Patents

Literature

66results about How to "Improve heat shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic recording medium

InactiveUS20050260456A1Increased strengthEnhance in durability , storabilityMagnetic materials for record carriersBase layers for recording layersPolyesterMagnetic layer

A magnetic recording medium comprising: a nonmagnetic support; and a magnetic layer containing ferromagnetic powder and a binder, wherein the nonmagnetic support contains polyester, the nonmagnetic support has gauche / trans peak intensity ratio of 0.50 or less as determined by a ATR-FT-IR method, and a shrinkage percentage of the magnetic recording medium after storage for 1 week under a conditions of 70° C. and 5% RH is 0.040% or less.

Owner:FUJIFILM HLDG CORP +1

Heat-shrinkable polyolefin film

InactiveUS20040072002A1Acceptable adhesion strengthImprove heat shrinkageOrnamental textile articlesSynthetic resin layered productsVitrificationPolyolefin

A heat-shrinkable polyolefin-base film comprising a polypropylene-base resin, a petroleum resin in total and a cyclic polyolefin having a glass transition temperature not lower than 90° C. and lower than 140° C., and a multilayer heat-shrinkable film comprising a base layer which comprises a polypropylene-base resin, a petroleum resin in total and a cyclic polyolefin, and at least one outer layer which comprises a styrene resin and a polyolefin resin.

Owner:TOYO TOYOBO CO LTD

Coating forming agent for reducing pattern dimension and method of forming fine pattern therewith

InactiveUS20050175926A1Effectively formSatisfactory profileSemiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersWater soluble polymersChemistry

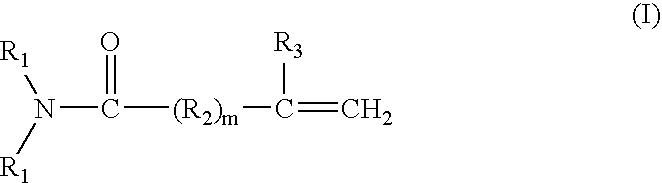

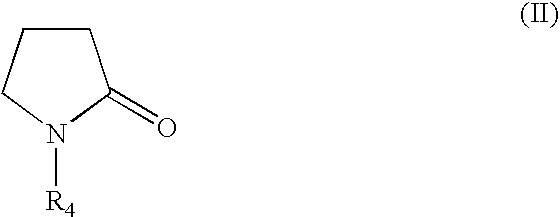

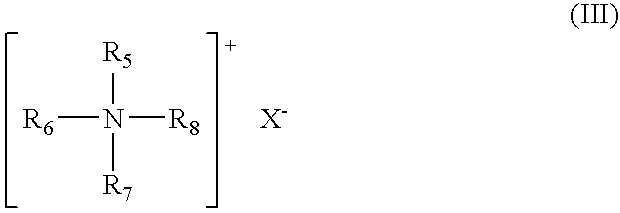

It is disclosed an over-coating agent for forming fine patterns which is applied to cover a substrate having thereon photoresist patterns and allowed to shrink under heat so that the spacing between adjacent photoresist patterns is lessened, with the applied film of the over-coating agent being removed substantially completely to form or define fine trace patterns, further characterized by containing either a water-soluble polymer and an amide group-containing monomer or a water-soluble polymer which contains at least (meth)acrylamide as a monomeric component. Also disclosed is a method of forming fine-line patterns using any one of said over-coating agents. According to the invention, the thermal shrinkage of the over-coating agent for forming fine patterns in the heat treatment can be extensively increased, and one can obtain fine-line patterns which exhibit good profiles while satisfying the characteristics required of semiconductor devices.

Owner:TOKYO OHKA KOGYO CO LTD

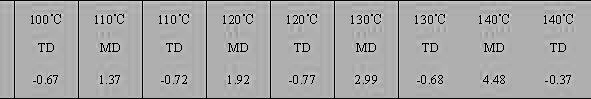

Polyimide film with high dimensional stability and preparation method of polyimide film

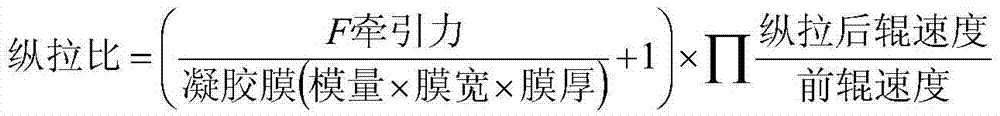

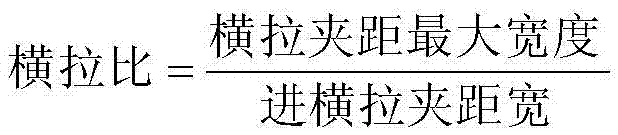

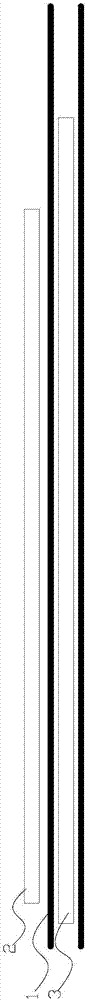

The invention discloses a polyimide film with high dimensional stability and a preparation method of the polyimide film. The polyimide film is prepared from at least one aromatic dianhydride containing a rigid structure and at least one aromatic diamine containing a rigid structure through a solution polycondensation reaction and an imidization reaction, wherein the sum of mole numbers of the aromatic dianhydride containing the rigid structure and the aromatic diamine containing the rigid structure accounts for 70-85% of the sum of mole numbers of totally reacted dianhydrides and diamines; the film thickness is 5-75 microns; the thermal shrinkage ratios of the film in the longitudinal direction and the transverse direction are respectively less than or equal to 0.1%; the coefficient of linear thermal expansion is less than or equal to 16ppm; and the operating requirements of a polyimide film base material of a flexible copper clad laminate are met. According to the preparation process of the film, a roll-to-roll production manner of performing continuous longitudinal stretching technology according to a constant speed ratio and transverse high-temperature stretching and online thermosetting treatment is adopted, the prepared polyimide film has excellent dimensional stability performance, and the production manner adopted by the film is simple, convenient, high-efficiency and reliable.

Owner:RAYITEK HI TECH FILM CO LTD

High-temperature safety battery cell

ActiveCN107204415AReduce the likelihood of exposureAvoid short circuitCell seperators/membranes/diaphragms/spacersFinal product manufacturePole pieceEngineering

The invention discloses a high-temperature safety battery cell. The high-temperature safety battery cell comprises diaphragms, a positive pole piece and a negative pole piece, wherein the diaphragms are arranged between the positive pole piece and the negative pole piece at intervals, two adjacent diaphragms are fixed in a bonding manner, and a bonding point is disposed at the outer side of the positive pole piece or the negative pole piece. The high-temperature safety battery cell has the advantages that due to the fixing effect of the bonding point, the heat shrinkage and high temperature resistance of the diaphragms are improved, the contact probability of the positive pole piece and negative pole piece is reduced, and the high-temperature short-circuit risk is decreased; and meanwhile, the diaphragms are fixed in an assisting manner in a stacking structural unit, so that the shifting of the positive pole piece and negative pole piece is avoided, the short circuit caused by the loose folding of the diaphragms can be prevented, the safety potential hazard is avoided, the structure is stable, the safety is high, and the good quality of the battery cell is guaranteed.

Owner:ETRUST POWER ETP GRP LTD

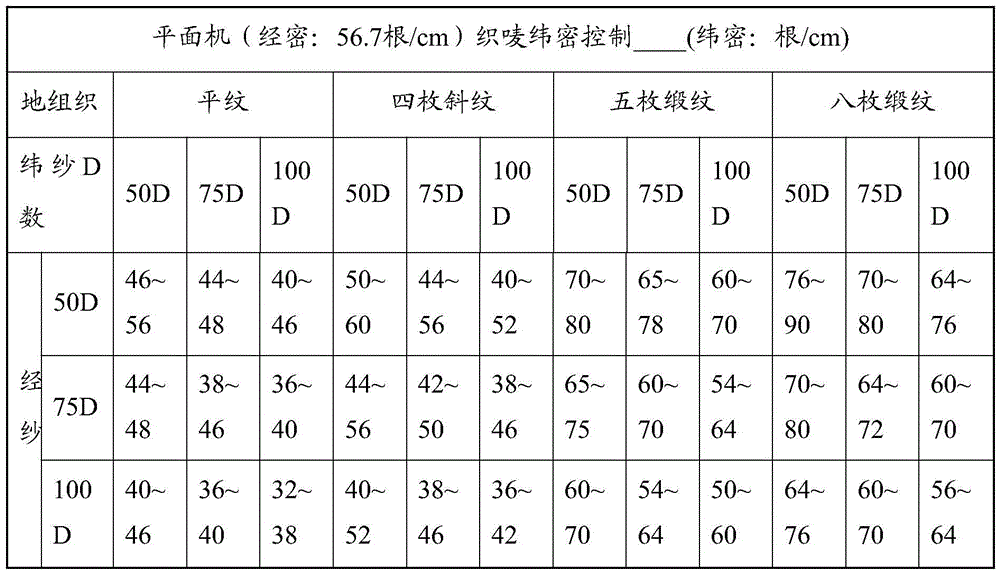

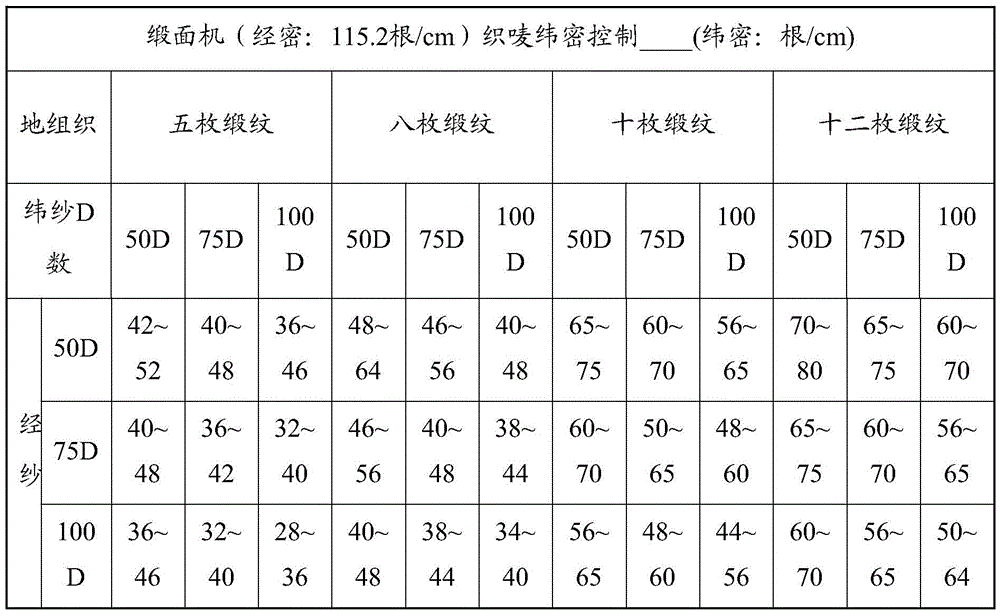

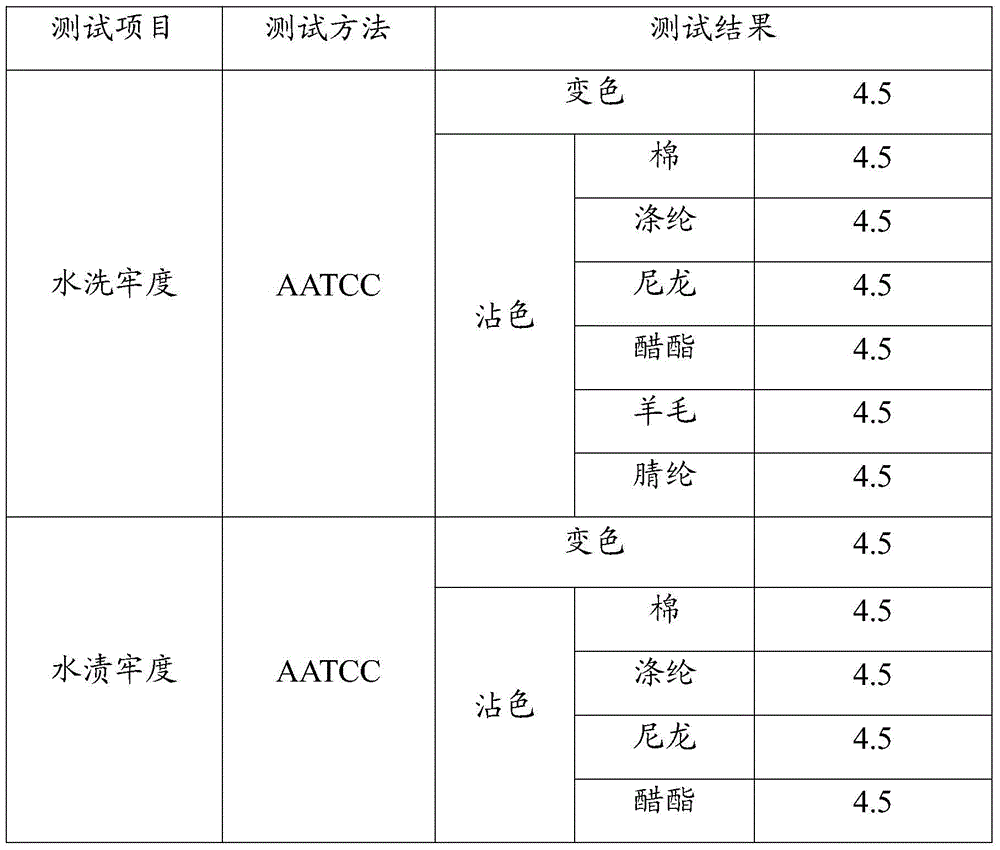

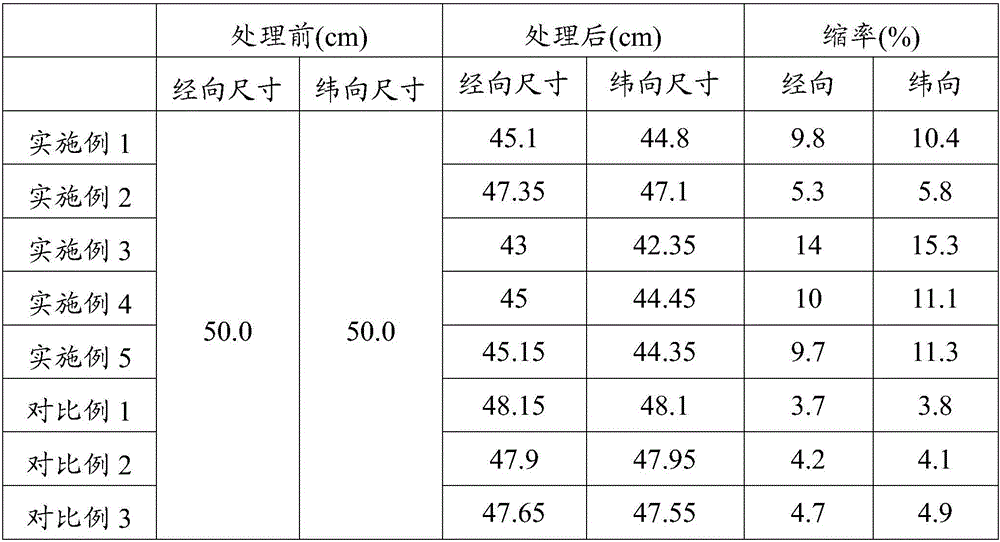

Polyester woven label and preparation method thereof

ActiveCN105525417AImprove heat shrinkageHigh fastnessSevering textilesWoven fabricsPolyesterShrinkage rate

The invention discloses a polyester woven label and a preparation method thereof. The preparation method includes following steps: (1), warp pretreatment; (2), weft selection; (3), pattern printing; (4), label weaving; (5), cutting and slitting. The polyester woven label made by the preparation method does not need to go through wash care and ironing processes, and the polyester woven label is less prone to wrinkling and contracting when being subjected to subsequent dyeing and wash care at 60-100 DEG C and press-ironing and drying at 100-160 DEG C. By using the preparation method, production period is shortened, production cost is lowered, fastness of the woven label in each aspect can be controlled at four or higher grade, and heat shrinkage rate of the woven label can be controlled below 3%.

Owner:广东康派环创科技有限公司

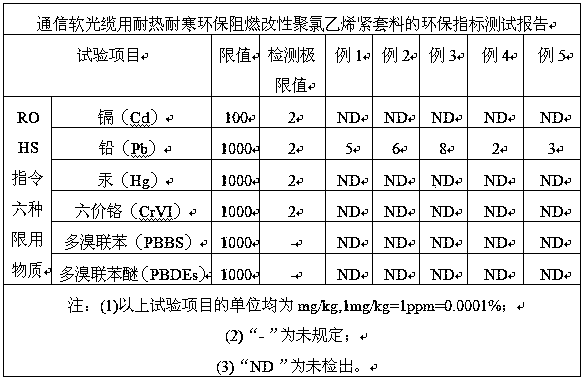

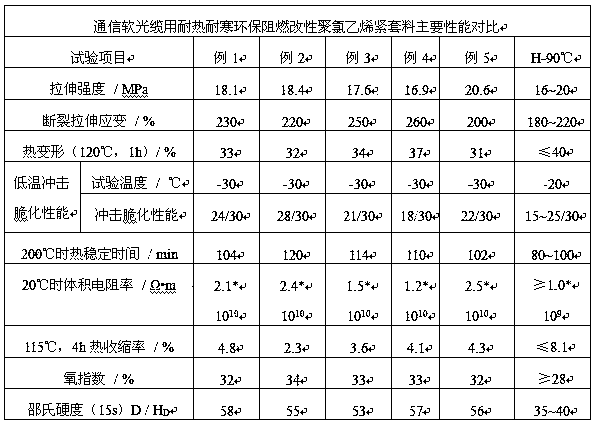

Environment-friendly modified polyvinyl chloride tight buffering material for soft communication optical cable and preparation method of material

InactiveCN104312057AOutstanding high temperature resistanceHighlight environmental protectionShrinkage ratePlasticizer

The invention discloses an environment-friendly modified polyvinyl chloride tight buffering material for a soft communication optical cable and a preparation method of the material. The material comprises the following raw materials in parts by weight: 95-100 parts of polyvinyl chloride resin, 30-35 parts of an environment-friendly plasticizer, 5-8 parts of a cold-resistant plasticizer, 5-8 parts of an environment-friendly stabilizer, 20-35 parts of a filling agent, 3-8 parts of a flame retardant, 0.5-2 parts of a lubricant, 4-9 parts of an anti-impact modifier and 3-5 parts of an anti-heat shrinkage modifier. Due to the addition of the cold-resistant plasticizer, the material is outstanding in high temperature resistance, low temperature resistance and environmental protection property; due to the anti-heat shrinkage modifier, the material is relatively low in heat shrinkage rate; due to the flame retardant, the material is relatively good in flame retardant property. According to the preparation method, the process is simple, the temperature is reasonable, and the produced material is guaranteed to be relatively good in flame retardant property, high and low temperature resistance and small in heat shrinkage rate.

Owner:JIANGSU JIANGYANG TECH

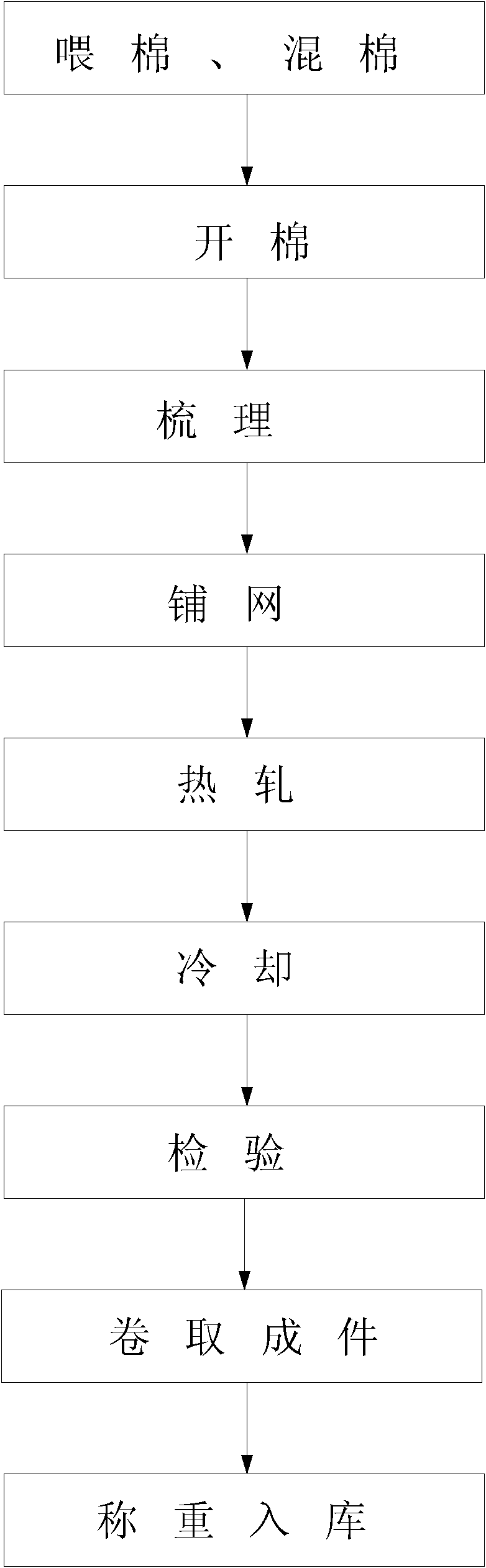

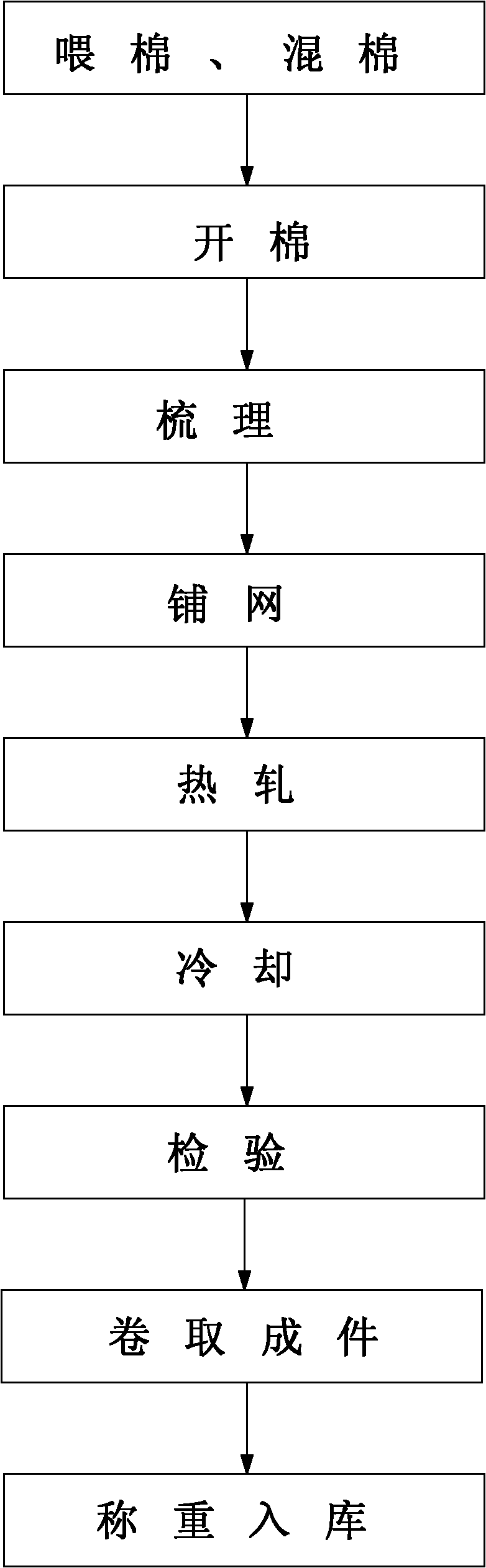

Process for producing hot rolling thin nonwoven fabric

The invention discloses a process for producing hot rolling thin nonwoven fabric, sequentially comprising the following steps of: feeding cotton, mixing cotton, adding ES fiber (ethylene-propylene side by side) in fiber raw material, opening, carding, lapping, hot rolling, cooling, testing, reeling into products, weighing and warehousing. The process disclosed by the invention has the advantages that: ES fibers are added, thus washing fastness of the supported hot rolling thin nonwoven fabric is greatly improved compared with a common nonwoven fabric, and the supported hot rolling thin nonwoven fabric is resistant to pilling; the cloth cover of a base fabric is smoother and the fastness is greatly improved, the washing fastness, washing shrinkage and heating shrinkage are all obviously improved, and the quality is above the national textile industry standard FZ / T6004-93.

Owner:HANGZHOU JINMUZHI GARMENT ACCESSORIES

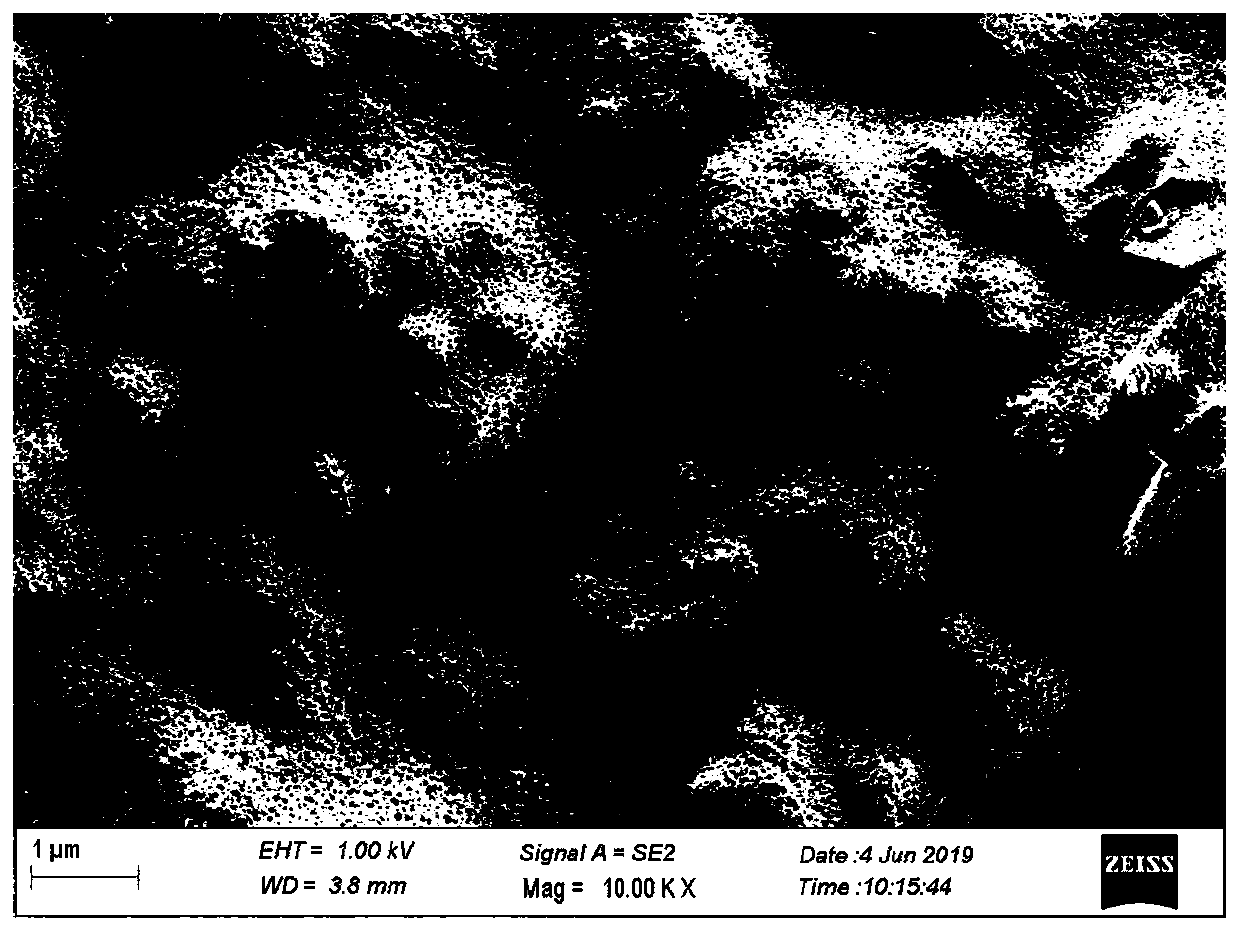

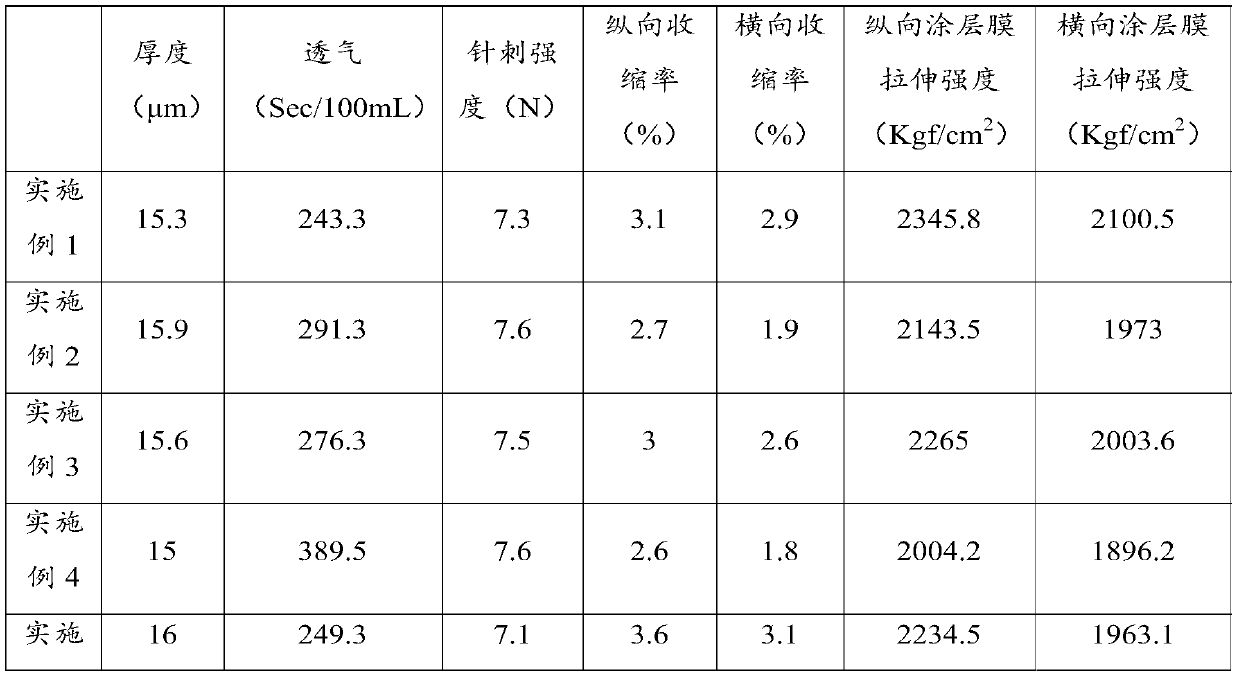

Aramid fiber coating liquid, preparation method thereof, diaphragm based on aramid fiber coating liquid and application

ActiveCN110707265AImprove diaphragm shrinkageImprove acupuncture strengthCell component detailsFiber coatingCeramic particle

The invention discloses an aramid fiber coating liquid, a preparation method thereof, a diaphragm based on the aramid fiber coating liquid and application, the preparation method comprises the following steps: stirring and sanding ceramic particles and dimethylacetamide to obtain a first mixture; under the atmosphere of nitrogen or inert gas, stirring the first mixture and m-phenylenediamine, cooling to 0-5 DEG C after stirring, adding isophthaloyl dichloride, stirring, heating to 78-90 DEG C after stirring, adding calcium hydroxide, and stirring to obtain a second mixture; and mixing and stirring the second mixture and an organic matter, and adjusting the viscosity to 280-400 mpa.s to obtain the aramid fiber coating liquid. Starting from the synthesis direction, substances required by a diaphragm coating are added in the synthesis process, so that the pulping time is shortened while the cost is saved, and the safety performance of thermal shrinkage, needling and the like of the aramidfiber diaphragm is improved.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

Preparation method of corona-treated polypropylene coarsened capacitor film

The invention discloses a preparation method of a polypropylene capacitor film which allows double-sided metalization. The method comprises the following steps: (1) selecting and preparing raw materials; (2) extruding cast sheets through an extruder; (3) cooling with a chilling roll or an air shower; (4) performing longitudinal stretching; (5) performing lateral stretching; (6) measuring thickness, cutting edges and performing corona treatment; (7) rolling; (8) performing first aging treatment; (9) cutting, and (10) performing second aging treatment. Compared with the prior art, the polypropylene capacitor film prepared by the method has the characteristics of low hot shrinkage rate and stable performance at high temperature, namely good high-temperature stability.

Owner:NINGBO GREAT SOUTHEAST WAN XIANG SCI & TECH

Completely degradable biobased heat shrink film

InactiveCN106494046AImprove heat shrinkageHigh tear strengthSynthetic resin layered productsPlasticizerEngineering

The invention provides a completely degradable biobased heat shrink film. The heat shrink film is composed of an inner film and an outer film. The outer film is prepared from the following raw materials by weight: 0-70 parts of outer biobased copolyester, 30-100 parts of outer polylactic acid, 1-25 parts of an outer plasticizer, 0-3 parts of an outer lubricant, 0-2 parts of an outer nucleating agent, 0-5 parts of an outer chain extender, and 0.2-5 parts of an outer stabilizer. The inner film is prepared from the following raw materials by weight: 5-80 parts of inner biobased copolyester, 20-100 parts of inner polylactic acid, 1-30 parts of an inner plasticizer, 0-3 parts of an inner lubricant, 0-2 parts of an inner nucleating agent, 0-5 parts of an inner chain extender, and 0.2-11 parts of an inner stabilizer. The completely degradable biobased heat shrink film provided by the invention adopts completely degradable materials, and realizes production of multi-layer co-extruded heat shrink films.

Owner:TIANJIN GREENBIO MATERIAL CO LTD

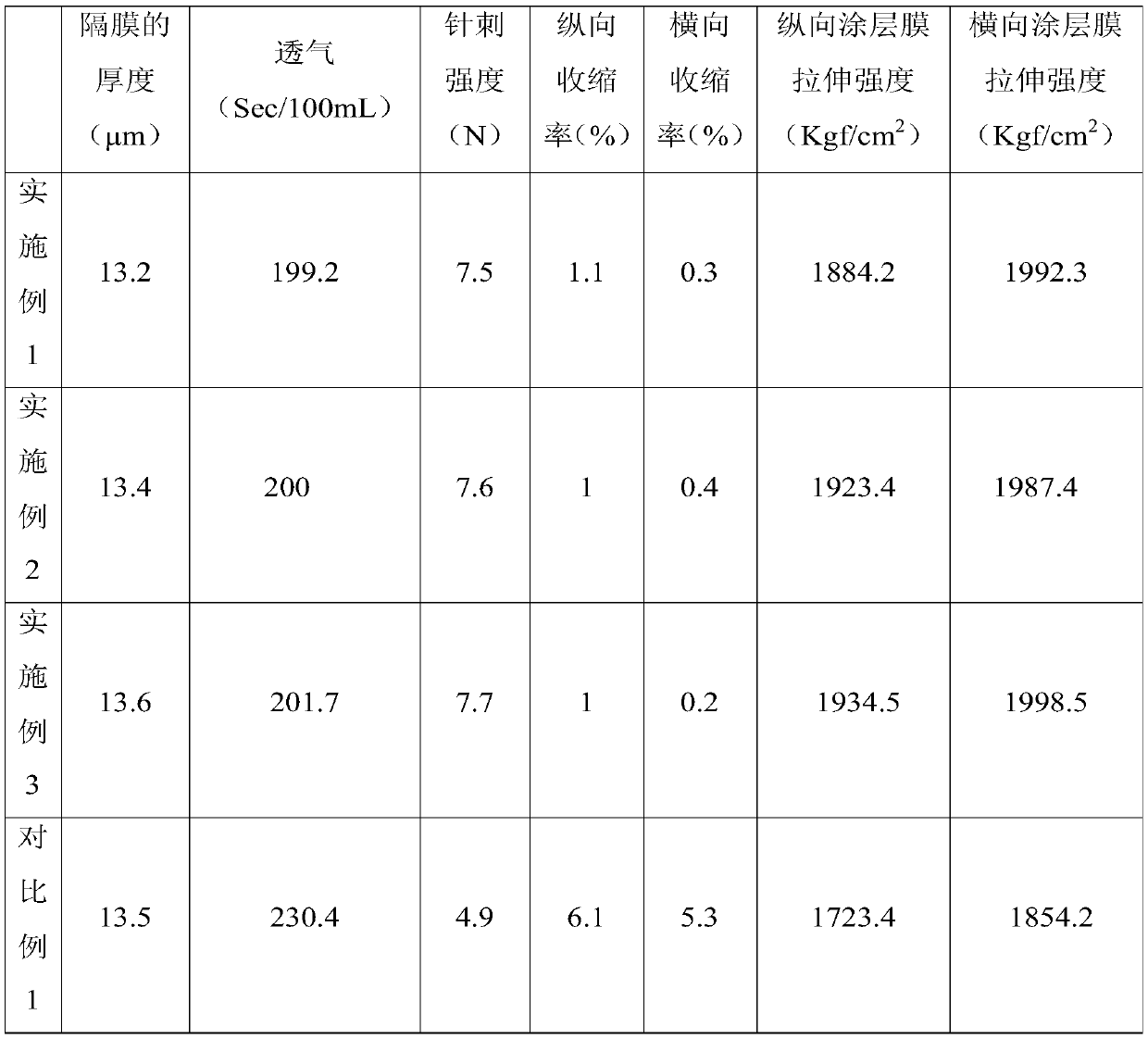

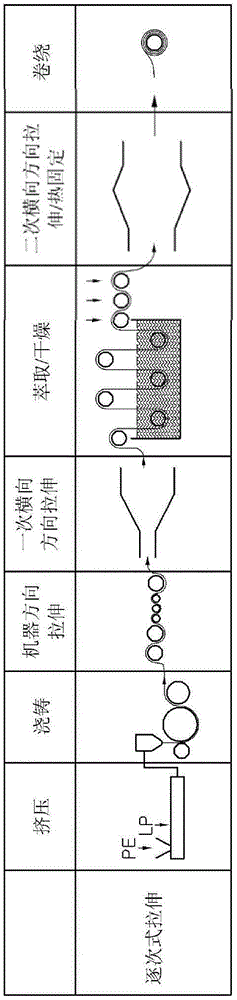

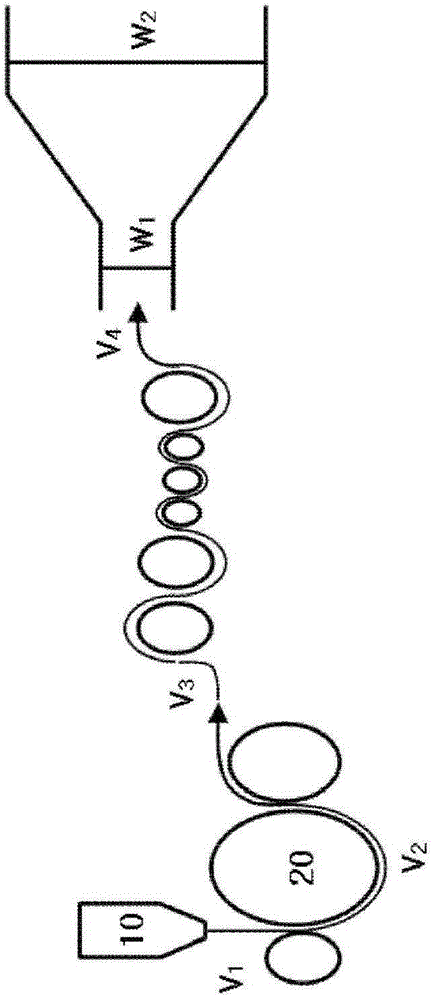

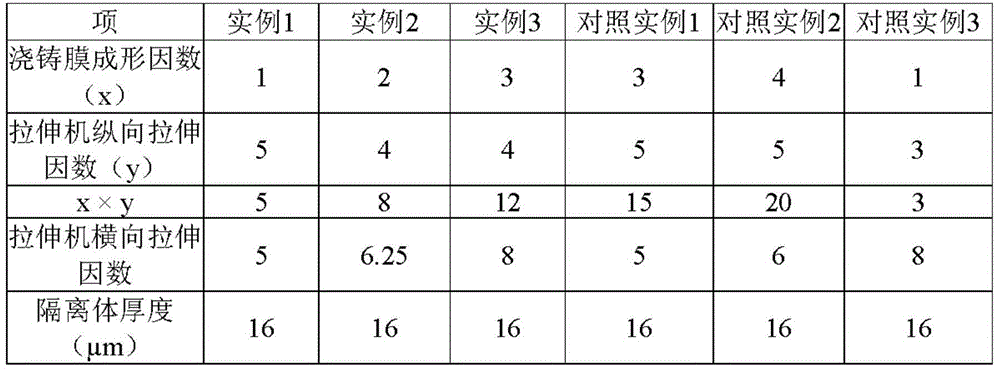

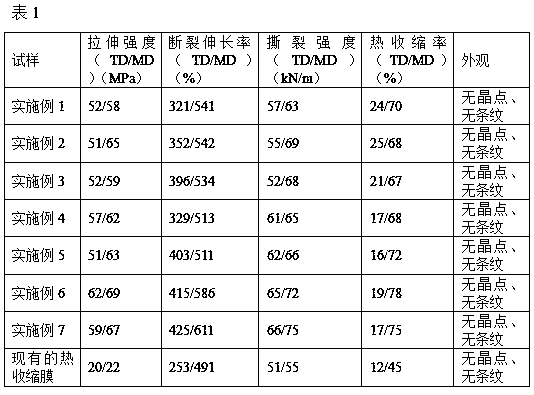

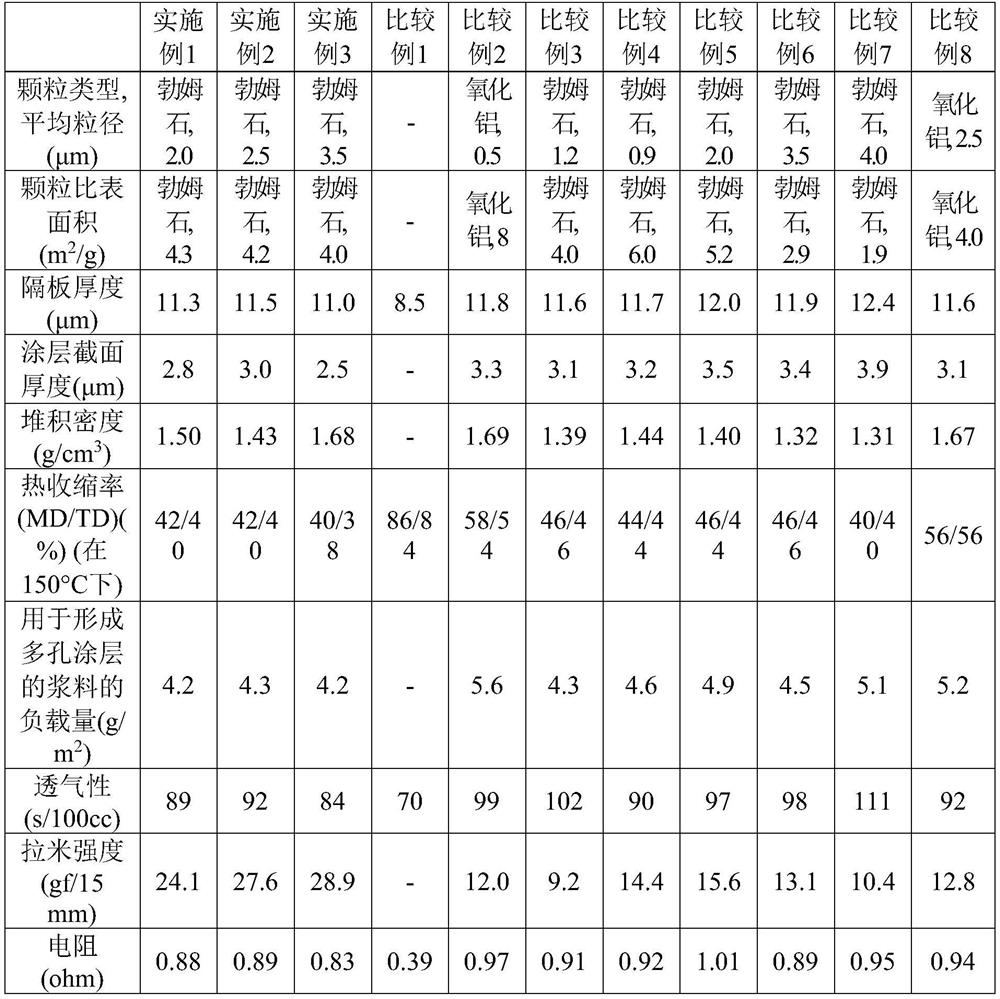

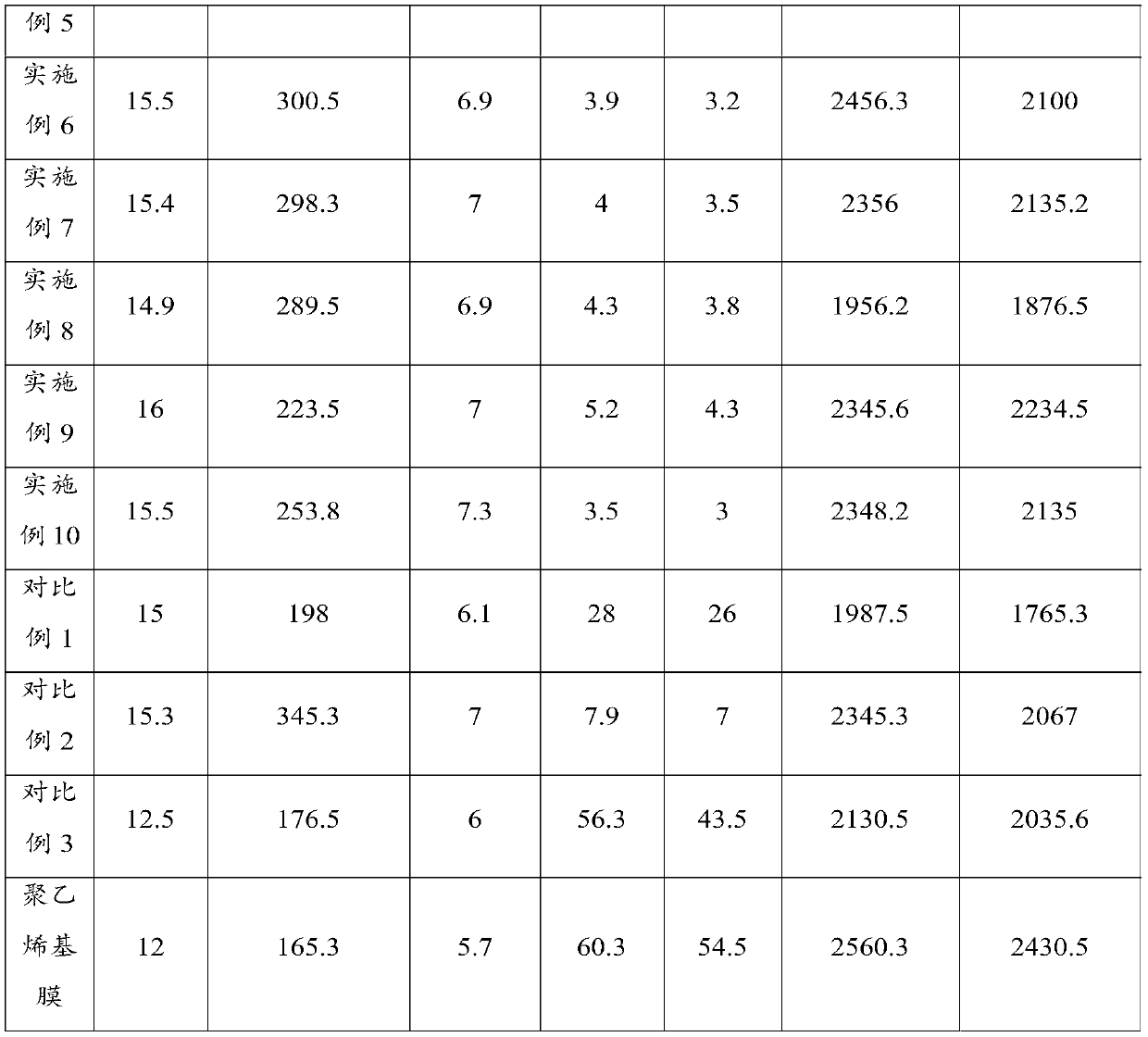

Method for producing separation membrane, and said separation membrane and battery using same

InactiveCN104871342AHigh tensile strengthHigh heat shrinkageCell seperators/membranes/diaphragms/spacersFinal product manufacturePolyolefinElectrical battery

The present invention relates to a method for producing a polyolefin-based porous separation membrane and, more particularly, to a method for producing a separation membrane having improved tensile strength and thermal shrinkage rate by adjusting the stretching factor of a base film during the casting and stretching processes of a separation membrane production process. Also, the present invention relates to a polyolefin-based porous separation membrane having a small difference in tensile strength between the longitudinal direction and the transverse direction of the separation membrane, excellent tensile strength, and improved thermal shrinkage rate and improved puncture strength. Further, the present invention relates to an electrochemical battery of which the dimensional stability under heat and tension is improved using the separation membrane.

Owner:SAMSUNG SDI CO LTD

PEF heat shrinkable film and preparation method thereof

ActiveCN111267449AImprove recyclingApparently stableLamination ancillary operationsSynthetic resin layered productsAntioxidantThermal shrinkage

The invention is applicable to the technical field of materials, and provides a PEF heat shrinkable film. The PEF heat shrinkable film comprises an outer film layer, a middle film layer and an inner film layer, wherein each of the outer film layer and the inner film layer is prepared from, by weight, 40-55 parts of high-pressure low-density polyethylene, 15-25 parts of high-density polyethylene, 10-15 parts of an ethylene-vinyl acetate copolymer, 5-10 parts of polyurethane acrylate, 5-10 parts of modified argil, 4-6 parts of oleamide and 2-5 parts of an antioxidant; and the middle film layer is prepared from, by weight, 25-35 parts of high-pressure low-density polyethylene, 20-30 parts of high-density polyethylene, 10-15 parts of the ethylene-vinyl acetate copolymer, 2-6 parts of modifiedgas silicon, 4-6 parts of oleamide and 1-3 parts of the antioxidant. The PEF heat shrinkable film formed by compounding the raw materials which are nontoxic and wide in source is stable in appearance,has good physical and mechanical properties such as the heat shrinkage rate, the tensile property and the tearing strength, is suitable for package and transportation of articles including but not limited to foods, electronic products and the like, and has good development prospects.

Owner:汕头市明佳热收缩膜有限公司

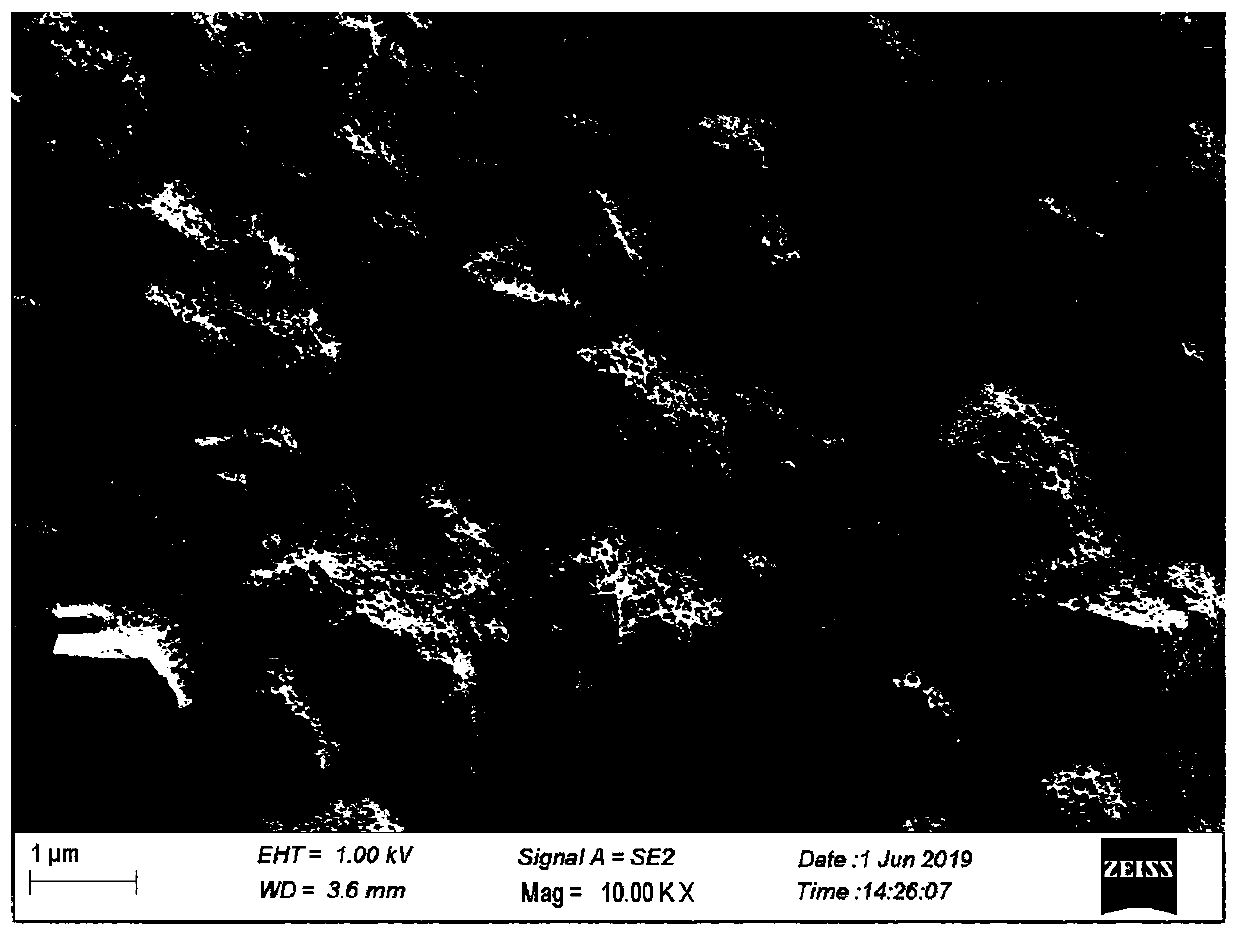

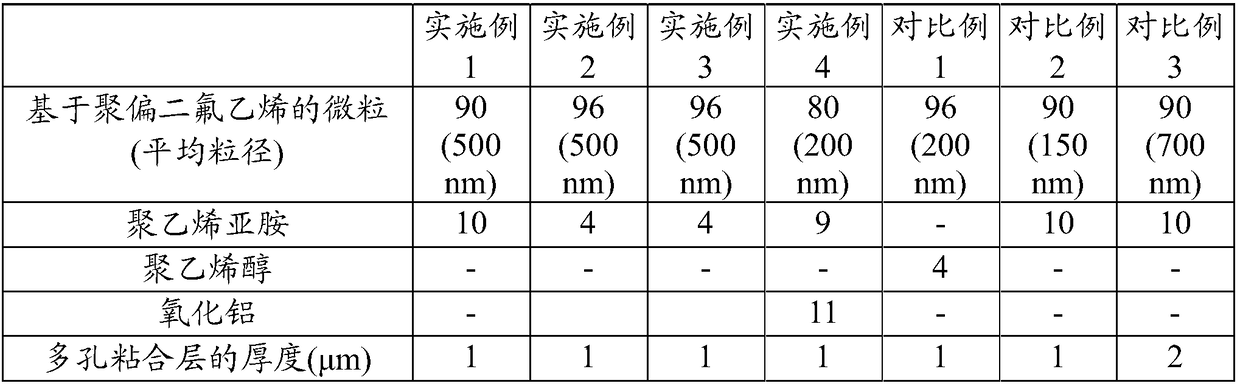

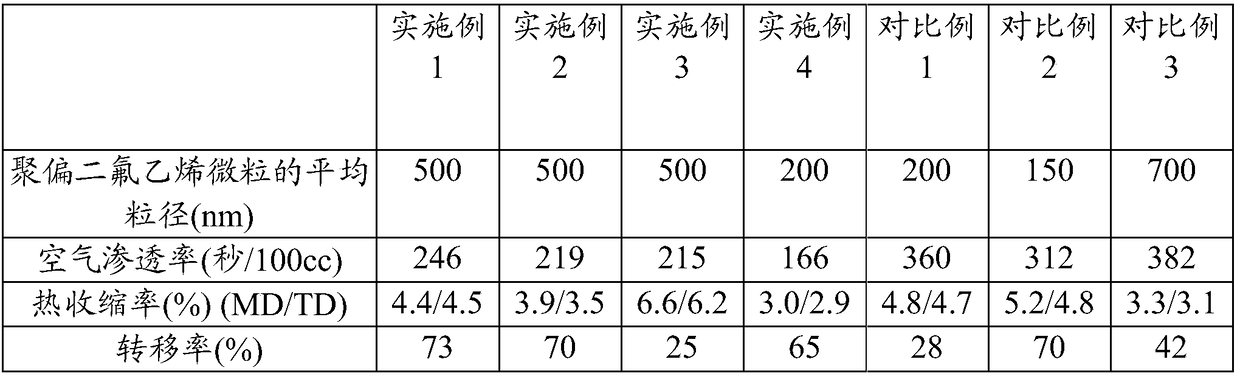

Separator comprising porous adhesive layer, and lithium secondary battery using same

PendingCN109075291AImprove heat shrinkageImprove adhesionCell seperators/membranes/diaphragms/spacersFinal product manufacturePorous substrateAdhesive

The present invention relates to a separator, a manufacturing method therefor, and a lithium secondary battery comprising the same, the separator comprising: a porous substrate; and a porous adhesivelayer formed on one surface or both surfaces of the porous substrate, wherein the porous adhesive layer comprises a nitrogen-containing binder and polyvinylidene fluoride-based polymer microparticleshaving an average diameter of 200-700 nm, and the total thickness of the porous adhesive layer is 1 [mu]m or less.

Owner:SAMSUNG SDI CO LTD

Barium sulfate diaphragm and preparation method thereof

ActiveCN112350028ALow costSimple processLi-accumulatorsCell component detailsPhysical chemistryMembrane surface

The invention relates to a barium sulfate diaphragm and a preparation method thereof. The barium sulfate diaphragm comprises a base membrane; and a modified barium sulfatemicro-layer arranged on at least one surface of the base membrane, wherein the modified barium sulfate is coupling agent modified barium sulfate, and the surface of the base membrane is covalently connected with the modified barium sulfate micro-layer. According to the barium sulfate diaphragm disclosed by the invention, the thickness is not obviously increased, and the air permeability is basically kept unchanged, and meanwhile, the barium sulfate diaphragm has improved thermal shrinkage and wetting properties, so that the safety of a lithium battery in application is improved.

Owner:NINGDE ZHUOGAO NEW MATERIAL TECH CO LTD

PVC release film

The invention provides a PVC release film. The PVC release film comprises a thin film layer which comprises the following raw materials by weight: PVC, TPX, PP, 2-ethyl methacrylate, nano-barium sulfate, polyether imide, phenolic resin, polyarylester, carbon fiber, organic montmorillonite, ethylene glycol, a silane coupling agent, an antioxidant, a light stabilizer, a defoamer and a thickener. The PVC release film has a smooth and clean surface and good peel strength and tensile strength; secondly, the PVC release film has good heat stability and heat shrinkage rate, is capable of resisting light aging and can be repeatedly used; and the PVC release film has relatively balanced comprehensive performance and extremely good water resistance, solvent resistance, chemical resistance, corrosion resistance, temperature resistance, weather resistance and adhesiveness. Besides, the PVC release film provided by the invention is environmentally friendly and nontoxic, a synthetic method is simple, the operation is simple and convenient, conditions are mild, and the synthetic method is applicable to industrial production.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

TPX (methyl pentene copolymer) release film

The invention provides a TPX (methyl pentene copolymer) release film. The TPX release film comprises a thin film layer; the thin film layer is prepared from the following raw materials in parts by weight: TPX, PC (Polycarbonate), 2-ethyl methacrylate, polyurethane, polyimide, polyetheretherketone fibers, carbon fibers, organic montmorillonite, ethylene glycol, a silane coupling agent, an antioxidant, a light stabilizer, a de-foaming agent and a thickener; the TPX release film has a flat and smooth surface and has good peeling strength and tensile strength; secondly, the TPX release film has good thermal stability and thermal shrinkage rate, can resist light aging and can be repeatedly used for a plurality of times; furthermore, the TPX release film provided by the invention is environment-friendly and has no toxin; a synthesis method is simple, is simple and convenient to operate, has moderate conditions and is suitable for industrial production.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

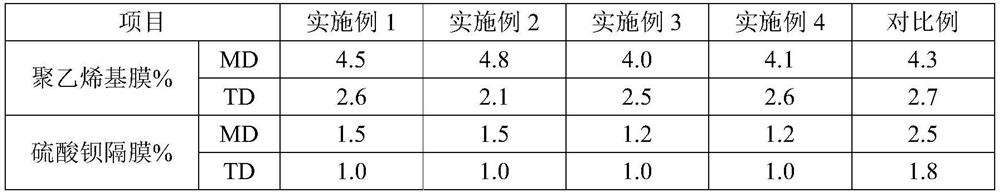

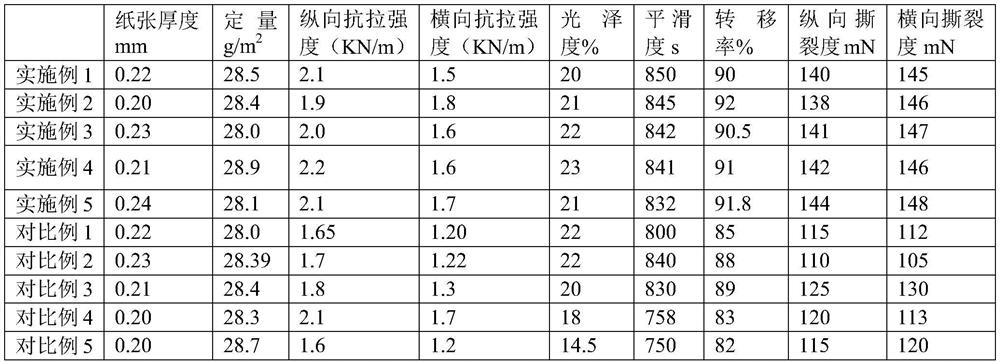

Preparation method of anti-permeation heat-stable low basis weight transfer printing base paper

ActiveCN111676732AIncrease binding areaAvoid cut-off effectSpecial paperPulp beating methodsTextile printerPolymer science

The invention relates to the technical field of papermaking, aims to solve the problems that transfer printing base paper is poor in universality and resources are wasted, and provides a preparation method of an anti-permeation heat-stable low basis weight transfer printing base paper. The preparation method comprises the following steps: (1) mixing and pulping raw material slurry and an auxiliaryagent to prepare mixed slurry; (2) sequentially carrying out white dextrin solution soaking, net part dehydration, squeezing and pre-drying on the mixed pulp to obtain raw material paper; (3) carrying out surface sizing on the raw material paper by adopting a modified hexadecyl methacrylate-N-hydroxymethyl acrylamide-styrene polymer; and (4) carrying out post-stage drying, calendaring finishing and rolling on the paper sheet subjected to surface sizing treatment to obtain a finished product. The printing base paper has the advantages of being low in basis weight, good in paper toughness, highin thermal stability, capable of preventing ink permeation, good in tensile strength and good in paper uniformity, sizing is conducted by introducing a small amount of polymer macromolecules with a good film-forming property, and the strength of low basis weight paper sheets is enhanced by combining and changing a pulping process.

Owner:XIANHE CO LTD

Preparation method of high-temperature-resistant biaxially-oriented polypropylene film

The invention discloses a preparation method of a high-temperature-resistant biaxially-oriented polypropylene film, and particularly relates to the technical field of plastics. The prepared biaxially-oriented polypropylene film has a relatively low heat shrinkage rate, has relatively good heat resistance, and has excellent mechanical property and wear resistance. Nano-scale potassium feldspar andbasalt fibers are used as a core material, and a hydroxyapatite coating layer is generated in situ on the surface of the core material, so that the obtained product has good wear resistance. Meanwhile, hydroxyl is introduced into the surface layer of the obtained product, and then epichlorohydrin reacts with hydroxyl of the surface of the obtained product, so that a grafting effect is achieved, and epoxy groups are introduced. The introduced epoxy groups can be subjected to a ring-opening polymerization reaction with the subsequently added octaamino silsesquioxane, so that the octaamino silsesquioxane is introduced into the surfaces of the hydroxyapatite-coated potash feldspar and basalt fibers, and then the purpose of modification is achieved.

Owner:含山县金中环装饰材料有限公司

Separator for electrochemical device and electrochemical device containing same

PendingCN112020784AImprove heat shrinkageHybrid capacitor separatorsCell electrodesPorous coatingPolymer substrate

Owner:LG ENERGY SOLUTION LTD

High weather resistance type release film and preparation method thereof

InactiveCN108285756AImprove stabilityApply smooth and smoothFilm/foil adhesive release linersWeather resistanceHigh humidity

The invention discloses a high weather resistance type release film and a preparation method thereof. The release film comprises a base material, the upper end face of the base material is marked as aB1 surface, the lower end face of the base material is marked as a B2 surface, and the B1 surface of the base material is coated with a release agent. According to the provided high weather resistance type release film and the preparation method thereof, the stability of the release agent itself is improved, a very stable release force can be maintained, and excessive influences from high temperature and high humidity and other environmental factors on the release film are not caused. On the basis of the situation that the excessive influences on the release film are not caused, the peeling stability of bonded adhesive products is improved, the bonded adhesive products are easy to peel, and a sticking phenomenon is not caused. The release agent is flat and smooth to smear and has no obvious unevenness, good heat shrinkage rate and thermal stability and higher stability than general release films in an ordinary environment, and obvious changes do not occur.

Owner:SHAOXING XUYUAN NEW MATERIAL TECH

Lithium ion battery ceramic diaphragm coating composition

PendingCN112467306AImprove heat shrinkageExcellent ion permeabilityCell component detailsAdhesiveShrinkage rate

The invention discloses a lithium ion battery ceramic diaphragm coating composition which comprises the following components in percentage by mass: 94-97% of ceramic powder, 2.5%-5.5% of an adhesive,and 0.3%-0.5% of a dispersing agent. Compared with the prior art, the ceramic diaphragm coating composition has the advantages of being small in thickness, low in thermal shrinkage rate and good in air permeability, and the prepared corresponding ceramic diaphragm has excellent low thermal shrinkage rate and ion permeability.

Owner:湖南高瑞电源材料有限公司

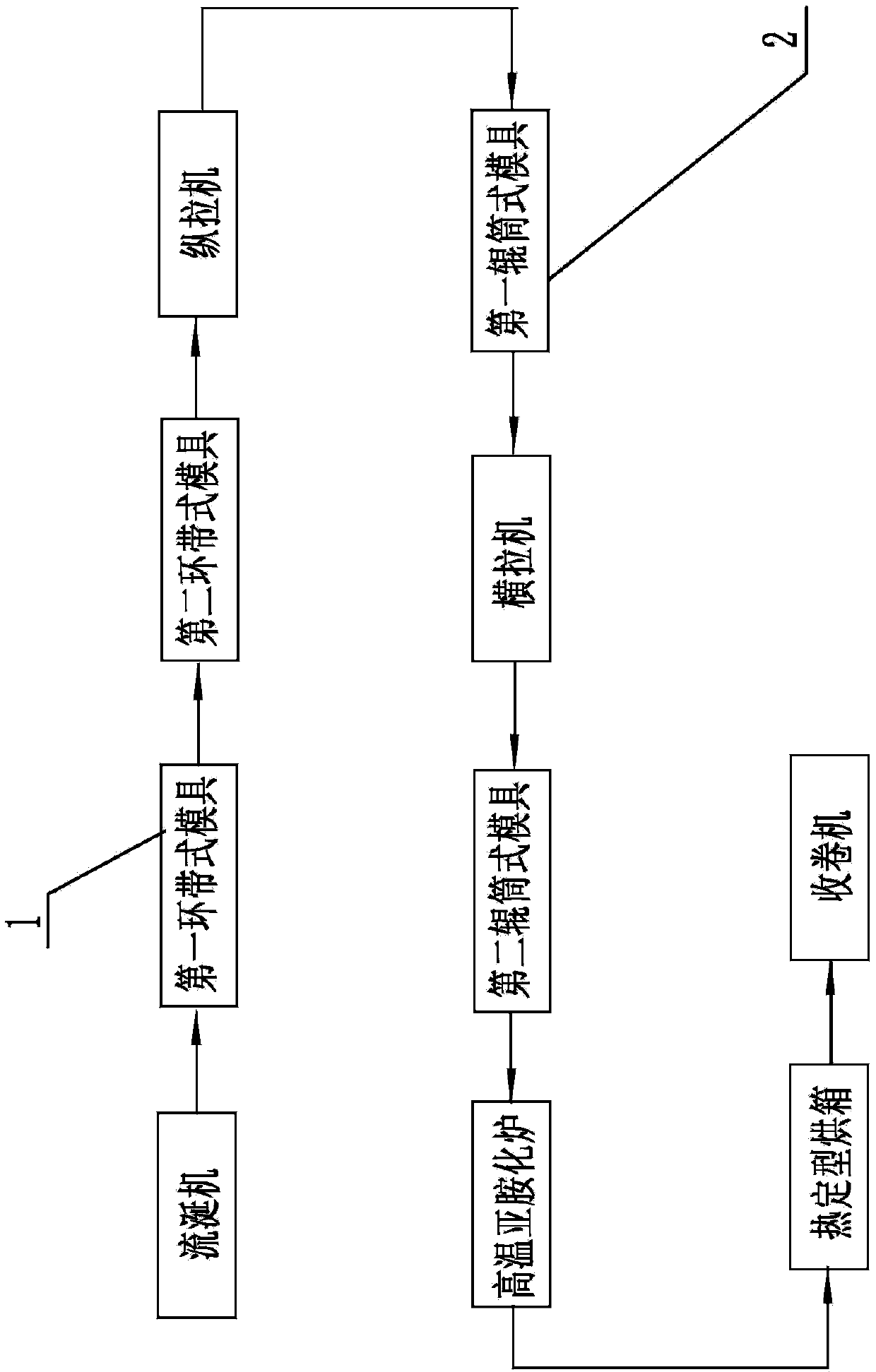

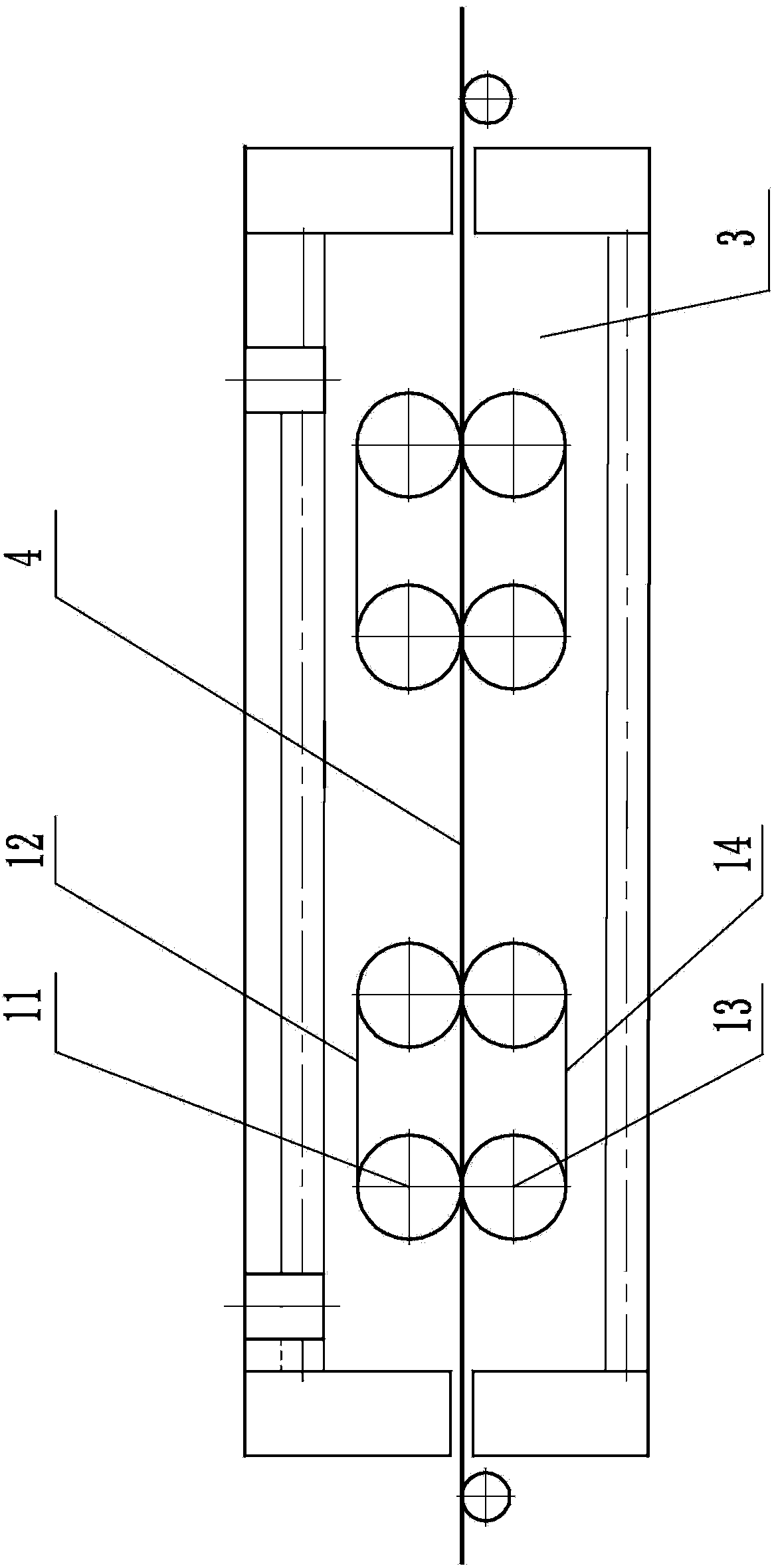

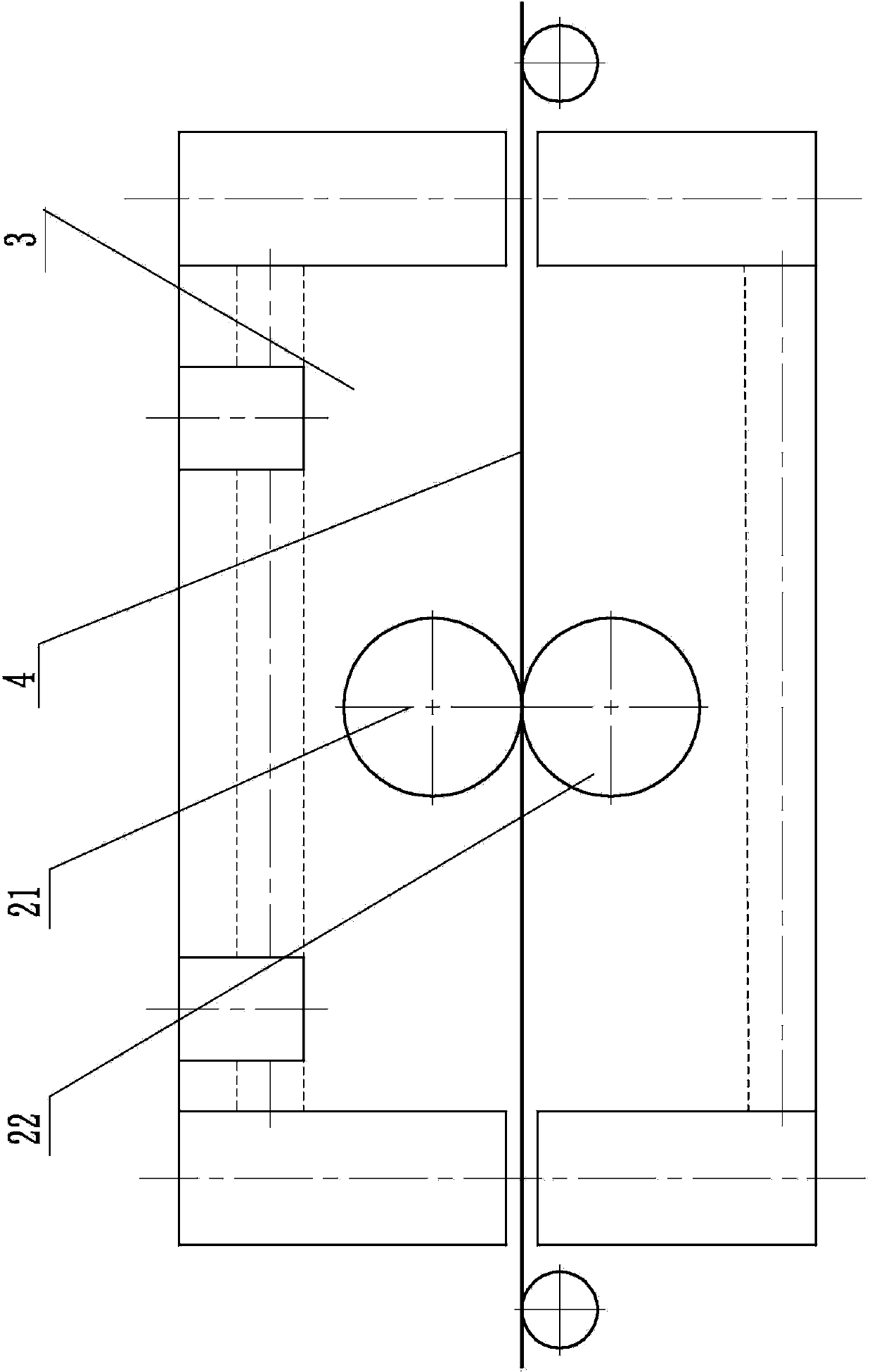

Method for improving physical properties of polyimide film and polyimide film production line

ActiveCN104191635AGood physical propertiesImprove flatnessFlat articlesProduction lineHeat conducting

The invention relates to a method for improving physical properties of a polyimide film and a polyimide film production line. According to the method, a polyamide acid film obtained by casting is rolled for one to three times and then enters a drawing process; during rolling, the content of a solvent in the polyamide acid film is 30-100 percent; after longitudinal drawing and / or transverse drawing, the polyamide acid film is also rolled for one to three times; during rolling, the temperature is 50-180 DEG C. On the production line, one to three rolling moulds are arranged behind a casting machine, and one to three rolling moulds are arranged behind a drawing machine. The rolling moulds are roller type moulds or endless belt type moulds, each roller type mould comprises two same rolling rollers respectively positioned on and below the film, and each endless belt type mould comprises an upper rolling steel belt and a lower rolling steel belt which are the same and respectively encircle two rollers. The rolling moulds are positioned in a rolling oven, and / or a circulation channel is formed in each roller and used for receiving heat-conducting media. The method significantly improves the thickness uniformity, surface quality and roller smoothness of a following-up polyimide film product. The polyimide film production line is simple in structure and easy to implement.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Synthetic fiber fabric and quick dimension stabilization method thereof

ActiveCN106758154AImprove heat shrinkageSevere contractionFibre typesHeating/cooling textile fabricsPolymer scienceSteam pressure

The invention relates to a quick dimension stabilization method for a synthetic fiber fabric, which includes the following steps: liquid ammonia treatment: the synthetic fiber fabric is obtained, liquid ammonia padding is carried out on the synthetic fiber fabric, the pressure of a padder is 0.1Mpa to 0.5Mpa, the speed is 10m / min to 60m / min, and the temperature is 70 DEG C to 100 DEG C; steam drying: a steam drying device is adopted to carry out steam drying on the synthetic fiber fabric treated by liquid ammonia, and the steam pressure in the steam drying device is 1kg / cm<2> to 5kg / cm<2>; post-treatment: the steam-dried synthetic fiber fabric is washed with water and dried. The method can remarkably increase the dimensional stability and product quality of the synthetic fiber fabric, and is particularly applicable to synthetic fibers with low melting points, such as polypropylene fibers, the efficiency of treatment is remarkably increased, and moreover, the production cost is low.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Diaphragm coating liquid, preparation method thereof, diaphragm, preparation method of diaphragm, and secondary battery

ActiveCN109860483AGood heat shrinkabilityRetain stabilityCell component detailsInorganic particlePolyetherimide

The invention belongs to the technical field of secondary batteries, and relates to a diaphragm coating liquid, a preparation method thereof, a diaphragm, a preparation method of the diaphragm, and asecondary battery. The preparation method of the diaphragm coating liquid provided by the invention comprises the following steps: providing first dispersion liquid formed by polyetherimide solution,a binder and a pore-forming agent; providing second dispersion liquid formed by inorganic particles, a dispersing agent and an organic solvent; mixing the first dispersion liquid and the second dispersion liquid, and performing separating to obtain the diaphragm coating liquid. According to the invention, the method can maintain the original stability of the polyetherimide solution to the maximumextent, and meanwhile, the method enables the diaphragm coating liquid to have good thermal shrinkage performances through the adding of the inorganic particles. The diaphragm coating liquid preparedby the method can improve the performance of a base membrane on the whole. In addition, the invention also provides the diaphragm containing the diaphragm coating liquid, a manufacturing method of thediaphragm and the secondary battery.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

High-temperature-resistant adhesion-resistant release film

The invention provides a high-temperature-resistant adhesion-resistant release film which comprises a thin film layer. The thin film layer comprises the following raw materials in parts by weight: TPX, PP (polypropylene), ethyl 2-methacrylate, polyurethane, polyarylester, glass fibers, carbon fibers, organic montmorillonite, ethanediol, a silane coupling agent, an antioxidant, a light stabilizer, a defoaming agent and a thickener. The high-temperature-resistant adhesion-resistant release film has the advantages of smooth surface, favorable peel strength, favorable tensile strength, favorable filling property and favorable separability. The high-temperature-resistant adhesion-resistant release film has favorable temperature resistance and heat shrinkage rate, can resist photoaging, and can be used repeatedly. Besides, the high-temperature-resistant adhesion-resistant release film provided by the invention is environment-friendly and nontoxic. The synthesis method is simple, is convenient to operate and mild in conditions, and is suitable for industrial production.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

Photodiffusion release film

The invention provides a photodiffusion release film. The photodiffusion release film comprises a film layer, wherein the film layer contains the following raw materials in parts by weight: TPX, PC, PFA, PBT, nano barium sulfate, nano-silica, polyetherimide, phenol-formaldehyde resin, polyurethane, polyimide, 2-ethyl methacrylate, organic montmorillonite, ethylene glycol, a silane coupling agent, an antioxidant, a photostabilizer, an antifoamer and a thickener. The photodiffusion release film has an excellent optical diffusion effect and has good peeling strength and tensile strength; secondly, the photodiffusion release film is flat and smooth in surface, has good thermal stability and thermal shrinkage ratio, can resist photoaging and can be reused repeatedly; in addition, the photodiffusion release film provided by the invention is environmentally friendly and non-toxic, the synthesis method is simple, is simple and convenient in operation and moderate in condition and is applicable to industrial production.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

Wet diaphragm and preparation process thereof

InactiveCN111477814AExtended service lifeSmall particle sizeCell seperators/membranes/diaphragms/spacersNanoceramicAnti oxidant

The invention discloses a wet-process diaphragm and a preparation process thereof. The wet-process diaphragm comprises the following components: polyethylene, a pore-forming agent, an antioxidant andnano ceramic powder, wherein the mass mixing ratio of the polyethylene to the pore-forming agent is 1:1-1:5.5, and the mass of the antioxidant and the mass of the nano ceramic powder account for 0.1%-1% of the mass of the polyethylene. By adjusting the formula and preparation process of the product, the finally prepared diaphragm has the advantages of high-power discharge resistance, long servicelife and high safety performance.

Owner:泰州衡川新能源材料科技有限公司

PET (polyester) release film

The invention provides a PET release film, comprising a film layer, and the film layer includes the following raw materials by weight: PET, PC, 2-ethyl methacrylate, polyurethane, polyimide, natural latex, stearic acid Calcium, ethylene glycol, silane coupling agent, antioxidant, light stabilizer, defoamer and thickener; the PET release film has a smooth surface and good peel strength and tensile strength; The PET release film described has good thermal stability and thermal shrinkage rate, is resistant to light aging and can be used repeatedly; in addition, the PET release film provided by the present invention is environmentally friendly and non-toxic, has a simple synthesis method, and is easy to operate. The conditions are mild and suitable for industrial production.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

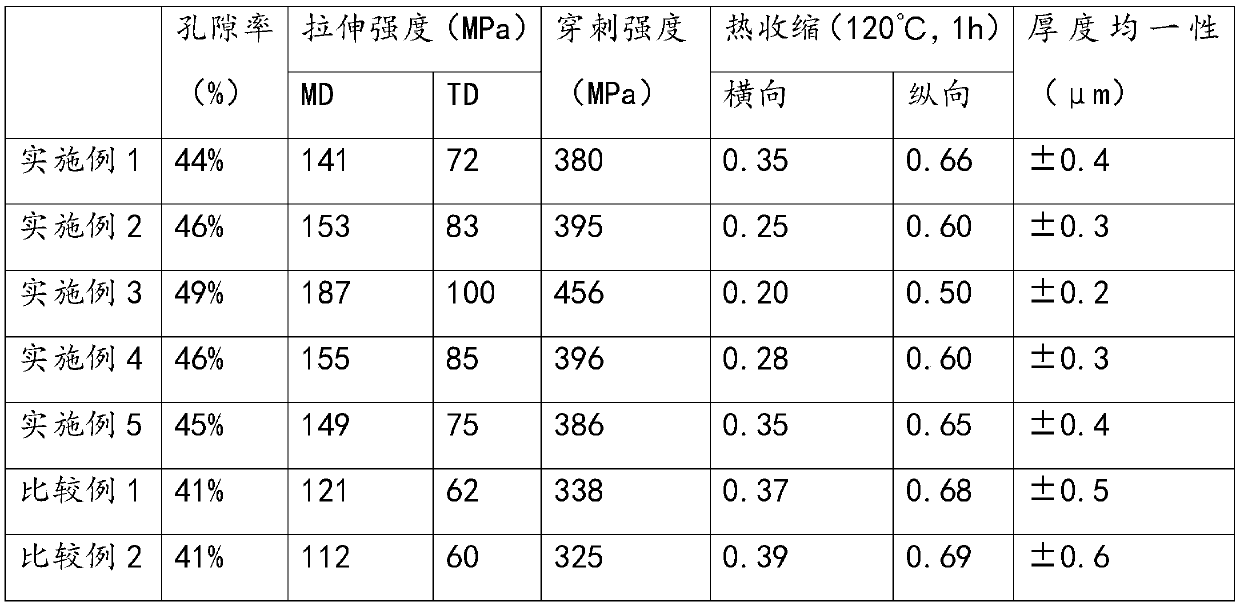

Matte insulating polyimide black film and preparation method thereof

The invention discloses a preparation method of a matte insulating polyimide black film, which comprises the following steps: S1, in an inert atmosphere, reacting an aromatic dianhydride with an aromatic diamine of which the molar weight is excessive relative to that of the aromatic dianhydride in an aprotic polar solvent to obtain a polyamide acid solution of which the amine is excessive; s2, adding silane coupling agent modified polyimide powder and carbon black color paste into the polyamide acid solution with excessive amine, uniformly dispersing, and then adding an aromatic dianhydride for reaction to obtain a polyamide acid mixed solution; s3, subjecting the polyamide acid mixed solution to film forming and imidization, and obtaining the matte insulating polyimide black film. The polyimide black film prepared by the method has the characteristics of good appearance, low glossiness, high insulating strength and the like, and the tensile strength, the elongation at break, the thermal shrinkage rate and other properties of the polyimide black film are improved.

Owner:ANHUI GUOFENG PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com