Automobile lightweight component adopting composite formation technology

A molding process and composite material technology, applied in household components, applications, household appliances, etc., can solve the problems of insufficient strength of exterior decoration parts, poor application effect, heavy weight, etc., and achieve flexible production methods, superior mechanical properties, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

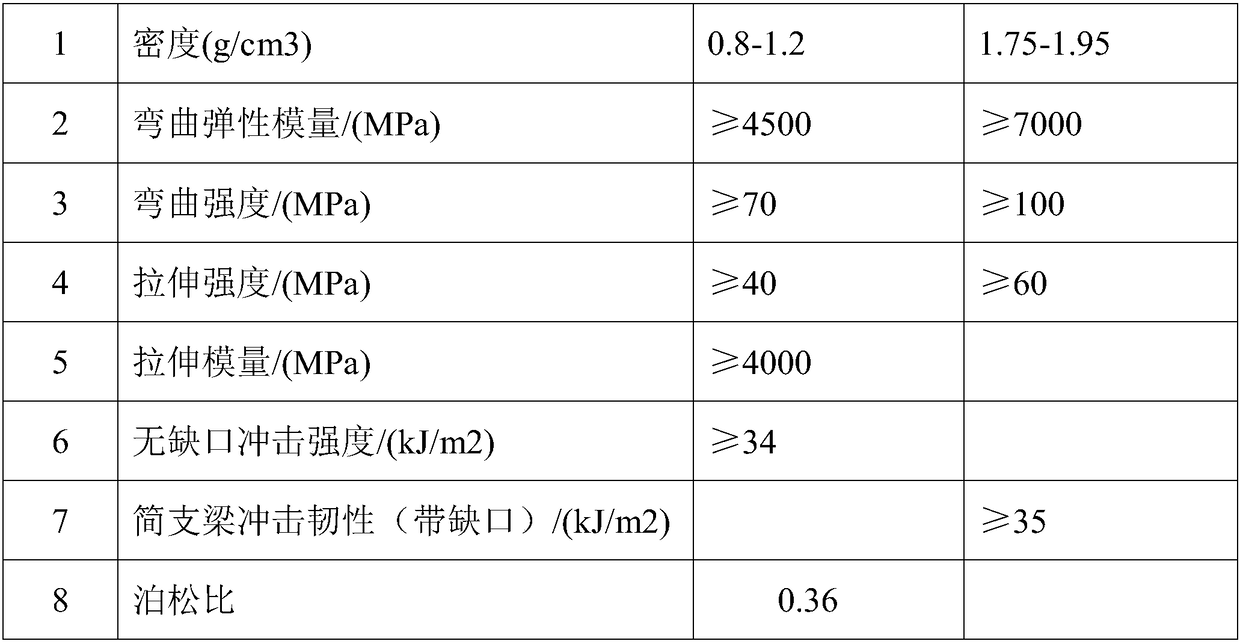

[0010] A lightweight component of an automobile using a composite material molding process, using the following process,

[0011] The sheet or roll of long glass fiber is formed by blister equipment to obtain the surface layer of the component. The blister mold is a single-sided mold structure. The blister mold is equipped with water channels, air channels and vacuum chambers. The water channels are used for mold temperature control. Control, air circuit and vacuum cavity are used for vacuum adsorption forming of plates. During plastic forming, mold temperature machine setting temperature: 1st and 4th quarters: 95±5°C; 2nd, 3rd quarters: 90±5°C; heating time: 65°C ±10s; Secondary vacuum (molding time): 50s; Air cooling delay: 30s; Air cooling time: 20s; Mold temperature: 80±5°C (within 3min after the device is turned on);

[0012] The surface layer of the component and the polyurethane fiberglass material are foamed and molded through the foaming mold and foaming equipment. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com