Macromolecular/ metal composite conductor and manufacture method thereof

A composite wire and metal composite technology, which is applied in filament/wire forming, conjugated synthetic polymer artificial filament, textiles and papermaking, etc. Problems such as difficulties in the silk process, to achieve good spinnability, excellent electrical conductivity, and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In this embodiment, the skin layer is polyethylene terephthalate PET (melting point 256°C), the core layer is tin-bismuth metal alloy (melting point 150-180°C), and the weight ratio of the skin layer / core layer is 87:13.

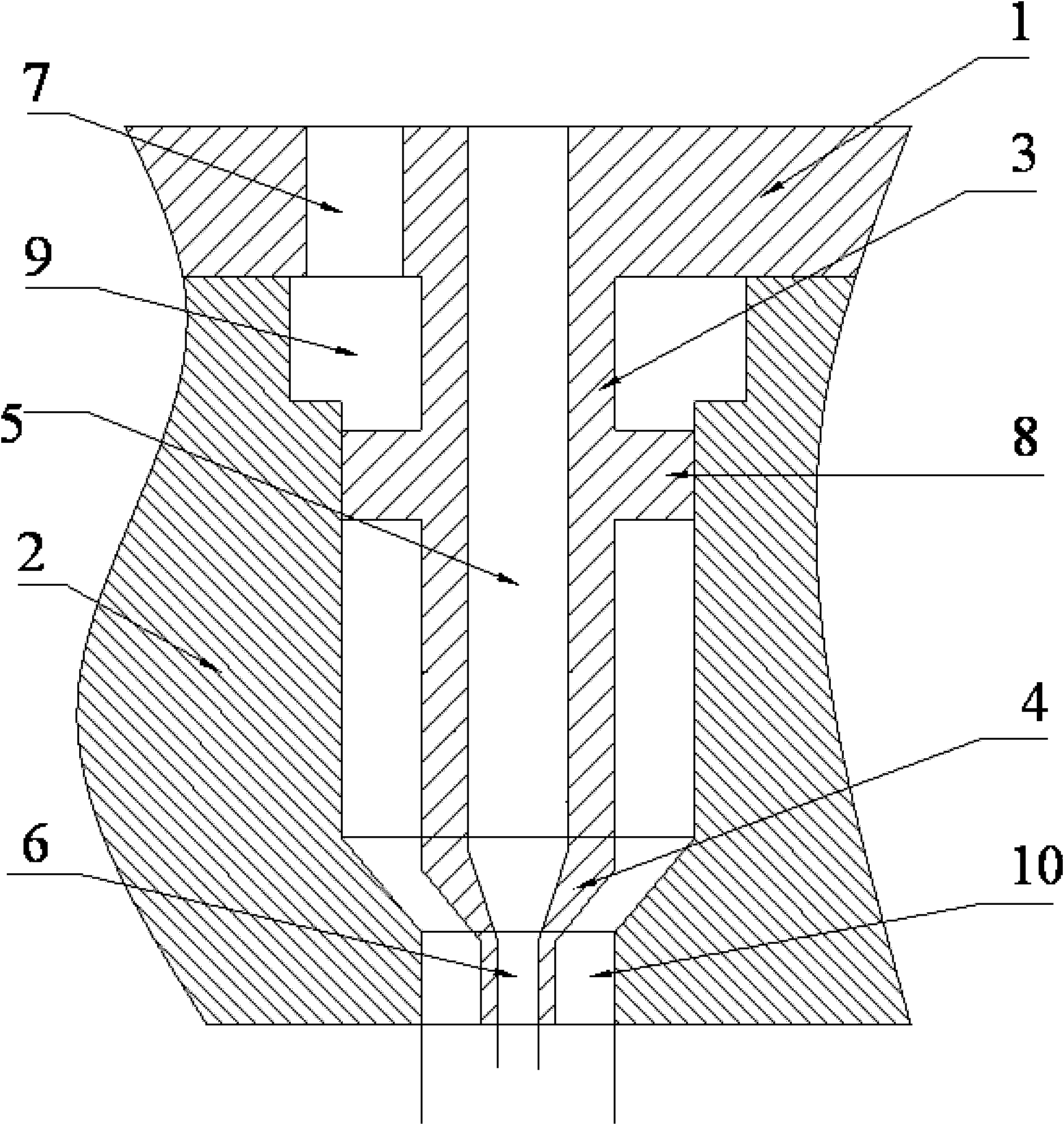

[0052] According to the above-mentioned raw materials and weight ratio of the skin and core components, they are processed into melts through a screw extruder and an electric heating furnace, and then transported to the extrusion die through their respective melt pipelines. The melts enter the same composite extrusion die, and pass through their respective melt flow channels without contacting each other before entering the lower die plate. The cross-section of the fibers is realized by the design of the extrusion micropores.

[0053] The distribution plate is located above the lower template, and the distribution pins correspond to the extrusion micro-holes of the lower template. The melt of the core component flows into the through hole of the lower...

Embodiment 2

[0056] see figure 2 . On the basis of Embodiment 1, the difference of this embodiment is that the cross section of the fiber is trilobal. Composite wire fineness 21μm, tensile strength 750MPa, elongation 7.8%, specific resistance value 1.0×10 -3 Ω·cm.

Embodiment 3

[0058] On the basis of Example 1, the difference of this example is: the skin / core weight composite ratio is 75:25. The fineness of the composite wire is 17μm, the tensile strength is 820MPa, the elongation is 7.2%, and the specific resistance value is 8×10 -4 Ω·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com