Packaging box and manufacturing process thereof

A production process and packaging box technology, applied in the field of packaging boxes, can solve the problems of not being able to keep up with the growth rate, consume manpower and material resources, and difficult processing methods, and achieve the effects of convenient and fast packaging, environmental protection, and novel overall structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

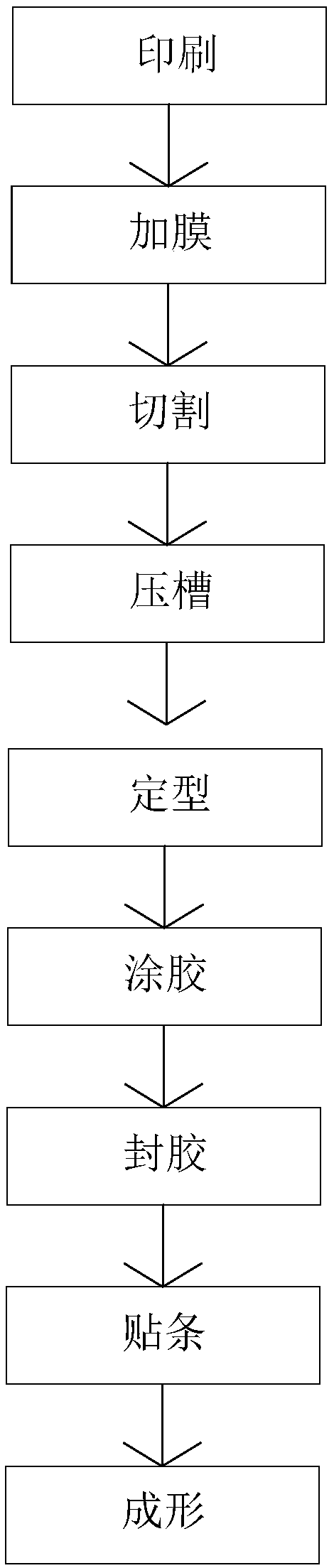

Method used

Image

Examples

Embodiment 1

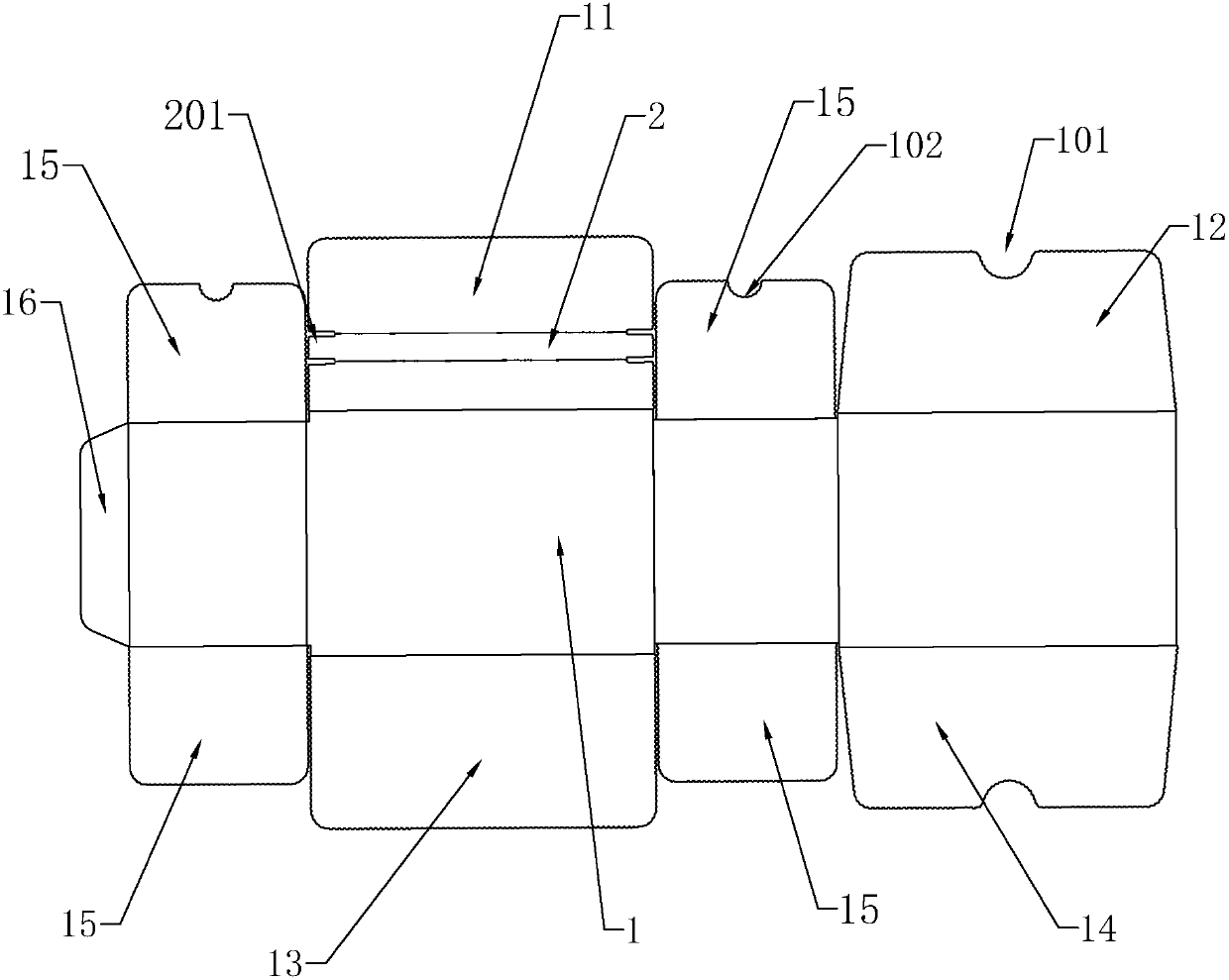

[0060] A box such as figure 2 As shown, in the unclosed state, the plane laying is clearly visible, including the box body 1 and the cover assembly integrally provided with the box body 1 and rotatably flipped and connected, including the first cover plate 11 arranged above the box body 1, The second cover plate 12 and two side plates 15 installed on both sides of the first cover plate 11, followed by the third cover plate 13, the fourth cover plate 14 and the third cover plate 13 installed on the bottom of the box body 1 There are two side plates 15 on both sides. In addition, a connecting plate 16 is provided on the left side of the box body 1 . The connecting plate 16 can also be arranged on the right side of the box body 1 in actual production.

[0061] The first cover plate 11, the second cover plate 12, the third cover plate 13, the fourth cover plate 14 and the side plates 15 on both sides of the first cover plate 11 are also provided with a first groove 101, a second ...

Embodiment 2

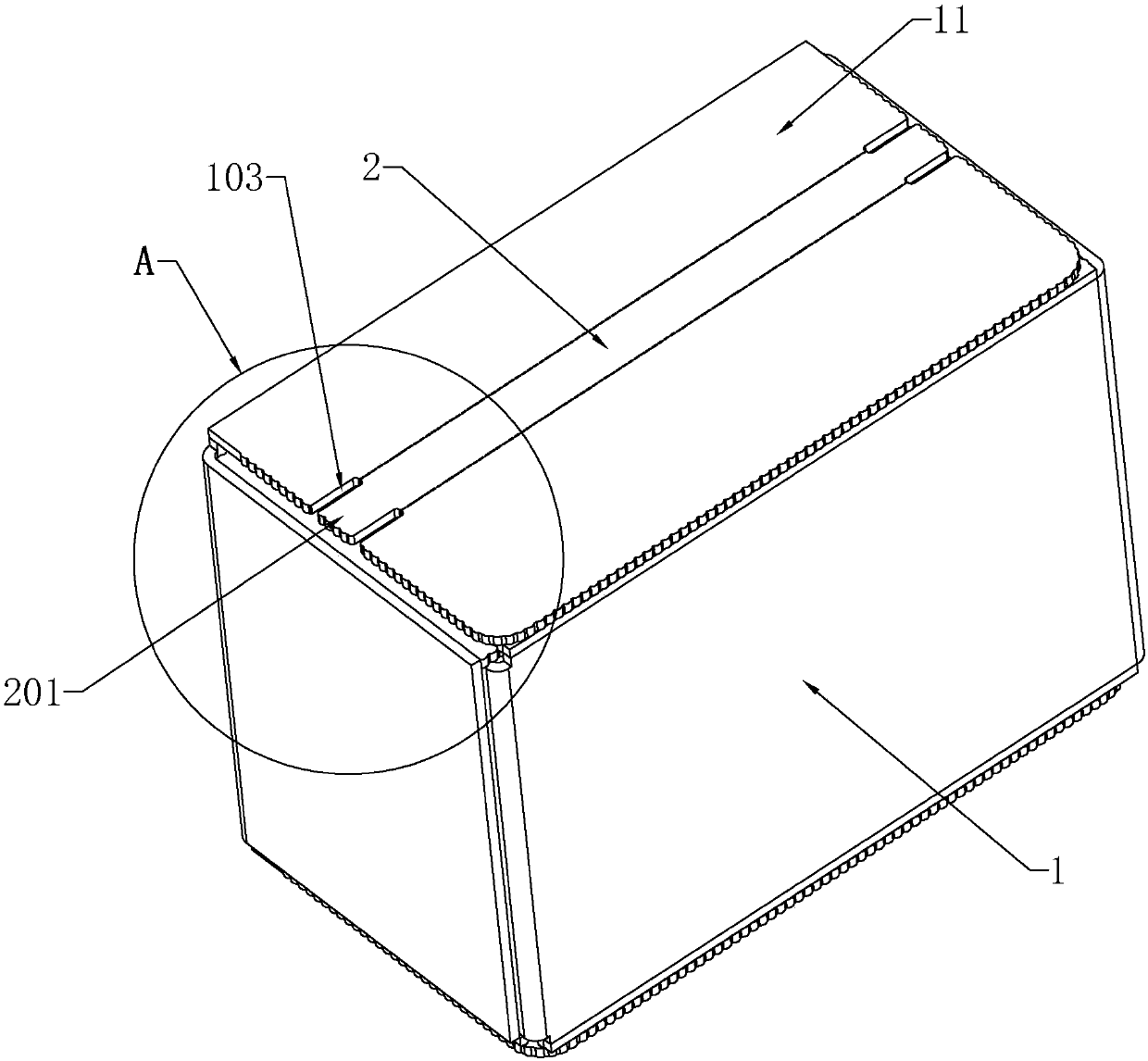

[0068] Compared with Example 1, as Figure 5 As shown, in Embodiment 1, the two ends of the tear strip, the ends of the protruding strip 201 and the two sides of the first cover plate 11 are arranged on each other. In practice, it is easy to be hung on the protruding strip 201 and cause the tear groove 104 to be damaged. , so that the end part of the tear strip is disconnected, so further improvements are needed on this basis; Figure 6 As shown, the two third grooves 103 forming the convex strip 201 are connected, and the two third grooves 103 are arranged in a "┒" shape, and the curved parts of the two third grooves 103 are connected.

Embodiment 3

[0070] Compared with Embodiments 1 and 2, in actual use of Embodiment 1 and Embodiment 2, after the tear strip is pulled off, the first cover plate 11 is divided into upper and lower parts, and cannot be closed again for use. , needs to be further improved on this basis; combined with Figure 12 and Figure 13 As shown, the first cover plate 11 is provided with a third gluing strip 33, the 3rd gluing strip 33 includes a gluing layer 3 and an isolation layer 4 covered on the gluing layer 3, the 3rd gluing strip 33 is located at the first Between a cover plate 11 and the connection end 01 of the box body 1 and the tear strip; there are two tabs 41 on the isolation layer 4 , and they are respectively installed at both ends of the isolation layer 4 .

[0071] After setting like this, after the user tears off the tear tape, the first cover plate 11 is divided into two parts, the first part will be stuck on the second cover plate 12 by the first glue strip 31, and the second part i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com