Automatic butting device of radio frequency plug

An automatic docking and radio frequency technology, which is applied to the parts of the connecting device, the device for connecting/disconnecting the connecting parts, the coupling device, etc., can solve problems such as impossible, and achieve easy implementation, control of manufacturing costs, and simple automatic docking device. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

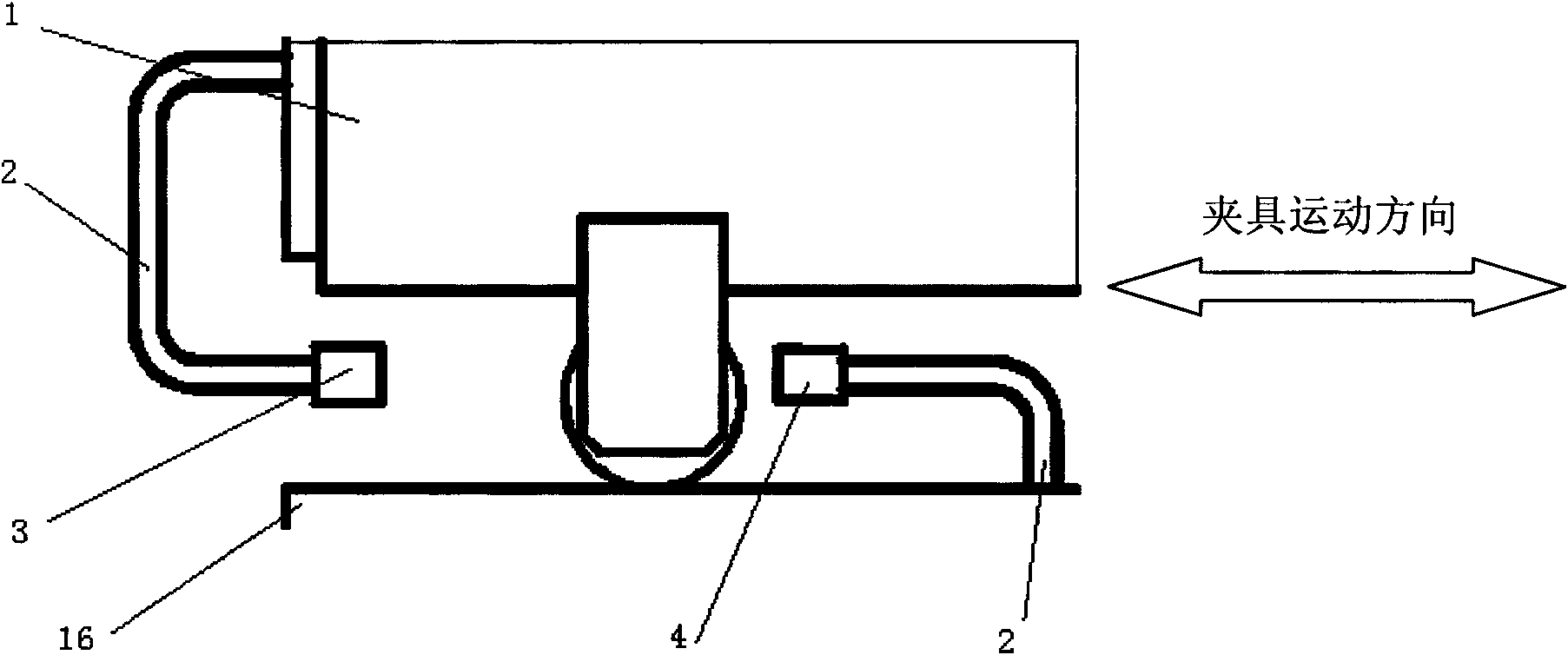

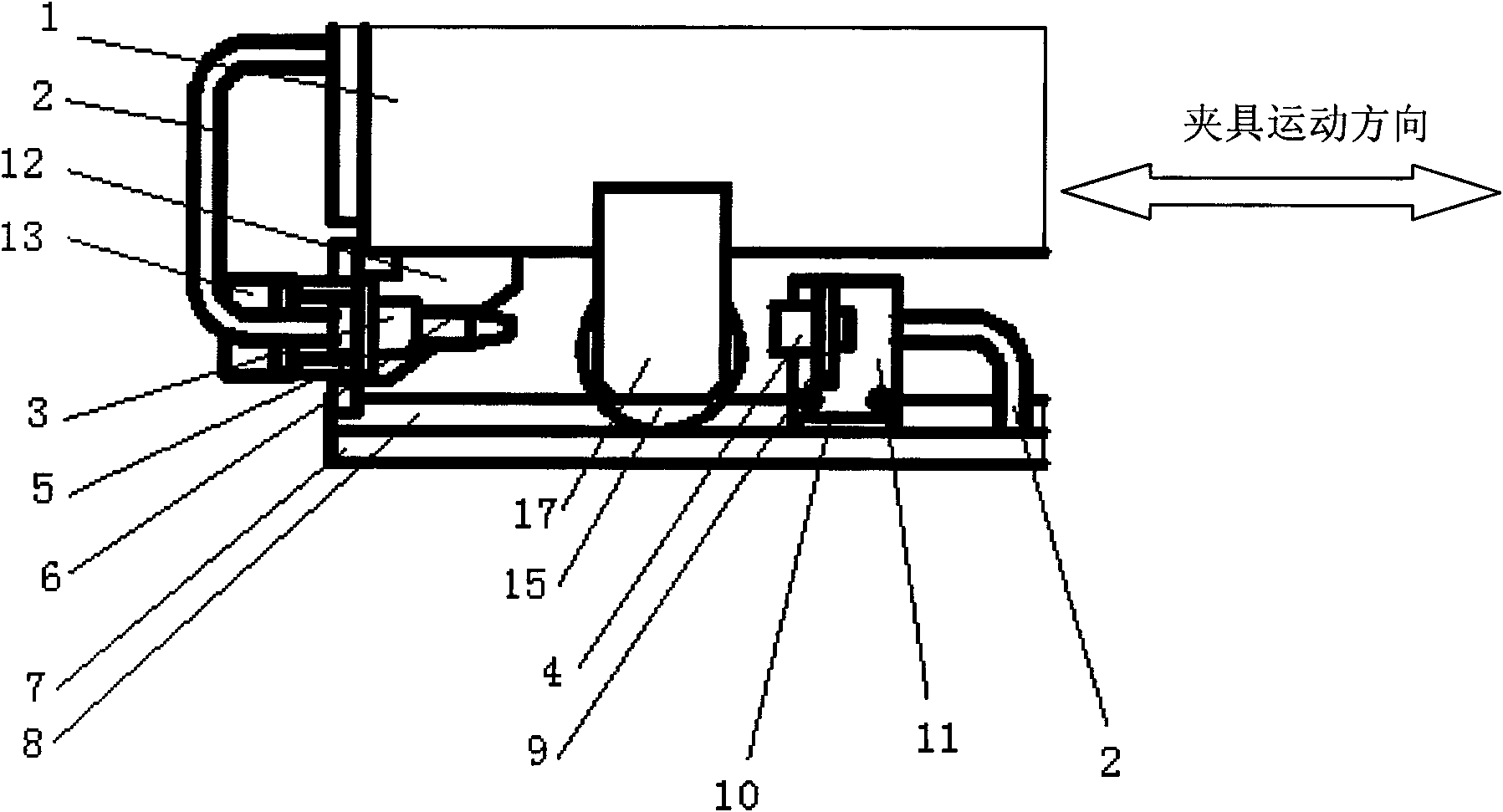

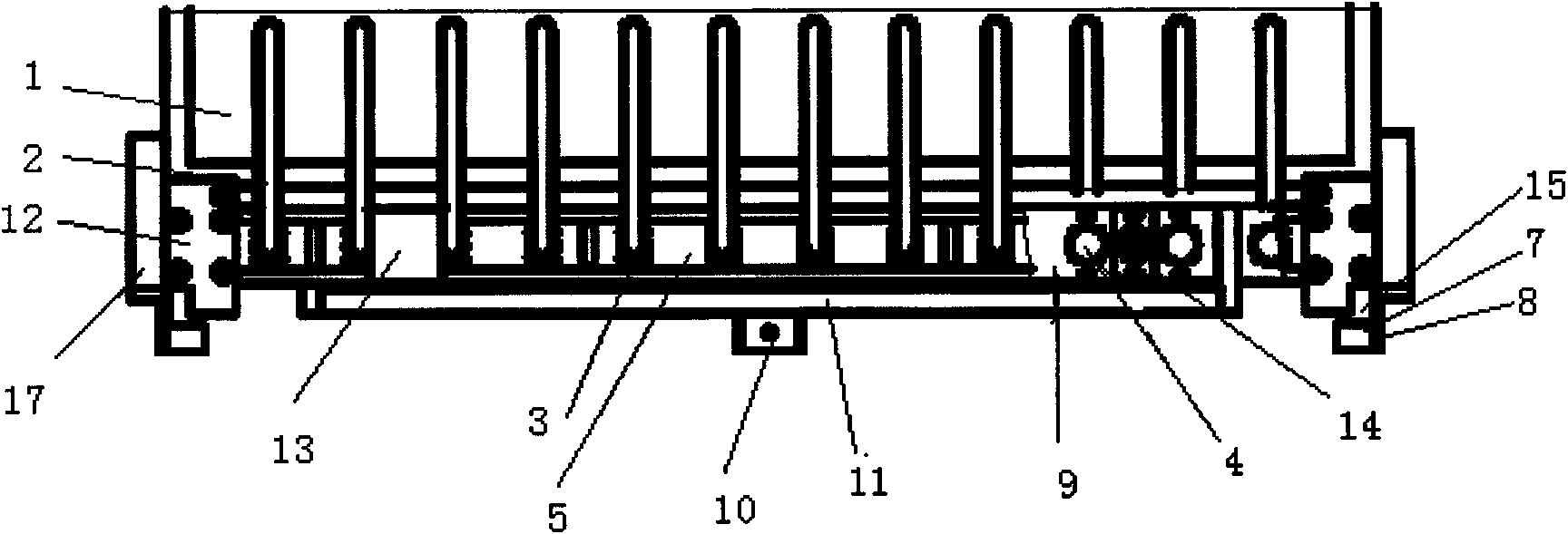

[0034] A specific embodiment of the present invention see figure 2 , as shown in 3 and 4, the installation effect is shown in Figure 7 and Figure 8 .

[0035] The automatic docking mechanism of the radio frequency plug of the present invention after installation can be divided into two parts: the first part is the part fixed on the fixture, including the female electrode plate 5; the guide post 6; the bracket 12; the traction part 13 and the fixture 1; the radio frequency cable 2; RF plug female head 3; fixture casters 15, etc.

[0036] The RF plug female 3 is installed on the female electrode plate 5, the RF plug female 3 is connected to the electrode in the fixture 1 through the RF cable 2, the female electrode plate 5 is fixedly connected to the fixture 1 through the bracket 12, and the traction part 13 is connected to the female Head electrode plate 5 is connected (also can be in other positions), and guide post 6 is installed on female head electrode plate 5, and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com