Polyester woven label and preparation method thereof

A polyester woven label and polyester technology, used in textiles, fabrics, textiles and papermaking, etc., can solve the problems of incomplete chromatogram, long cycle, easy to loose filaments, etc., to reduce thermal shrinkage damage and improve the color fastness of woven labels. , Reduce the effect of fastness damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A kind of preparation method of polyester woven label of the present invention comprises the following steps:

[0041] (1) warp pretreatment

[0042] The polyester warp yarn (white or inorganic salt colored polyester warp yarn) is treated with high temperature hot water at 125°C-145°C for 20-60min, the liquor ratio is 1:8-10, dehydrated, and then pre-dried at below 80°C until the moisture content is 10 ~30%, and then baked at 150-170°C for 5-10 minutes at high temperature to obtain;

[0043] (2) Selection of weft yarn

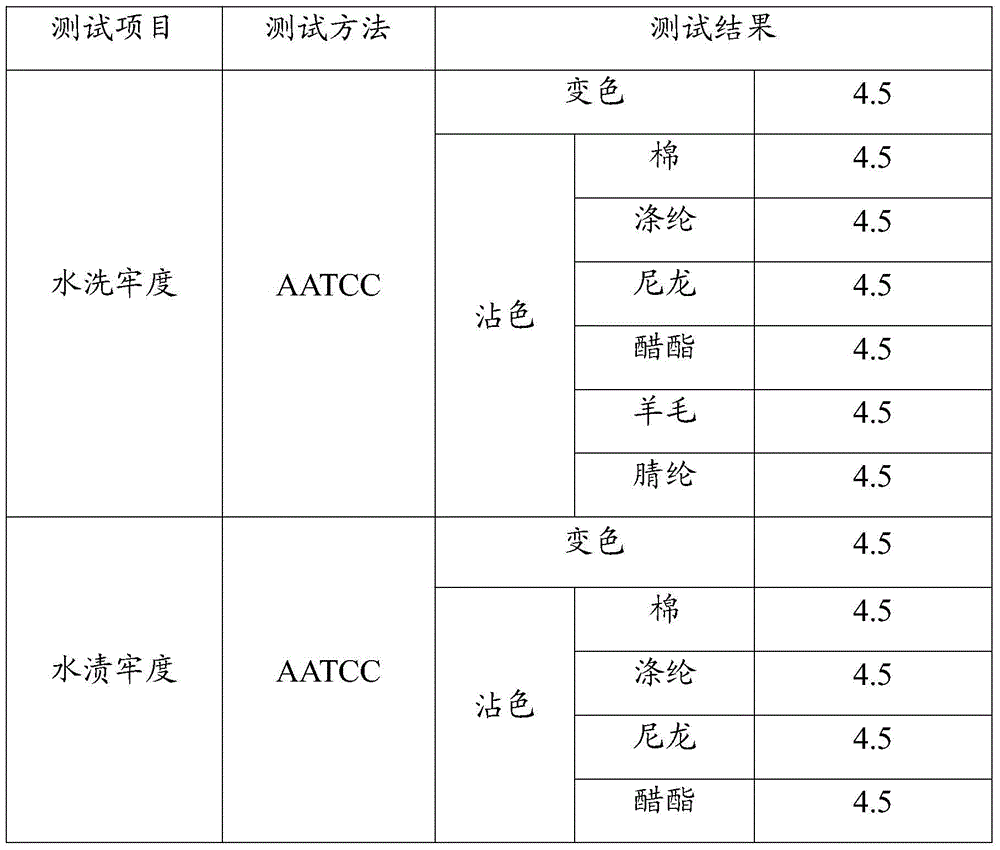

[0044] Select the weft yarn that meets the following conditions: Dye the polyester weft yarn at 125-135°C for 20-60 minutes, then reduce and wash it at 90-115°C for 1-3 times, and press at 115-125°C for 15-20 seconds to test the yarn Color fastness, color fastness greater than 4.0 is qualified;

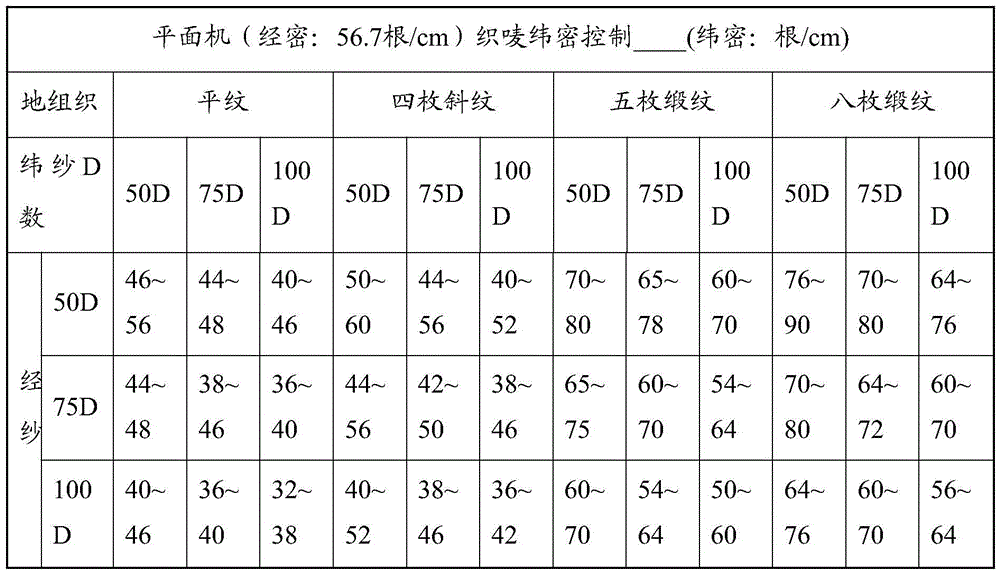

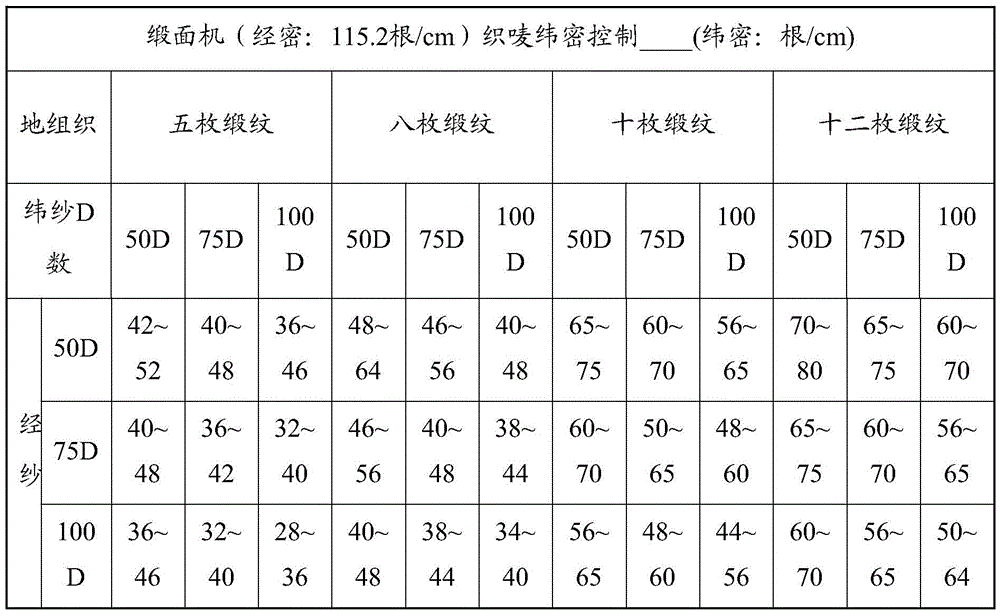

[0045] (3) Flower writing: Perform the flower writing operation to obtain the flower writing data required for the production of woven labels. The flower wri...

Embodiment 1

[0067] A kind of preparation method of polyester woven label of the present embodiment comprises the following steps:

[0068] (1) Polyester warp yarn pretreatment: add 10 kg of 75D polyester black warp cheese into the high temperature and high pressure cheese dyeing machine; add 100L of water, add degreasing agent JintergeLCF-185, 80~150g, heat up to 130℃~145℃, Keep warm for 30-60 minutes, drain, dehydrate, pre-bake at below 80°C to a moisture content of 10-30%, then bake in an oven at 150-170°C for 5-10 minutes, and warp.

[0069] (2) Selection of weft yarn

[0070] Select the weft yarn that meets the following conditions: Dye the polyester weft yarn at a high temperature of 125-135°C for 30-60 minutes, then reduce and wash it at 90-115°C for 1-3 times, and press at 115-125°C for 15-20 seconds to test the yarn Line color fastness, color fastness greater than 4.0 is qualified.

[0071] (3) Flower writing: use flower writing software to write flowers, and obtain the loom com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com