Package distributing and conveying all-in-one machine

An all-in-one machine and bag delivery technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of easy sticking of middle bags and slow speed, and achieve the effect of no damage, high efficiency and reducing the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

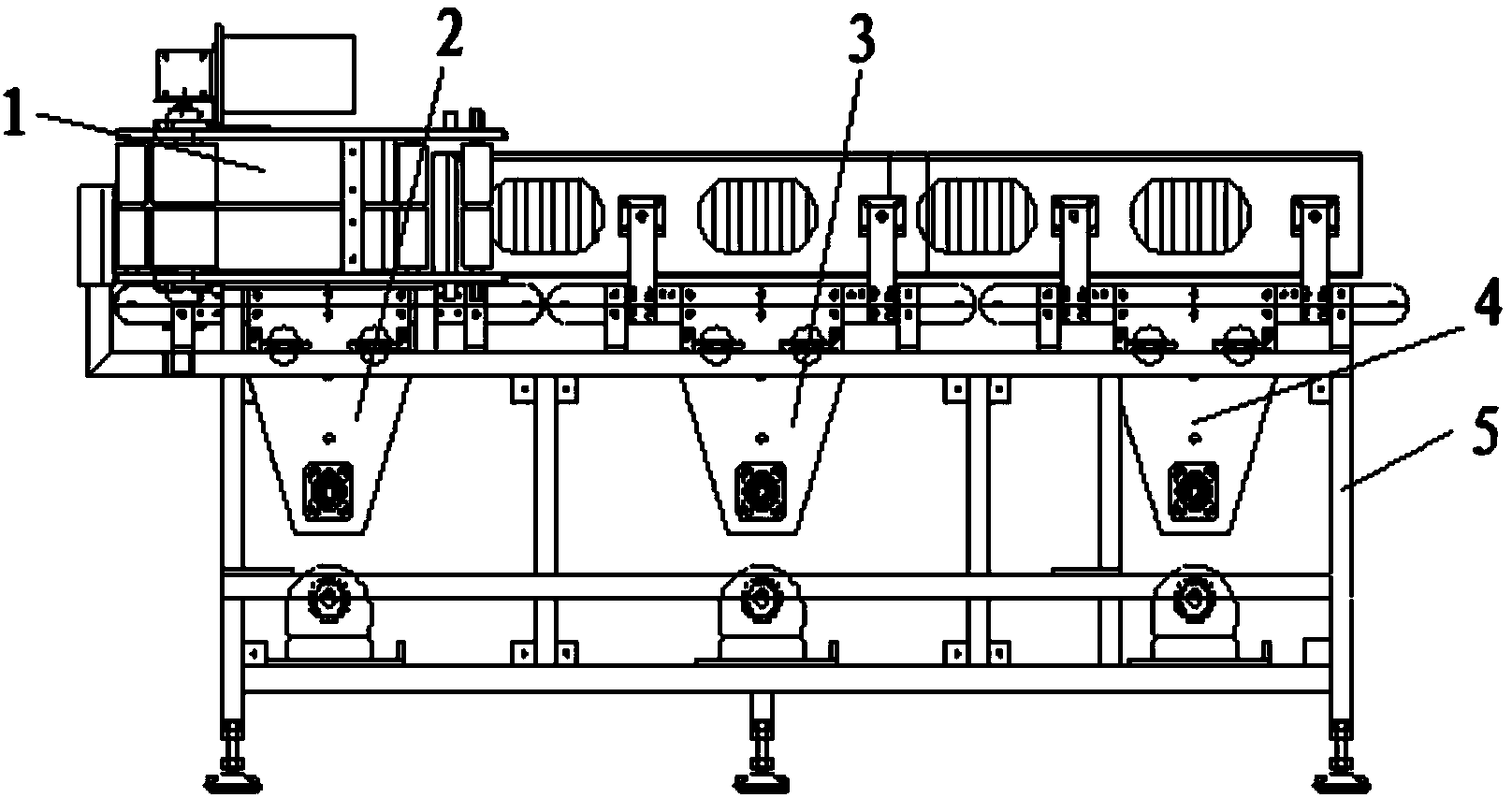

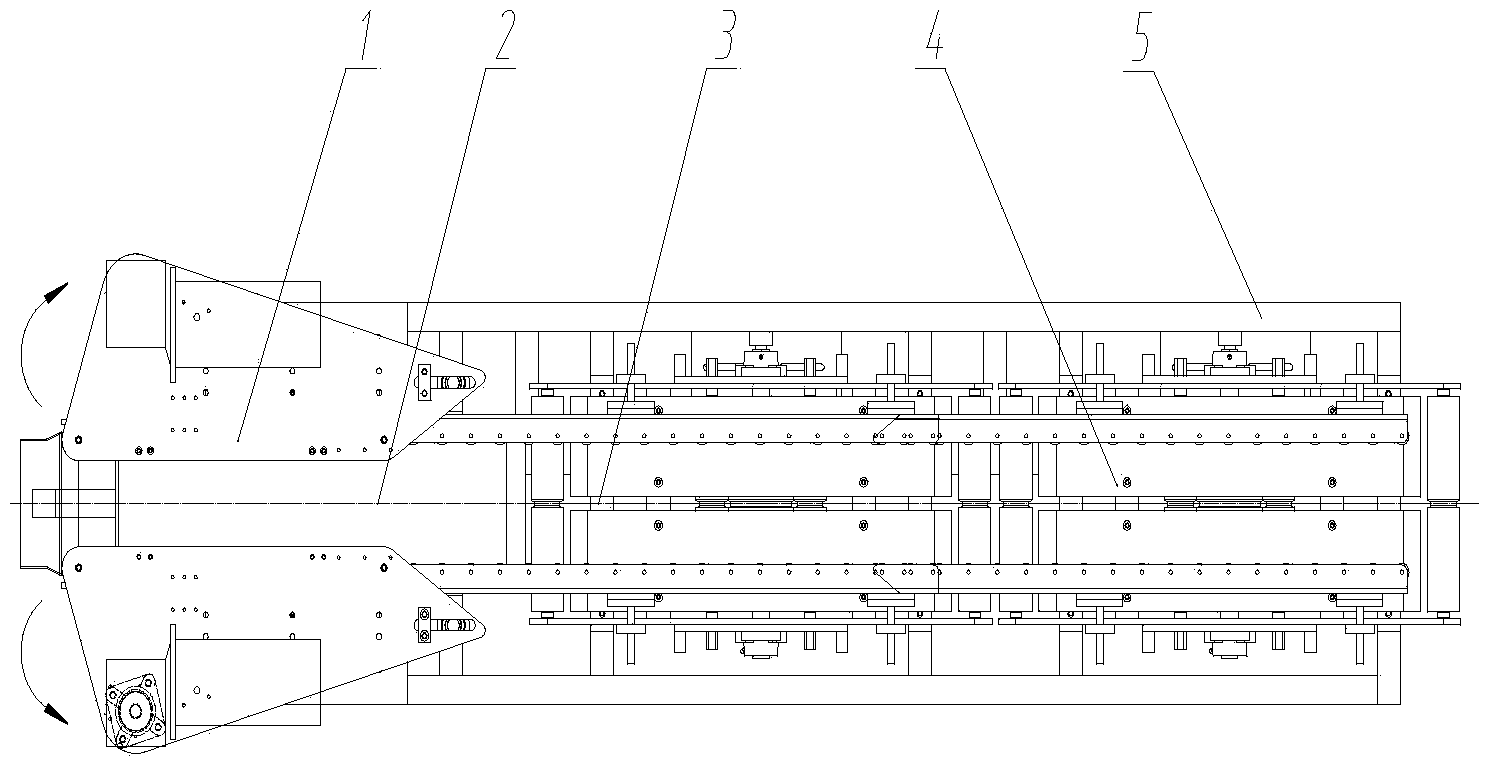

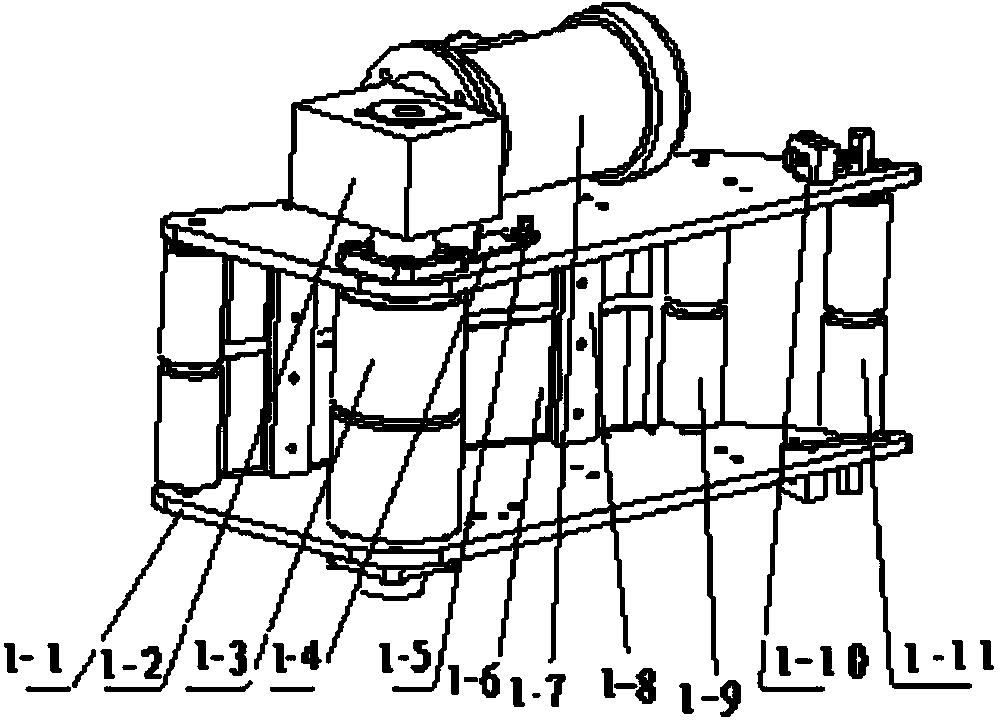

[0025] The present invention as figure 1 , figure 2 As shown, it includes two side bag delivery belt conveyors 1, bottom bag delivery belt conveyor 2, subpackage belt conveyor 3, transition belt conveyor 4, frame 5, and electrical control components; it is characterized in that: side bag delivery belt conveyor 1. The bottom delivery belt conveyor 2, the subpackage belt conveyor 3, and the transition belt conveyor 4 are respectively installed on the frame 5, the electrical control components are installed inside the frame 5, and the two side bag delivery belt conveyors 1 are installed on the machine frame The top of the front end of the frame 5 is arranged in a mirror image along the center, and below the two side bag delivery belt conveyors 1 is the bottom delivery belt conveyor 2, followed by the subpackage belt conveyor 3 and the transition belt conveyor 4. There is no bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com