Novel device for testing hot smoke

A test device, hot smoke technology, applied in the direction of combustion type, lighting and heating equipment, combustion method, etc., can solve the problems of continuous adjustment of fire source power, fire spread, inconvenient movement, etc., and achieve flexible and diverse smoke generation methods , reduce transportation costs, and facilitate the use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

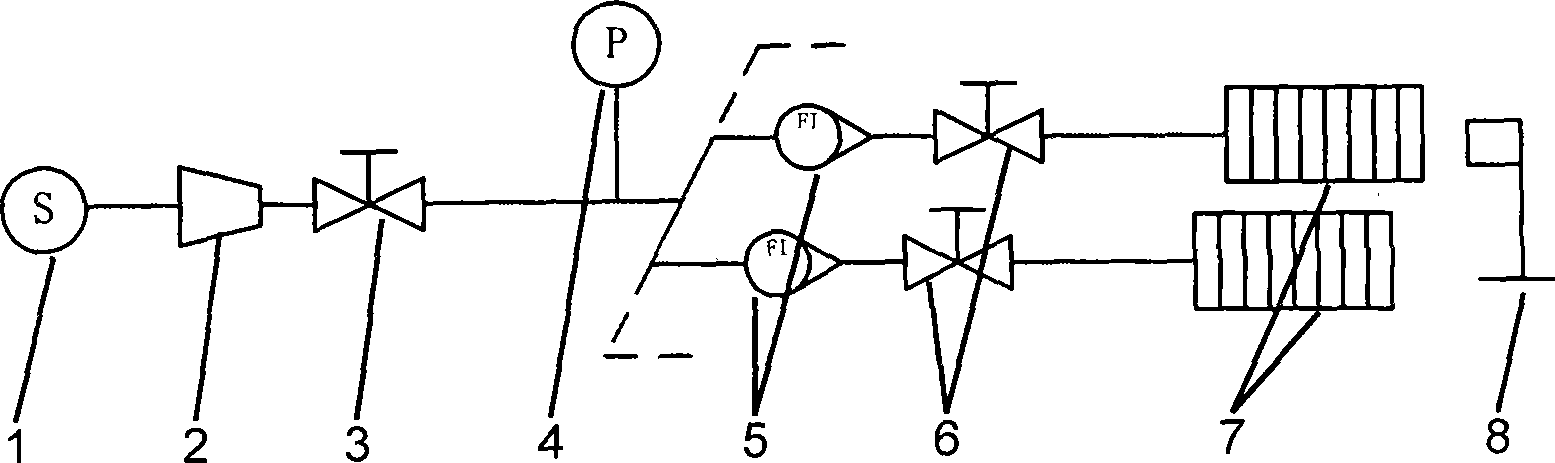

[0033] see figure 1 , the new hot smoke test device includes a gas source 1, a gas pipeline, a burner 7, and a smoke generating mechanism 8; a pressure reducing valve 2, a main valve 3, a flow meter 5 and a unit valve 6 are installed in series on the gas pipeline , connect the pressure gauge 4 in parallel between the flowmeter 5 and the main valve 3;

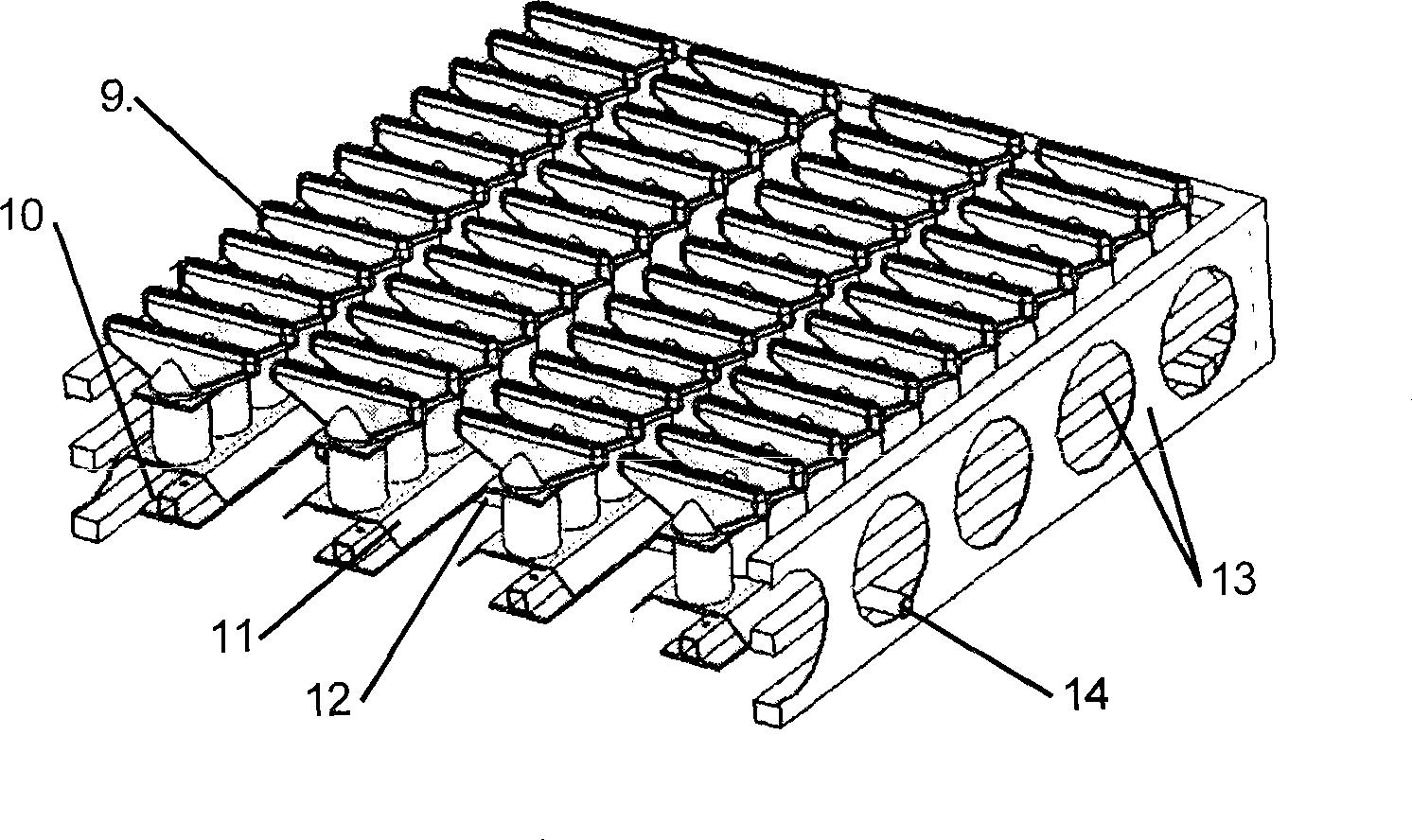

[0034] see figure 2 , the burner includes a box-shaped frame 13, the bottom of the frame 13 is equipped with an intake pipe 14 that runs through the bottom of the frame, and the diameter of the intake pipe 14 is 10 mm; Four nozzle pipes 10; Every nozzle pipe 10 is communicated with intake pipe 14 by branch pipe, and 15 nozzles are evenly distributed on the upper pipe wall of every nozzle pipe 10, and nozzle diameter is 1-2 millimeter; Every nozzle pipe 10 The upper cover is equipped with a strip-shaped masking plate 11, the long sides of the masking plate 11 are bent downwards, and 15 premixing nozzles 9 are evenly distribute...

Embodiment 2

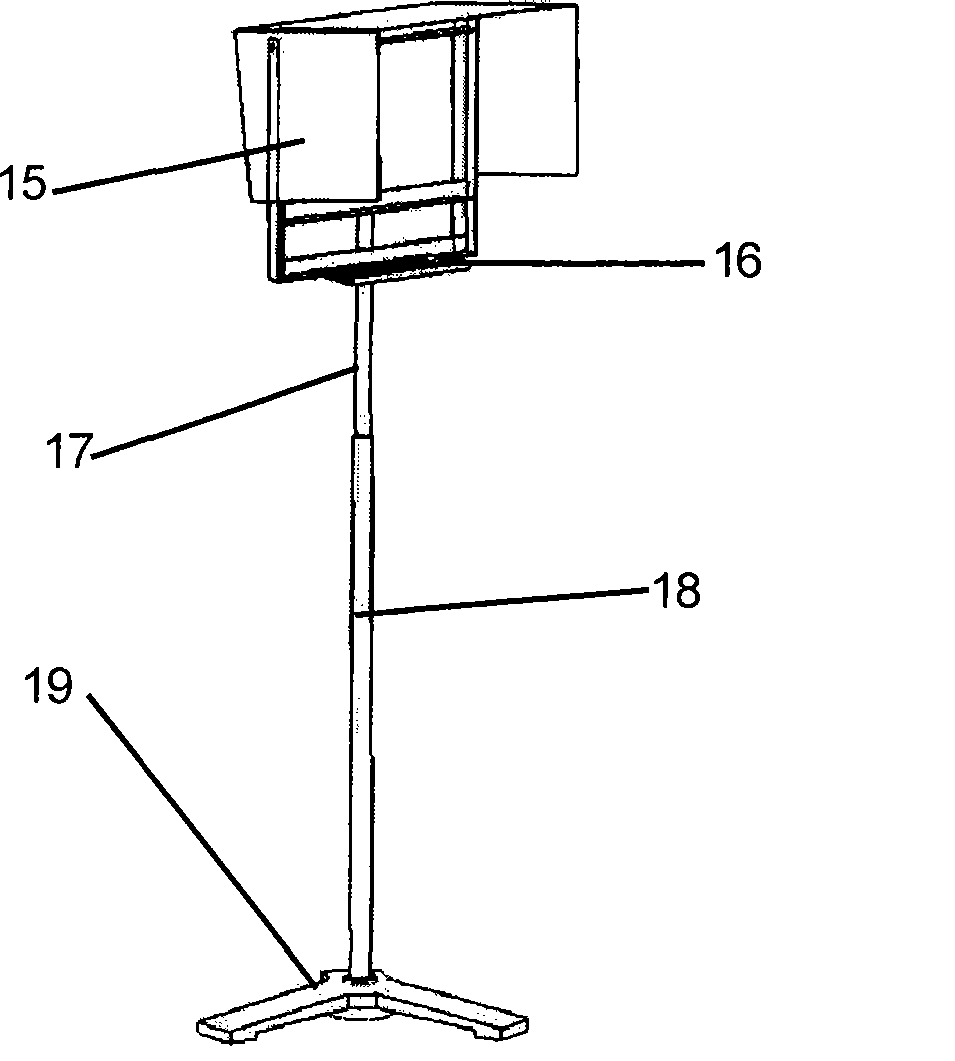

[0040] see Figure 4, the intake pipes of the four burners 7 are respectively connected in parallel through the gas branch pipes, and then connected to the gas pipelines, and each gas branch pipe is provided with a unit valve 6 and a flow meter 5 in turn; the four burners 7 are arranged in a square shape, with a gap of about It is 10cm. A smoke generating mechanism 8 is arranged on both sides of the four burners arranged in a square shape. The height of the smoke generating mechanism is adjusted to 1.6m through the telescopic sleeve, and it is arranged in the center of the side of the array. The outlet of the smoke shield faces the burner. Direction, the outer edge of the outlet is about 20cm from the edge of the burner.

[0041] Others are with embodiment 1.

[0042] This example is applicable to the hot smoke test of flat above-ground and underground buildings with a construction area of 1,000 square meters to 2,000 square meters, and atrium-style buildings with a volume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com