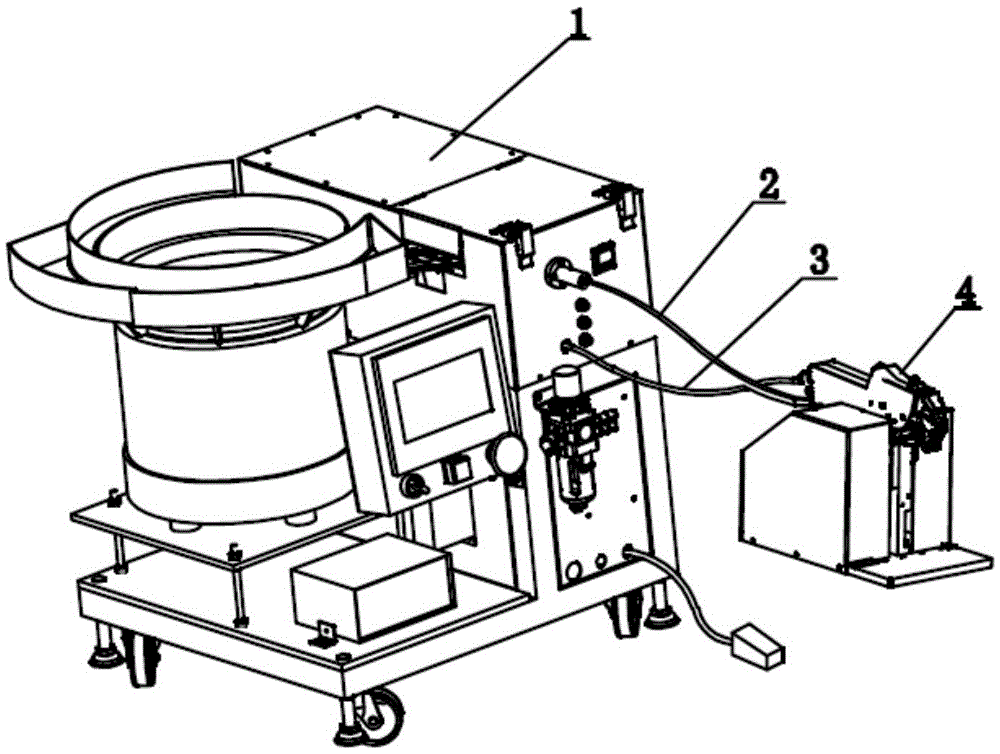

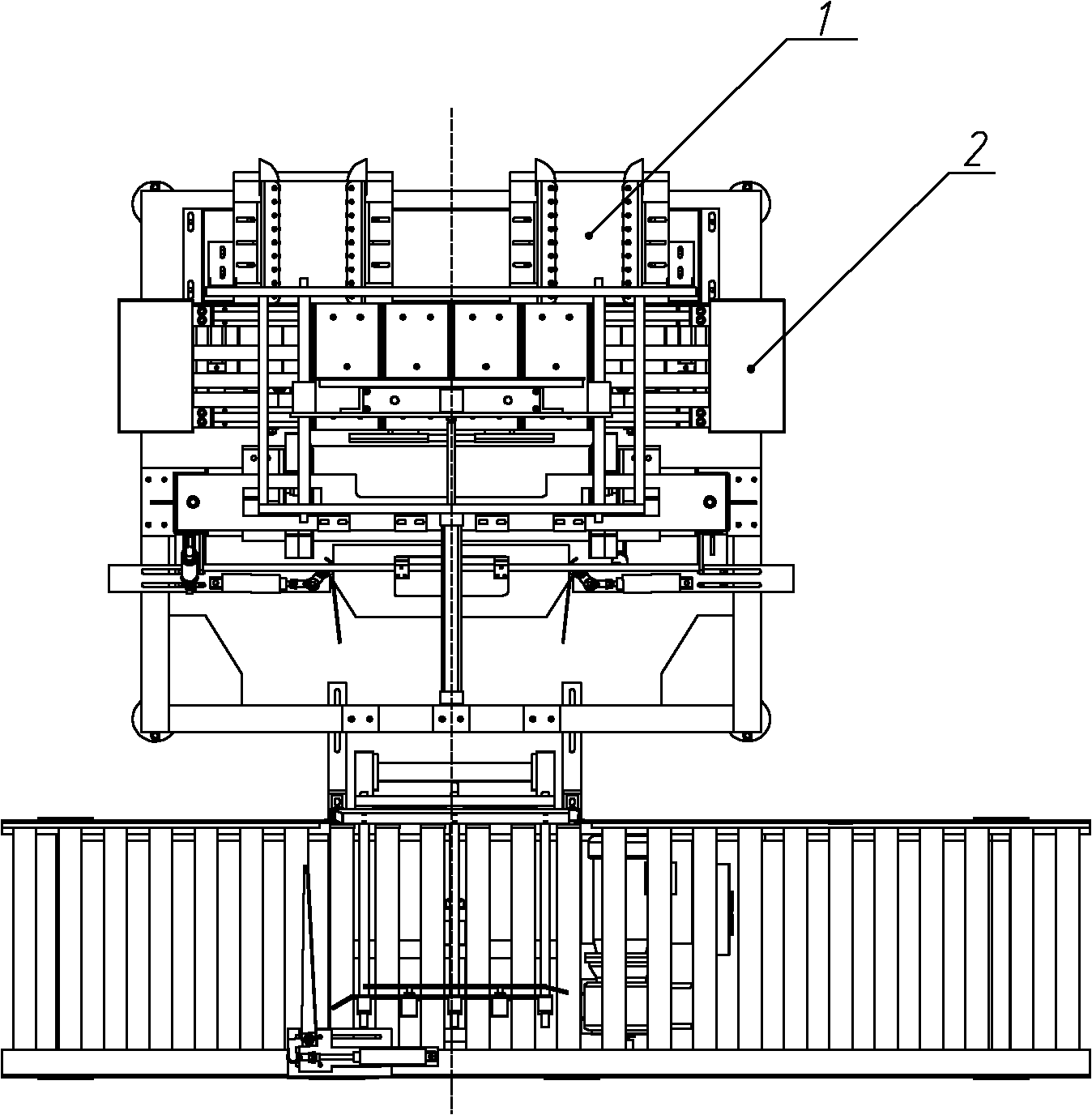

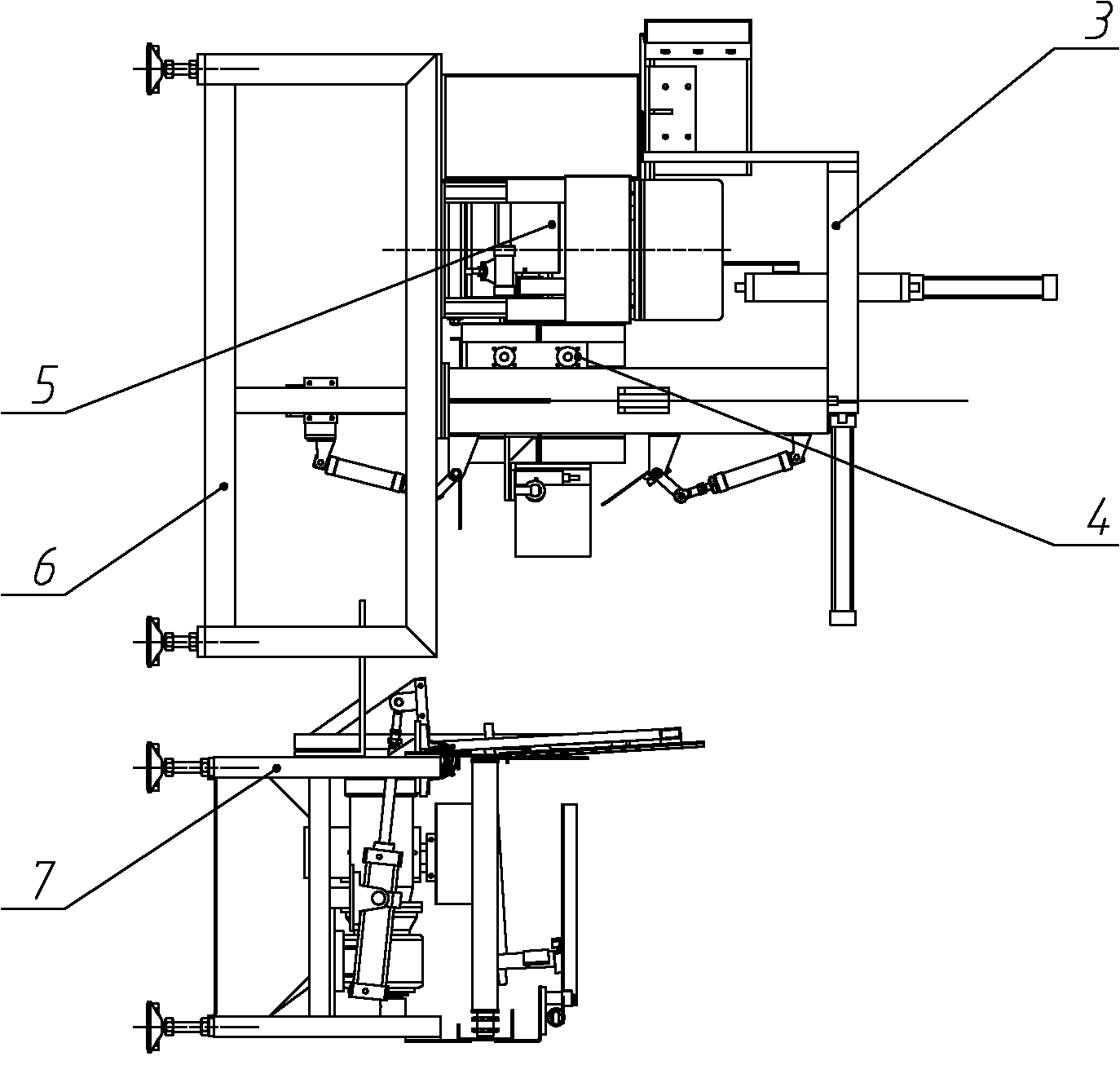

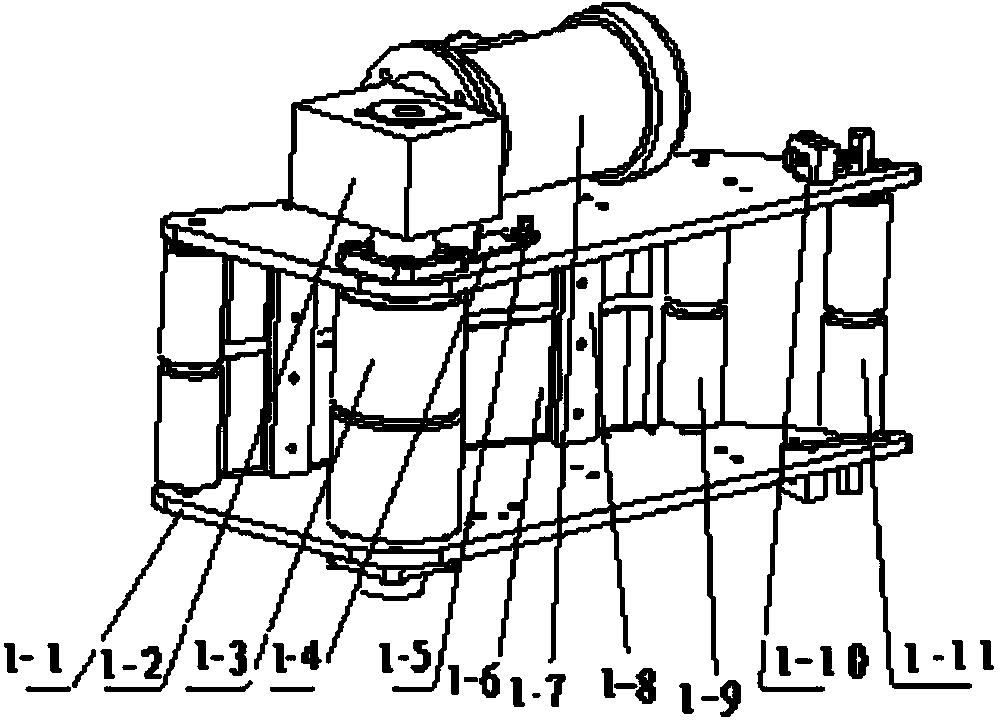

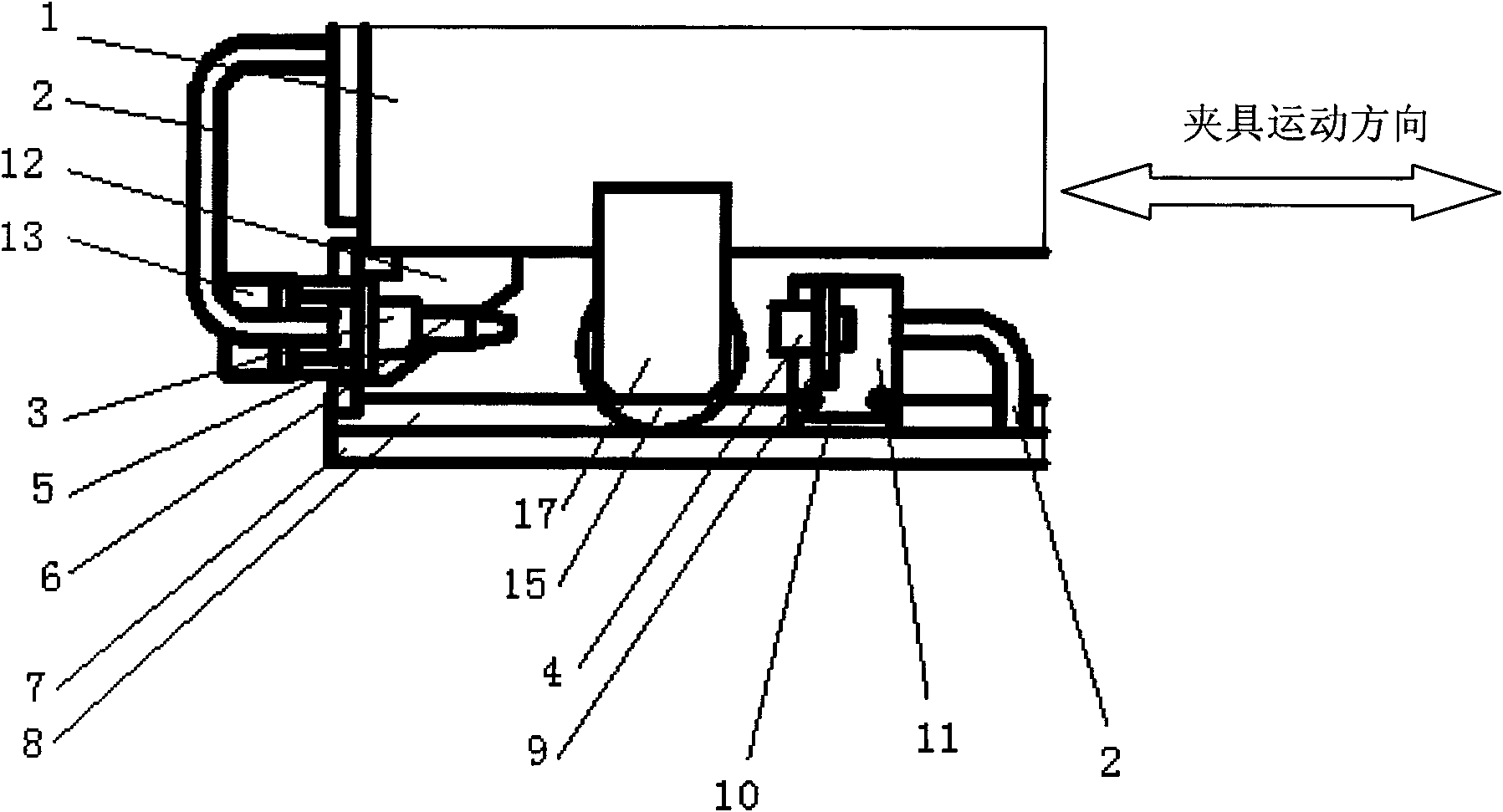

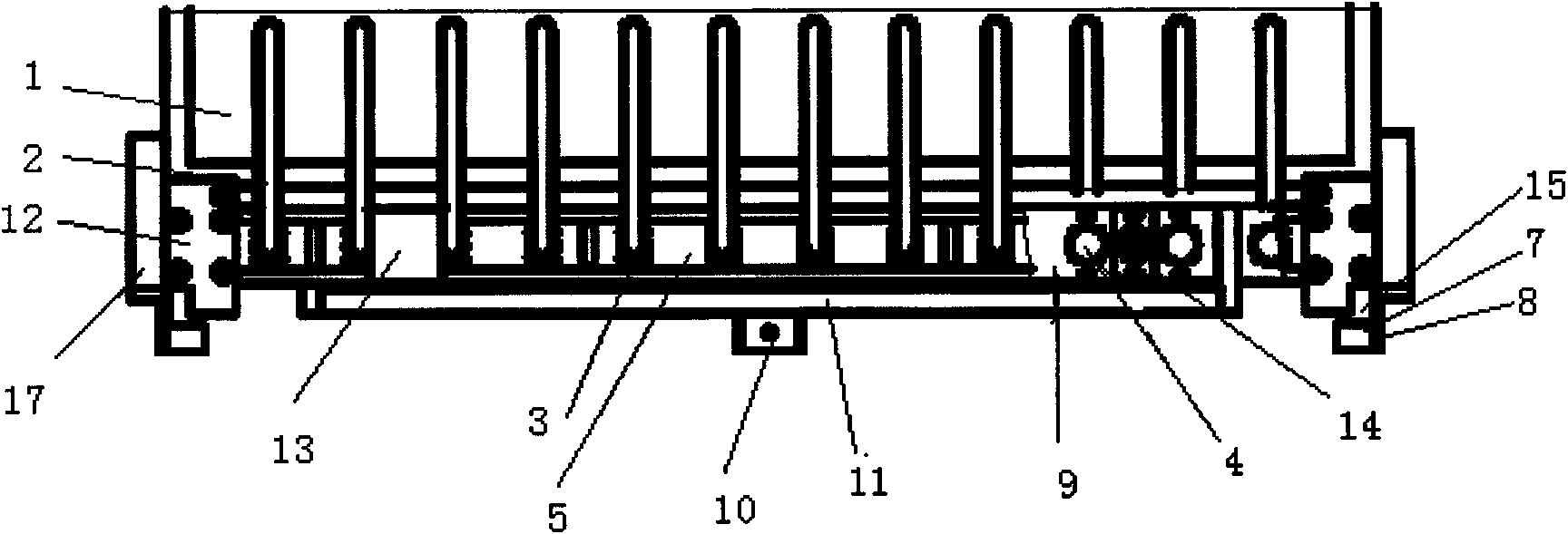

Automatic strapping tool for narrow and small space

ActiveCN105460260ASolve the problem of automatic cable tiesSolve the problem of inefficiencyBinding material applicationPaper/cardboard containersStrappingElectric machinery

The invention provides an automatic strapping tool for a narrow and small space. The tool comprises a host machine, a feeding pipe and a data line. The host machine is connected with the feeding pipe and the data line. The tool further comprises a fixed type automatic strapping working head for the narrow and small space. The host machine is connected with the fixed type automatic strapping working head for the narrow and small space through the feeding pipe and the data line. The tool has the beneficial effects that automatic strapping in the small space is achieved; the trouble that efficiency is low because motors are manually strapped since the birth of the motors is avoided; a bottleneck station in automatic operation of the motors is eliminated so that whole-line automatic production of the motors can be achieved; the flexible conveying pipe with a square section is used for feeding and the data line is used for transmitting signals so that the fixed type automatic strapping working head for the narrow and small space can be separated from the host machine, miniaturization of the fixed type automatic strapping working head for the narrow and small space is facilitated, a flow line production mode of motor coils is facilitated, and the tool and a manipulator can be conveniently combined for use.

Owner:SHENZHEN SWIFT AUTOMATION TECH CO LTD

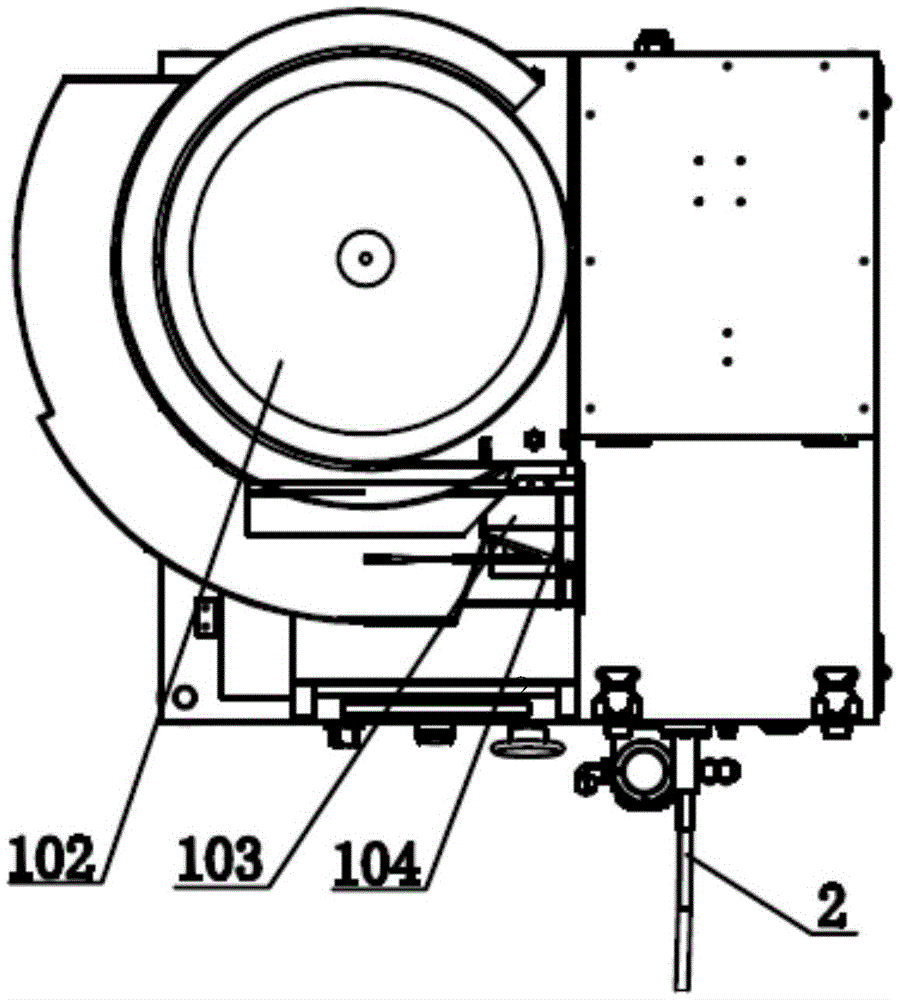

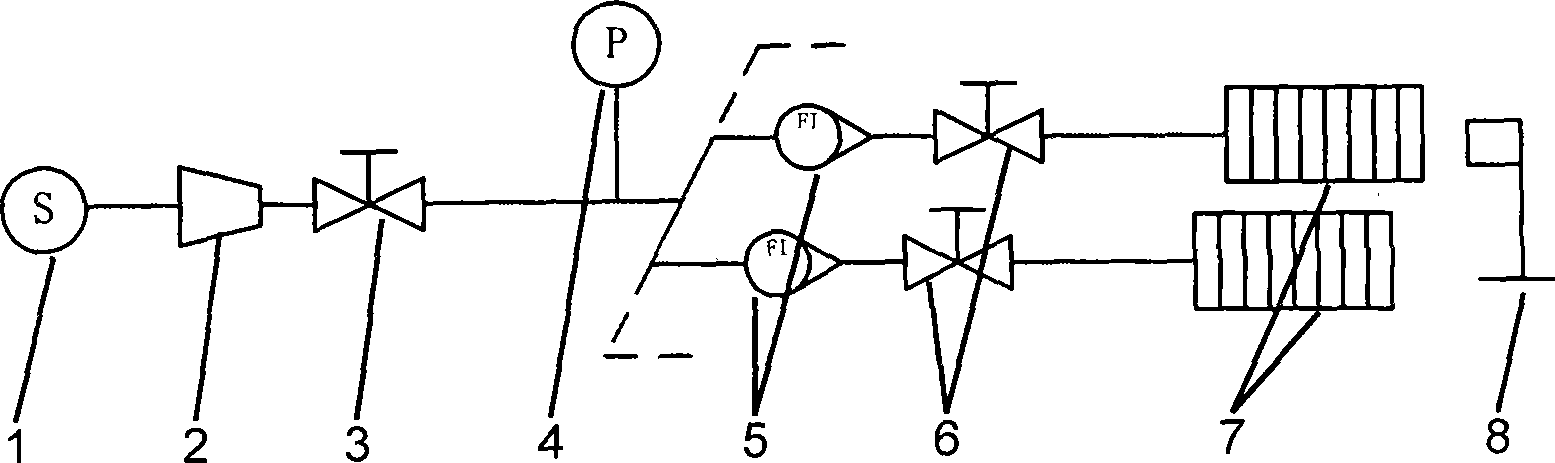

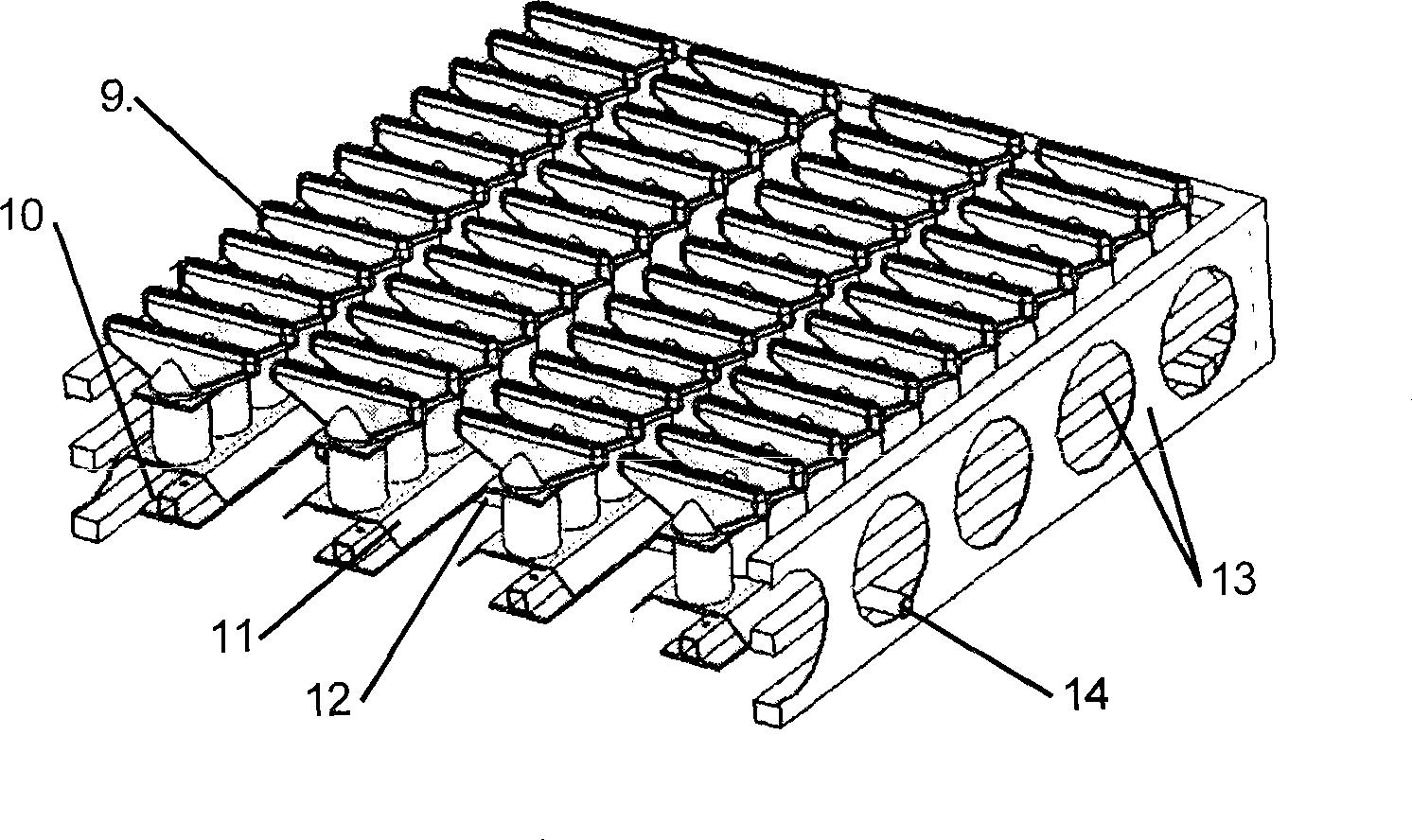

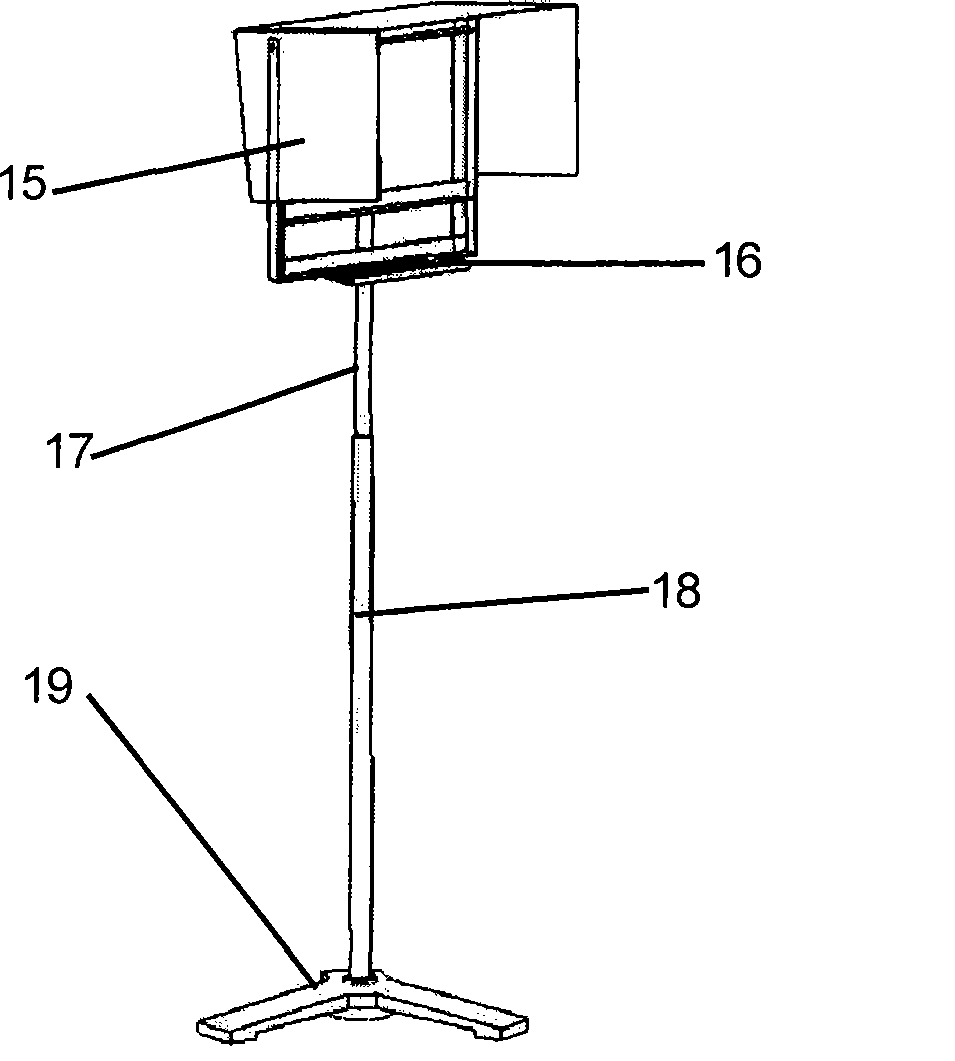

Novel device for testing hot smoke

InactiveCN101474467AAvoid fireShut down in timeFire rescueGaseous fuel burnerCombustorControl system

The invention relates to a novel thermal smoke testing device which is used for measuring and testing performance of a building smoke control system by using a simulating fire source and a smoke formation device under the condition of fire. The novel thermal smoke testing device comprises a combustor and a smoke formation mechanism; wherein, an air inlet pipe is arranged at the bottom in a frame of the combustor, and more than two jet tubes are evenly distributed above the air inlet pipe; the two jet tubes are communicated with the air inlet pipe and uniformly distributed with nozzles, and a strip-shaped housing plate is covered and arranged above each of the jet tubes; the housing plates are evenly provided with premixed nozzles, and the protruding end of the air inlet pipe is communicated with a fuel gas pipeline which is sequentially connected with a unit valve, a flowmeter, a master valve and the like in series, and a pressure gauge is connected between the flowmeter and the master valve in parallel; the smoke formation mechanism includes a smoke formation tray and a hood baffle. The novel thermal smoke testing device takes liquefied petroleum gas as fuel, thus improving the safety of the simulating fire source, strengthening the control to the simulating fire source, and enhancing the stability and the heat resistance of the simulating smoke source. Therefore, the novel thermal smoke testing device has adjustable and continuous fire source power, and is safe, clean and portable.

Owner:UNIV OF SCI & TECH OF CHINA

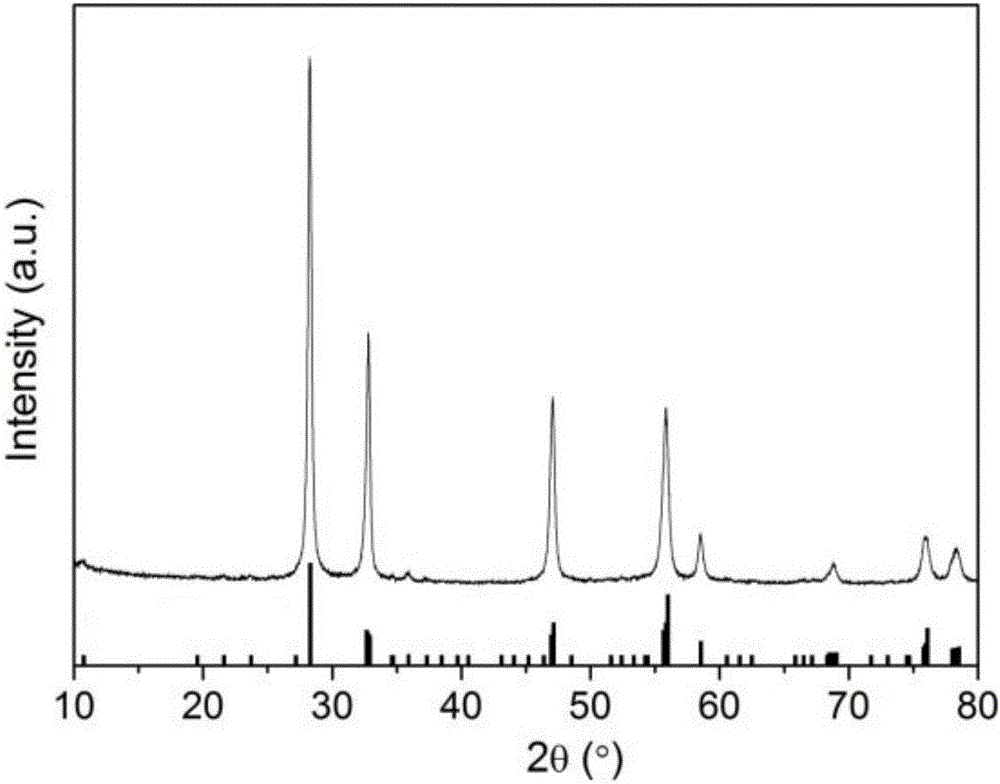

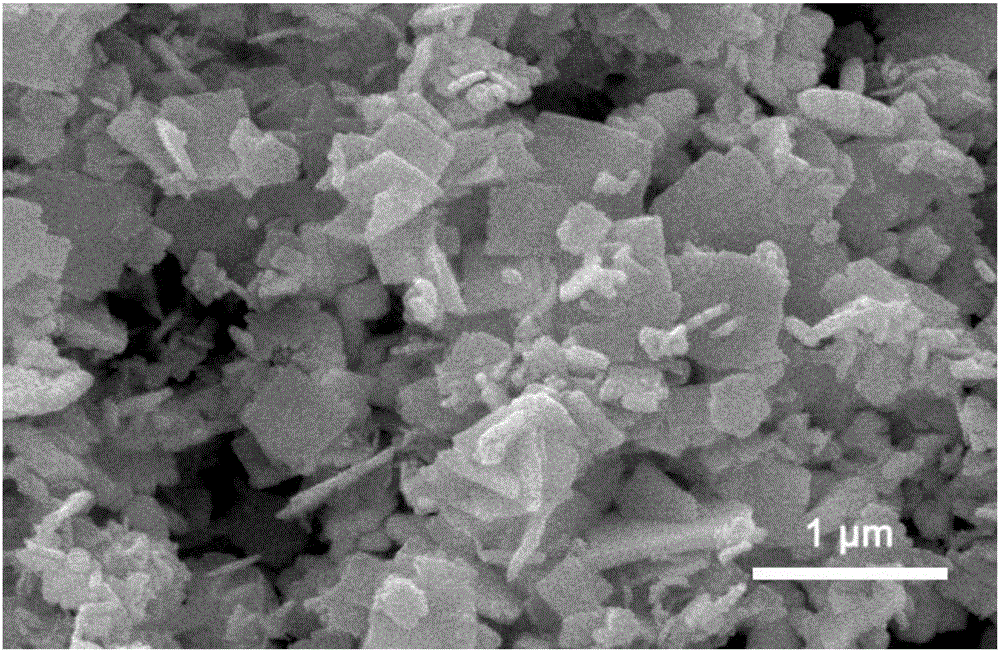

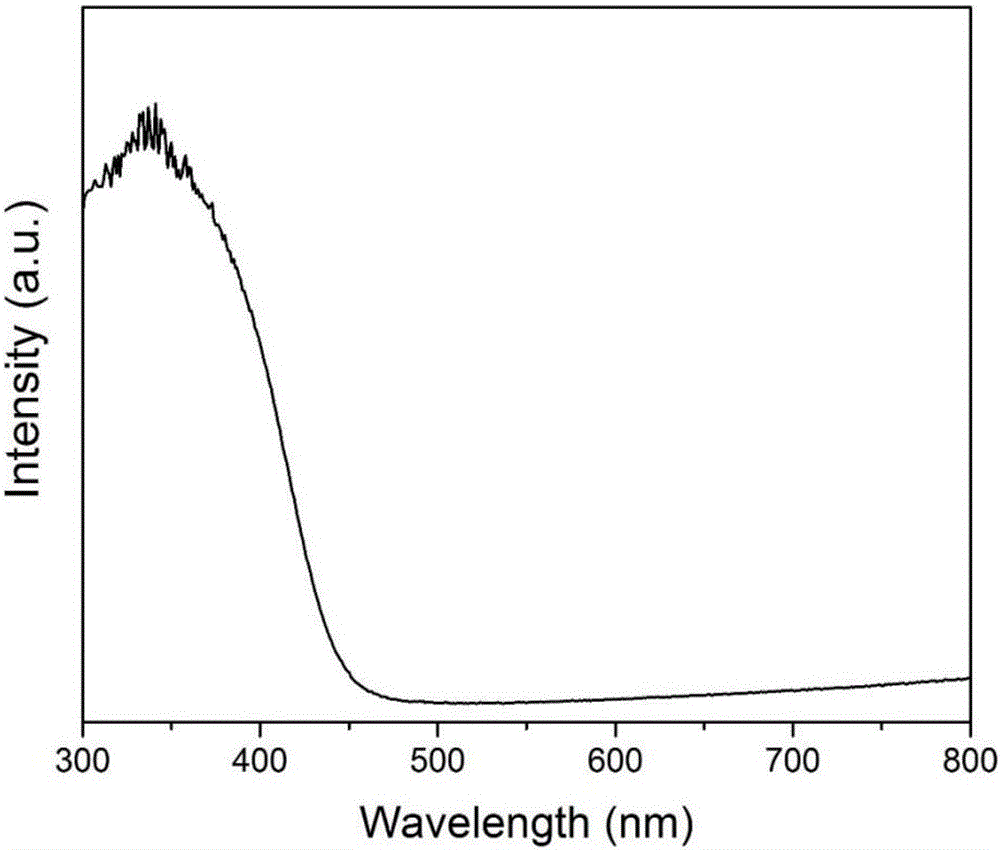

Bismuth tungstate nanometer photocatalyst and method for preparing same

ActiveCN105727932AEasy to operateGood repeatabilityGas treatmentDispersed particle separationTungstateTungsten

The invention discloses a method for preparing a bismuth tungstate nanometer photocatalyst. The method includes mixing bismuth sources, tungsten sources and critical water with one another to obtain mixtures; separating solid from liquid; drying solid portions to obtain the bismuth tungstate nanometer photocatalyst. The invention further discloses the bismuth tungstate nanometer photocatalyst prepared by the aid of the method and application of the bismuth tungstate nanometer photocatalyst in the aspect of photocatalysis. The method, the bismuth tungstate nanometer photocatalyst and the application have the advantages that the bismuth sources and the tungsten sources are mixed with one another under the condition of the critical water within a short time to obtain the bismuth tungstate nanometer photocatalyst, accordingly, the method is easy to implement, good in repeatability and high in yield, and the reaction time can be greatly shortened as compared with the prior art.

Owner:ZHEJIANG UNIV

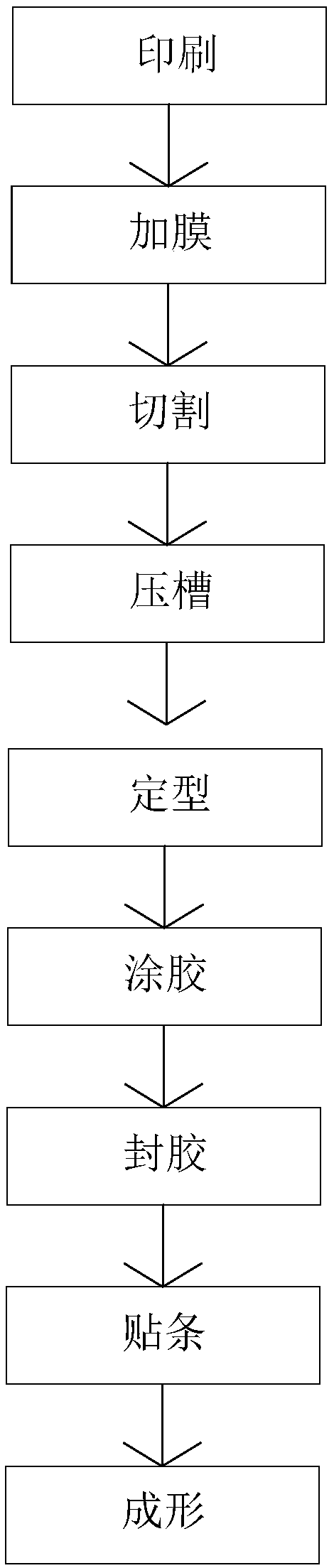

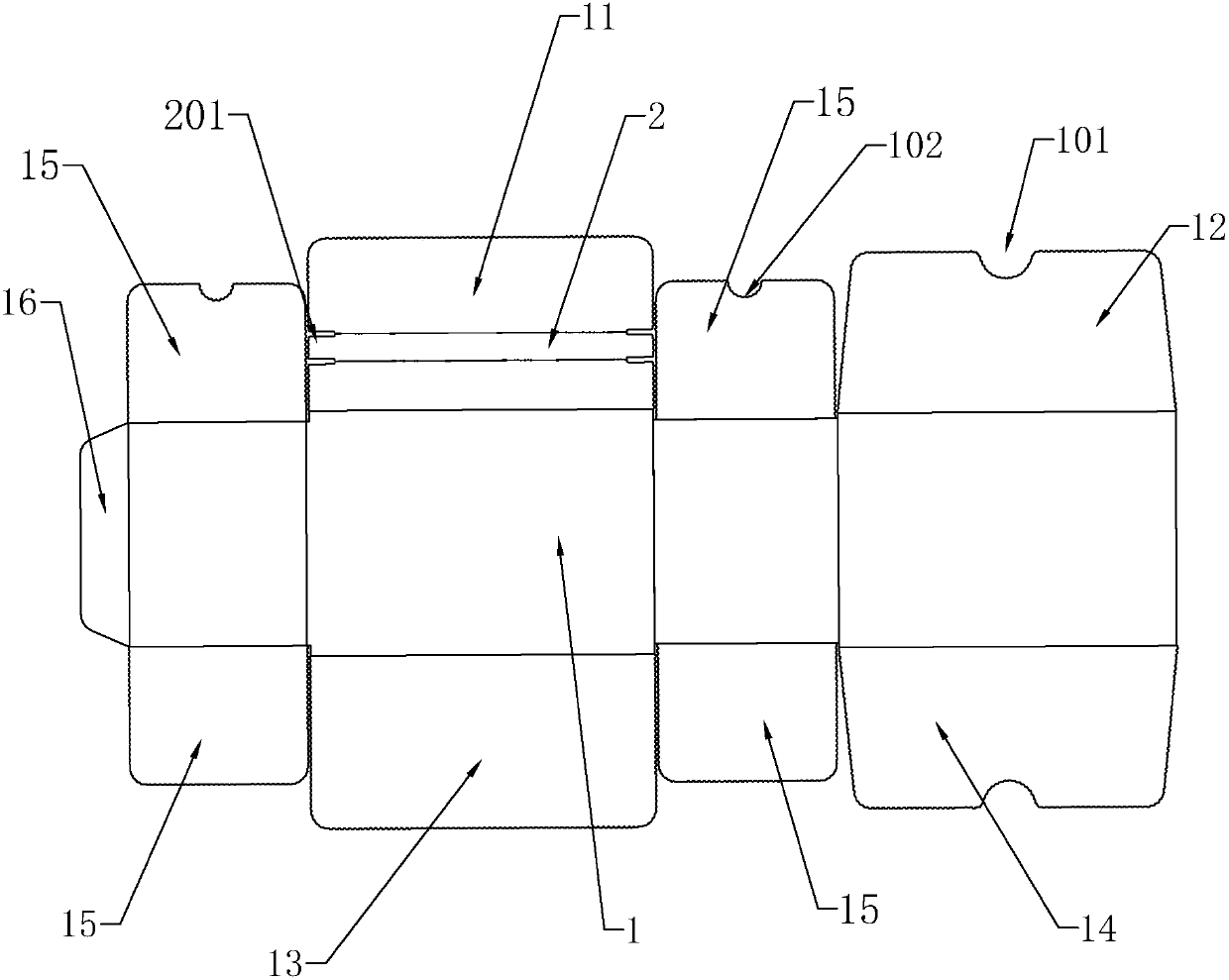

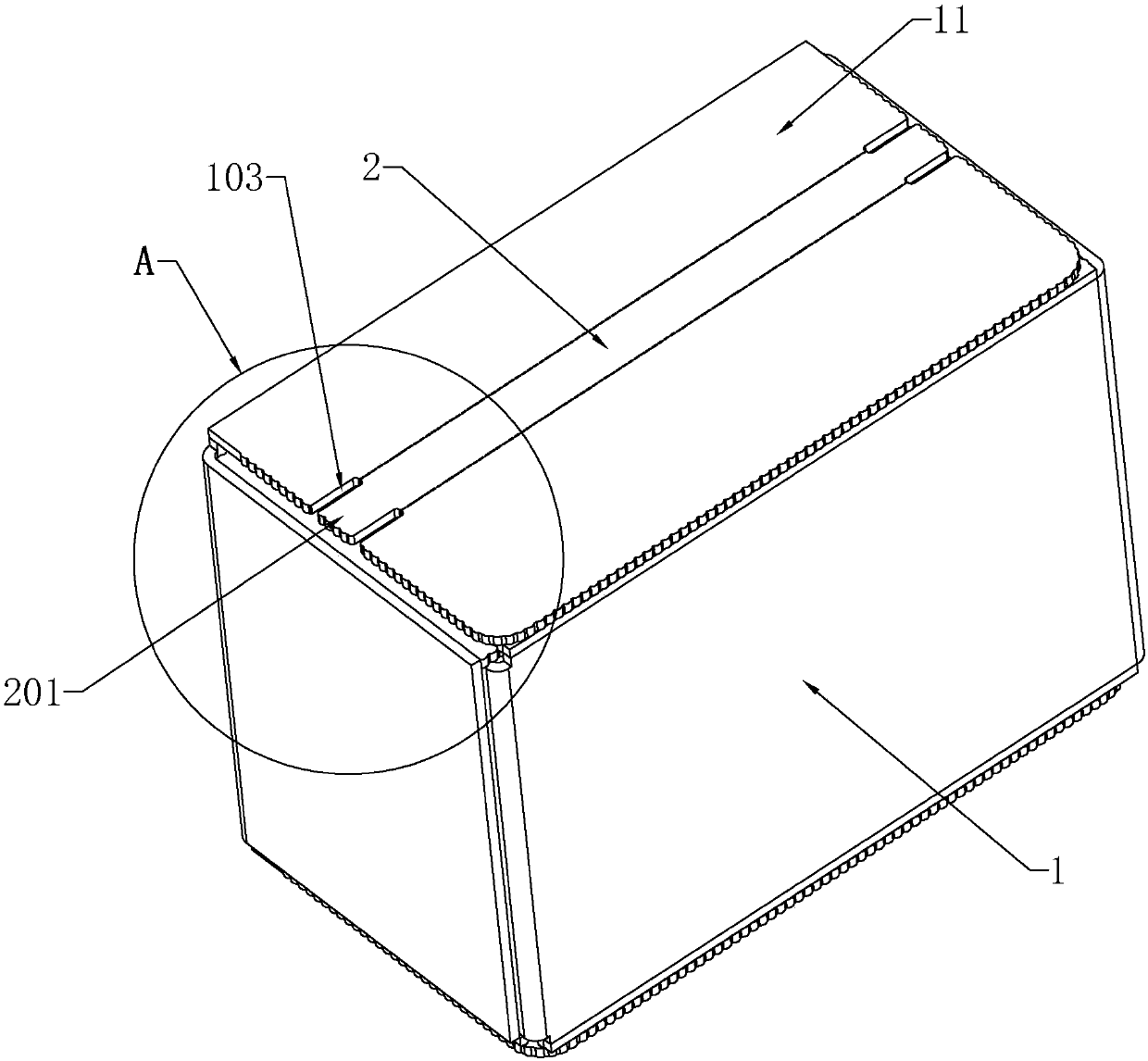

Packaging box and manufacturing process thereof

InactiveCN107839289AOptimize production methodsIncrease productivityBox making operationsPaper-makingIsolation layerEngineering

The invention discloses a packaging box and a manufacturing process thereof. The packaging box comprises a box body, a first cover plate, a second cover plate, a third cover plate, a fourth cover plate and side plates, the inner wall of the first cover plate and the inner wall of the third cover plate are each provided with a glue coating layer and an isolation layer covering the glue coating layer, and the gluing layer on the first cover plate is located between the reverse extending end, connected with the box body, of the first cover plate and a tearing belt. The packaging box is of a structure which is easy to tear and convenient to use, and when the packaging box is used actually, the box body can be sealed only by tearing the isolation layers on the surfaces of the glue coating layers and bonding the first cover plate and the second cover plate or the third cover plate and the fourth cover plate through glue; and when the packaging box needs to be opened, the end of the tearing belt is held by hand and pulled outwards with force, the tearing belt is separated from the first cover plate to divide the first cover plate into an upper part and a lower part, the upper part is connected with the second cover plate, and the lower part is connected with the box body.

Owner:HANGZHOU YONGHUA PRINTING & PACKING CO LTD

PP (Polypropylene) net-shaped filling rope and manufacturing method

InactiveCN108456362ASimplify production stepsEasy to produceFilament/thread formingTextile cablesParaffin waxChemistry

The invention discloses a PP (Polypropylene) net-shaped filling rope which comprises the following raw materials in percentage by mass: 50-75% of packing, 0.5-0.8% of a coupling agent, 13-35% of polypropylene, 4-9% of polyethylene, 1-1.3% of stearic acid, 2-2.6% of paraffin, 0.3-0.5% of an antioxidant and 2-3% of a defoaming agent. A preparation method comprises the following steps: performing pretreatment and weighing on raw materials; mixing the materials by using a high-speed mixing machine; discharging and cooling the materials; feeding the materials; extruding the materials by using a double-screw extruder; cooling in a water trough; cutting by using a first tractor; tensioning by using a hot extension plate; forming nets by using a netting machine; tensioning by using a second tractor; coiling by using a coiling machine; combining yarns by using a rope maker. The rope is produced by using the double-screw extruder, a calcium carbonate master batch preparation procedure is avoided, the production efficiency is simplified, the production efficiency is improved, the production cost is lowered, the PP filling rope produced by using the method is high in whiteness, low in hydroscopicity, relatively good in flexibility and high in strength, and a cable filled with the rope is appropriate in tightness, and cable cores can be round and tidy.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

Integrated stowing machine

InactiveCN101886900AReduce in quantityIncrease productivityAmmunition storagePackagingEngineeringMechanical engineering

The invention relates to an integrated stowing machine, which is assembled as follows: a package deliver component is arranged at the foremost end of a rack, and a package managing component, a lamination device and a package arranging component are arranged in sequence behind the package deliver component; a filling component is arranged below the stand of the package managing component; all the components are respectively arranged on the rack; a pneumatic electrical component is arranged in an electric cabinet in a rack component; a repacking component is fixed with the rack through a connection piece; and no relative movement exists between equipments. The invention has reasonable structure, reliable property, simple operation, convenient adjustment and high automaticity.

Owner:WUHAN RENTIAN PACKAGING TECH

Konjak dietary fiber meal replacement flour

InactiveCN103976368AEasy to eatSave timeFood preparationFood ingredient as replacerMeal replacementAmerican cranberry

The invention provides konjak dietary fiber meal replacement flour. The konjak dietary fiber meal replacement flour comprises the following components in parts by weight: 10 to 12 parts of konjac glucomannan, 66 to 70 parts of maltodextrin, 10 to 11 parts of niblet, 3 to 4 parts of carrot, 0.05 to 0.1 part of sucralose, 1.6 to 2.1 parts of sodium citrate, 1.6 to 2.1 parts of diced cranberry, and 3 to 4 parts of vitamin and mineral substance used for food. The konjak dietary fiber meal replacement flour is prepared by the following steps: uniformly mixing konjac glucomannan, vitamin and mineral substance, and sucralose for later use; uniformly mixing the prepared maltodextrin, niblet, diced carrot, sodium citrate and diced cranberry for later use; then uniformly mixing the prepared mixtures; and sterilizing to obtain the konjak dietary fiber meal replacement flour. The konjak dietary fiber meal replacement flour prepared by the mode above can be brewed with boiling water for eating, is comprehensive in nutrition, convenient to eat, saves time, and also overcomes the shortcomings in the prior art; in addition, the production method is simple and convenient, and the raw materials and cost are saved.

Owner:云南富源金田原农产品开发有限责任公司

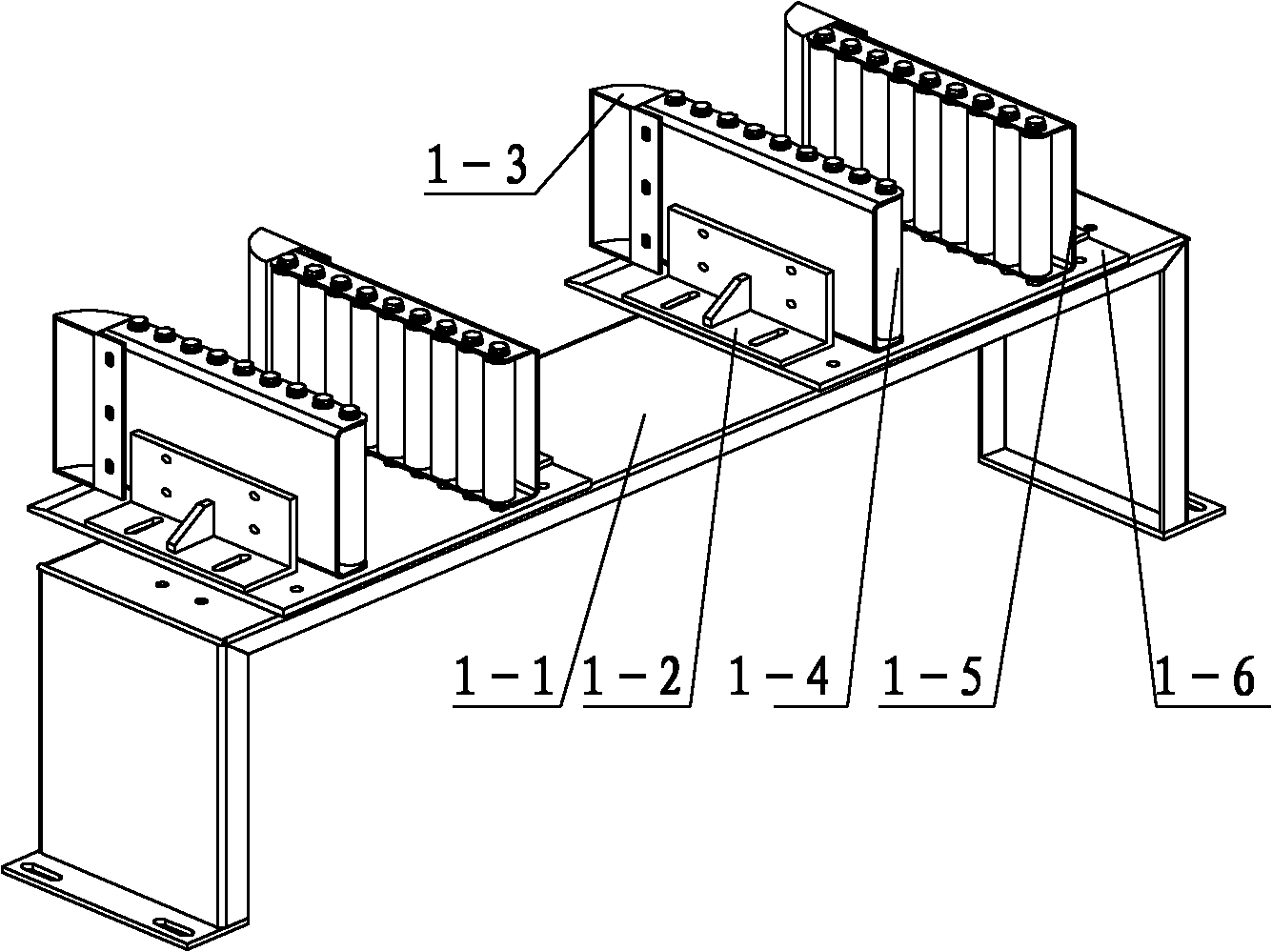

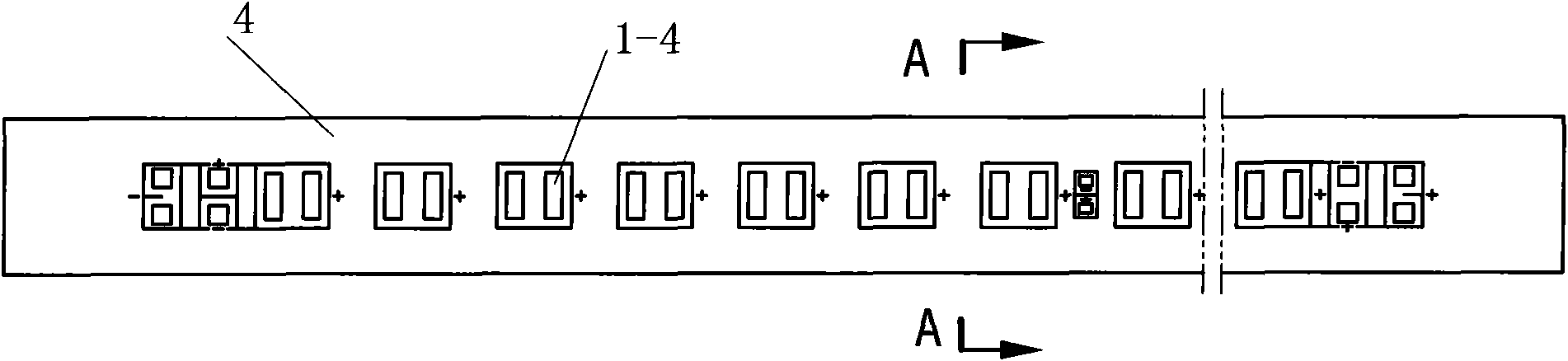

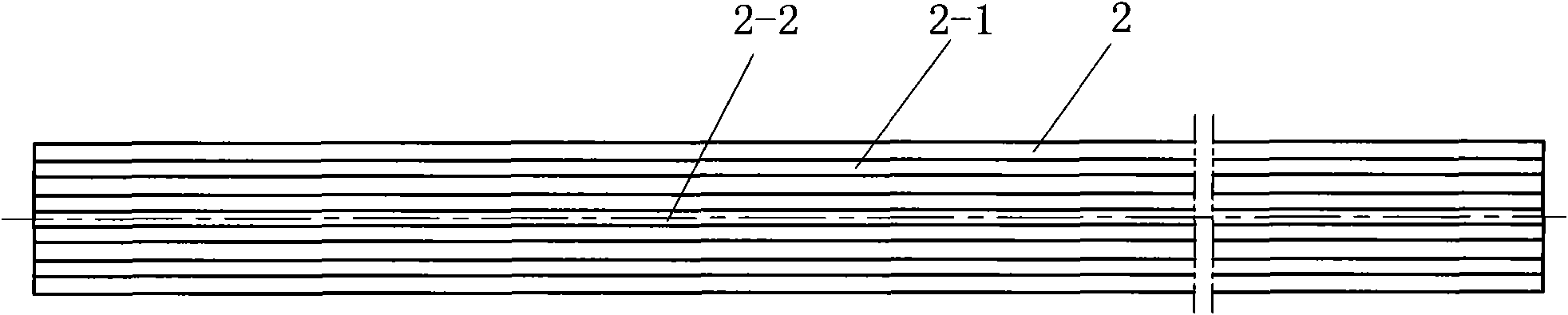

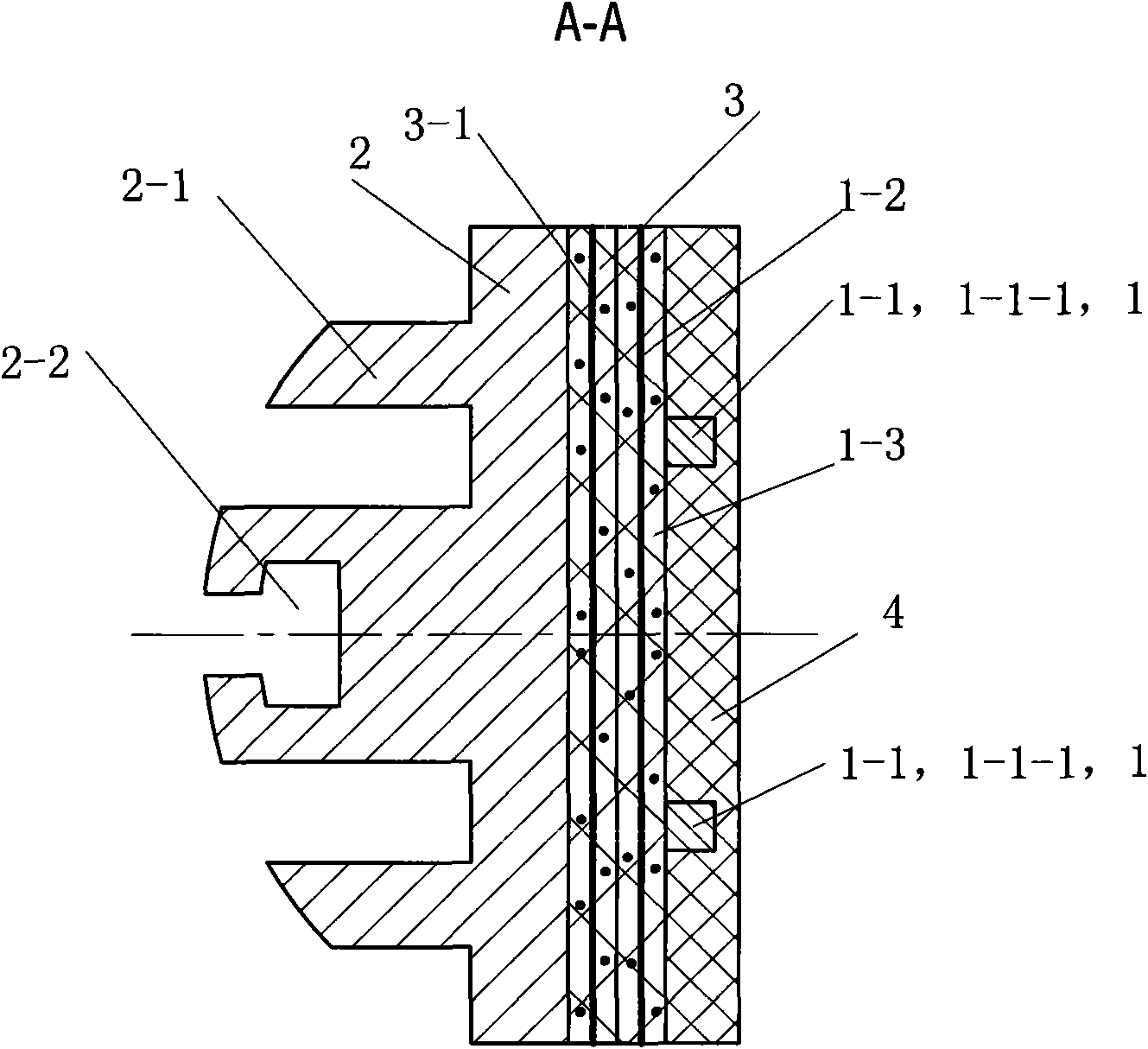

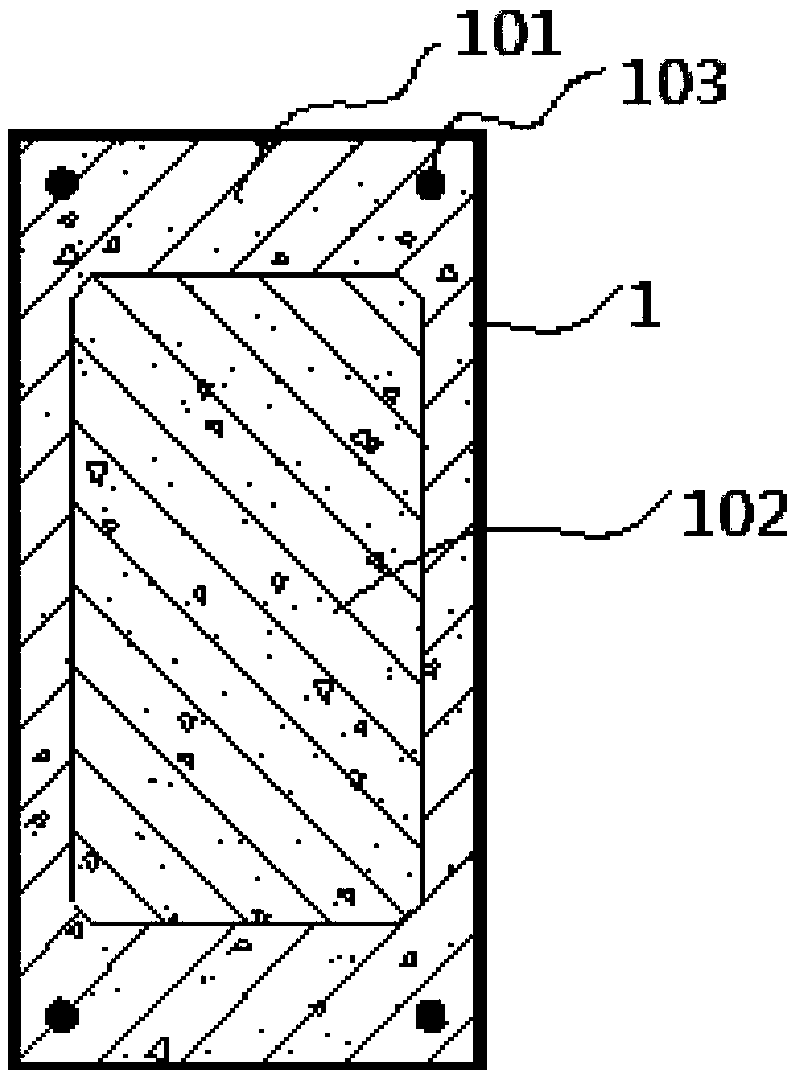

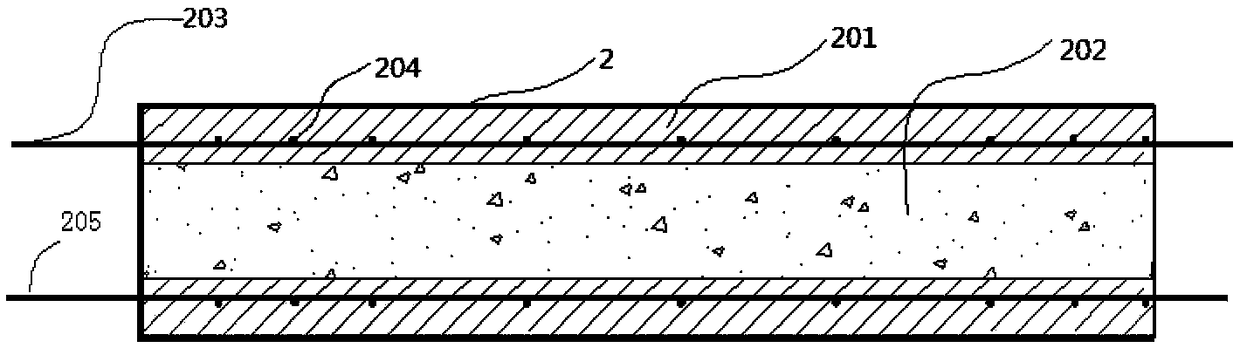

Clad copper foil printed circuit board laminating plate of radiator

InactiveCN101657066AReasonable structureImprove cooling effectPrinted circuit detailsLighting heating/cooling arrangementsResistHeat conducting

The invention discloses a clad copper foil printed circuit board laminating plate of a radiator, comprising a copper foil printed circuit board (1) and a radiator (2). The radiator (2) is used as a base body and (2) is integrally overlapped and bonded with the copper foil printed circuit board (1) into a whole through an insulating heat conducting layer (3); and an insulating solder-resist material layer (4) is arranged on the whole surface of the copper foil printed circuit board (1) located outside a pad (1-4). The invention has the characteristics of reasonable structure, favorable radiating effect, safe and reliable use, and the like.

Owner:常州市超顺电子技术有限公司 +1

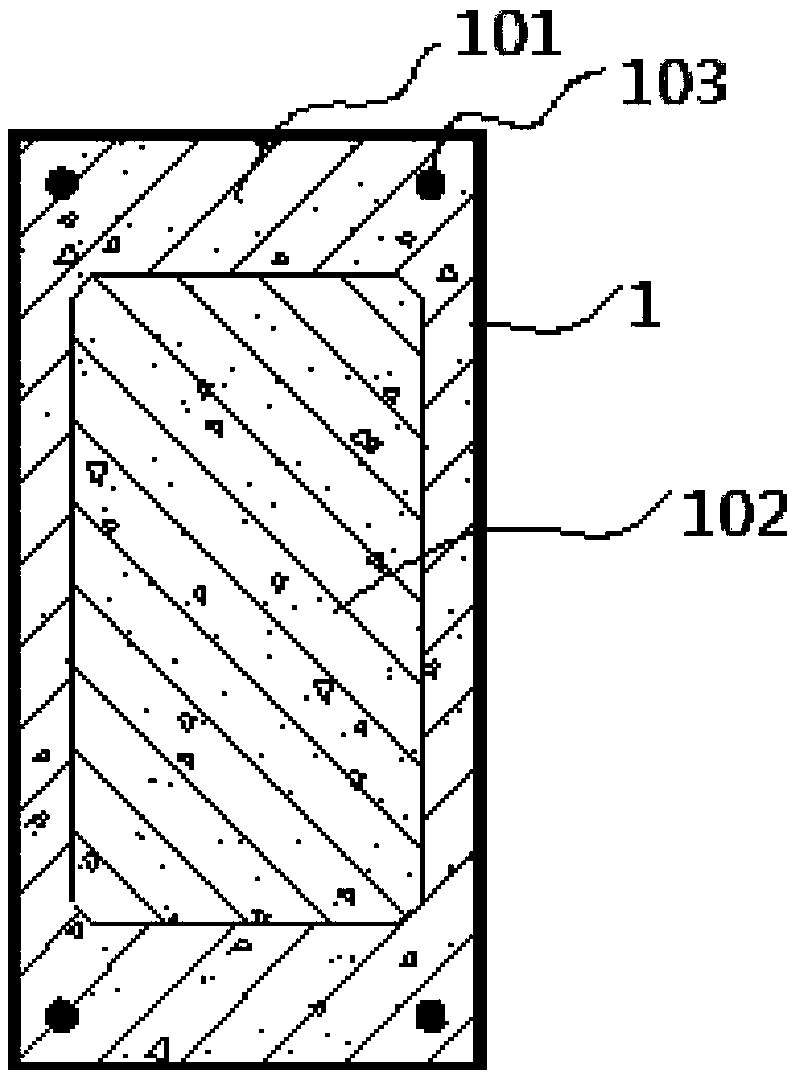

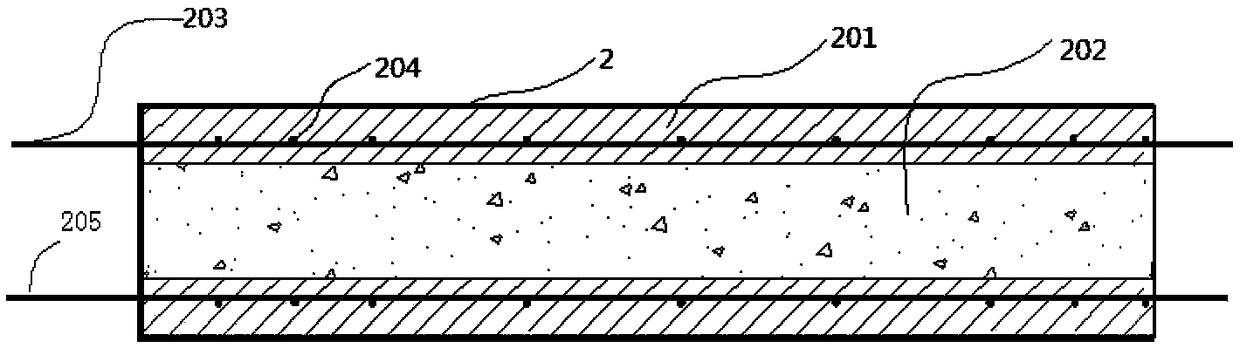

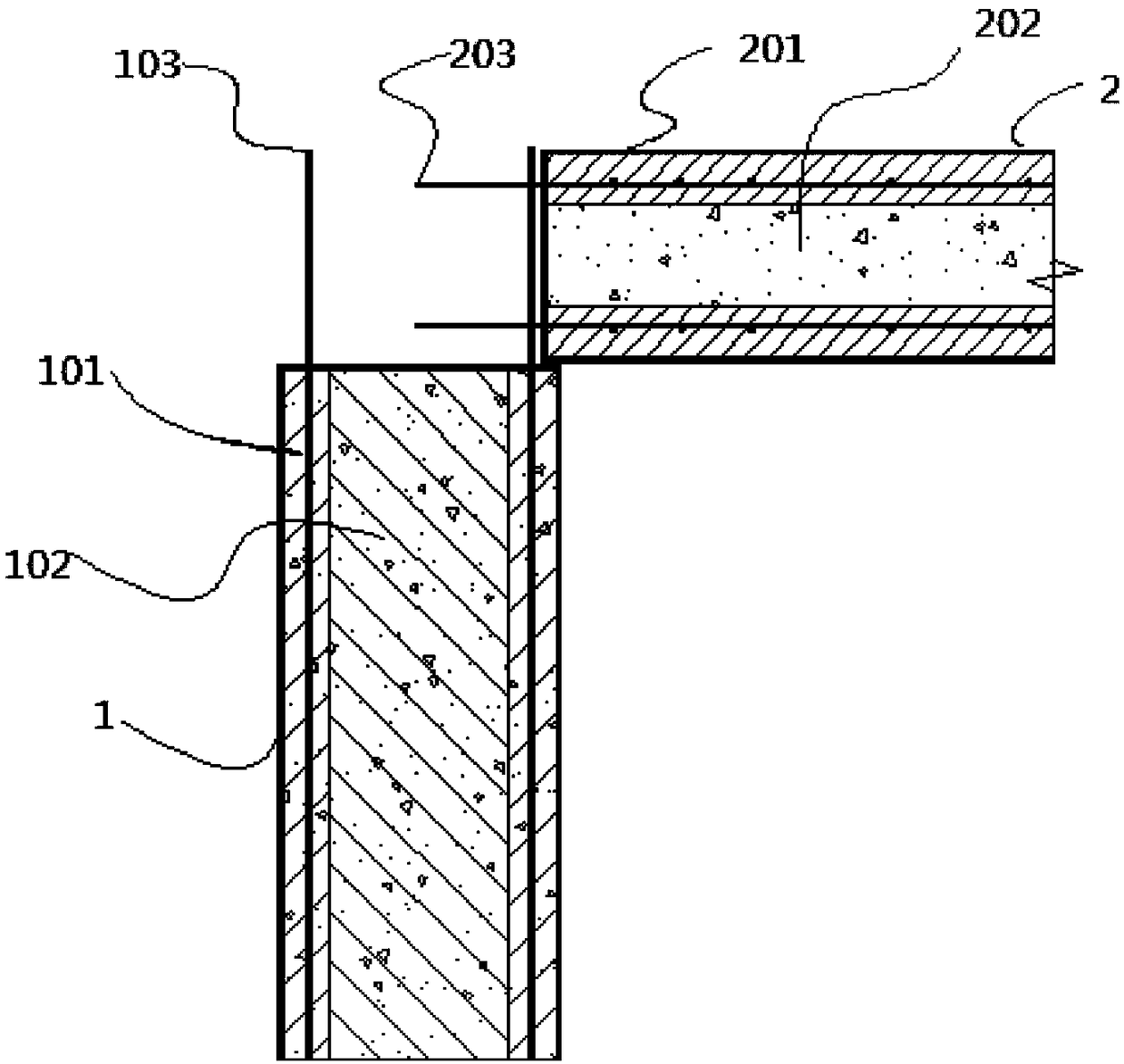

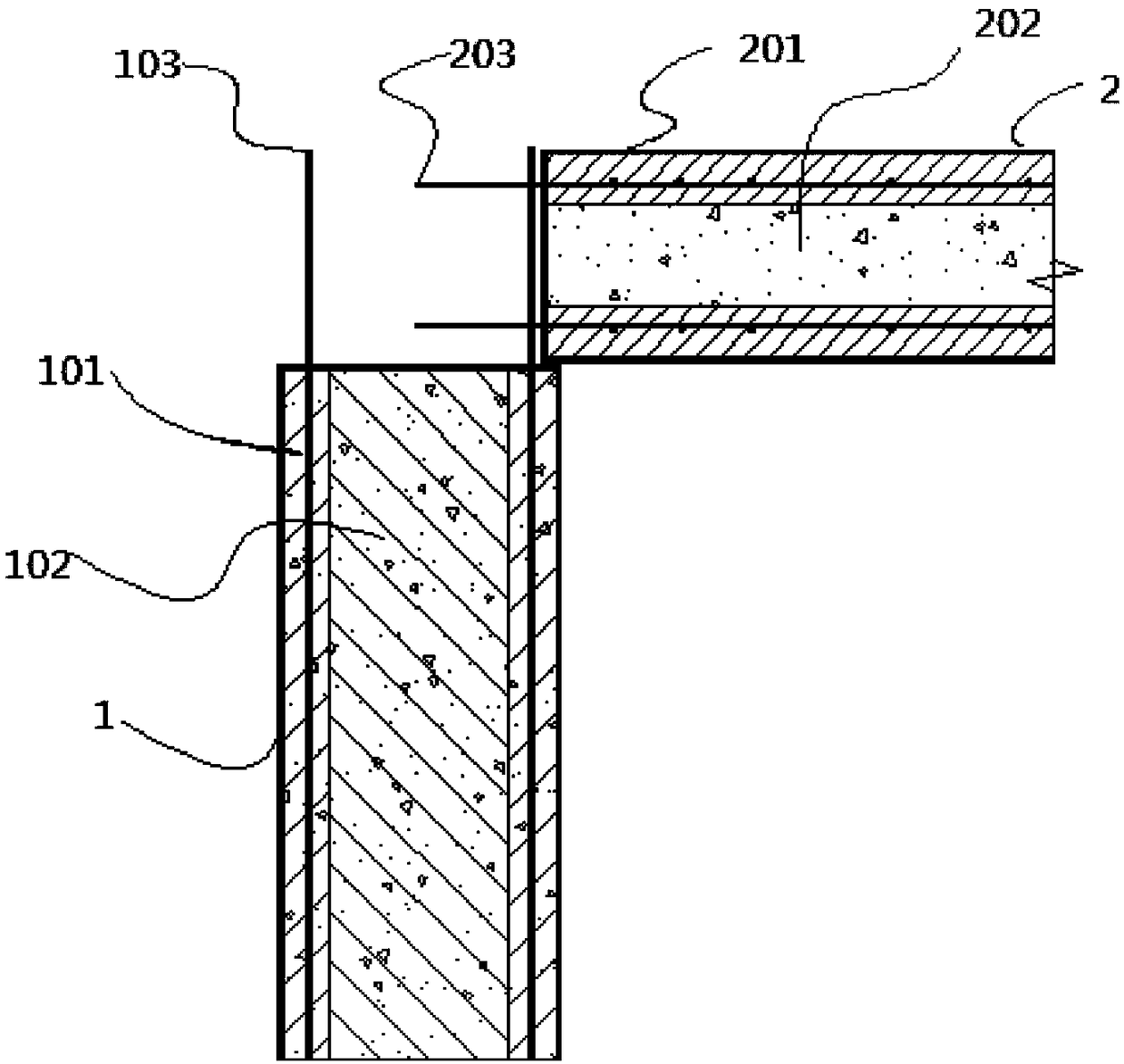

Frame structure system and construction method thereof

ActiveCN108343148AHigh strengthImprove stress resistanceProtective buildings/sheltersShock proofingConcrete beamsLap joint

The invention provides a frame structure system and a construction method thereof. The frame structure system comprises a plurality of composite columns and composite beams. Each composite column comprises a prefabricated column mold shell and a cast-in-situ concrete column inner core. Each composite beam comprises a prefabricated beam mold shell and a cast-in-situ concrete beam inner core. The top side of each prefabricated beam mold shell is provided with a grouting hole and an exhaust hole. 1-20cm of the end head of each composite beam is in lap joint with the edge of the top side of the corresponding composite column. The composite beams and the composite columns are connected through cast-in-situ concrete to form beam-column joints. The end heads of beam rebars of the composite beamsextend out of the ends of prefabricated beam mold shells and are anchored in the cast-in-situ concrete of the beam-column joints. The construction method comprises the following steps that prefabricated column mold shells are hoisted to the predetermined positions; the cast-in-situ concrete beam inner cores of the composite columns are formed through grouting; the prefabricated beam mold shells are hoisted, and 1-20cm of the end heads of the prefabricated beam mold shells are in lap joint with the edges of the top sides of the prefabricated column mold shells; templates at the beam-column joints are erected; the cast-in-situ concrete beam inner cores of the composite beams are formed through grouting; the concrete at the beam-column joints is grouted; and the steps are repeated until construction of the building frame is completed.

Owner:江苏千禧杭萧装配式建筑科技有限公司

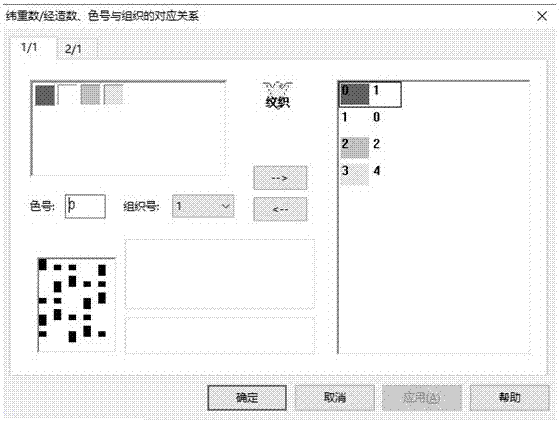

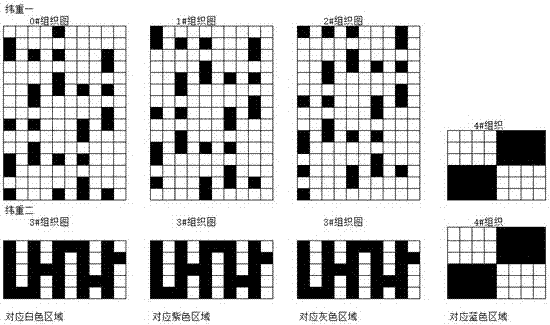

Preparing method of weaving molding home textile products

ActiveCN107299442AReduce production laborLow manufacturing costMulti-ply fabricsDesign innovationWoven fabric

The invention discloses a preparing method of weaving molding home textile products. The method comprises the steps that a woven fabric organizational structure design innovation is combined with a figured weaving technology, a large jacquard loom is used for preparing a stereo structure, home textile set products such as bedding bags and pillowcases are directly woven out, most steps such as cutting, splicing and sewing in home textile production processing are saved, and the preparing method has overturning value significance for the home textile manufacturing industry.

Owner:WEIQIAO TEXTILE

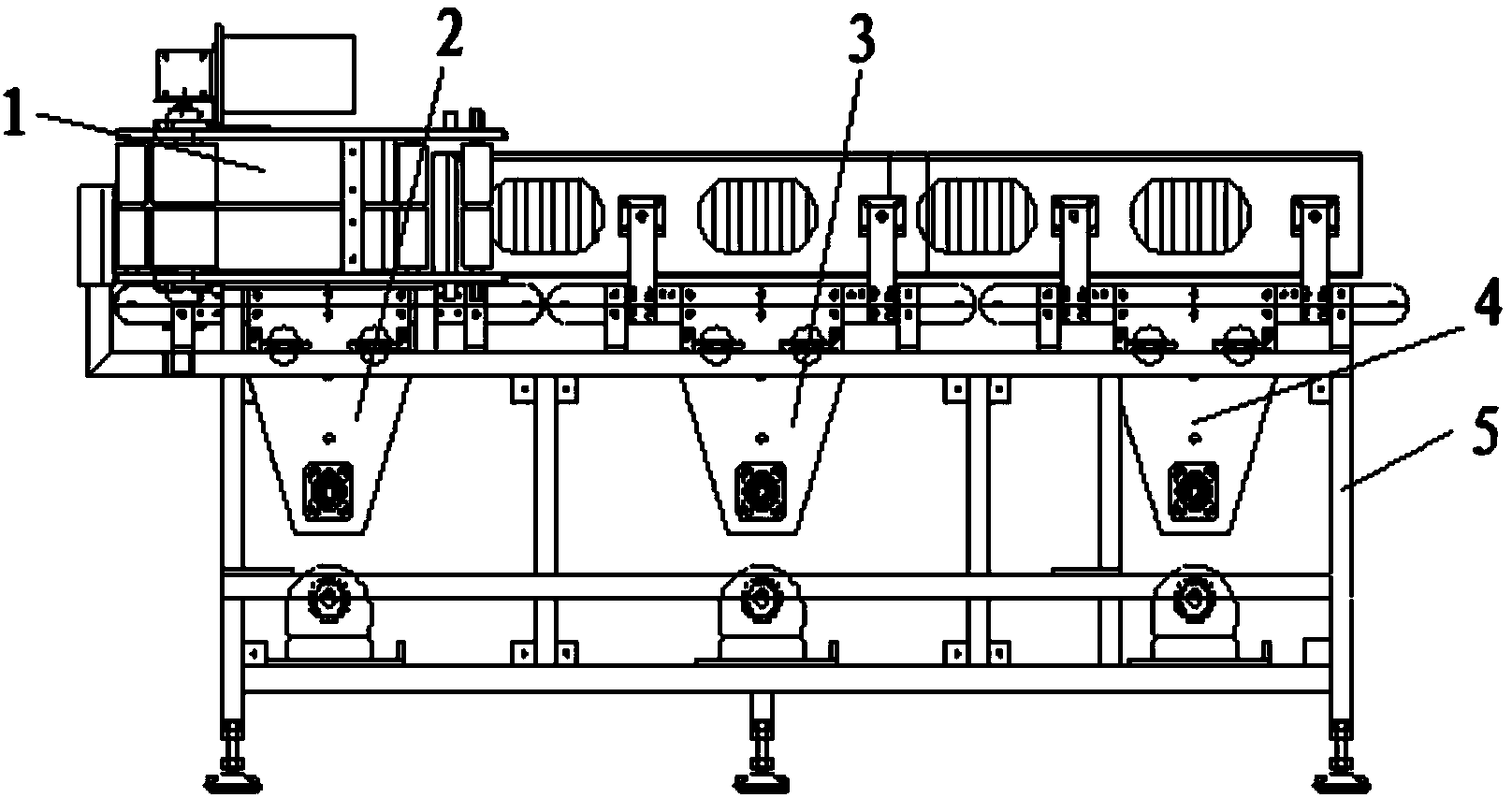

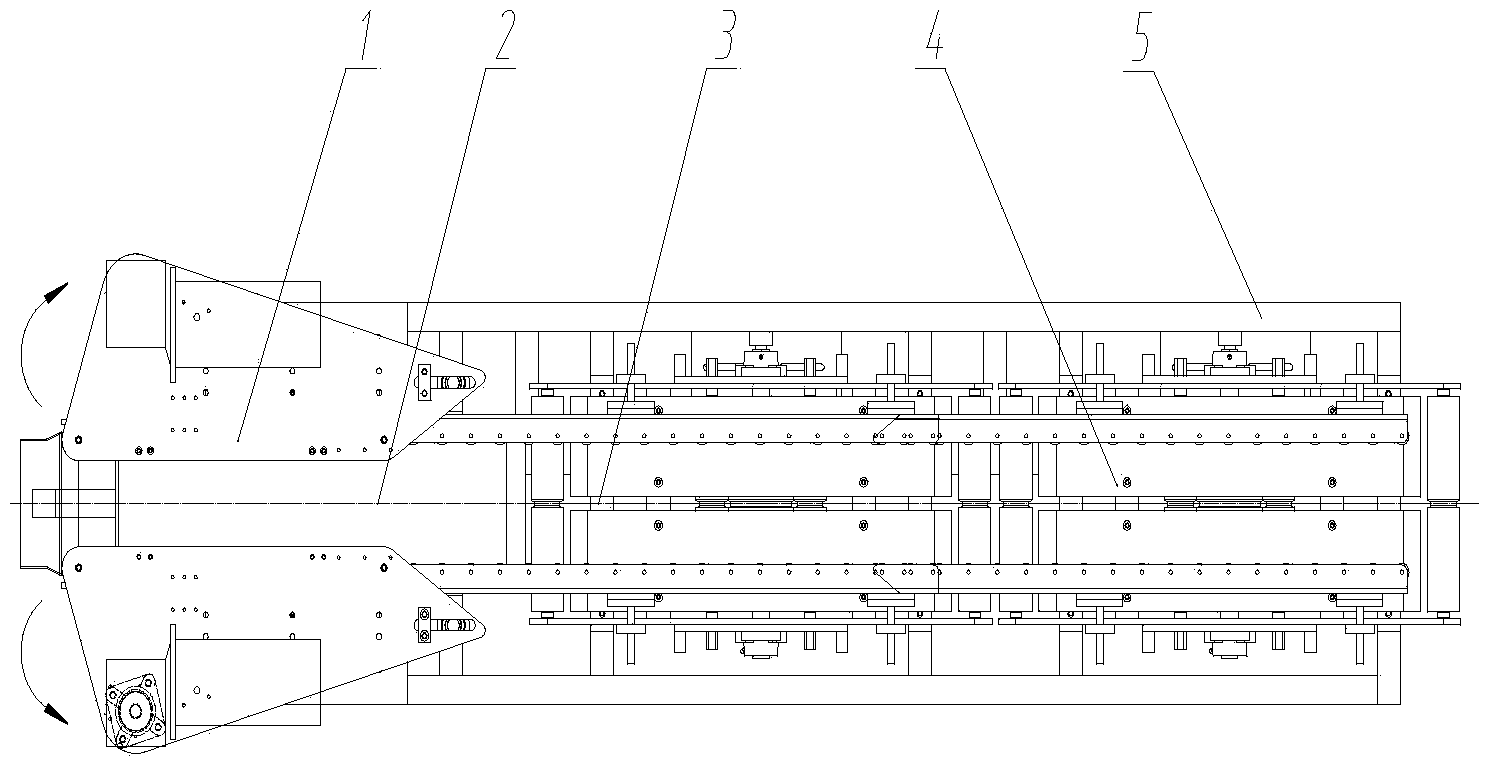

Package distributing and conveying all-in-one machine

ActiveCN103407774AReduce in quantityReduce resistanceConveyor partsElectrical controlElectric control

The invention relates to a package distributing and conveying all-in-one machine. The package distributing and conveying all-in-one machine has such a structure that two lateral package conveying belt conveyors, a bottom package conveying belt conveyor, a package distributing belt conveyor and a transitional belt conveyor are installed on a rack respectively; an electric control part is installed inside the rack, the two lateral package conveying belt conveyors are installed at the upper part of the most front end of the rack and are arranged along a central mirror image; the bottom package conveying belt conveyor is located below the two lateral package conveying belt conveyors; the package distributing belt conveyor and the transitional belt conveyor are sequentially behind the bottom belt conveying conveyor; no relative movement exists between each two belt conveyors; the electric control part controls the two lateral package conveying belt conveyors, the bottom package conveying belt conveyor, the package distributing belt conveyor and the transitional belt conveyor respectively to cooperate together so as to convey middle packages to a next device. The package distributing and conveying all-in-one machine has high production efficiency, improves production efficiency greatly and reduces number of operators; each unit is installed on the rack, is compact in structure and occupies little space; cartridges are protectively conveyed by adopting a roller in the package distributing belt conveyor and the transitional belt conveyor, so that low resistance, no damage and high efficiency are achieved.

Owner:WUHAN RENTIAN PACKAGING TECH

Technical method for rapid asexual propagation and anti-enhancement of hybrid bollgard F1

The invention relates to a technical method for rapid asexual propagation and anti-enhancement of hybrid bollgard F1, which comprises the main steps of: firstly, identifying perennial cotton germplasm resources capable of naturally overwintering, and resisting fusarium wilt resistance and greensickness; adopting the perennial cotton germplasm resources as rootstock, scioning and grafting with the hybrid bollgard F1, and cultivating perennial root to obtain grafted plants; and secondly, carrying out large-scale propagation of hybrid bollgard F1 seedlings by using the method, and directly using the hybrid bollgard F1 seeldings for agricultural production. According to the technical method for rapid asexual propagation and anti-enhancement of the hybrid bollgard F1, field cotton hybrid seed production is free, the seed production process of the hybrid bollgard F1 is simplified, the seed purity of the hybrid bollgard F1 is improved, and the disease resistance of the hybrid bollgard F1 is enhanced. The method can be used for large-scale propagation of hybrid bollgard F1 seedlings with obviously improved anti-enhancement property, and is applied to agricultural production.

Owner:HUBEI PROVINCIAL SEED GRP CO LTD

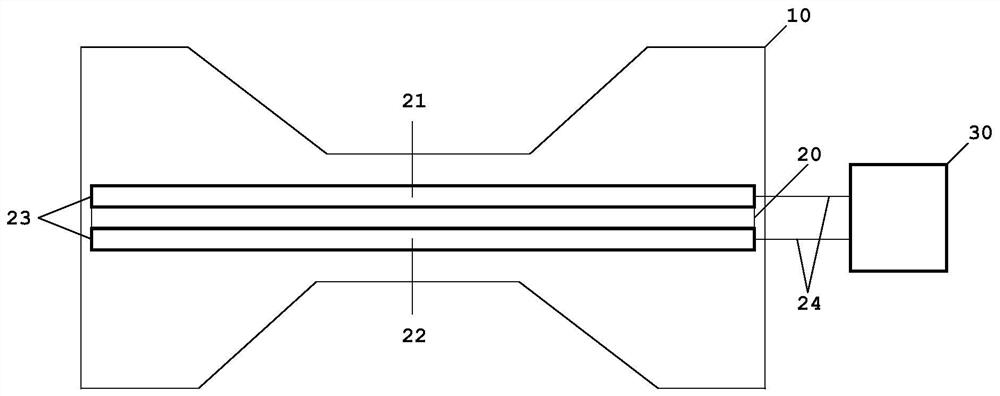

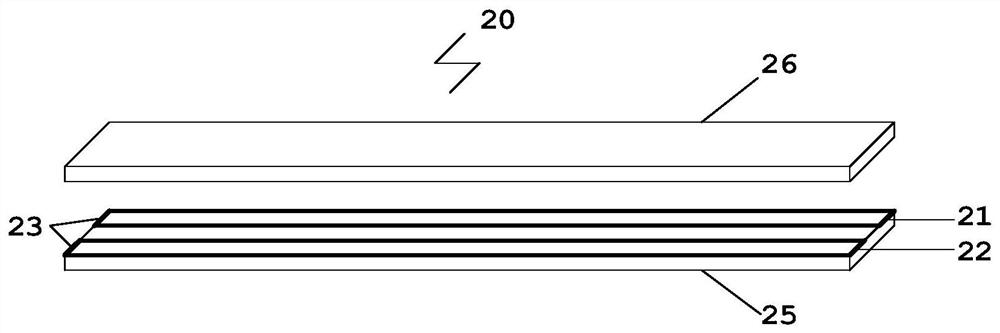

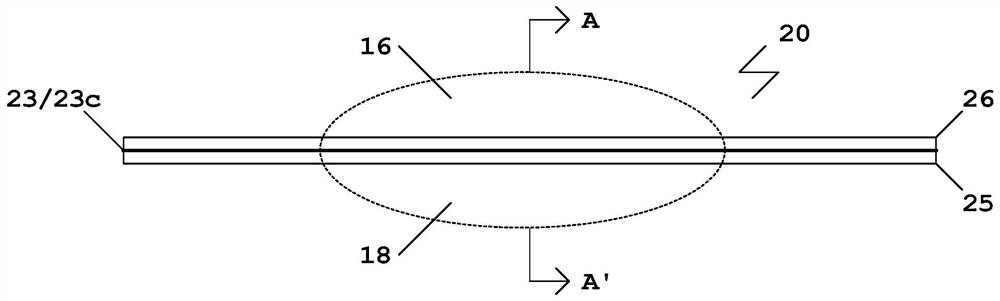

Disposable absorbent article absorption state monitoring sensor and related article and method

ActiveCN112315667ARealize the function of distinguishing between urine and urineSimple production methodAbsorbent padsCapacitanceEngineering

The invention provides an absorption state monitoring sensor suitable for being arranged in a disposable absorption product for use, which comprises a first detection loop, a waterproof protection mechanism and an infiltration and diffusion control mechanism, the first detection loop comprises a first detection electrode and a second detection electrode, and the first detection electrode and the second detection electrode comprise protected electrode parts and unprotected electrode parts; when excrement containing electrolyte liquid exists in the absorption article, an electric double-layer capacitor is generated between the first detection electrode and the second detection electrode, the capacitance value of the capacitor is in positive correlation with the specific surface area of the part, not soaked by the electrolyte liquid, of the protection electrode, and the capacitance value of the capacitor is gradually increased under the action of a soaking diffusion control mechanism. Theinvention further provides a disposable intelligent absorption article capable of providing absorption state information, a manufacturing method of the absorption state monitoring sensor, a manufacturing method of the disposable intelligent absorption article and a urine and excrement distinguishing method. The sensor has the advantages of being low in cost, easy to produce, good in universalityand the like.

Owner:SHENZHEN CDIAPER TECH LTD

Beam column joint and construction method thereof

ActiveCN108301510AHigh strengthImprove stress resistanceBuilding constructionsConcrete beamsLap joint

The invention provides a beam column joint and a construction method thereof. The beam column joint comprises a composite column and a composite beam. The composite column comprises a prefabricated column mould shell and a cast-in-place concrete column inner core, the composite beam comprises a prefabricated beam mould shell and a cast-in-place concrete beam inner core, and a grouting hole and anexhaust hole are formed in the top side of the prefabricated beam mould shell. The portion, within 1-20cm, of the end of the composite beam is in lap joint to the edge of the top side of the compositecolumn, and the composite beam and the composite column are connected through cast-in-place concrete to form the beam column joint. The end of a beam reinforcing steel bar of the composite beam extends out of the end of the prefabricated beam mould shell and is anchored in the cast-in-place concrete of the beam column joint. The length of the beam reinforcing steel bar anchored in the beam columnjoint is 35 to 40 times the diameter of the beam reinforcing steel bar. The construction method comprises the following steps that the prefabricated column mould shell is hoisted to a predetermined position; the cast-in-place concrete column inner core of the composite column is poured and formed; the prefabricated column mould shell is hoisted and the portion, within 1-20cm, of the end is in lapjoint to the edge of the top side of the prefabricated column mould shell; a formwork is arranged at the beam column joint; the cast-in-place concrete beam inner core of the composite beam is pouredand formed; and concrete at the beam column joint is poured.

Owner:河南三禾建筑工程有限公司

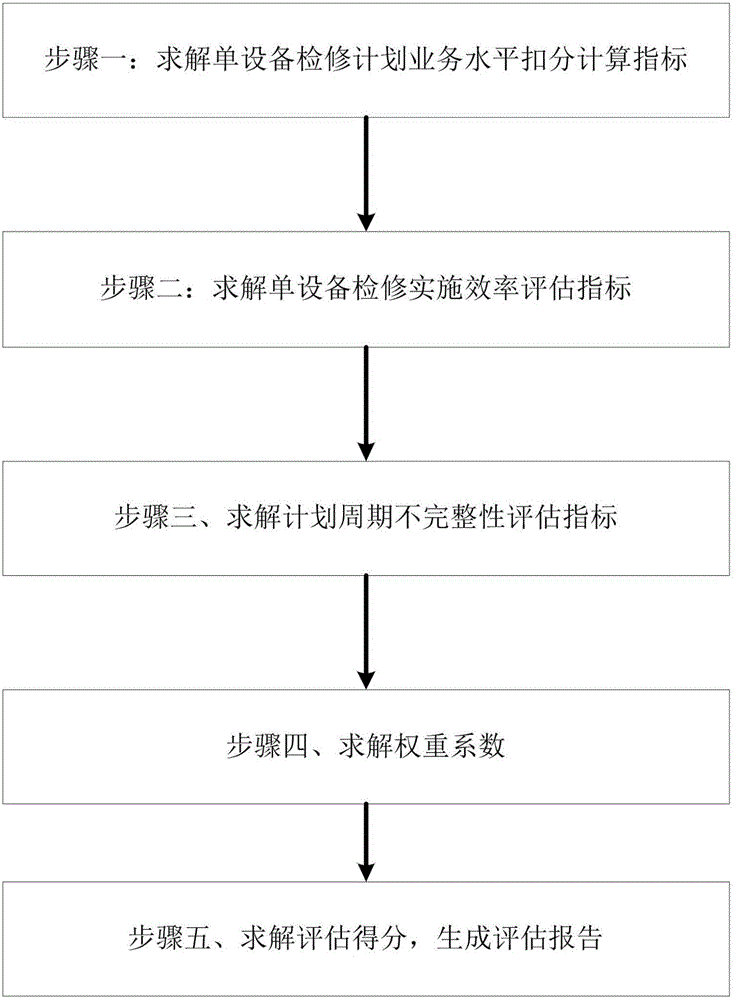

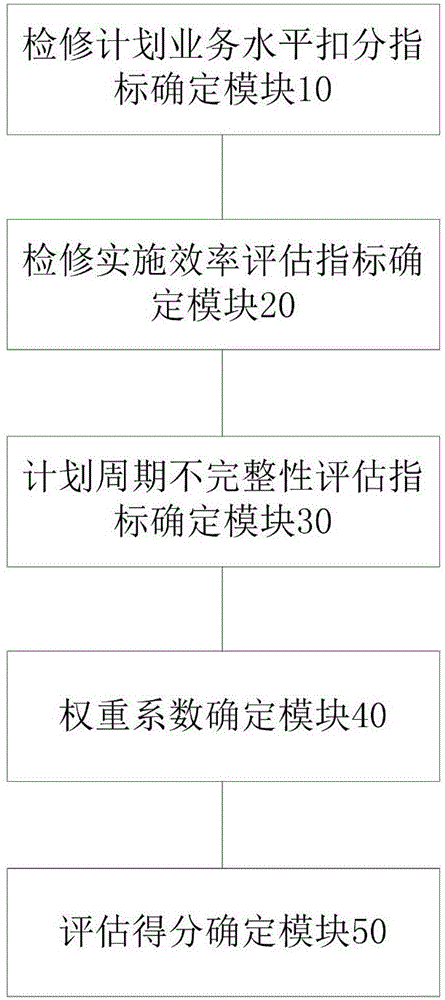

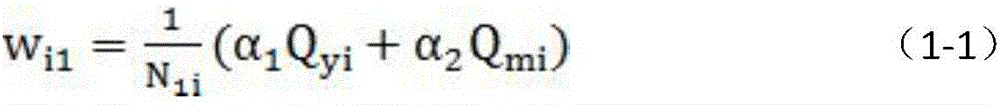

Outage maintenance plan making business level assessment method and system

InactiveCN106845755AOptimize production methodsGuaranteed safe operationTechnology managementResourcesIntegrity assessmentWeight coefficient

The invention relates to an outage maintenance plan making business level assessment method and system. The method comprises the steps that assessment object maintenance plan business level deduction indexes are determined; assessment object maintenance implementation efficiency assessment indexes are determined; assessment object plan cycle incompleteness assessment indexes are determined; weight coefficients beta1, beta2 and beta3 are determined; and assessment scores of assessment objects are determined, and assessment reports are generated. Targeting the making process and implementation conditions of an outage maintenance plan, the indexes capable of comprehensively examining outage maintenance plan business are established, the assessment objects are ranked and assessed through a quantification method in combination with a reasonable assessment model, in this way, all the assessment objects are promoted to improve the production mode of maintenance, production efficiency is improved, and therefore safe operation of a power grid is guaranteed.

Owner:CHINA ELECTRIC POWER RES INST +1

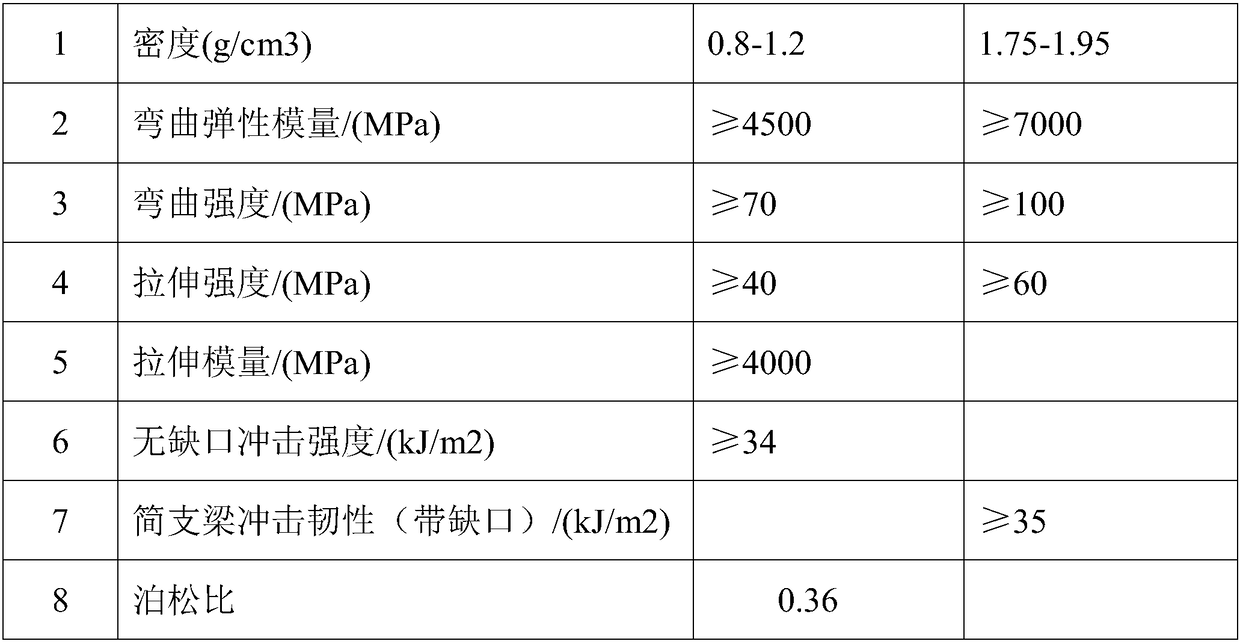

Automobile lightweight component adopting composite formation technology

The invention discloses an automobile lightweight component adopting the composite formation technology. According to the automobile lightweight component adopting the composite formation technology,after blister formation is conducted on long glass fiber, foamed hot-press forming is conducted on a formed surface layer and polyurethane glass fiber, and then the automobile lightweight component isobtained. The automobile lightweight component adopting the composite formation technology has the characteristics of overall appearance, high rigidity, light weight, low investment cost, flexible production manner and the like. The automobile lightweight component has good thermal stability and excellent mechanical performance. The automobile lightweight component, as a molded piece, can achievemore excellent mechanical performance and good appearance.

Owner:JIANGSU XINQUAN AUTOMOTIVE TRIM

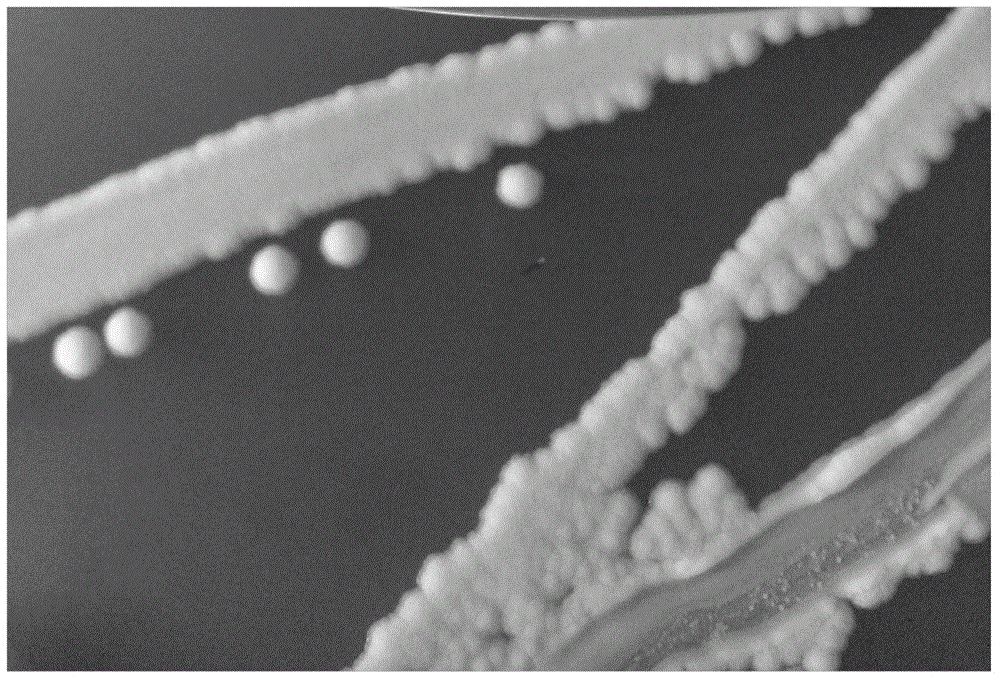

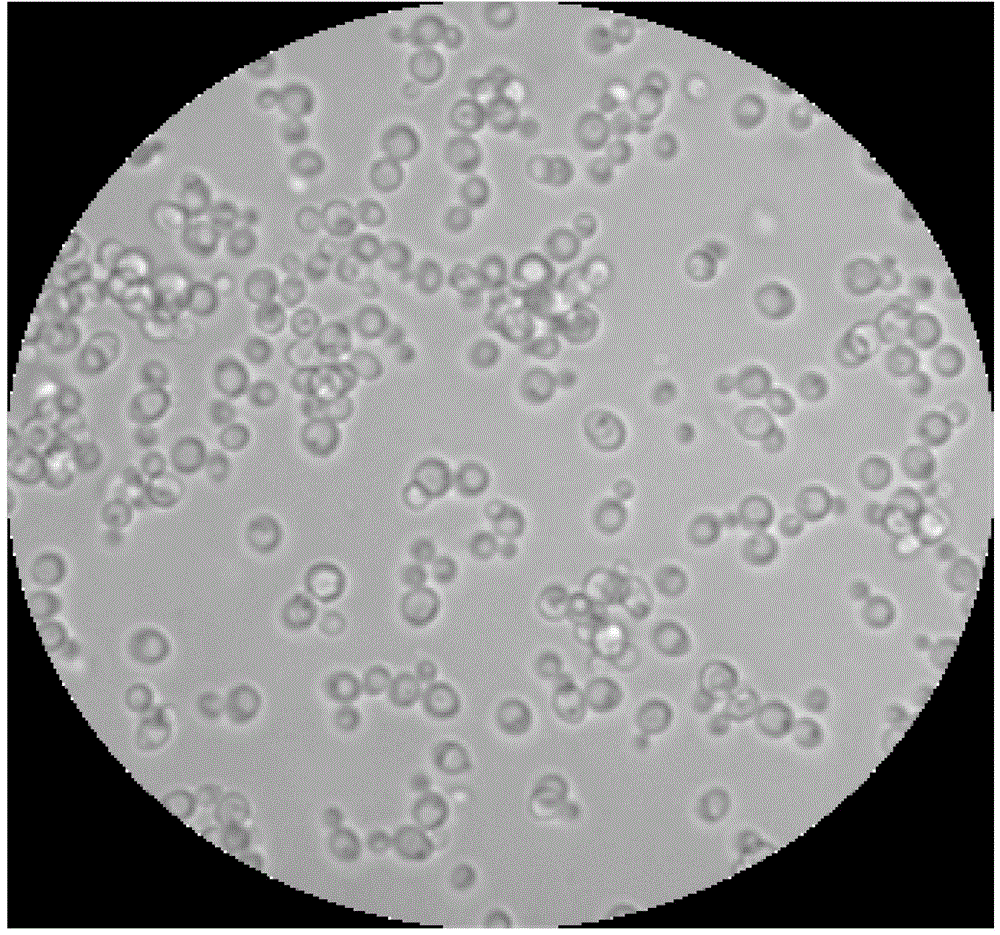

Strain of yeast capable of decomposing cellulose and applications thereof

The invention discloses a strain of yeast capable of decomposing cellulose and applications thereof, and relates to yeast having characteristic physiological functions. The yeast is separated from a producing area of Luzhou-flavor liquor in Yibin. The preservation number of the yeast is CGMCC No.9140. The yeast is named as Debaryomyces hansenii. The growth temperature is 27 to 34 DEG C, the growth pH value is 4.5 to 6.5, the bacterium colony is white after being cultured in a YPD culture medium for 2 days at a temperature of 32 DEG C, the diameter is around 5 mm, the surface is wet, smooth, and projected, the bacterium colony is easy to pick up, and the cell is in a round shaped, and is produced through gemmation. After the yeast is cultured in a YPD liquid culture medium with a pH value of 5.8 for 36 hours at a temperature of 32 DEG C, the activity of the cellulose produced by the yeast is 1.837 U / mL. The yeast can be used to produce high protein feed mainly composed of cellulose, and the protein content of white vinasse can be increased by 60% or more. The yeast can also be used to produce vinasse-free liquor, and the quality and output of the vinasse-free liquor are both improved.

Owner:YIBIN UNIV

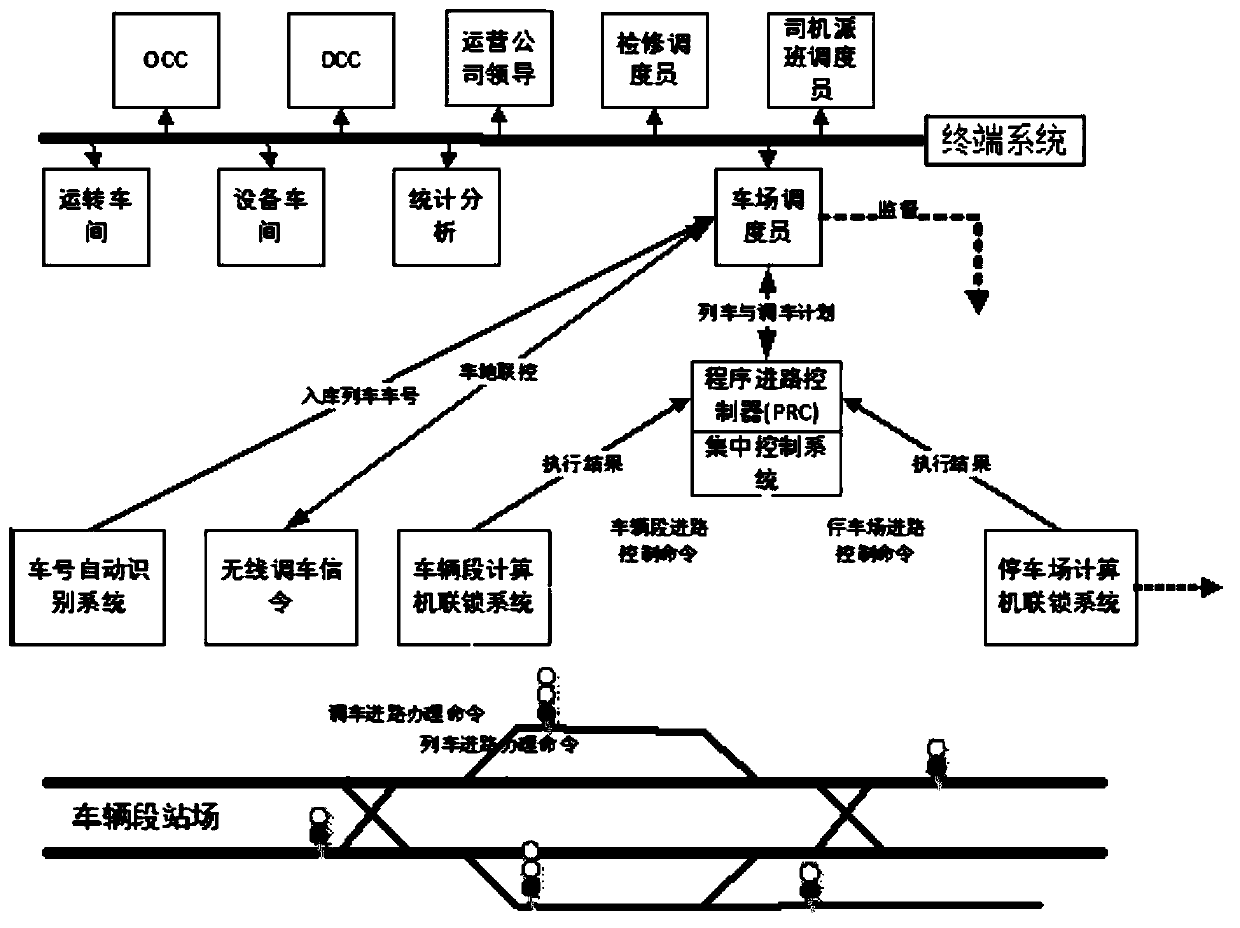

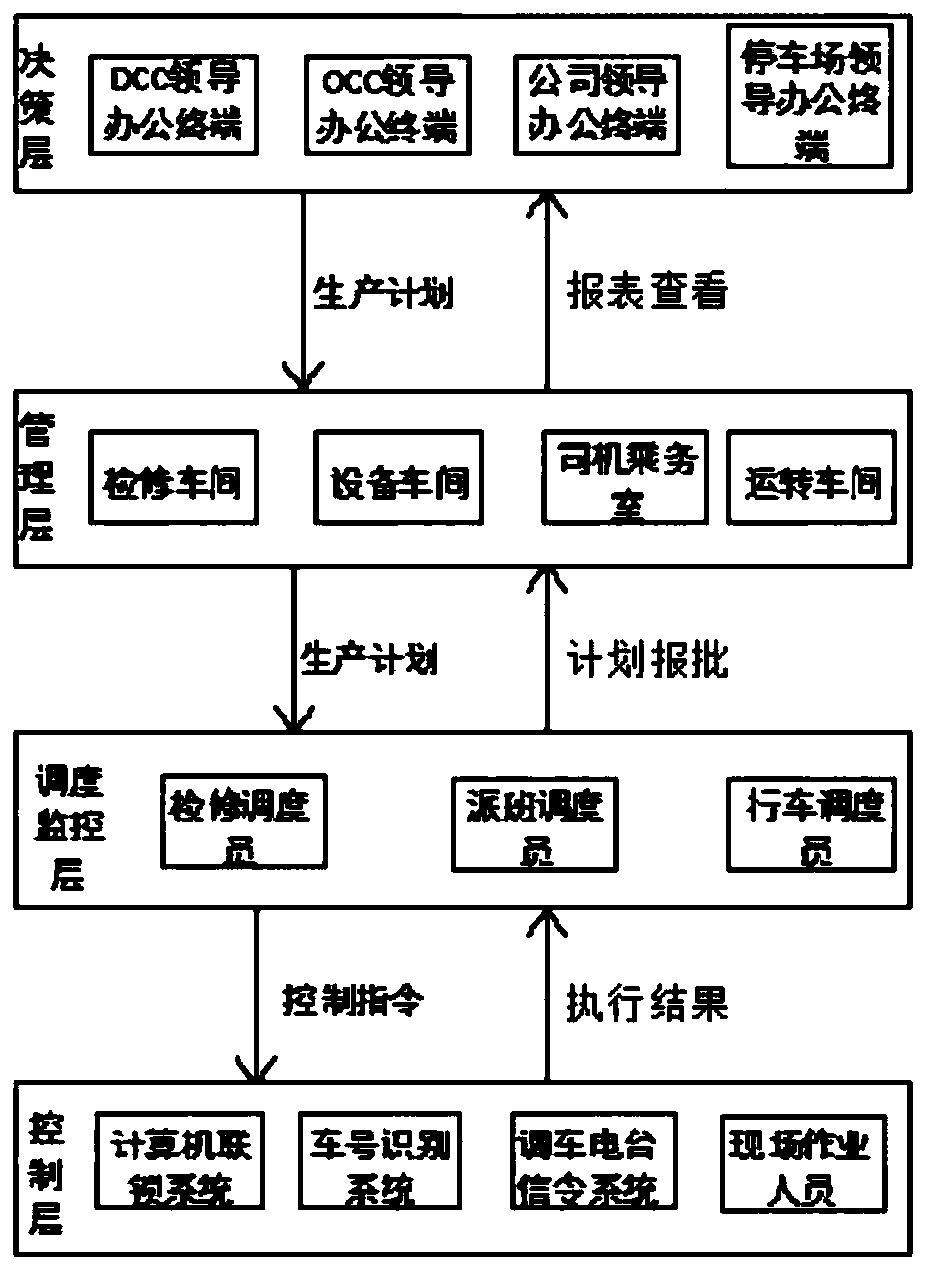

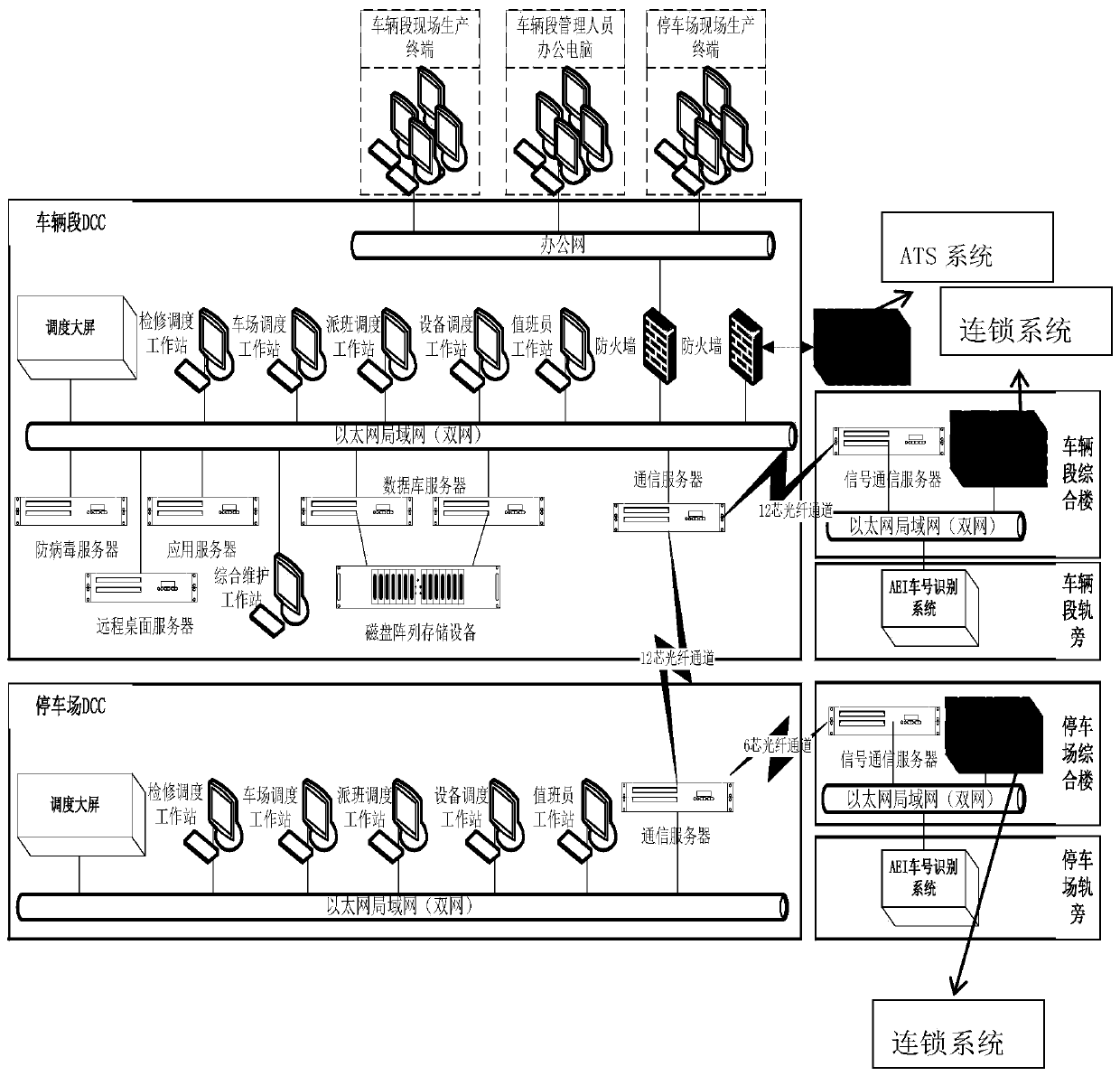

Remote monitoring and safety management system for train operation

InactiveCN110667657AImprove work efficiencyRealize regulationAutomatic systemsInformatizationSafety management systems

The invention discloses a remote monitoring and safety management system for train operation in the technical field of a train management system. The remote monitoring and safety management system comprises a terminal system, a route arrangement system, and an automatic identification system for vehicle numbers, and is based on information technology and signal control technology to improve the dispatch and command level of subway vehicle bases, improve the information management capability, and realize the comprehensive automation system of the subway vehicle base management and control integration. After comprehensive automation is realized, the level of automation, informatization and intelligence of the subway vehicle bases can be greatly improved, the physical and mental labor intensity of production personnel is reduced, staff reduction and efficiency improvement are realized, management levels and dispatching and commanding efficiency are improved, and the production capacity and security capability of the subway vehicle bases are increased. The remote monitoring and safety management system is of great significance to achieve the overall subway automation.

Owner:成都九壹通智能科技股份有限公司

Method for making ecological boiler

The invention provides a method for making an ecological boiler. The method comprises the following steps: heating ductile cast iron to 1,500-1,650 DEG C, melting into molten iron, pouring the molten iron into a die of the ecological boiler, and cooling to form a boiler blank; placing the cooled boiler blank into an electric furnace for heating, stopping heating when the heating temperature reaches 980-1,050 DEG C, preserving heat for 5-10 minutes, taking the boiler blank out of the electric furnace, and naturally cooling in the air to the room temperature; polishing the inner side surface of the boiler blank, and removing slag on the inner side surface of the boiler blank till the surface become smooth. Since the ecological boiler is made of the ductile cast iron which is high in toughness, the ecological boiler is prevented from being broken and deformed; the ductile cast iron can be used for conducting heat rapidly and is heated uniformly, and heat can be transferred rapidly during use of the made ecological boiler, thereby preventing the temperature of the inner side surface of the boiler body from getting too high, preventing the oil temperature from reaching a smoke point and realizing a smoke-free effect. The made ecological boiler is free from a chemical coating and ceramics falling, and has a rust prevention function.

Owner:福建南安市鑫鼎厨具有限公司

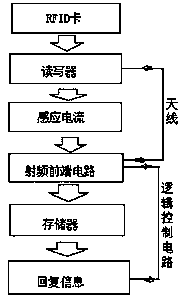

RFID (Radio Frequency Identification Device) Internet of things chip

InactiveCN104036306AImprove productivityOptimize production methodsCo-operative working arrangementsLogisticsAutomatic controlProduction rate

The invention discloses an RFID (Radio Frequency Identification Device) Internet of things chip. The RFID Internet of things chip comprises a reader-writer, an RFID chip, a storage, a power supply, an antenna and a radio-frequency field, wherein an RFID card enters the radio-frequency field of the reader-writer; induced current is obtained through the antenna, and is taken as the power supply of the chip through a booster circuit; a digital signal of the induction current is detected through a radio-frequency front-end circuit, and is transmitted into a logic control circuit for performing information process; reply information is obtained from the storage, is returned to the radio-frequency front-end circuit through the logic control circuit, and is transmitted back to the reader-writer through the antenna. The antenna determines the communication channel and communication way between the RFID card and the reader-writer, automatic control and monitoring are realized on a production assembly line by using an RFID technology, the productivity is increased, the production way is improved, and the cost is saved.

Owner:镇江东软信息技术有限公司

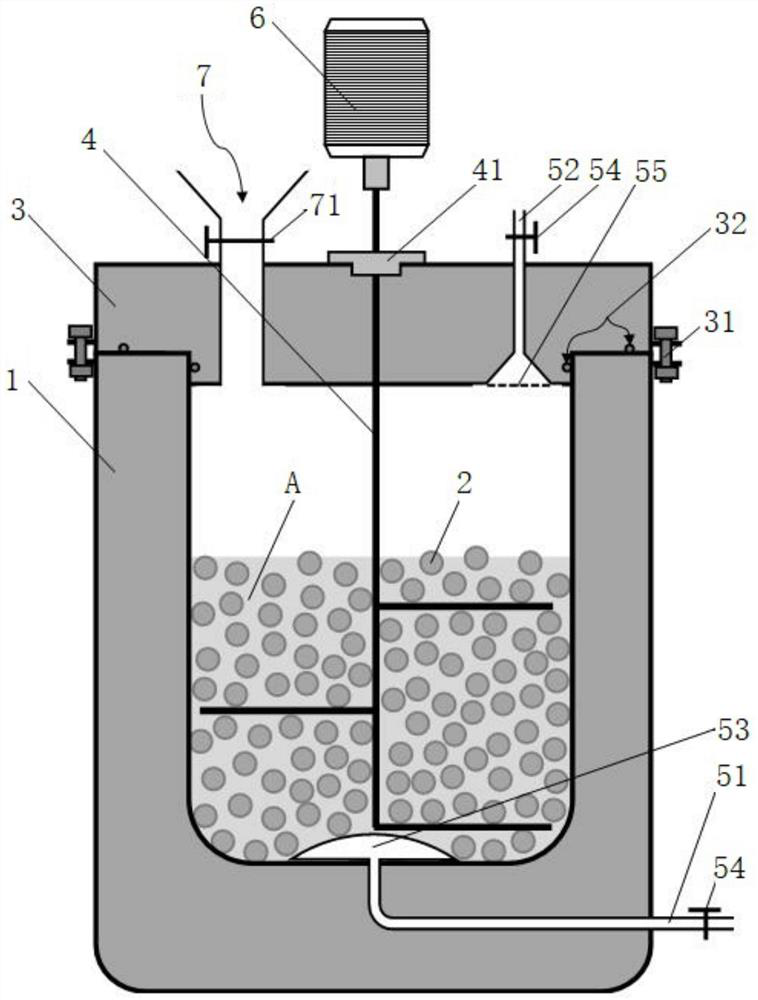

Vertical continuous stirring ball-milling equipment and working method thereof

PendingCN112808393ARealize uninterrupted continuous productionEconomy of productionGrain treatmentsControl systemAir pump

The invention discloses vertical continuous stirring ball-milling equipment which comprises a barrel, a plurality of grinding balls, a barrel cover, a stirrer and an air inlet and outlet control system; the barrel is vertically arranged; the plurality of grinding balls are arranged in the barrel; the barrel cover covers a top opening of the barrel in a sealing manner; the stirrer penetrates through the barrel cover, extends into the barrel and can rotate; materials placed in the barrel are ground by the grinding balls under the rotation of the stirrer; the air inlet and outlet control system comprises an air inlet channel and an air outlet; one end of the air inlet channel is arranged on the bottom surface of the barrel and communicated with the inside of the barrel, and the other end is communicated with a pressurized air tank or an air pump outside the barrel; the air outlet is formed in the barrel cover; the air inlet and outlet control system further comprises a spherical crown type cover plate, and the spherical crown type cover plate is arranged in the barrel, covers a port of the air inlet channel and is connected with the bottom face of the barrel through an elastic piece; and a feeding hole penetrating through the inside and the outside of the barrel is formed in the barrel cover. The vertical continuous stirring ball-milling equipment has the advantages of continuous processing, accurate product particle size control, high efficiency, energy saving and the like.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

Method for preparing microbial flocculant through enteromorpha hydrolysate fermentation

InactiveCN105039417AReduce manufacturing costOptimize production methodsMicroorganism based processesFermentationBiotechnologyMicroorganism

The invention discloses a method for preparing a microbial flocculant through enteromorpha hydrolysate fermentation. The method comprises the steps of preparation of liquid strain, fermentation and product aftertreatment. The fermentation process comprises the steps that 1, fresh enteromorpha is cleaned, salt, sediment and unwanted algae are removed, then the fresh enteromorpha is smashed and added to a hydrolysis tank, water is added to regulate acidity, alkali is added for neutralization, filter pressing and clarification are conducted, and then a hydrolysate is obtained; 2, the hydrolysate is diluted till the sugar concentration of reducing sugar is 15-30 g / L, fermentation liquor is prepared and added to a fermentation tank, and high-temperature sterilization and cooling are conducted; 3, a seed solution is inoculated into the fermentation tank for fermentation, and fermentation is ended after the content of residual sugar in the fermentation liquor is reduced to the level below 3 g / L. According to the method, enteromorpha is used as the raw material, microbial flocculant fermentation is directly conducted after acid hydrolysis filtration, the production method is simple, production cost is low, grain is saved, and waste is turned into wealth.

Owner:青岛美能达生物科技有限公司

Magnesite-based lightweight high-strength concrete for wallboard and preparation method thereof

The invention discloses a magnesite-based lightweight high-strength concrete for wallboard and a preparation method thereof, the concrete is prepared from the following raw material components in parts by weight: 300 to 600 parts of magnesium oxide, 150 to 300 parts of magnesium chloride, 50 to 100 parts of coal ash, 20 to 50 parts of silicon powder, 0.5 to 1.0 part of hydroxypropyl methylcellulose, 150 to 400 parts of ceramsite, 150 to 350 parts of water, 7 to 15 parts of a halogenide-resistant agent and 5 to 15 parts of a water-resistant agent. The invention adopts the ceramsite with betterdurability as a filling aggregate, and adds auxiliary blending materials such as coal ash, silicon powder and the water-resistant agent to mitigate the problems of easy halogenation and poor water resistance of magnesite material self, which reduces the volume weight of a wallboard and improves the seismic performance of the wallboard without lowing the strength of concrete self, and in addition greatly improves the durability, thermal insulation property and sound insulation of the wallboard, thereby solving the problem of poor durability, unsatisfactory thermal insulation property and soundinsulation property of a traditional magnesite wall.

Owner:HEFEI GUORUI INTEGRATED CONSTR TECH CO LTD

Single-face dyeing method for woven fabric

InactiveCN100560856CReduce dosageEasy emissionsSingeingHeating/cooling textile fabricsAdhesiveSewage

The invention discloses a single-side dyeing method of woven fabrics, which belongs to the new technical field of textile printing and dyeing. A method for single-side dyeing of woven fabrics, firstly pre-treating woven fabrics such as pure cotton, tencel, and elastic fabrics, including gray cloth turning over, singeing, desizing, scouring, bleaching, mercerizing, etc.; secondly, full-width single-side dyeing, One-side dyeing of woven fabrics is to apply the color paste glue A to the woven fabric through a coating machine, and then go through high-temperature hot air tentering, oxidation, soaping, water washing, drying, and falling cloth; then apply the color paste glue B Coloring on woven fabrics, high temperature hot air tentering, and falling cloth through a coating machine. This technology realizes the fashion of denim clothing, casual clothing and children's clothing, and has obvious ecological functions; it also solves the problem that the fabric can be dyed on one side with sulfur dyes and paints on the coating and setting machine. Technical problems; at the same time, it saves water, steam, and electricity compared with the conventional processes of vat and reactive dyes, and reduces a large amount of dyeing sewage discharge. The side of the single-side dyed fabric that is in contact with the human skin does not contain any dyes, chemicals, and additives. It is ecological and environmentally friendly. It is an ideal fabric for denim, casual wear and children's wear.

Owner:SHANXI CAIJIA PRINTING & DYEING

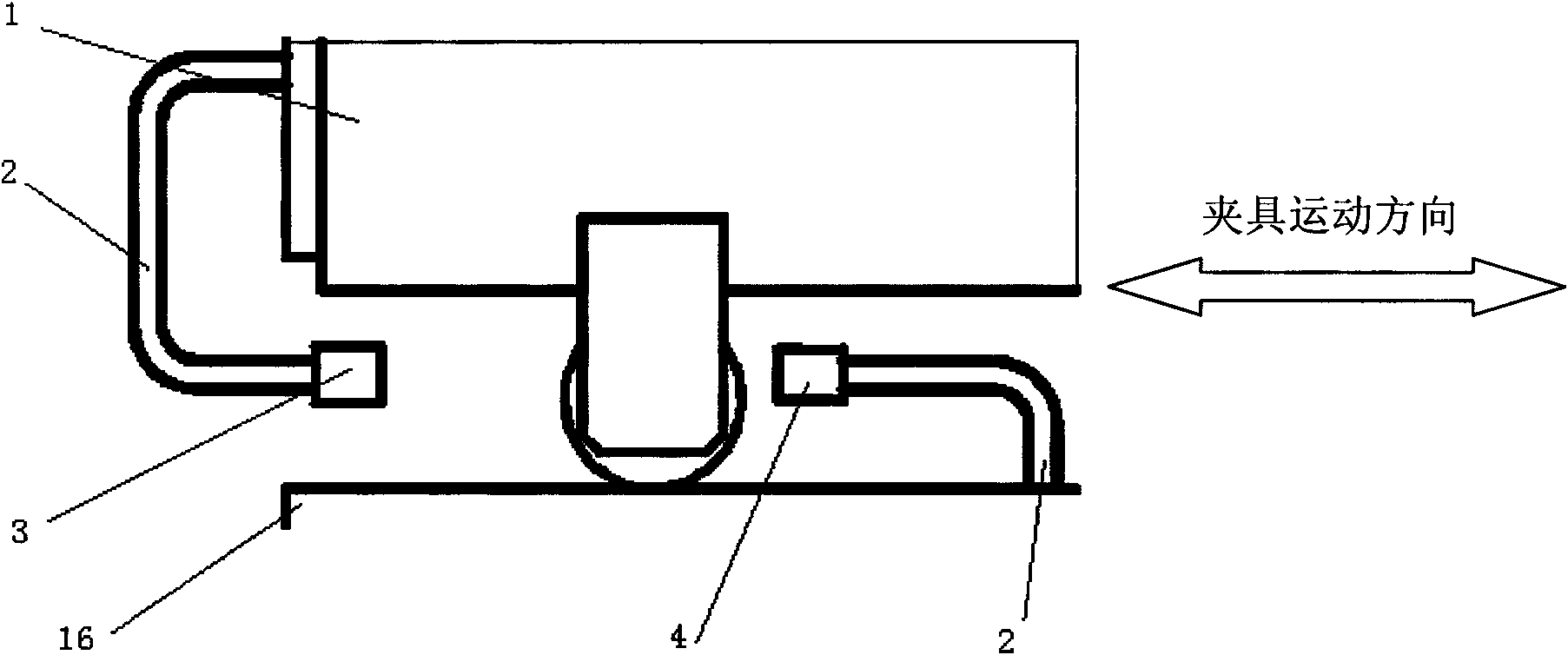

Automatic butting device of radio frequency plug

ActiveCN101626122AReduce control difficultyImprove docking efficiencyEngagement/disengagement of coupling partsPush and pullEngineering

The invention relates to an automatic butting device of a radio frequency plug. A jig, a radio frequency male joint and a radio frequency female joint are respectively provided with positioning devices on the basis of the prior radio frequency plug butting way; when the jig is manually pushed and pulled, a radio frequency plug (the male joint and the female joint) is rapidly butted and pulled by the positioning devices. Compared with the prior manual plugging radio frequency plug, the invention can greatly improve the butting efficiency, realize mechanization and automation and liberate people from heavy and dangerous work so as to thoroughly improve the production way. The automatic butting device is simple and effective, does not increase the control difficulty of a machine, is quite easy to realize and can effectively control the manufacture cost.

Owner:北京清大天达光电科技股份有限公司

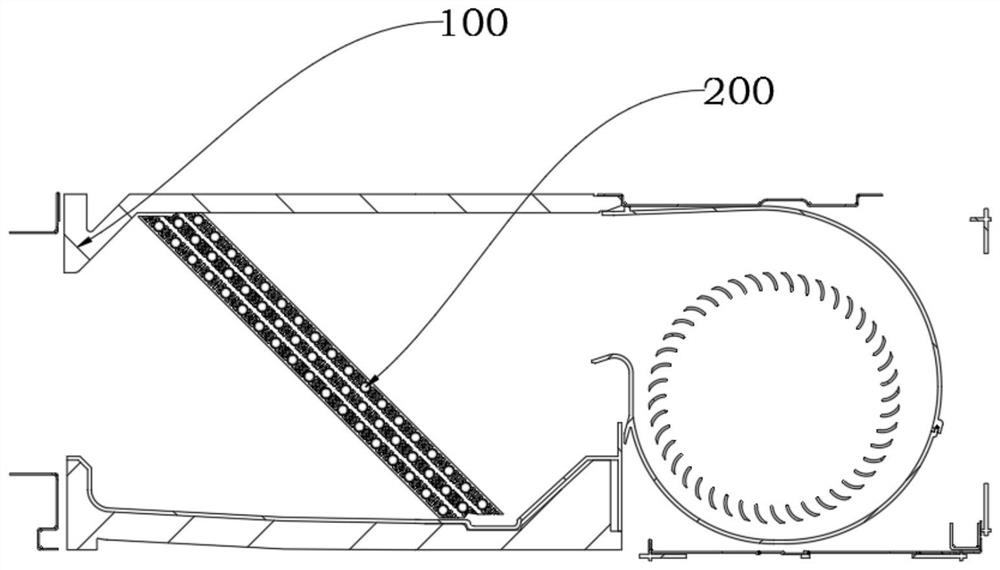

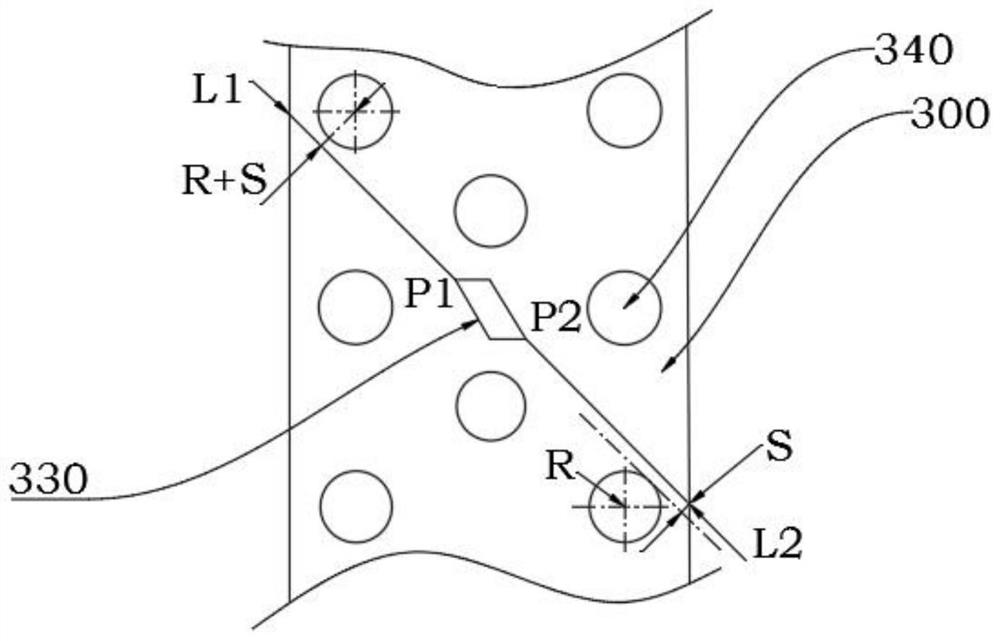

Indoor air conditioner and fin production method

PendingCN112283794ASolve the problem that the safety distance of pipe hole cutting cannot be metAddress process complexityLighting and heating apparatusAir conditioning systemsProcess engineeringIndoor air

The invention discloses an indoor air conditioner and a fin production method. The indoor air conditioner is internally provided with a heat exchanger, and the heat exchanger comprises a plurality ofheat exchange tubes and a heat dissipation device. The heat dissipation device comprises a plurality of parallel fins, in the fin production process, fin machining adopts a beveling machining method,and the beveling machining method comprises the two procedures of pre-punching and beveling. According to the indoor air conditioner and the fin production method, the fins are cut through one set ofcutters, the problem that an existing beveling process cannot meet the requirement for the pipe hole cutting safety distance is solved, and the problems that two sets of cutters are adopted for special-shaped cutting, the process is complex and the cost is high are also solved.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com