Preparation method of anti-permeation heat-stable low basis weight transfer printing base paper

A transfer printing base paper and low basis weight technology, applied in the pulp beating method, pulp beating/refining method, special paper, etc., can solve the problems of low basis weight, poor universality, waste of resources, etc., and reduce the generation of small broken fibers , enhance strength, increase the effect of fiber bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

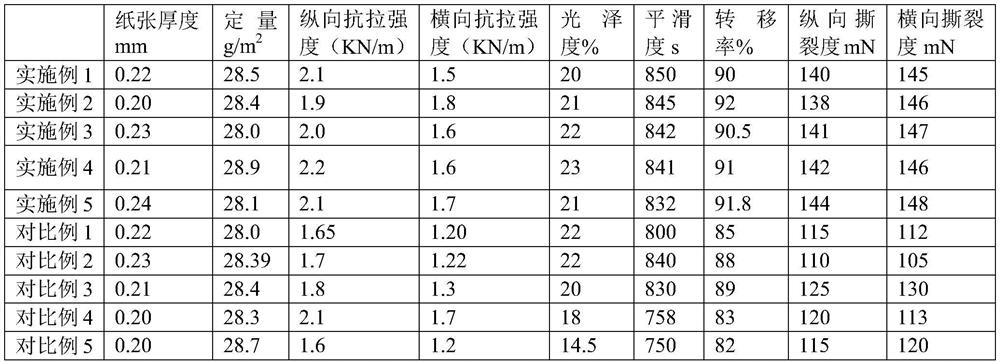

Examples

preparation example Construction

[0042] A preparation method of anti-penetration heat stable low quantitative transfer printing base paper, comprising the following preparation steps:

[0043] (1) Preparation of pulp: mix and beat raw material pulp and additives to prepare mixed pulp; raw material pulp contains 20-40% long-fiber bleached coniferous wood pulp and 60-80% short-fiber bleached broadleaf Pulp; additives and their dosages are: degassing agent, the dosage per ton of paper is 0.5-0.8kg; defoamer, the dosage per ton of paper is 0.3-0.6kg.

[0044] The preparation process of fibers in raw material slurry includes:

[0045] 1) Preparation of long-fiber pulp: the bleached softwood long-fiber wood pulp with a fiber length of 3-3.5mm is pulverized by a hydraulic pulper and transferred to the knocking pool, and then passed through a double-disk refiner and transferred to long-fiber pulp. Tap the back pond, and control the beating power to 160-180kwh, the beating concentration to 3.7-4.0%, and the beating d...

Embodiment 1

[0056] A preparation method of anti-penetration heat stable low quantitative transfer printing base paper, comprising the following preparation steps:

[0057] (1) Prepare slurry: mix and beat raw material slurry and auxiliary agents to prepare mixed slurry; raw material slurry contains 30% long-fiber bleached softwood pulp and 70% short-fiber bleached hardwood pulp; auxiliary agent And its dosage is respectively: degassing agent, the consumption per ton of paper is 0.65kg; defoamer, consumption per ton of paper is 0.45kg.

[0058] The preparation process of fibers in raw material slurry includes:

[0059] 1) Preparation of long-fiber pulp: the bleached softwood long-fiber wood pulp with a fiber length of 3-3.5mm is pulverized by a hydraulic pulper and transferred to the knocking pool, and then passed through a double-disk refiner and transferred to long-fiber pulp. Tap the back pond, and control the beating power to 170kwh, the beating concentration to 3.9%, and the beating ...

Embodiment 2

[0069] The difference from Example 1 is that a method for preparing an anti-penetration thermally stable low-quantity transfer printing base paper includes the following preparation steps:

[0070] (1) Preparation of slurry: mix and beat the raw material slurry and auxiliary agents to prepare a mixed slurry; the raw material slurry contains 25% long-fiber bleached softwood pulp and 75% short-fiber bleached hardwood pulp; auxiliary agent And its dosage is respectively: degassing agent, the consumption per ton of paper is 0.65kg; defoamer, consumption per ton of paper is 0.45kg.

[0071] The preparation process of fibers in raw material slurry includes:

[0072] 1) Preparation of long-fiber pulp: the bleached softwood long-fiber wood pulp with a fiber length of 3-3.5mm is pulverized by a hydraulic pulper and transferred to the knocking pool, and then passed through a double-disk refiner and transferred to long-fiber pulp. Tap the back pond, and control the beating power to 170k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com