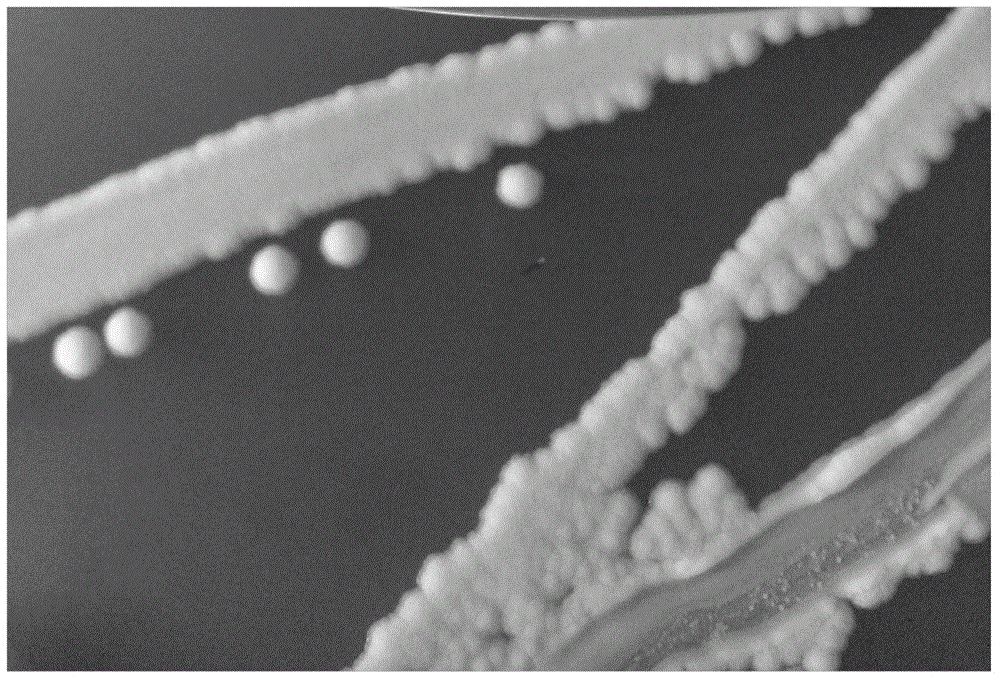

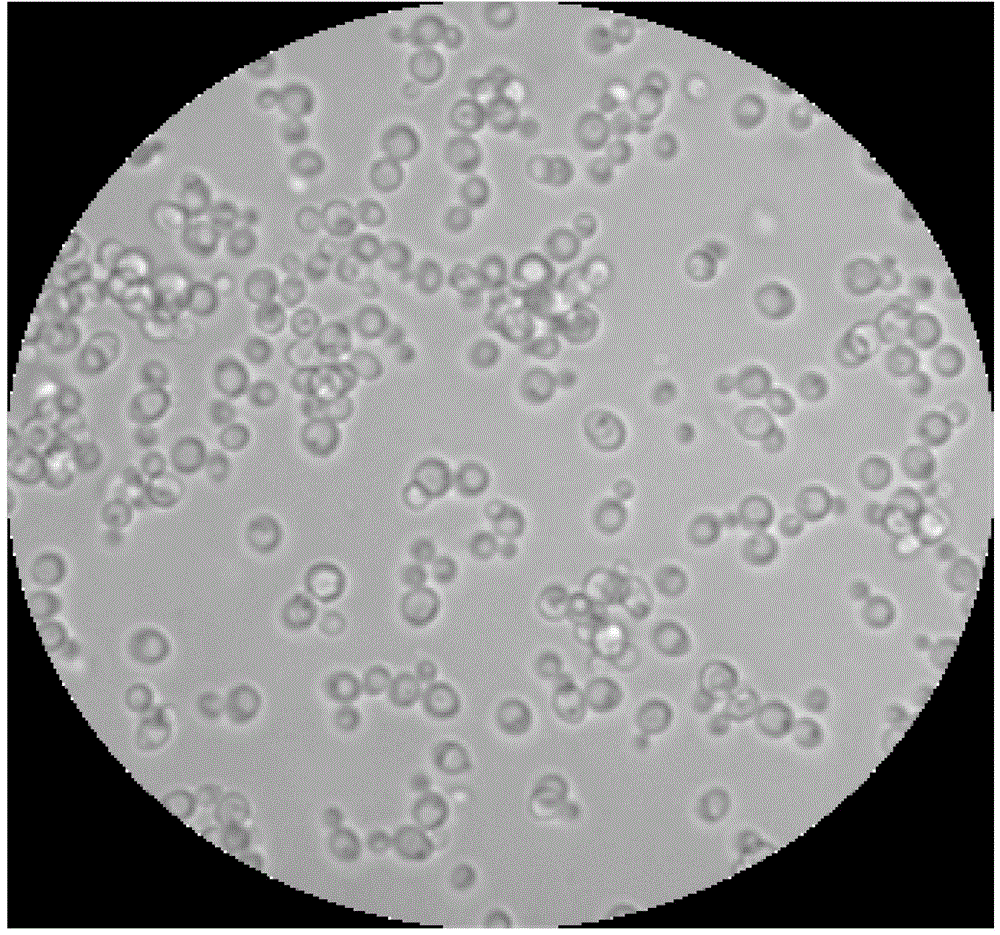

Strain of yeast capable of decomposing cellulose and applications thereof

A cellulose and yeast technology, applied in the field of yeast, can solve the problem of less yeast, and achieve the effects of short production cycle, good adaptability and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 Utilizes yeast of the present invention to produce high-protein feed with cellulose as the main raw material

[0023] First, inoculate 1 loop of the yeast strains preserved on the slant into YPD liquid medium with an inoculation needle, and cultivate at 32°C for 1 day, then centrifuge the obtained yeast suspension at 3000rpm for 5min at 25°C, and pour off the supernatant. After adding sterile water, mix well and centrifuge again under the same conditions, wash the bacteria, and make a yeast suspension with a concentration of 0.5OD;

[0024] According to the inoculum amount of 4%, use the sprayer to directly spray the yeast suspension into the fresh distiller's grains, mix well, pile up in the open air for 2-3 days, monitor the change of acidity, and detect the protein content of the distiller's grains until the pH rises to about 5, reaching 16- 18% can be processed into high-protein grain powder feed according to the conventional grain powder feed processin...

Embodiment 2

[0025] Example 2 Utilize the yeast of the present invention to produce distilled grains wine, improve the yield and quality of distilled grains wine

[0026] Yeast suspension was prepared according to the method in Example 1. While mixing koji powder, it was inoculated into the distiller's grains fermented with Daqu complex grains by 1% inoculation amount, and fermented in the cellar to produce distiller's grains wine. Compared with fermented distilled grains fermented with yeast, it can increase the yield of distilled grains wine by 0.8-1%, while not affecting other physical and chemical indicators of distilled grains wine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com