Integrated stowing machine

A filling machine and frame technology, which is applied in the storage and packaging of weapon accessories, ammunition, etc., can solve the problems of low production efficiency, many operators, and large floor space, and achieve high production efficiency, improve production efficiency, and save space. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

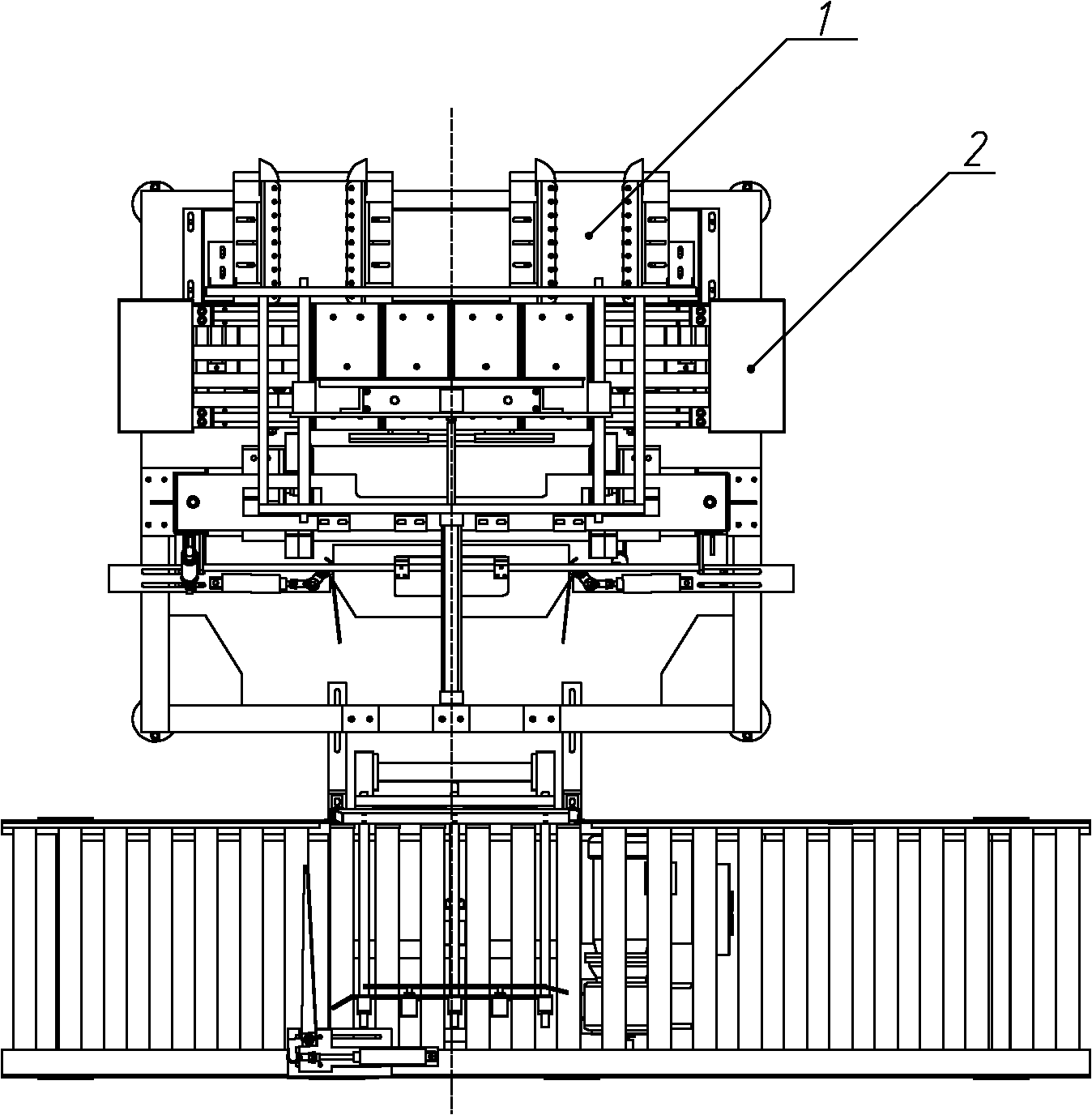

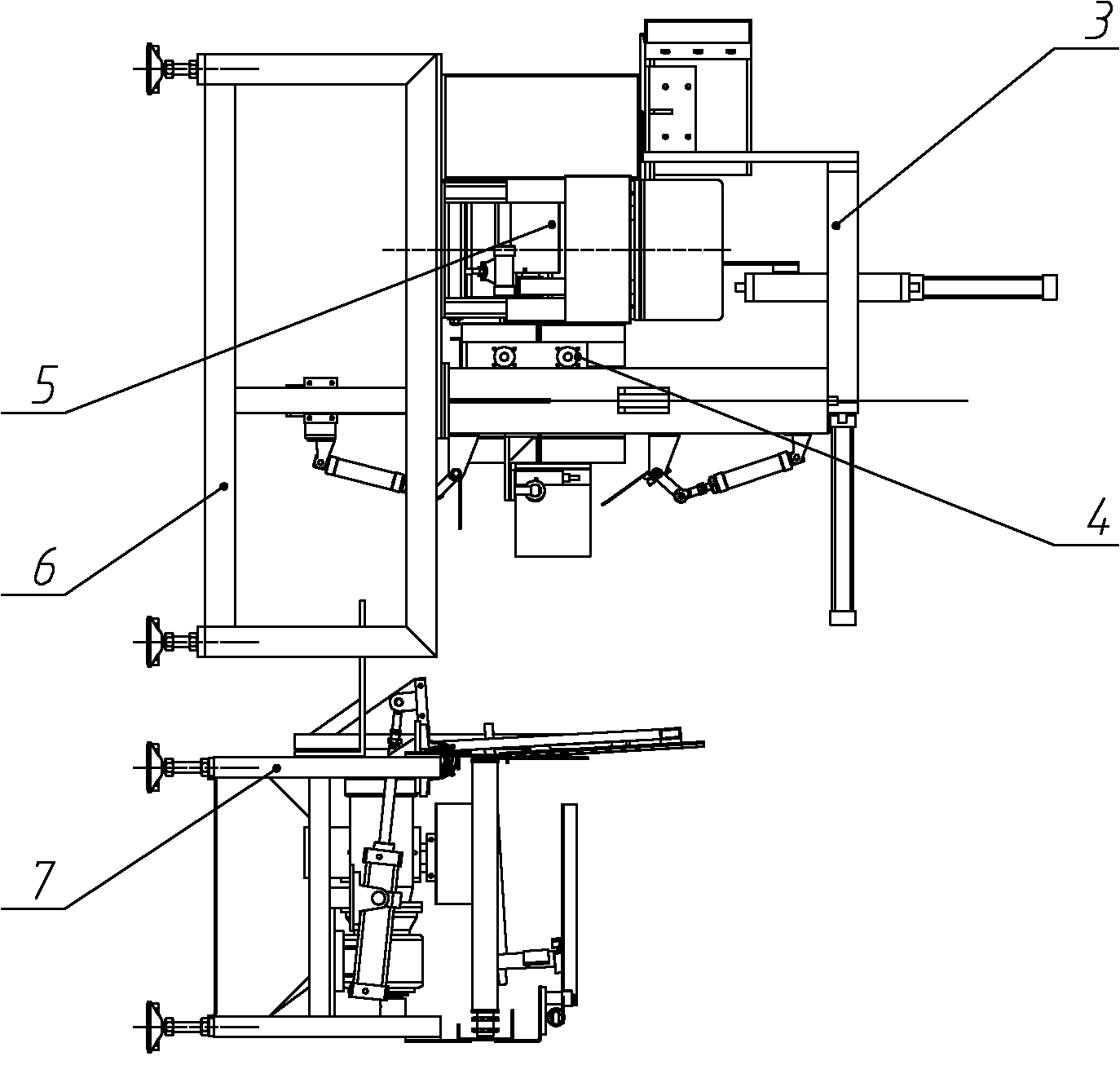

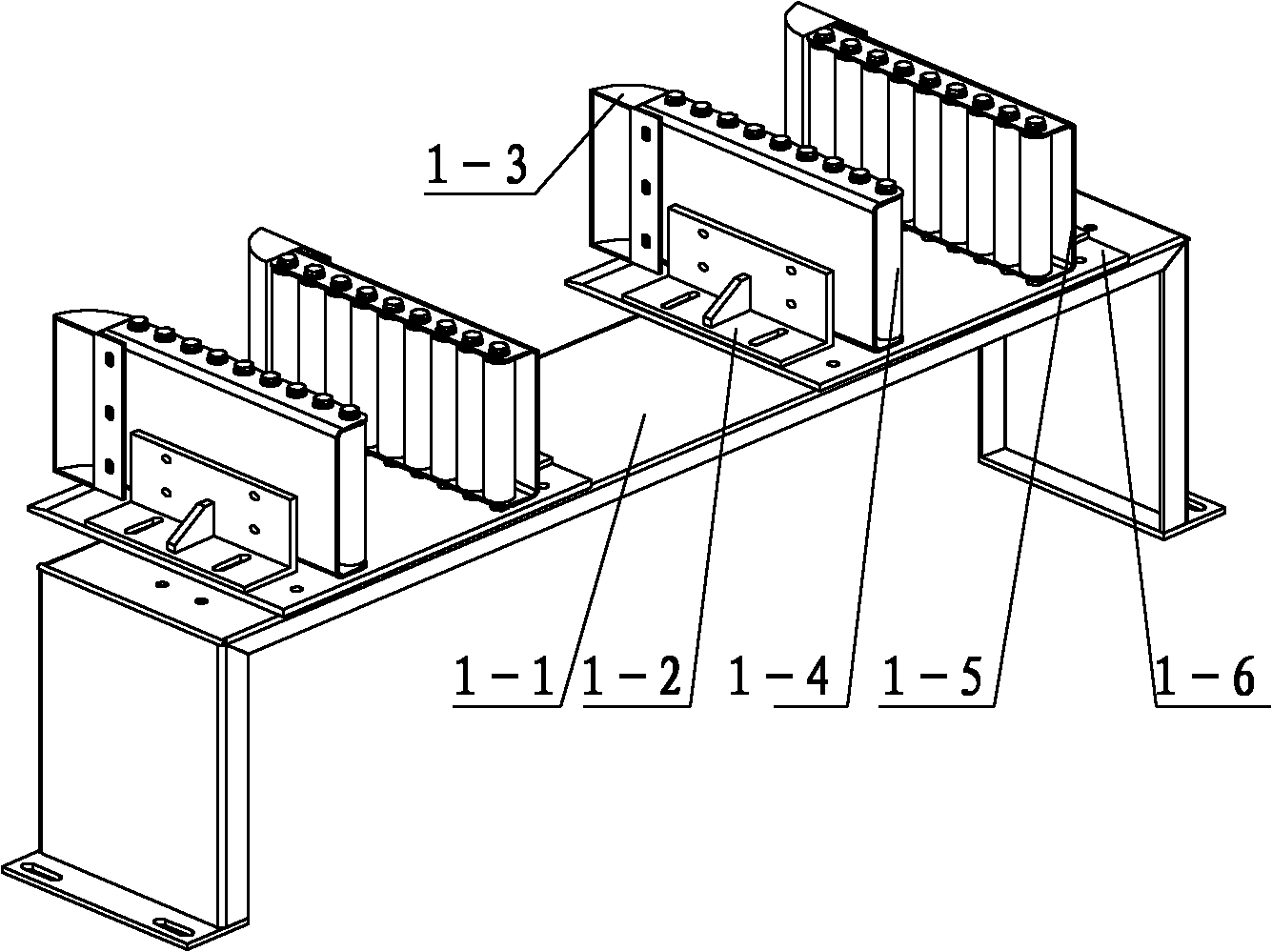

[0025] As shown in Fig. 1, the present invention is mainly made up of package sending part 1, unpacking part 2, packing part 3, lamination shaping part 4, filling part 5, frame 6, box turning part 7, dynamic electrical part, turning over The box part is composed of a conveyor and a box-turning device. The bag-feeding part is installed at the front end of the frame, followed by the unpacking part, the stacking part, and the packing part. The box device is located on the side of the conveyor, and the box-turning plate of the box-turning device faces the bag-pushing plate of the filling part, and is at the corresponding position directly in front of the bag-pushing plate of the filling part. The layer shaping parts and filling parts are installed on the frame respectively, and the pneumatic and electrical parts are installed in the electric cabinet inside the frame part, and resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com