Patents

Literature

55results about How to "Reduce heat shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microwave modification method of plant fiber and application thereof

InactiveCN101725032AIncrease polarityHigh tensile strengthPhysical treatmentVegetal fibresFiberFilling materials

The invention discloses a microwave modification method of plant fiber and application thereof. The method comprises the steps of: firstly smashing the plant fiber; preprocessing the smashed plant fiber with coupling agent; and processing the preprocessed plant fiber by means of microwave radiation, so that the coupling agent is grafted at the surface of the plant fiber to obtain the microwave-modified plant fiber, wherein the microwave-modified plant fiber can be used as filling material of composite material for the field of high molecular material. The modification method is environment-friendly, and has no pollution, low production cost and remarkable economic benefit; and the microwave-modified plant fiber has obvious polarity change, wherein the nonpolarity is obviously enlarged, thereby obviously improving the interface consistency with non-polarity high molecule substances and improving the combination property of the composite material.

Owner:JINAN UNIVERSITY

Pore Protected Multi Layered Composite Separator and the Method for Manufacturing the Same

InactiveUS20130287937A1Improve permeabilityExcellent shutdown functionMembranesSemi-permeable membranesPorous coatingPolyolefin

Disclosed are a multi-layer composite porous film and a manufacturing method thereof. More particularly, a manufacturing method, which includes filling pores on at least one face of a polyolefin microporous film substrate using a solvent, and then, applying a coating solution that contains a polymer binder or the polymer binder and inorganic particles, to the film to form a porous coating layer, as well as the multi-layer composite porous film manufactured by the same, are disclosed. The method for manufacturing the multi-layer composite porous film according to the disclosure may provide a multi-layer composite porous film having excellent permeability and shutdown function, without clogging the pores, by improving a coating process. Moreover, if applying the foregoing porous film as a separator to a battery, the battery having superior performance and high safety may be manufactured.

Owner:SK INNOVATION CO LTD

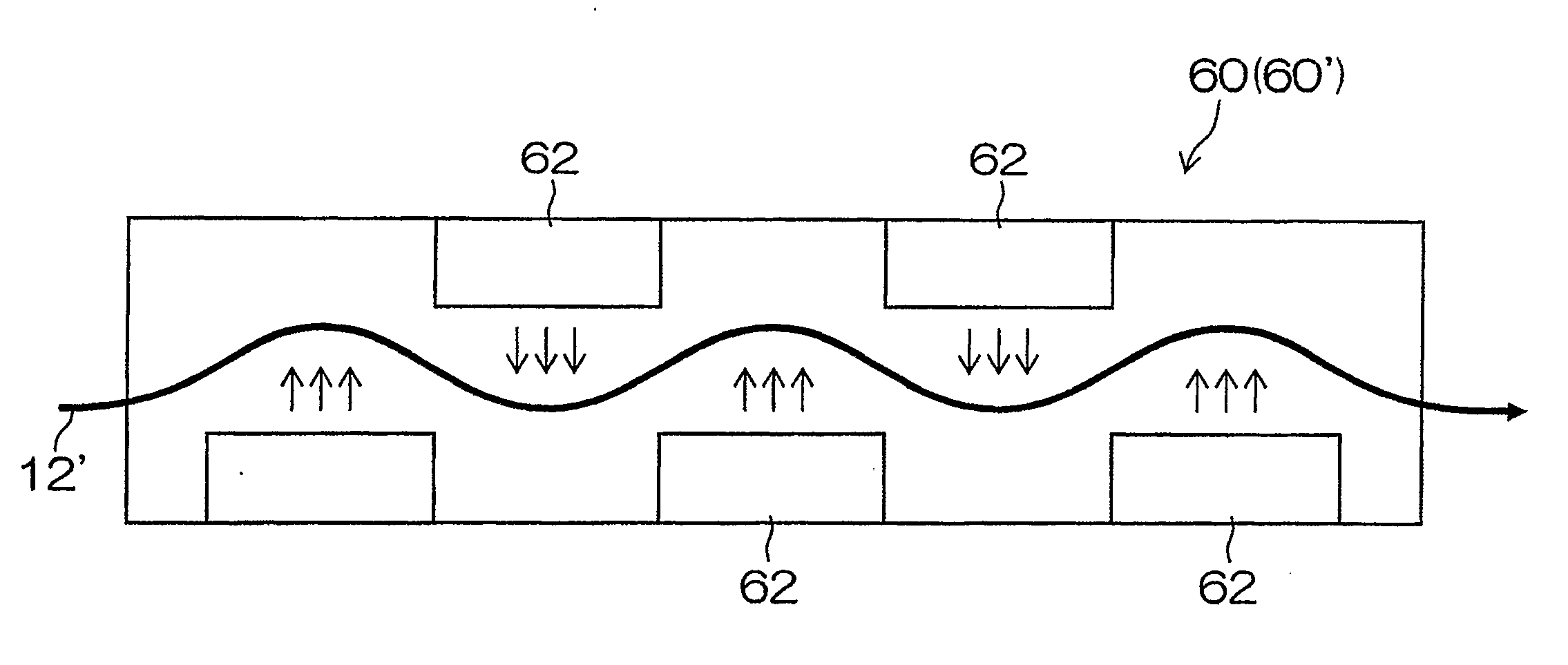

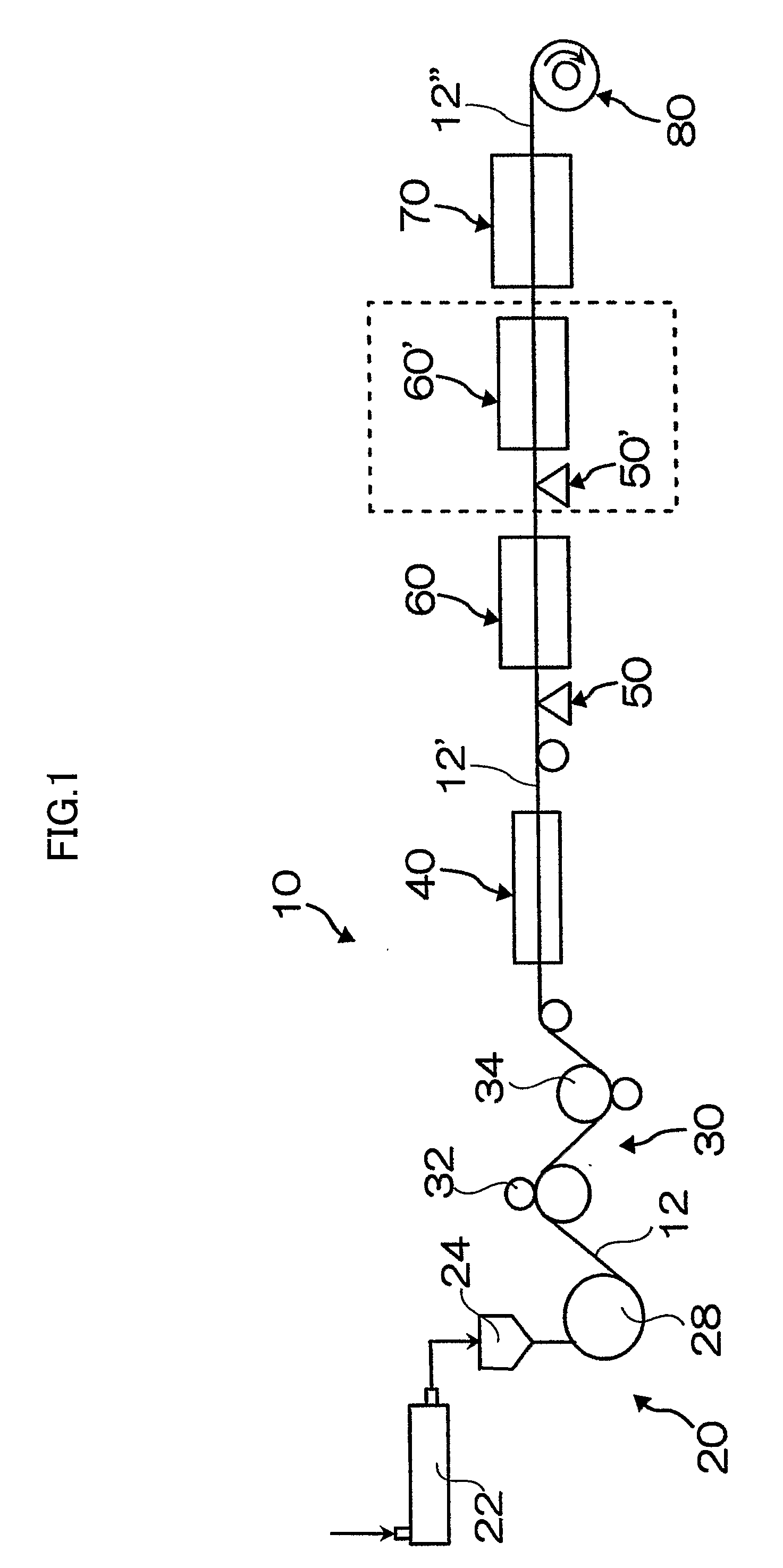

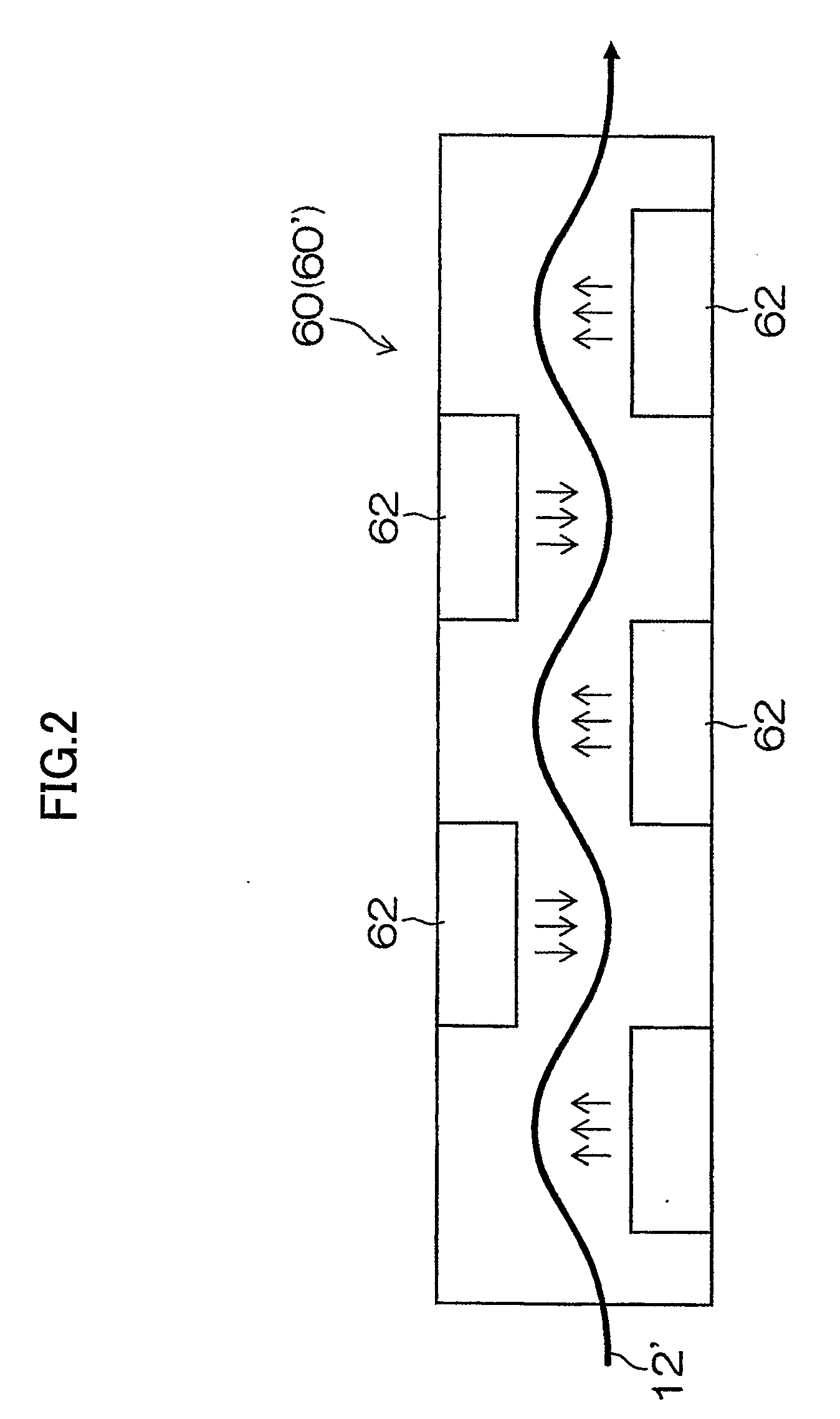

Optical film and method for producing the same

InactiveUS20090035596A1Low heat shrinkageGood dimensional stabilitySynthetic resin layered productsOptical articlesHeat treatedOptical film

It is an object of the present invention to provide an optical film having low heat shrinkage and a method for producing the same. A heat treatment (60) carrying a biaxially stretched film of a thermoplastic resin (12′) prepared by biaxial stretching in a heated atmosphere is conducted, and / or a heat treatment (70) carrying the biaxially stretched film while bringing the biaxially stretched film into contact with a heating roller (72) is conducted.

Owner:FUJIFILM CORP

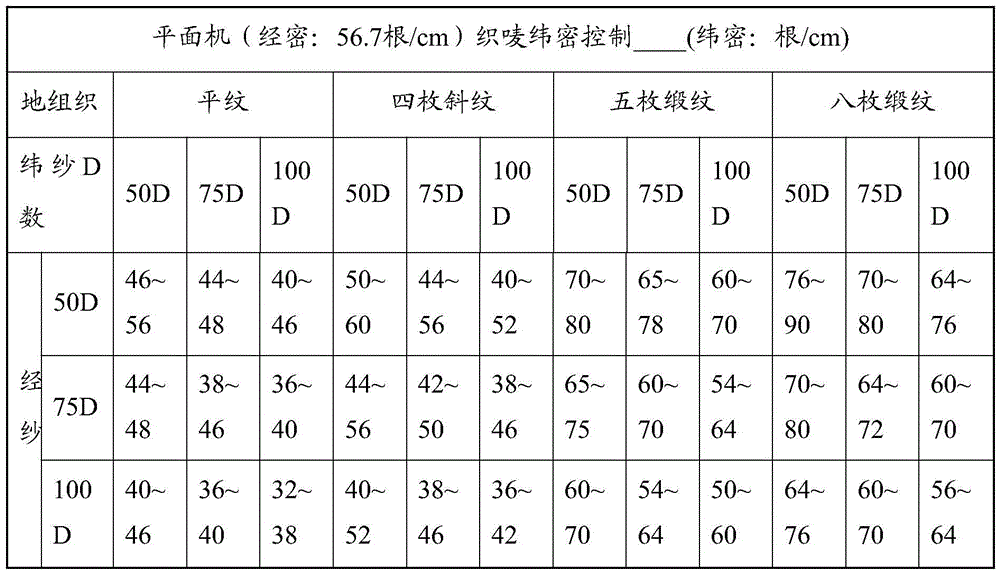

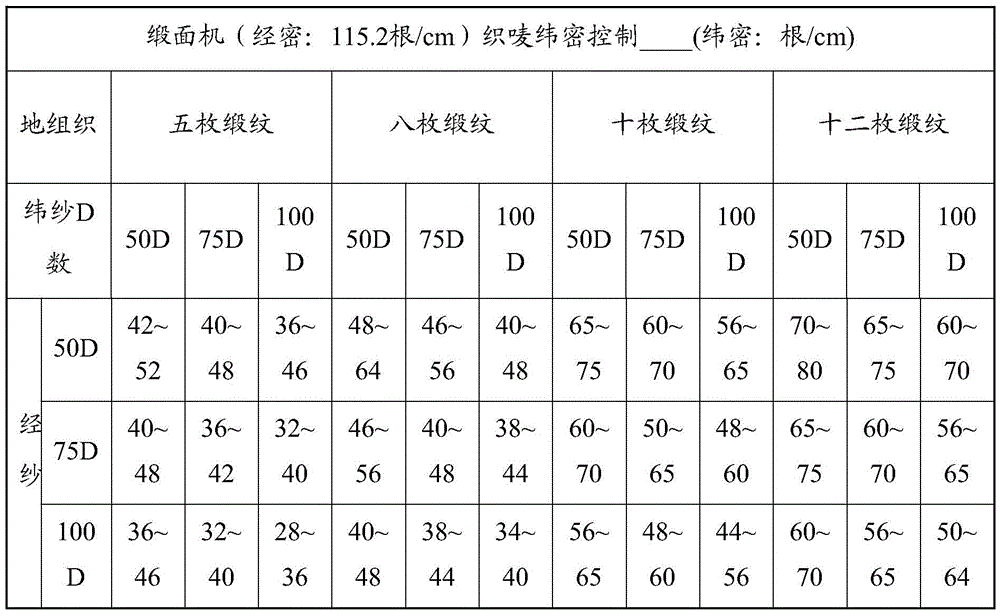

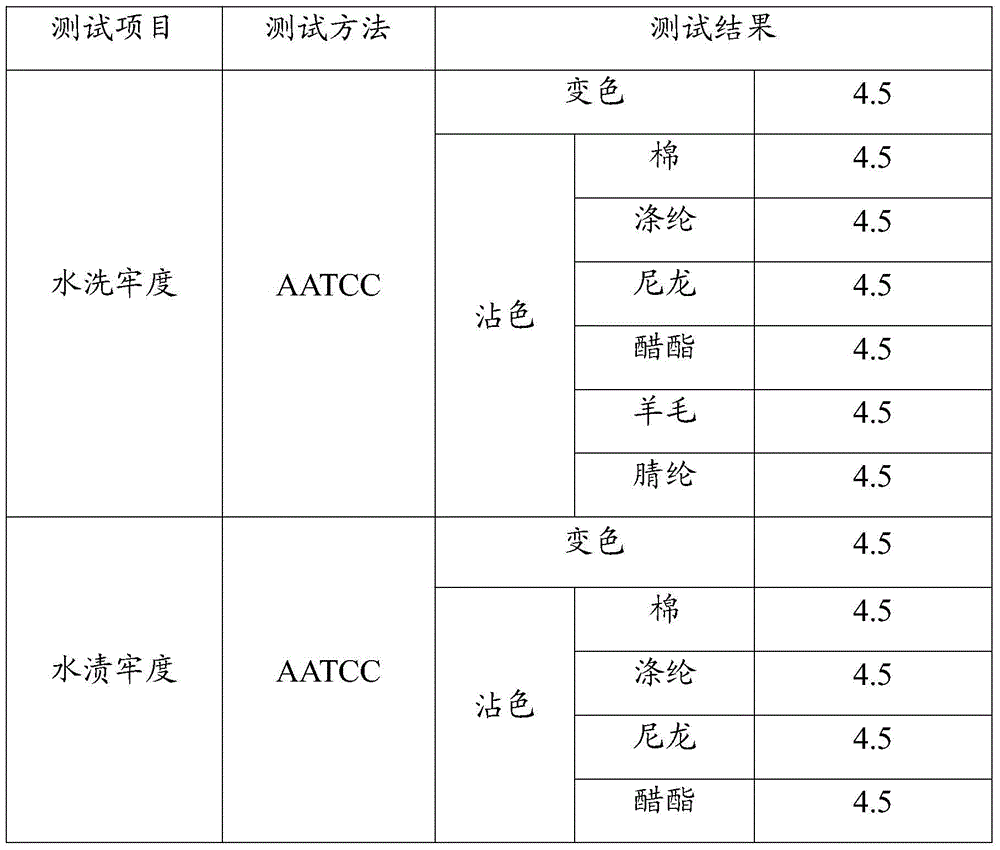

Polyester woven label and preparation method thereof

ActiveCN105525417AImprove heat shrinkageHigh fastnessSevering textilesWoven fabricsPolyesterShrinkage rate

The invention discloses a polyester woven label and a preparation method thereof. The preparation method includes following steps: (1), warp pretreatment; (2), weft selection; (3), pattern printing; (4), label weaving; (5), cutting and slitting. The polyester woven label made by the preparation method does not need to go through wash care and ironing processes, and the polyester woven label is less prone to wrinkling and contracting when being subjected to subsequent dyeing and wash care at 60-100 DEG C and press-ironing and drying at 100-160 DEG C. By using the preparation method, production period is shortened, production cost is lowered, fastness of the woven label in each aspect can be controlled at four or higher grade, and heat shrinkage rate of the woven label can be controlled below 3%.

Owner:广东康派环创科技有限公司

Bag of a heat-shrinkable gas-barrier thermoplastic film

ActiveUS8021049B2Reduce heat shrinkageMaterial minimizationFlexible coversWrappersThermoplasticMechanical engineering

Owner:CRYOVAC ILLC

Glass substrate for flat panel display and manufacturing method thereof

ActiveUS20130065748A1High Tg and strain pointExcellent devitrification resistanceGlass drawing apparatusGlass forming apparatusDevitrificationShrinkage rate

A flat panel display glass substrate includes a glass comprising, in mol %, 55-80% SiO2, 3-20% Al2O3, 3-15% B2O3, and 3-25% RO (the total amount of MgO, CaO, SrO, and BaO). The contents in mol % of SiO2, Al2O3, and B2O3 satisfy a relationship (SiO2+Al2O3) / (B2O3)=7.5-17. The strain point of the glass is 665° C. or more. The devitrification temperature of the glass is 1250° C. or less. The substrate has a heat shrinkage rate of 75 ppm or less. The rate of heat shrinkage is calculated from the amount of shrinkage of the substrate measured after a heat treatment which is performed at a rising and falling temperature rate of 10° C. / min and at 550° C. for 2 hours by the rate of heat shrinkage (ppm)={the amount of shrinkage of the substrate after the heat treatment / the length of the substrate before the heat treatment}×106.

Owner:AVANSTRATE INC

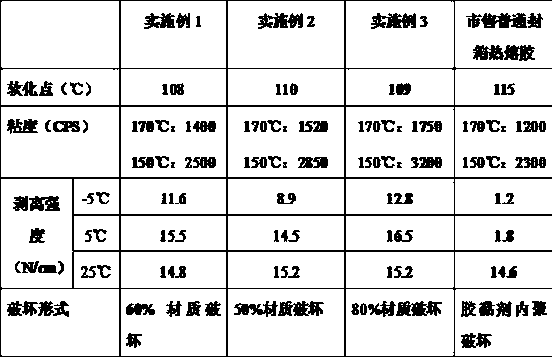

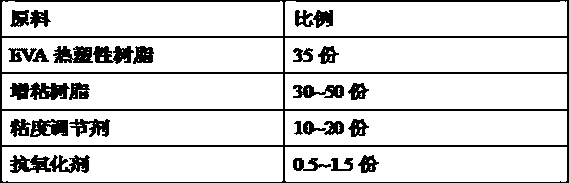

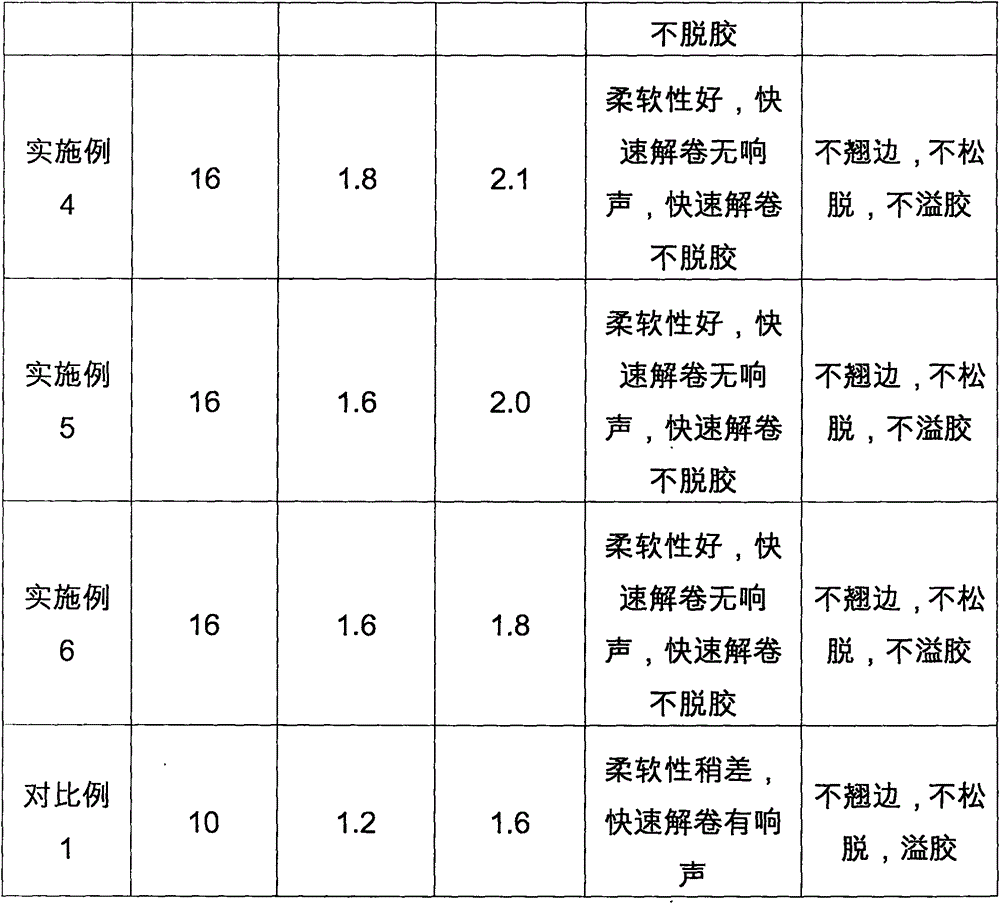

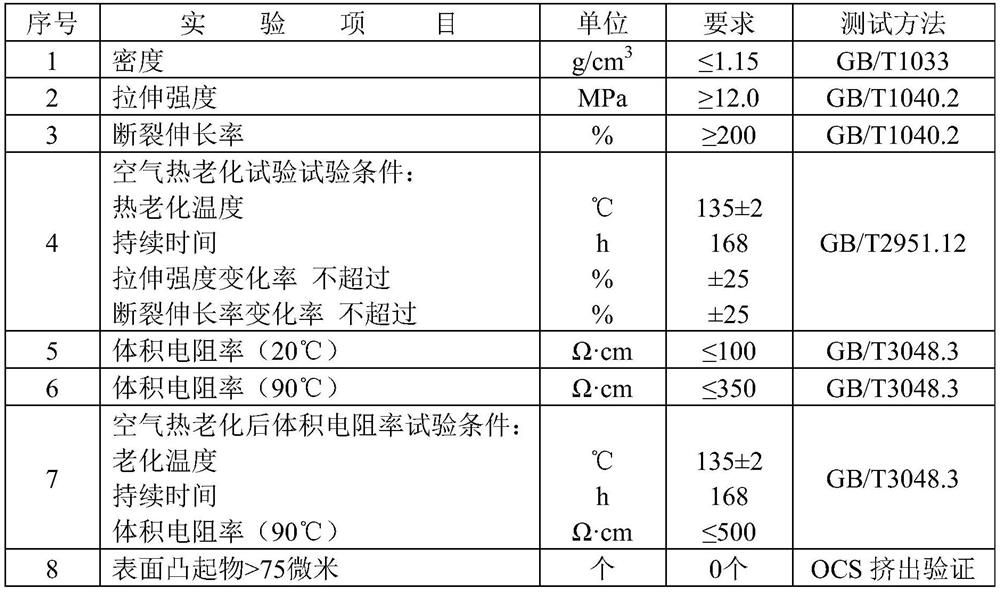

Hot melt adhesive for packaging

InactiveCN108395854AGood compatibilityImprove low temperature bonding performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesHigh surfacePackaging industry

The invention discloses a hot melt adhesive for packaging, and belongs to the field of adhesives. The hot melt adhesive is prepared at least from the following raw materials in parts by mass: 35 partsof ethylene-vinyl acetate (EVA) resin, 30-50 parts of tackifying resin, 10-20 parts of a viscosity regulator and 0.5-1.5 parts of an antioxidant. The hot melt adhesive provided by the invention has the advantages of environmental friendliness, no toxicity, no heavy metals, fast curing speed, excellent low-temperature resistance, high bonding strength to a carton with high surface paper strength (the wax picking degree of the carton surface paper reaches 20A or above), and the like. The hot melt adhesive solves the problems that cartons are open on a production line and in a warehouse when a conventional EVA hot melt adhesive is applied to the binding of cartons with high surface paper strength, and thus can be widely applied in the automatic packaging industry for food, beverages, beer and other industries.

Owner:朱俊帆

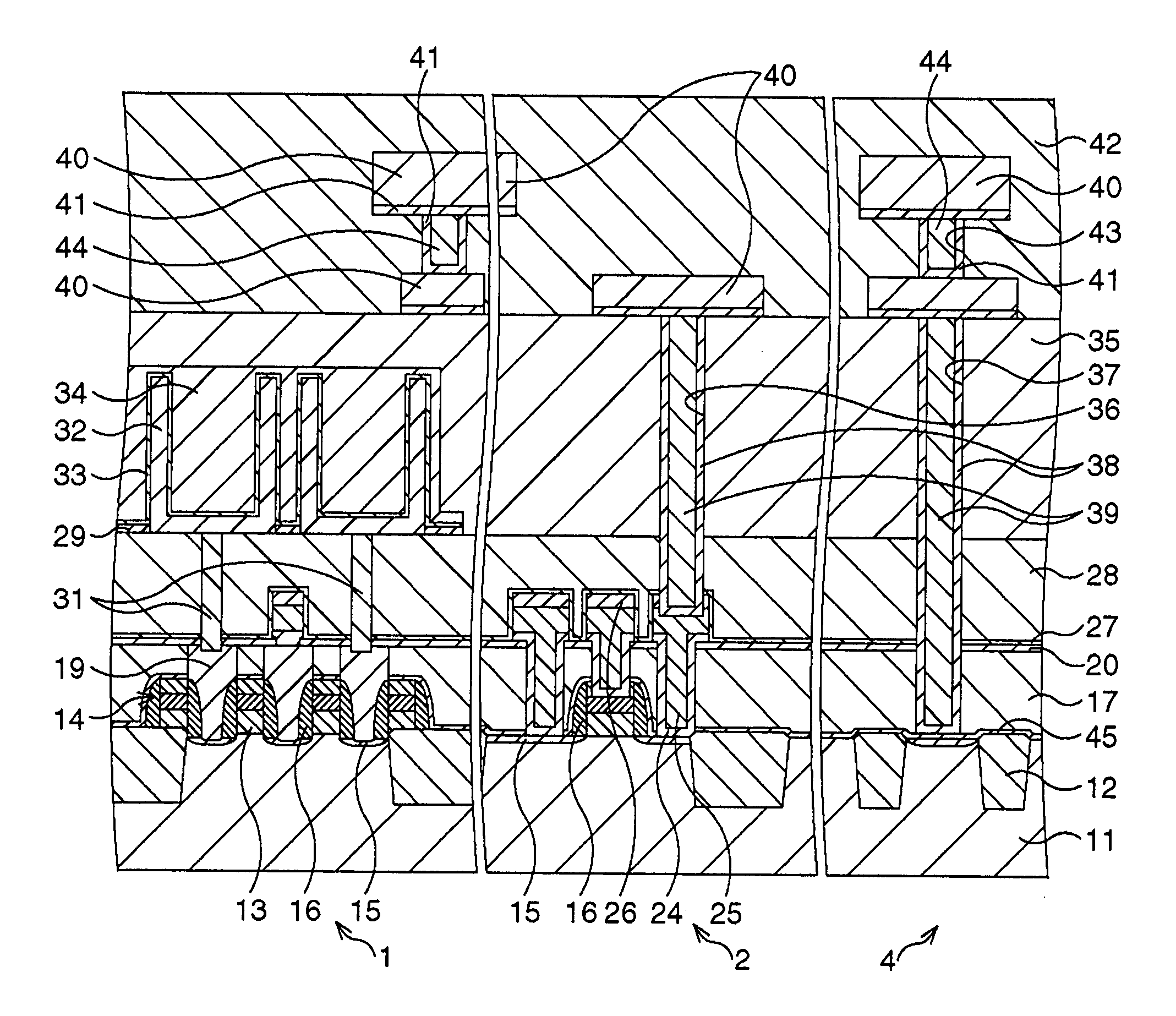

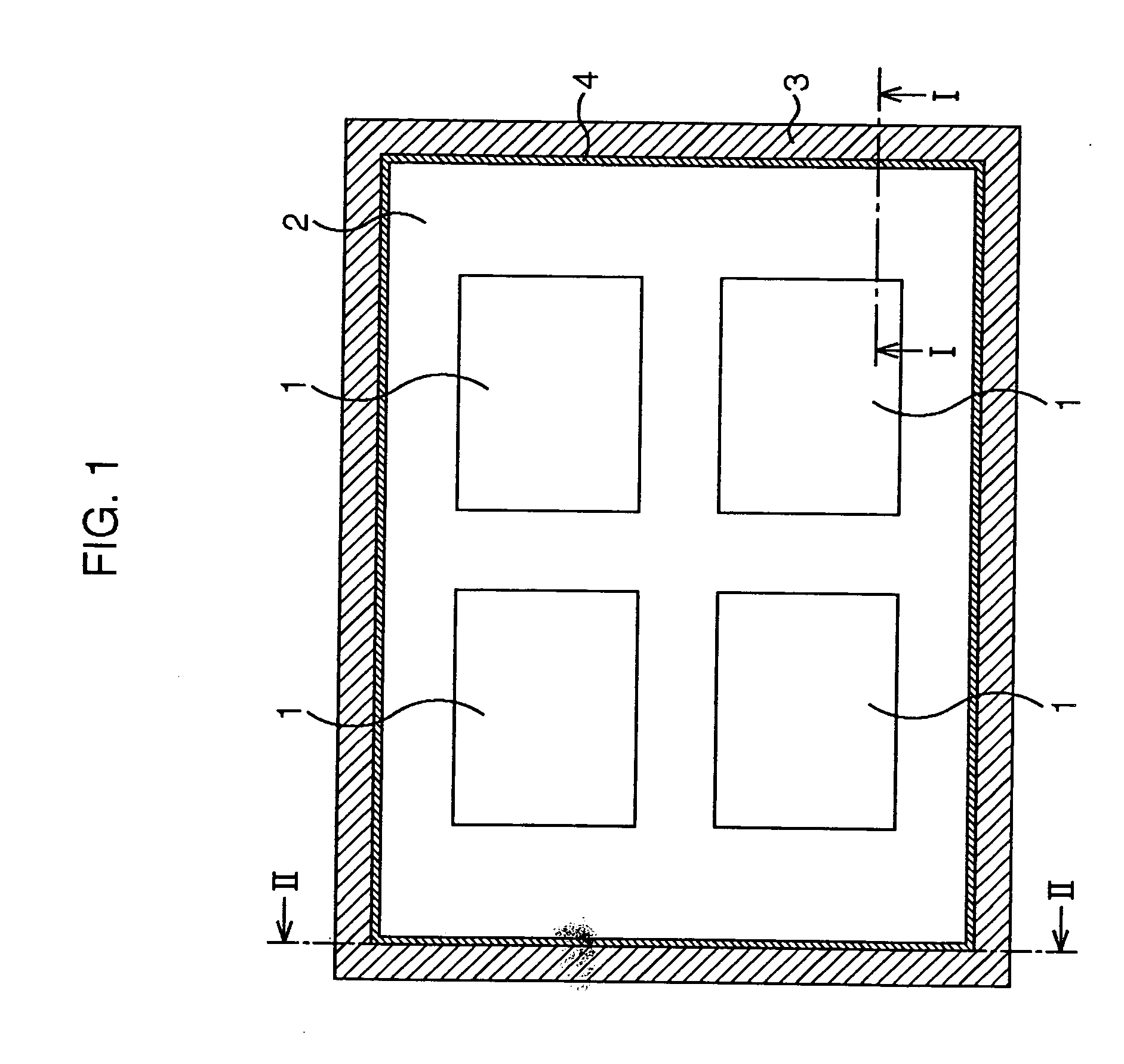

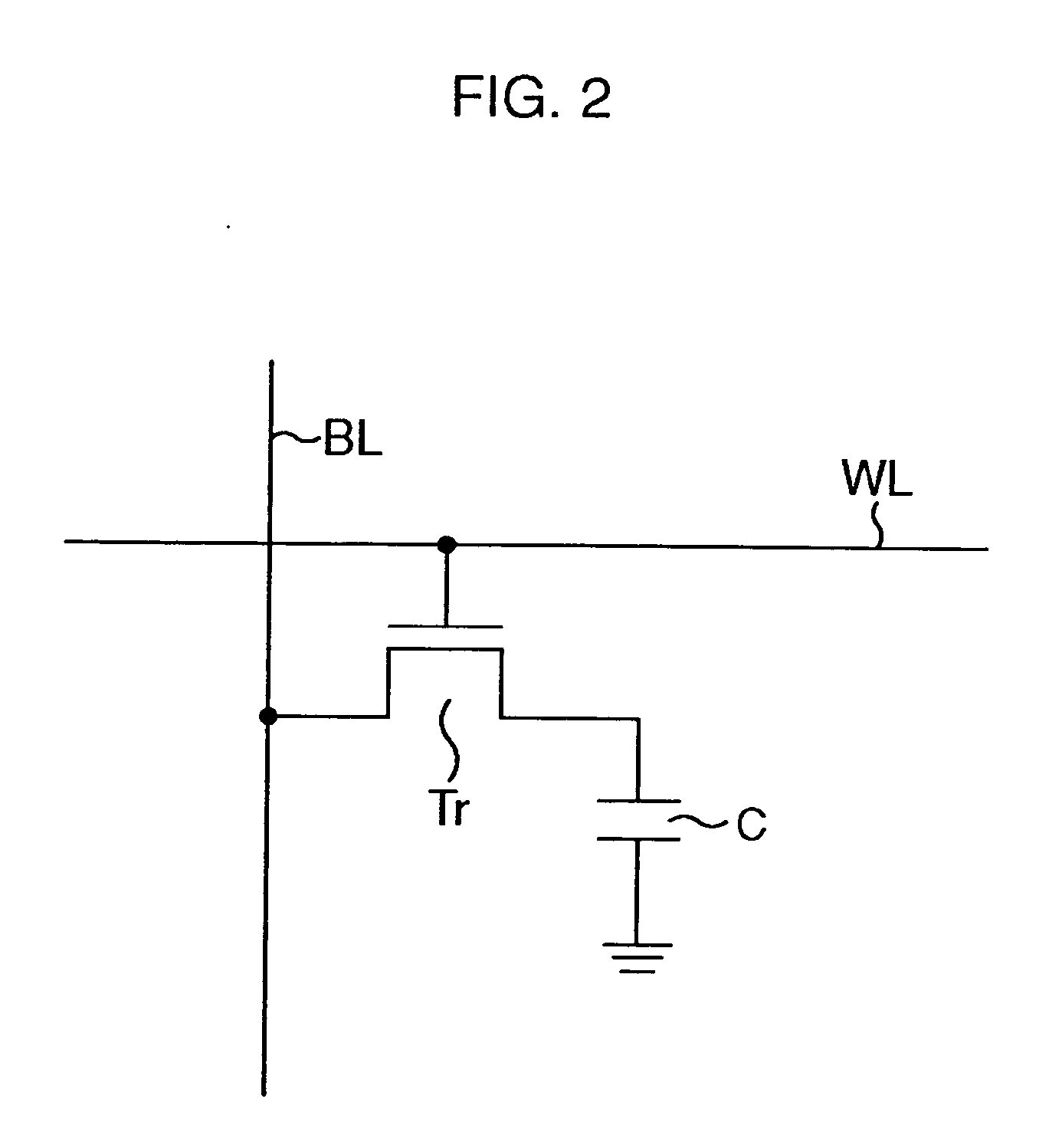

Semiconductor device having guard ring and manufacturing method thereof

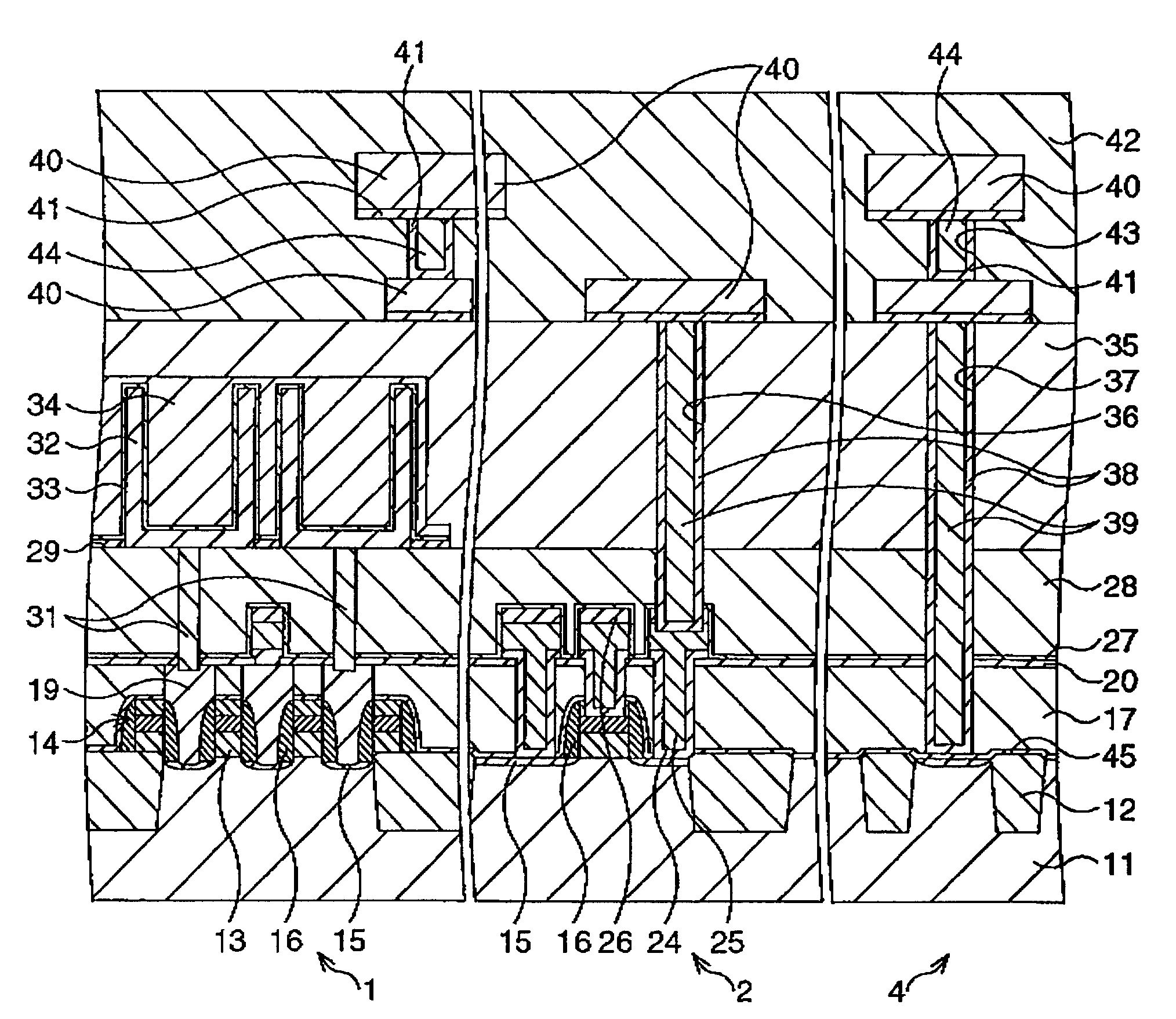

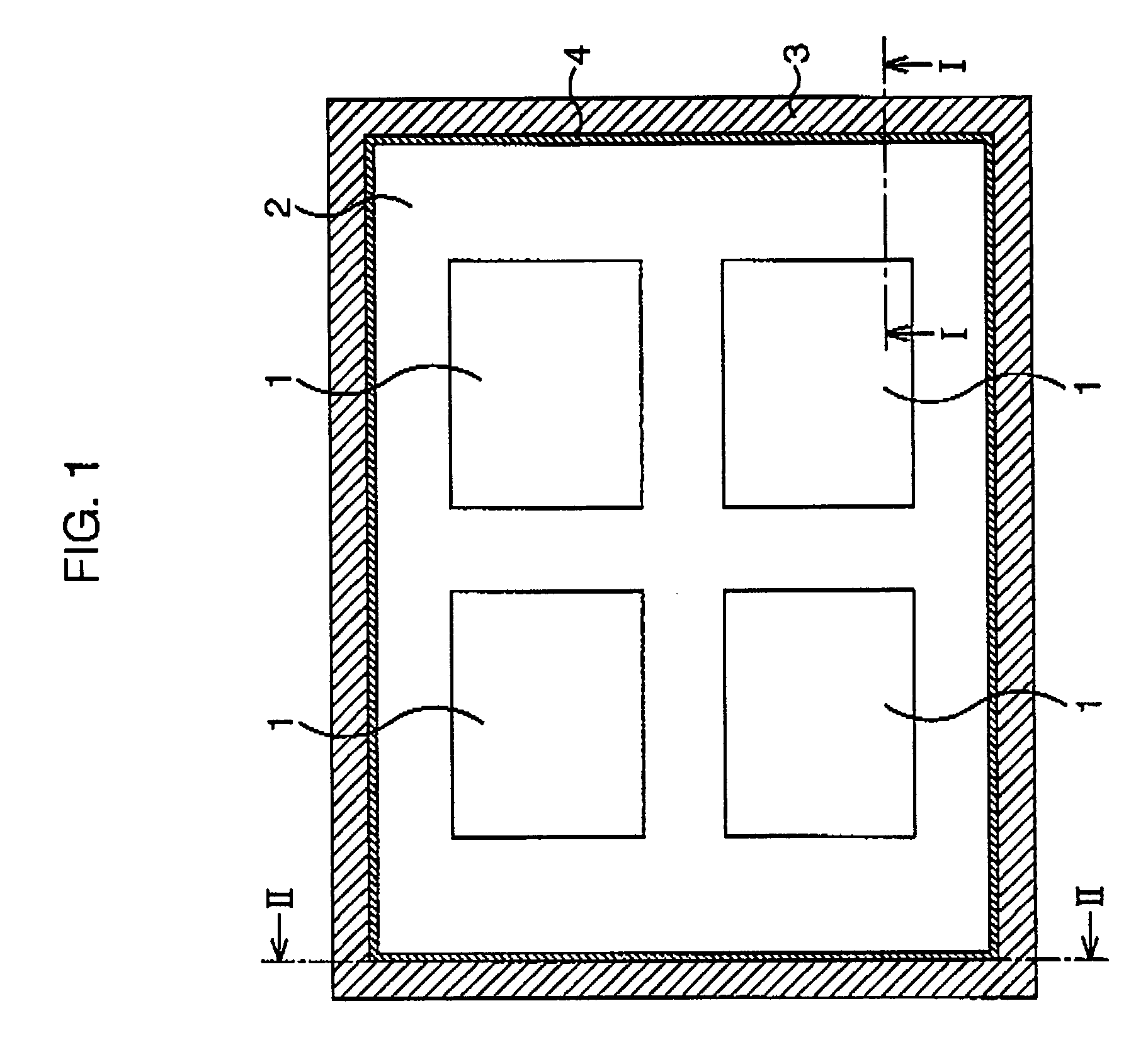

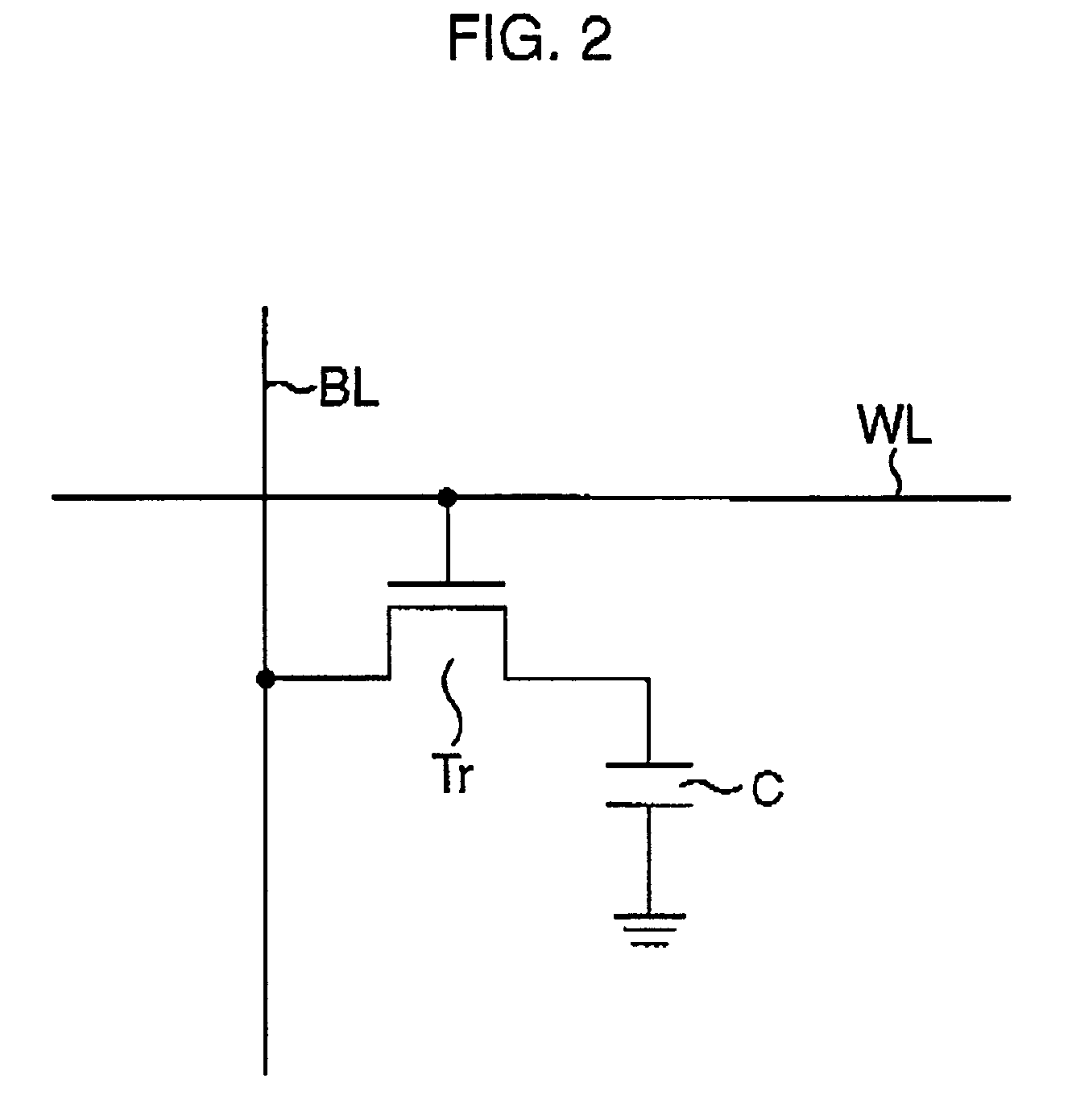

InactiveUS20070013011A1Avoid deformationReduce heat shrinkageTransistorSemiconductor/solid-state device detailsDevice materialEngineering

An interlayer insulation film is etched to form contact holes in an integrated circuit part. At this time, a trench is not formed in a guard ring part. Subsequently, ion implantation is carried out in source / drain regions in a peripheral circuit part for contact compensation, and high-temperature annealing is carried out in order to activate implanted impurities. Subsequently, an interlayer insulation film, a storage capacitor, and another interlayer insulation film are formed in sequence. Then, contact holes reaching a part of wiring layers are formed in the peripheral circuit part while, in the guard ring part, a trench reaching a diffusion layer is formed. Next, a barrier metal film is formed in each of the contact holes and the trench, and further, a contact plug comprising, for example, a W film is buried therein.

Owner:FUJITSU SEMICON LTD

Semiconductor device having guard ring and manufacturing method thereof

ActiveUS7132720B2Prevention of contact hole deformationAvoid deformationTransistorSemiconductor/solid-state device detailsIntegrated circuitContact hole

An interlayer insulation film is etched to form contact holes in an integrated circuit part. At this time, a trench is not formed in a guard ring part. Subsequently, ion implantation is carried out in source / drain regions in a peripheral circuit part for contact compensation, and high-temperature annealing is carried out in order to activate implanted impurities. Subsequently, an interlayer insulation film, a storage capacitor, and another interlayer insulation film are formed in sequence. Then, contact holes reaching a part of wiring layers are formed in the peripheral circuit part while, in the guard ring part, a trench reaching a diffusion layer is formed. Next, a barrier metal film is formed in each of the contact holes and the trench, and further, a contact plug comprising, for example, a W film is buried therein.

Owner:FUJITSU SEMICON LTD

Preparation method of porous composite separator

InactiveUS20160064711A1Increase productivityLow production costSecondary cellsCell component detailsThermal stabilityForming processes

The present disclosure provides a preparation method of a porous composite separator, which comprises steps of: (1) a forming process of a porous separator substrate: taking organic particles as a raw material to obtain a porous separator substrate; (2) a coating process of a functional material layer: coating a functional material layer on at least one surface of the obtained porous separator substrate to obtain a porous separator substrate having a functional material layer; (3) a heat treating process: drying the functional material layer and heating the porous separator substrate and the functional material layer on the surface of the obtained porous separator substrate to obtain a porous composite separator. The preparation method can prepare a porous composite separator with an excellent performance in high efficiency and low cost, the porous composite separator has high porosity, high air permeability, high binding performance, high mechanical strength and high thermal stability.

Owner:NINGDE AMPEREX TECH +1

Alkali-free glass

InactiveUS9023744B2Increase production capacityHigh strain pointOLED parametersElectroluminescent light sourcesAlkali freeAlkali metal oxide

Owner:NIPPON ELECTRIC GLASS CO LTD

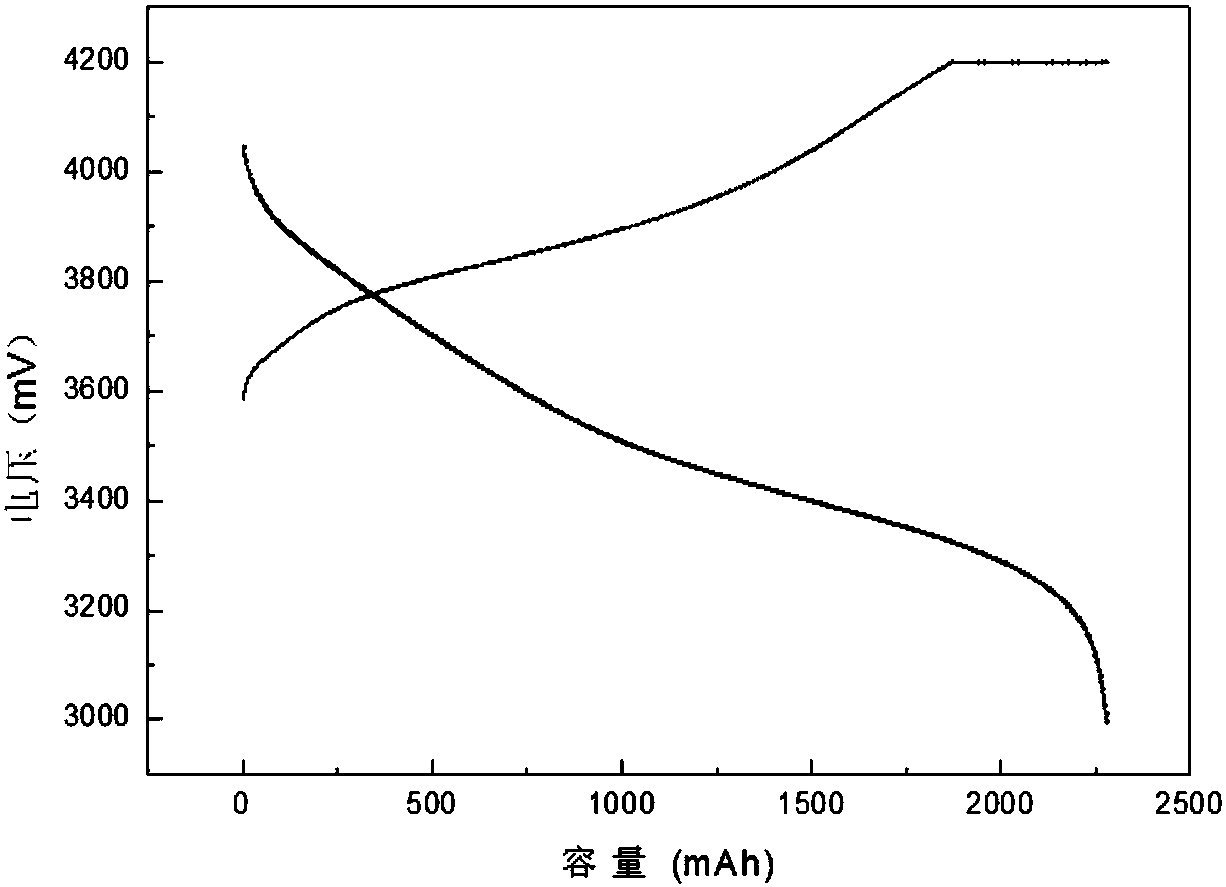

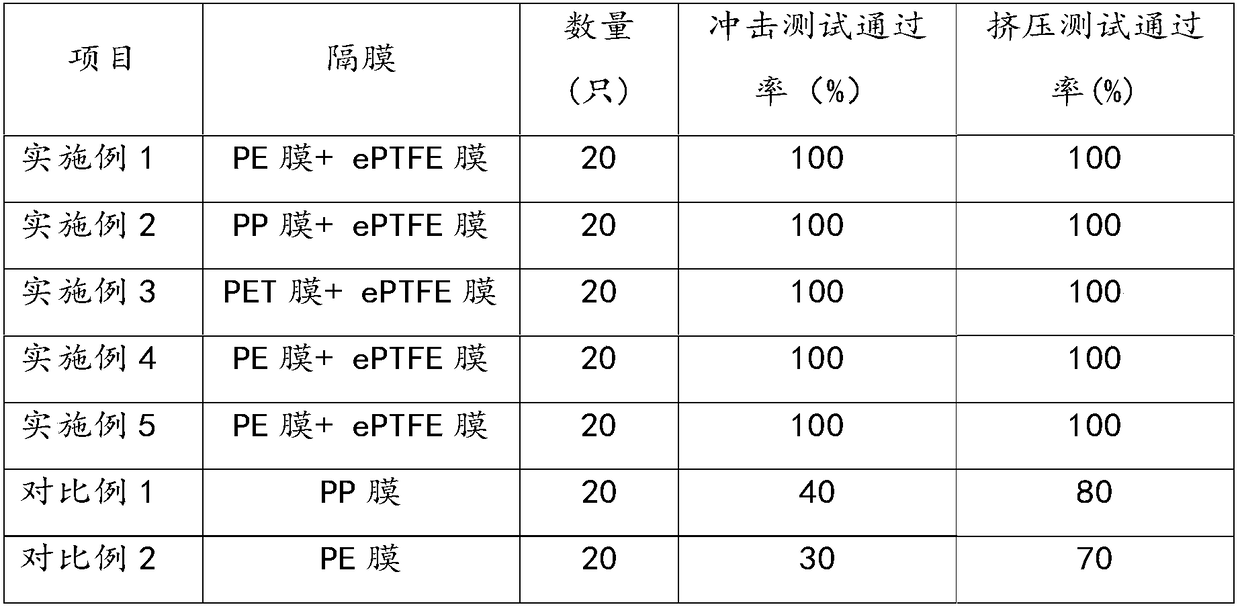

Lithium ion battery diaphragm, preparation method and lithium ion battery

InactiveCN108155327AImprove high temperature resistanceReduce heat shrinkageCell seperators/membranes/diaphragms/spacersSecondary cellsPhysical chemistryTemperature resistance

The invention belongs to the technical field of lithium ion batteries and relates to a lithium ion battery diaphragm, a preparation method and a lithium ion battery. The lithium battery diaphragm provided by the invention is of a two-layer film structure which comprises a high-molecular polymer film and a polytetrafluoroethylene microporous film; a binder is applied between the high-molecular polymer film and the polytetrafluoroethylene microporous film. The diaphragm provided by the invention integrates the advantages of both sub-films, including a closing function at relatively low temperature, fairly strong strength and excellent high-temperature resistance; the diaphragm can be used stably at 200 DEG C, a complete structure is maintained at 250 DEG C, the safety performance of the battery is remarkably enhanced, and the safety of the battery is guaranteed in needling, impact and other unfavorable conditions.

Owner:GUANGZHOU GREAT POWER ENERGY & TECH CO LTD

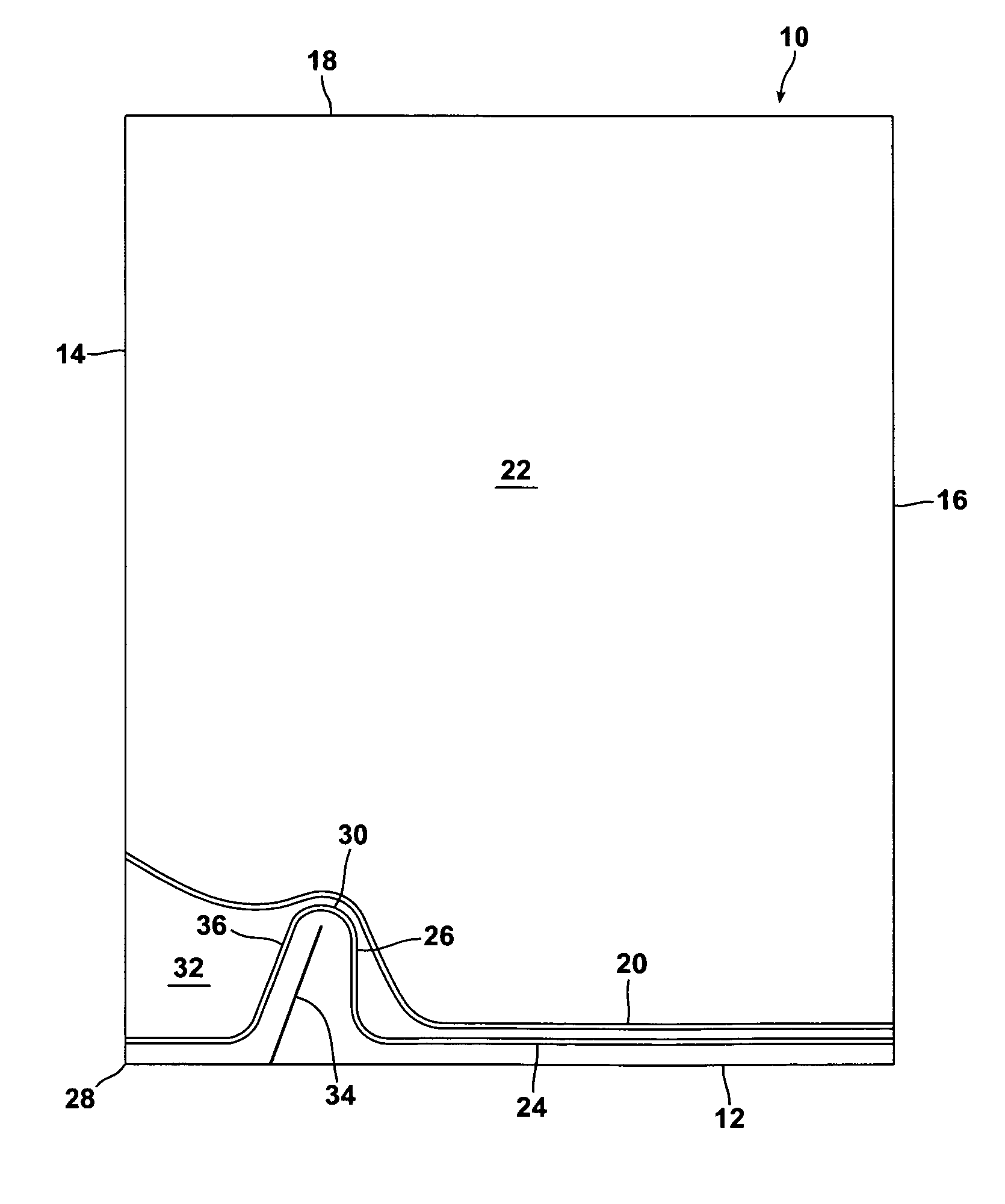

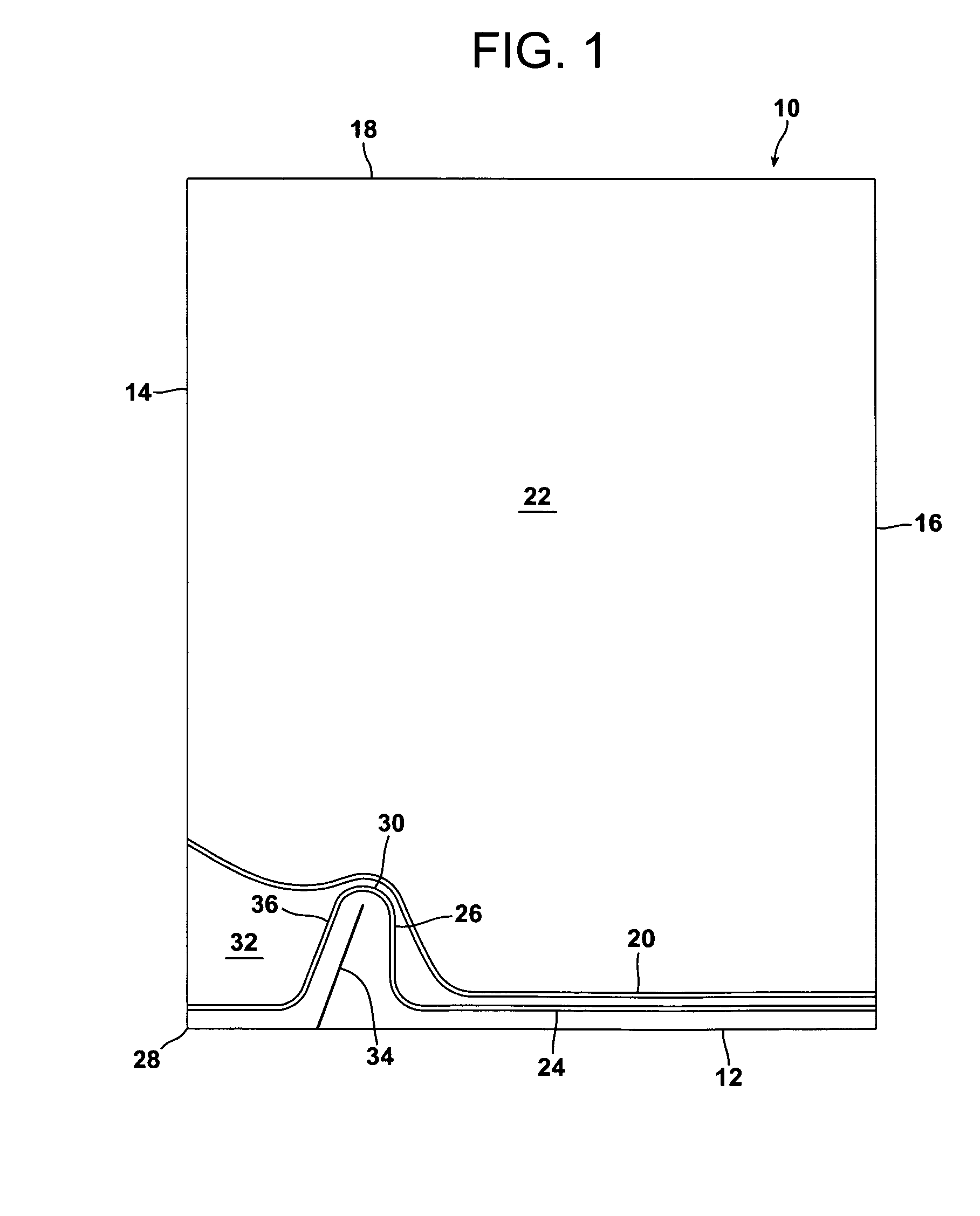

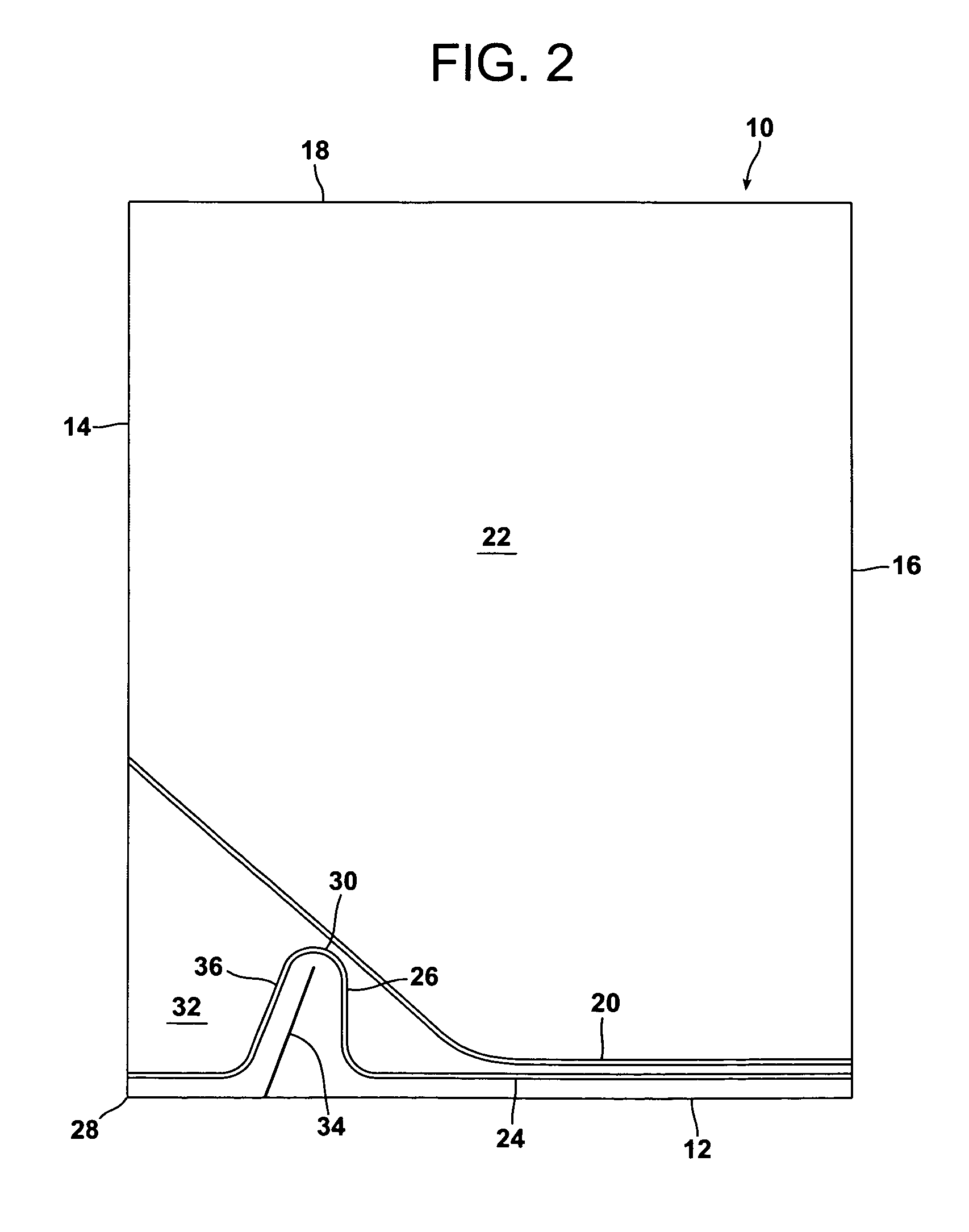

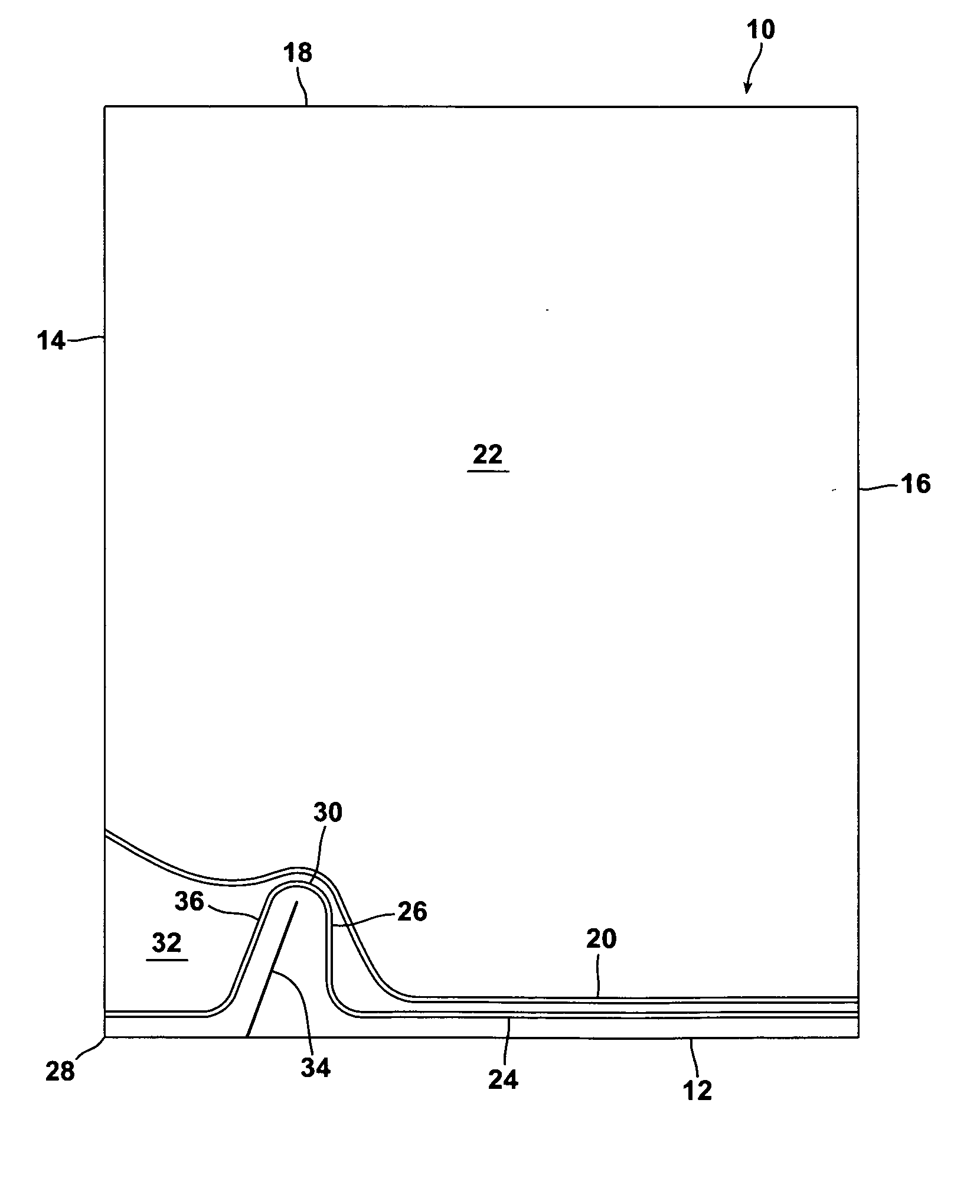

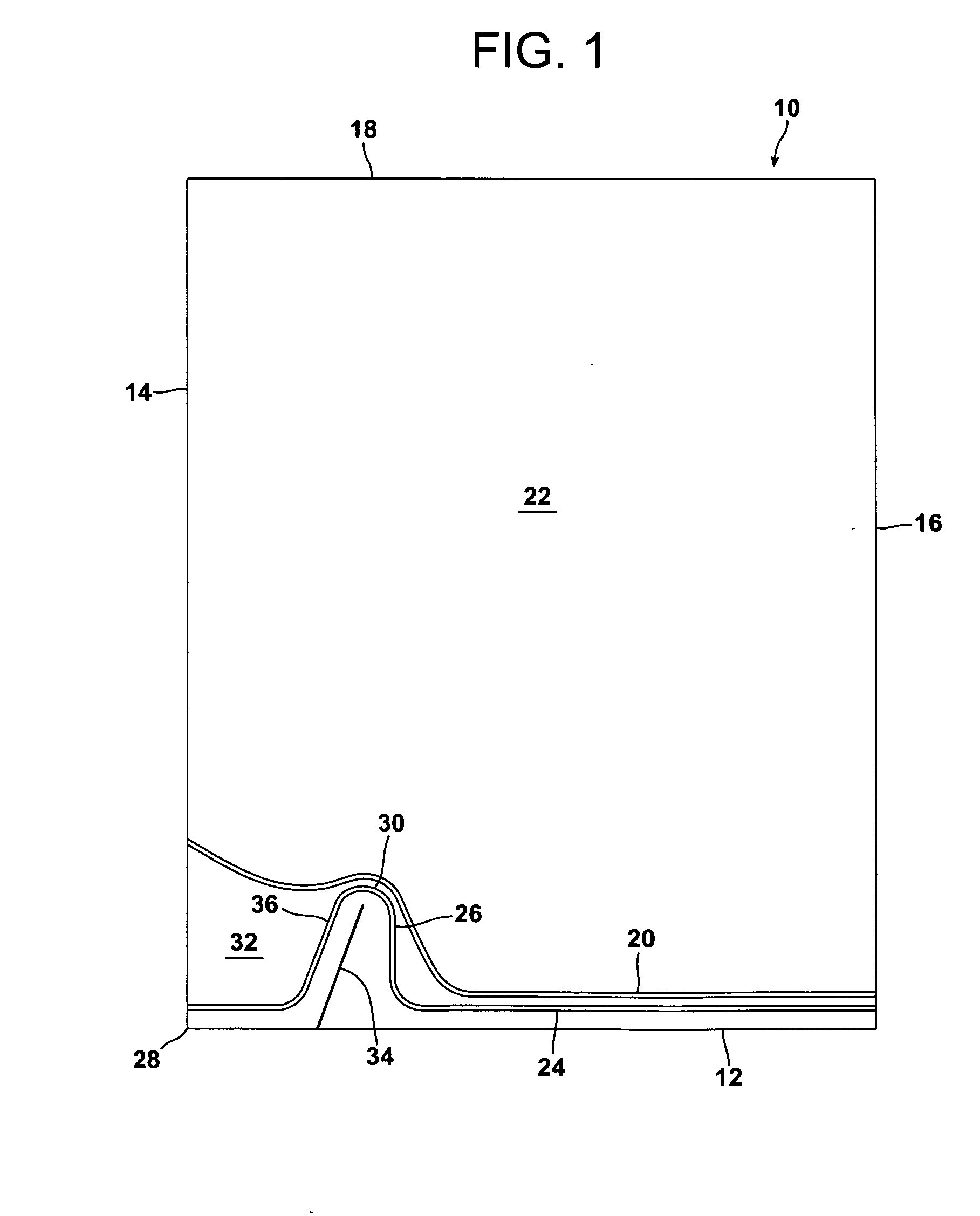

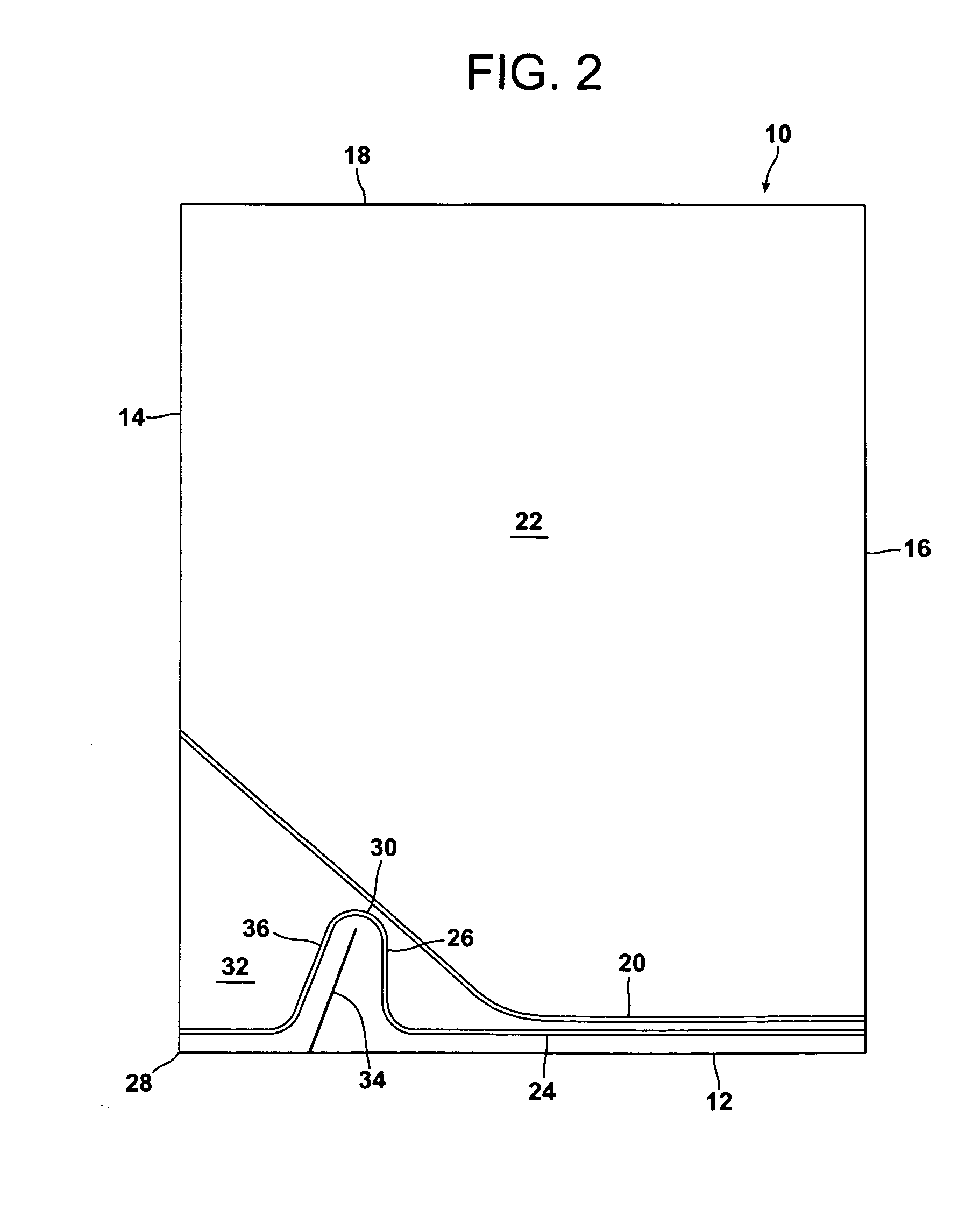

Bag of a heat-shrinkable gas-barrier thermoplastic film

ActiveUS20100140127A1Minimise excess materialMinimiseFlexible coversWrappersThermoplasticEngineering

A bag of a heat shrinkable, gas-barrier thermoplastic film for packaging an item comprises a first seal adjacent a bottom edge and connecting first and second side edges, and defining an area between it, the side edges and a top edge for receiving the item, a second seal along the bottom edge or between the bottom edge and the first seal and connecting the side edges, and having a shaped portion adjacent a corner of the bag at the first side edge and the bottom edge which projects towards the top edge, and a precut extending from the bottom edge towards an apex of the shaped portion, the first seal extending from the second side edge towards the shaped portion at a level below the apex and around the shaped portion to the first side edge, and a manually graspable tab being formed between the first side edge, the first and second seals adjacent the first side edge and the shaped portion.

Owner:CRYOVAC INC

Heat-shrinkable polyester film

ActiveUS20150218308A1Improve shrinkageRaise the gradeSynthetic resin layered productsThin material handlingPolyester resinEthylene

The invention provides a heat-shrinkable polyester film with high mechanical strength in a width direction that is orthogonal to the main shrinking direction and high tensile rupture elongation in the film width direction after being subjected to an aging treatment in a high-temperature environment. The heat-shrinkable polyester film is made from a polyester resin containing ethylene terephthalate as the main component and a monomer component that can serve as an amorphous component in an amount of 0 mol % or more and less than 1 mol % relative to the total amount of polyester resin components.

Owner:TOYO TOYOBO CO LTD

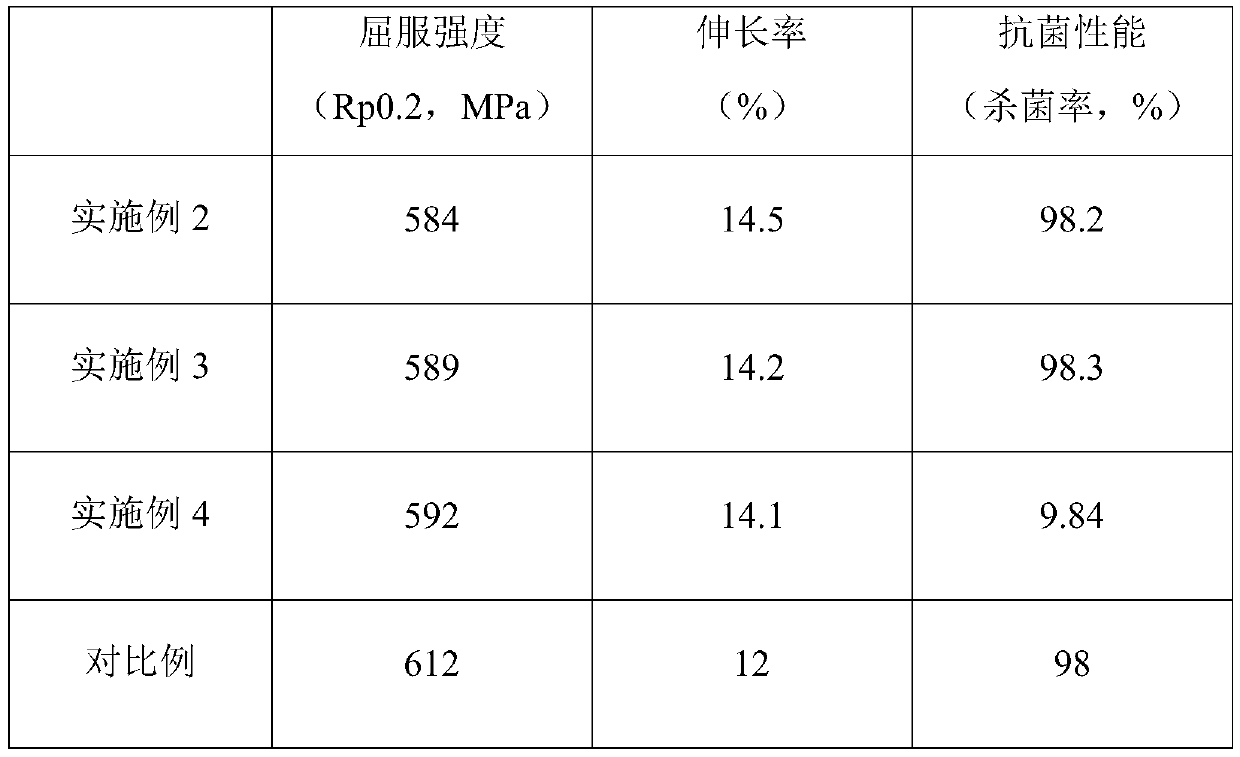

3D printed high-transparency zirconia ceramic crown material

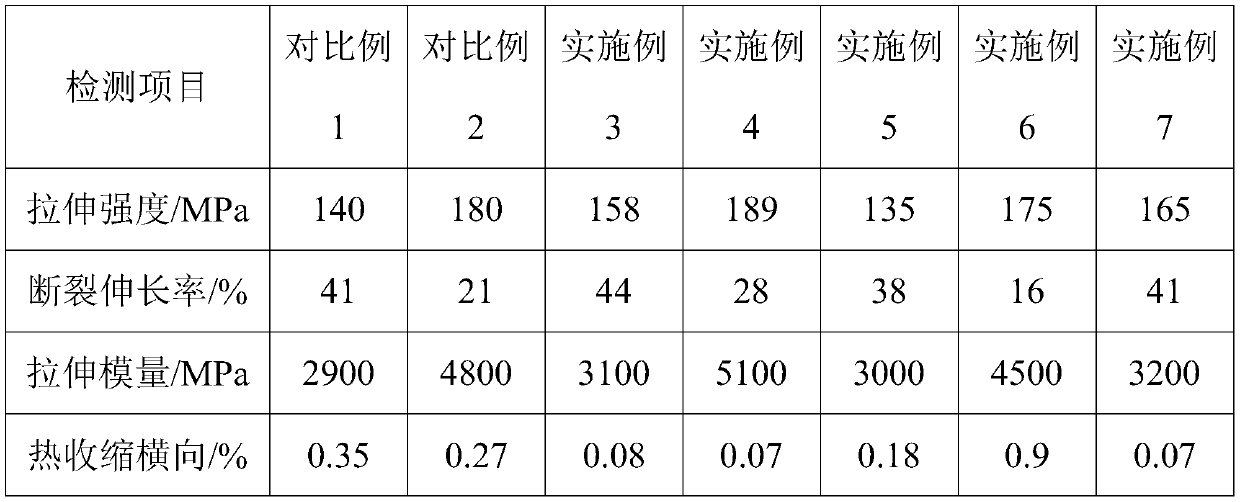

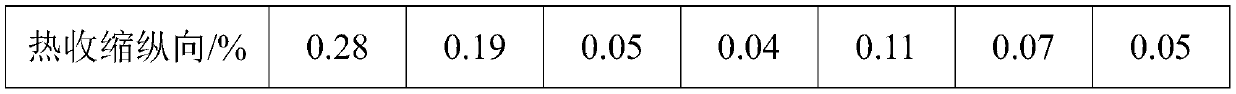

InactiveCN110917044AHigh yield strengthModerate elongation at breakImpression capsDentistry preparationsCeramic crownFiber

The invention discloses a 3D printed high-transparency zirconia ceramic crown material. The 3D printed high-transparency zirconia ceramic crown material is prepared from the following raw materials inparts by weight: 170-195 parts of zirconia, 240-270 parts of ethylene-vinyl acetate copolymers, 160-175 parts of hexanediol diacrylate, 30-37 parts of carboxy silica microspheres, 10-14 parts of nanotitanium dioxide, 15-20 parts of alumina fibers, 9-12 parts of edge-oxidized graphene, 1.2-1.5 parts of a photoinitiator, and 5-7 parts of a disperser. The 3D printed high-transparency zirconia ceramic crown (material) disclosed by the invention is high in yield strength, appropriate in elongation at break (close to alloy ceramic crown materials), excellent in mechanical property and long in service life, and has good bacterium resisting functions; and moreover, the 3D printed high-transparency zirconia ceramic crown (material) has the advantages of being non-toxic, good in wear resistance and the like.

Owner:嘉兴饶稷科技有限公司

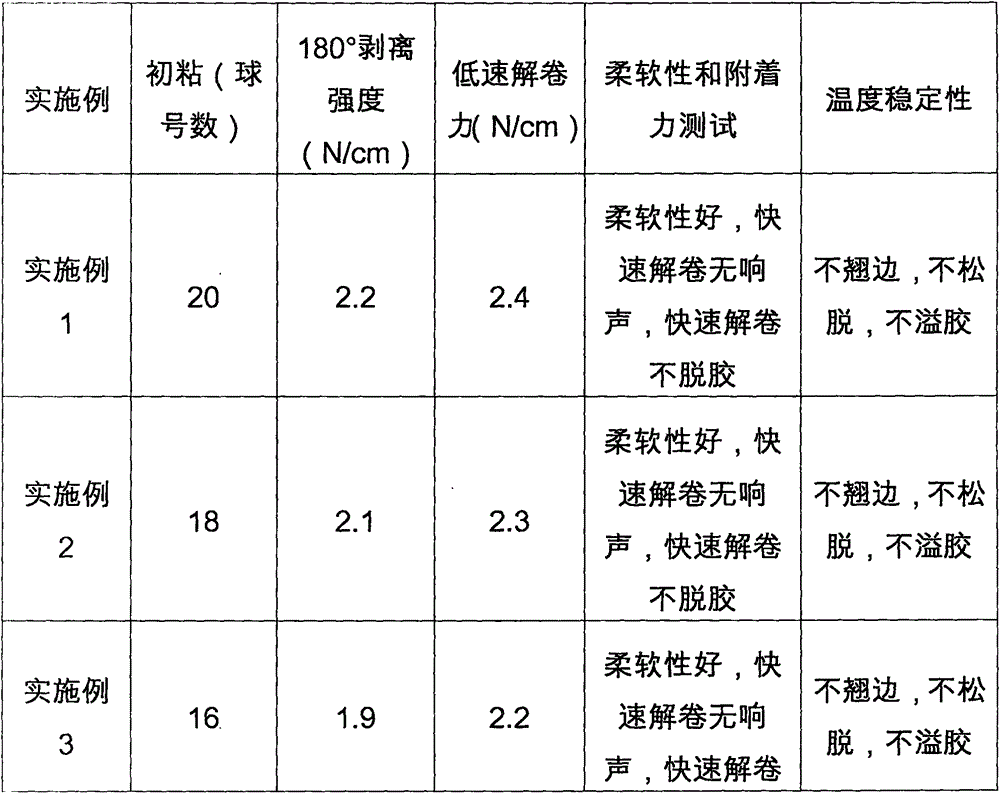

Polyvinyl chloride film suitable for coating of hot melt pressure sensitive adhesive and preparation method of polyvinyl chloride film

ActiveCN106188930AImprove high temperature resistanceReduce heat shrinkagePlasticizerPolyvinyl chloride

The invention provides a polyvinyl chloride film suitable for coating of a hot melt pressure sensitive adhesive and a preparation method of the polyvinyl chloride film. The polyvinyl chloride film suitable for coating of the hot melt pressure sensitive adhesive is mainly prepared from the following components in specific parts by mass of polyvinyl chloride resin, a polymeric plasticizer, a stabilizing agent and a filler. The polyvinyl chloride film suitable for coating of the hot melt pressure sensitive adhesive has excellent high-temperature-resistance, and is low in heat contraction percentage, and the thickness deviation of the polyvinyl chloride film can be controlled to 5 micrometers or below, through two thickness control units, the width of the polyvinyl chloride film can be made to be 2.5 meters or above. The preparation method of the polyvinyl chloride film suitable for coating of the hot melt pressure sensitive adhesive, disclosed by the invention, is simple in technology, high in production efficiency and suitable for mass production.

Owner:HEBEI YONGLE TAPE CO LTD

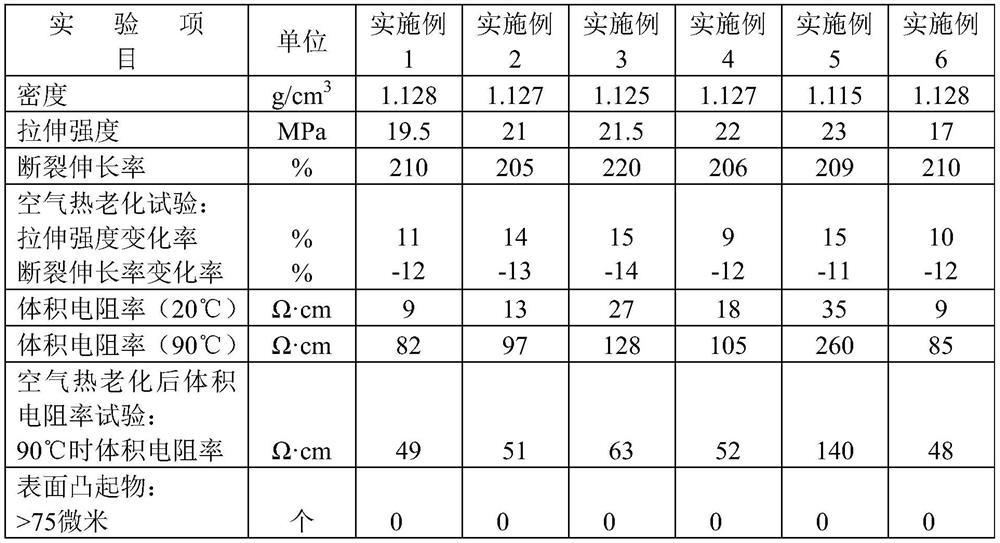

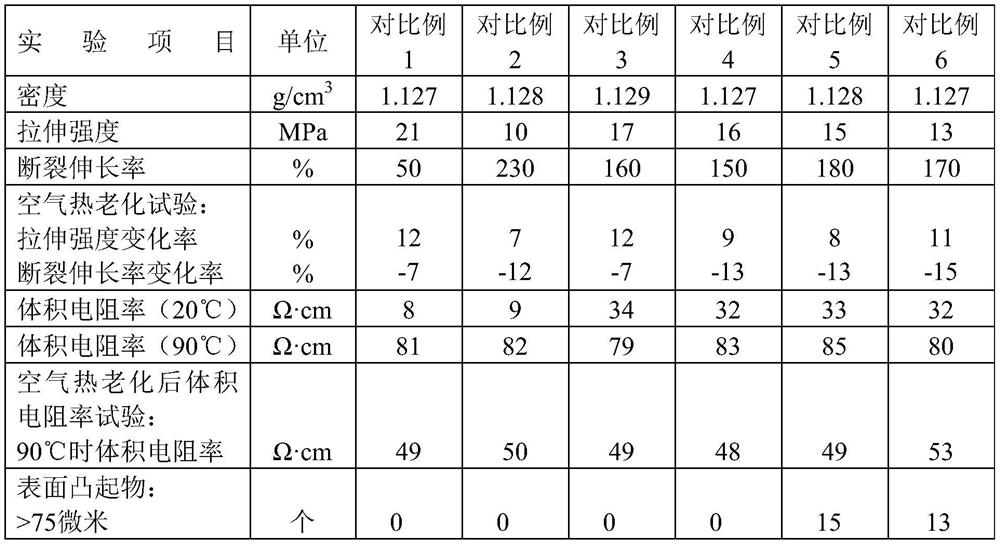

Semiconductive shielding material and preparation method and application thereof

ActiveCN112724500AAvoid separationWith skeleton support effectClimate change adaptationPower cables with screens/conductive layersPolymer scienceVulcanization

The invention provides a semiconductive shielding material and a preparation method and application thereof. The semiconductive shielding material comprises the following components: an ethylene-butyl acrylate copolymer, high-density polyethylene, conductive carbon black, PE wax, zinc stearate, a dispersing agent and an antioxidant. The mass ratio of the ethylene-butyl acrylate copolymer to the high-density polyethylene is 1:(0.05-0.2), preferably 1:(0.07-0.1). According to the semiconductive shielding material, the ethylene-butyl acrylate copolymer is used as a matrix, and the high-density polyethylene is added, so that the material has a skeleton supporting effect after being extruded, an insulating layer is prevented from being separated from a shielding layer, and a stress cracking phenomenon in a vulcanization process is prevented.

Owner:ZHEJIANG WANMA MACROMOLECULE MATERIAL

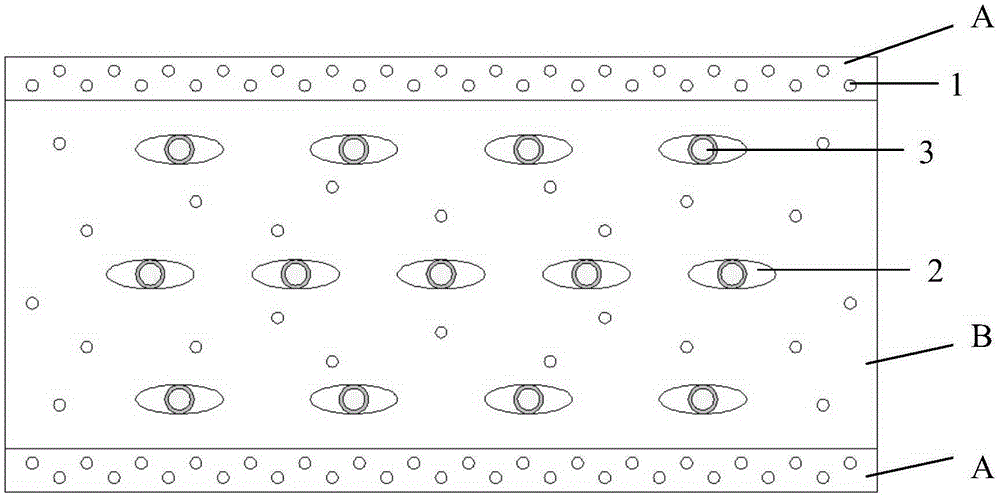

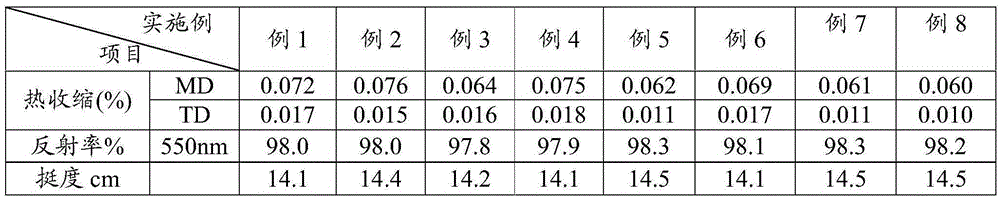

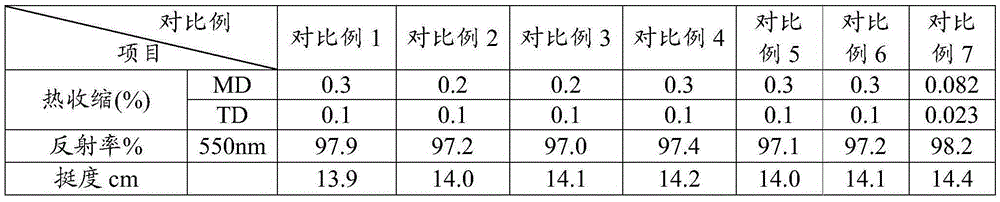

Preparation method of low-thermal-shrinkage polyester polyester reflective film

ActiveCN106671544AReduce heat shrinkageLow heat shrinkageLamination ancillary operationsSynthetic resin layered productsPolyesterHigh stiffness

The invention relates to an optical reflective film, especially to a preparation method of a low-thermal-shrinkage polyester polyester reflective film. In order to reduce thermal shrinkage of existing polyester reflective films, the invention provides a preparation method of a low-thermal-shrinkage polyester polyester reflective film. The polyester reflective film has an ABA three-layer co-extrusion structure. The B layer of the polyester reflective film has a foam structure therein. The preparation method comprises the following steps: (1) mixing raw materials for preparation of the polyester reflective film, melting and plasticizing, extruding by a three-layer co-extrusion process, and cooling a casting strip; longitudinally stretching the obtained casting strip and then transversely stretching; (2) carrying out heat-setting on the film obtained in the step (1) at the heat-setting temperature of 220-240 DEG C; and cooling and then carrying out heat treatment at the heat treatment temperature of 60-120 DEG C. The reflective film provided by the invention has low thermal shrinkage, excellent reflectivity and high stiffness.

Owner:NINGBO CHANGYANG TECH

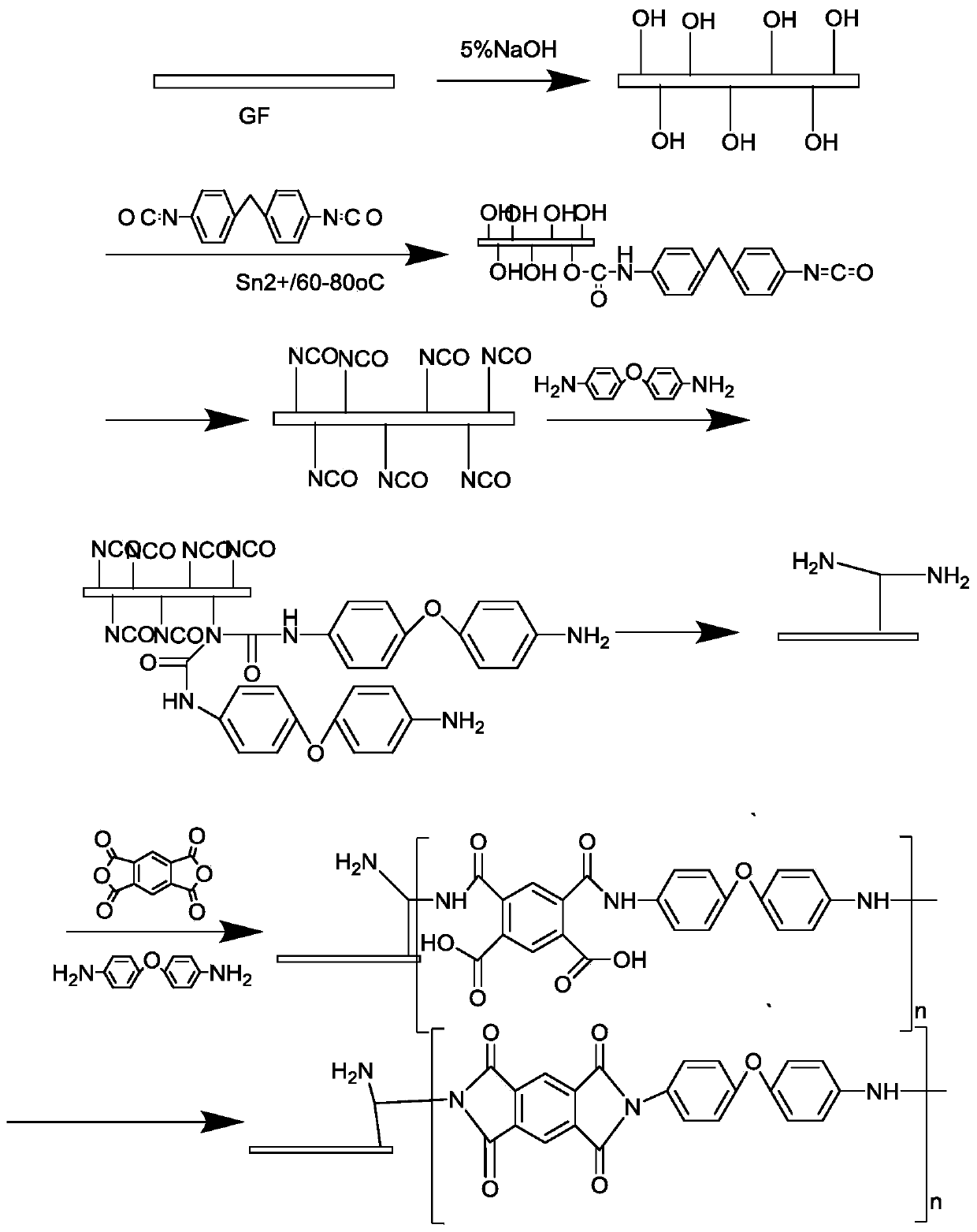

Superfine glass fiber, preparation method and application thereof, and polyimide film

The invention discloses a preparation method of superfine glass fiber, and the method comprises the following steps: S1, soaking glass fibers in a sodium hydroxide aqueous solution, washing, drying, uniformly dispersing in an organic solvent to obtain a solution A, adding diisocyanate and a catalyst, reacting, filtering, and washing a filter cake to obtain an intermediate material; and S2, uniformly dispersing the intermediate material in an organic solvent to obtain a solution B, adding diamine into the solution B in an inert gas atmosphere for reaction, filtering, washing a filter cake, anddrying to obtain the superfine glass fiber. The invention further discloses the superfine glass fiber which is prepared according to the preparation method of the superfine glass fiber. The inventionalso discloses application of the ultrafine glass fiber in a polyimide film. The invention further discloses a low-heat-shrinkage polyimide film. The surface of the prepared superfine glass fiber is grafted with-NH2, and the superfine glass fiber can be combined with polyimide to achieve the effects of reducing thermal shrinkage of the polyimide film and maintaining mechanical properties.

Owner:ANHUI GUOFENG PLASTIC

Process for preparing transparent ceramic through 3D printing

InactiveCN110951000AFast forming processHigh degree of automationAdditive manufacturing apparatusCeramic shaping apparatus3d printComputer printing

The invention discloses a process for preparing transparent ceramic through 3D printing, which comprises the following steps: A, mixing silicon nitride ceramic powder, silicon carbide fibers, ethoxylated trimethylolpropane triacrylate, aliphatic polyurethane diacrylate and tetra(3-mercaptopropionic acid) pentaerythritol ester, and performing ball milling in an ethanol solution in which a polymerization inhibitor, a dispersing agent and a defoaming agent are dissolved for 1-2h to obtain ball-milled slurry; B, adding a photoinitiator into the ball-milled slurry, mixing the photoinitiator and theball-milled slurry well, and adjusting the solid content to 78-85% to obtain 3D printing ceramic slurry; and C, printing the 3D printing ceramic slurry by adopting a DLP printer with the wavelength of 390-420nm, and carrying out drying to obtain the transparent ceramic. The process for preparing the transparent ceramic through 3D printing is high in forming speed, high in automation degree, capable of forming any complex shape and high in size precision, and the prepared transparent ceramic has excellent heat-conducting property and good mechanical property.

Owner:嘉兴饶稷科技有限公司

High-temperature nickel-metal hydride battery diaphragm

InactiveCN106159164AImprove breathabilityImprove temperature resistanceCell component detailsGastight accumulatorsPolyolefinPolymer science

The invention relates to a high-temperature nickel-metal hydride battery diaphragm. The diaphragm is prepared through the processes that nonwoven fabric base cloth prepared from polyolefin complex fibers and thermostable fibers is grafted with acrylate and / or sodium p-styrenesulfonate through radiation, and then hot rolling and shaping are carried out. Thermal shrinkage caused when the diaphragm encounters high temperatures in the processing and using processes can be effectively reduced, and the diaphragm can maintain high air permeability in the use process.

Owner:HENAN KEGAO RADIATION CHEM TECH

Heat-shrinkable polyester film

ActiveUS9920162B2Improve shrinkageWound around a battery very efficiently within a short period of timeSynthetic resin layered productsThin material handlingPolymer scienceThin membrane

The invention provides a heat-shrinkable polyester film with high mechanical strength in a width direction that is orthogonal to the main shrinking direction and high tensile rupture elongation in the film width direction after being subjected to an aging treatment in a high-temperature environment. The heat-shrinkable polyester film is made from a polyester resin containing ethylene terephthalate as the main component and a monomer component that can serve as an amorphous component in an amount of 0 mol % or more and less than 1 mol % relative to the total amount of polyester resin components.

Owner:TOYOBO CO LTD

Cable sheath

InactiveCN105623045AImprove heat resistanceReduce heat shrinkagePlastic/resin/waxes insulatorsInsulated cablesGlass fiberPlasticizer

The invention discloses a cable sheath and relates to the technical field of high molecular plastic. The cable sheath comprises, by weight, 50-70 parts of crosslinked polyethylene, 5-9 parts of plasticizer, 6-10 parts of lead-free stabilizer, 12-15 parts of antioxidant, 8-12 parts of blending modifier, 20-25 parts of glass fiber, 15-25 parts of polyether-ether-ketone and 10-15 parts of polyether sulfone. Compared with the prior art, the cable sheath has the advantage that thermal shrinkage degree of the cable sheath can be lowered.

Owner:LIUZHOU CITY QIANYANG MACHINERY & ELECTRIC

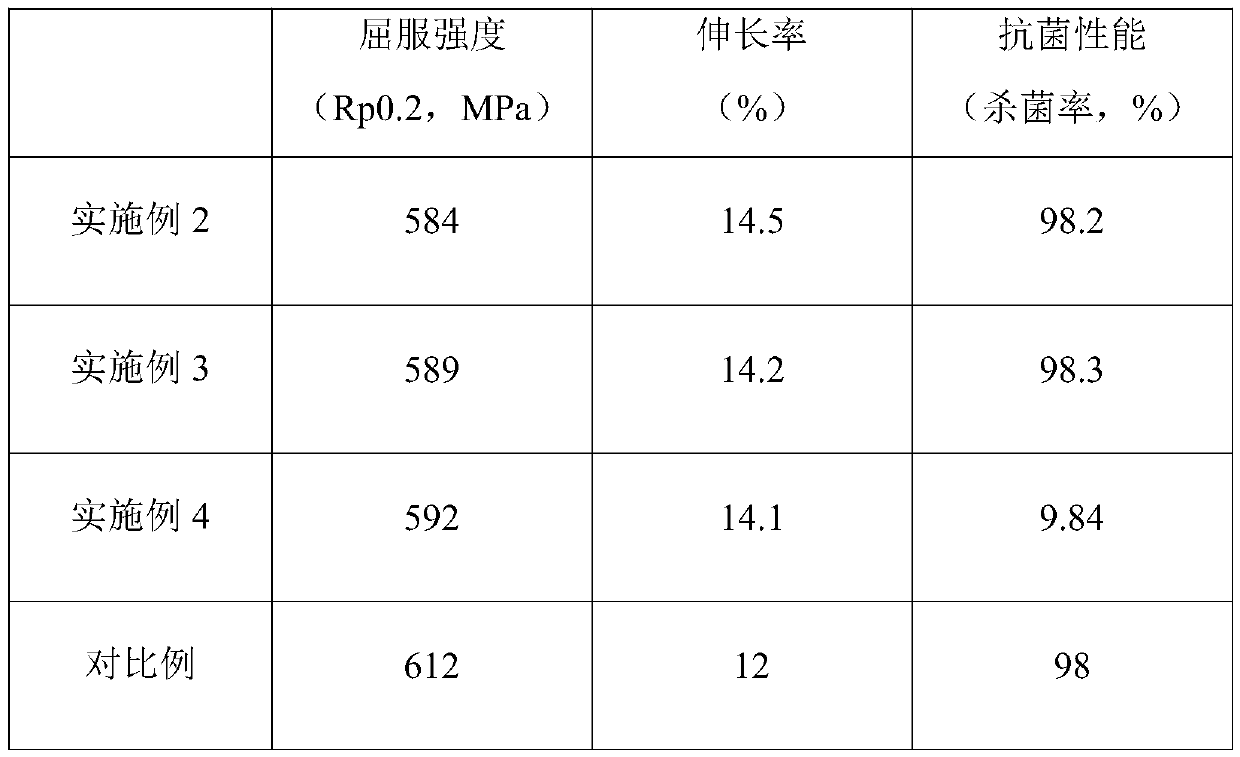

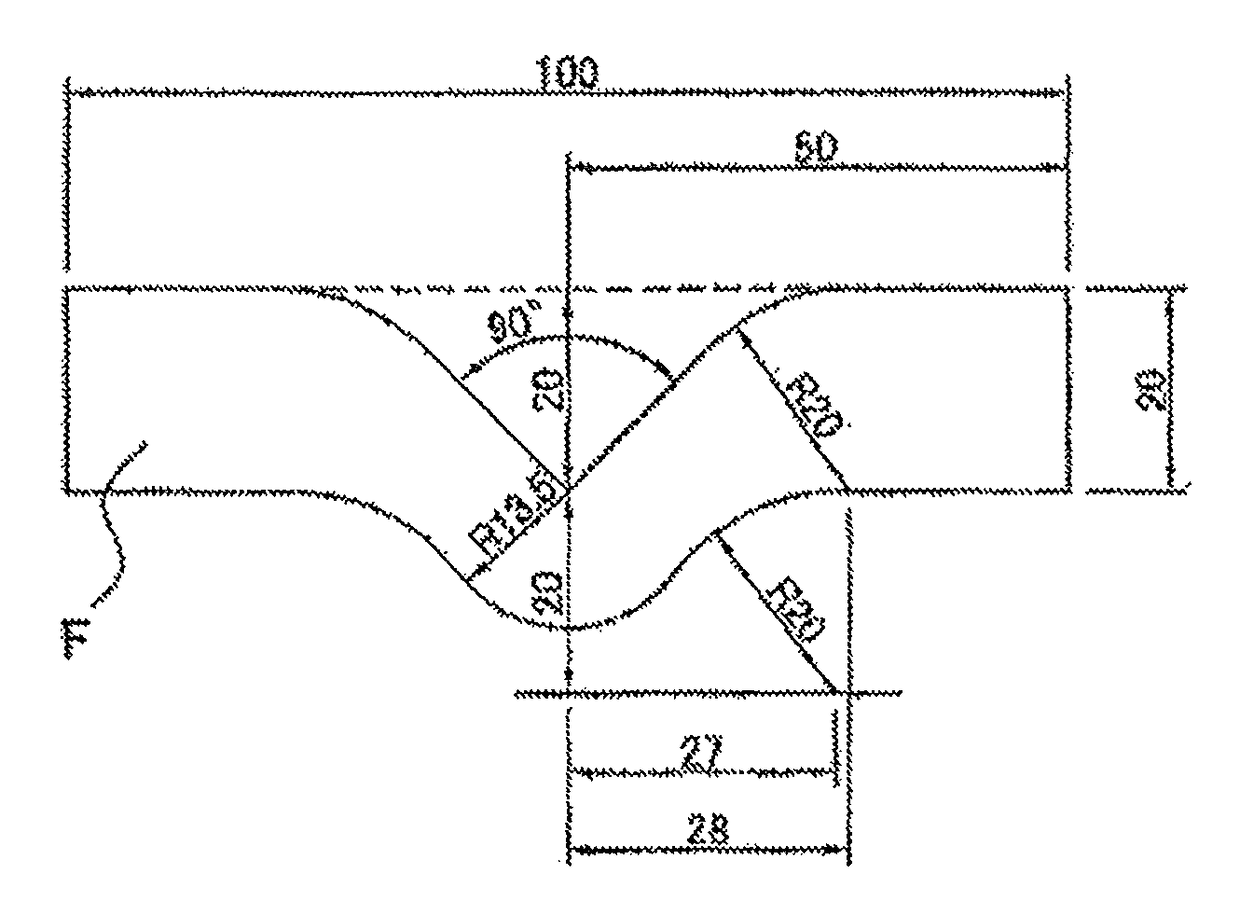

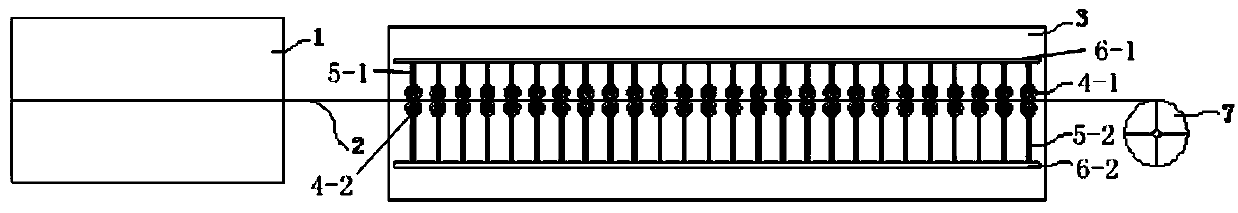

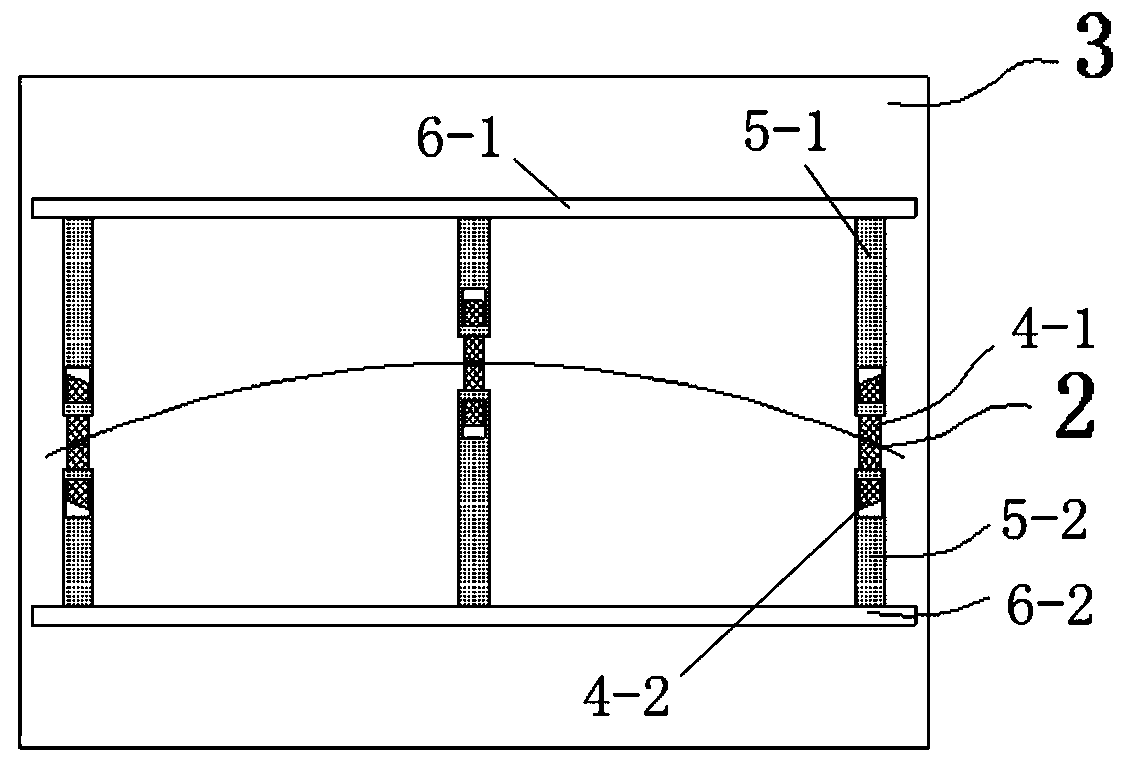

Oven with bent rail

InactiveCN110370799AReduce concentrationReduce heat shrinkagePrinting press partsFlexible circuitsPulp and paper industry

The invention belongs to the technical field of flexible circuit board ink baking devices, and in particular, relates to an oven with a bent rail. An upper roller bracket fixed plate and a lower roller bracket fixed plate are arranged in the oven; multiple rows of upper roller brackets are symmetrically arranged on the lower side of the upper roller bracket fixed plate in an oven access port direction, and the extension lengths of the upper roller brackets are gradually increased from middle row to two side rows; lower roller brackets matched with the upper roller brackets of the upper rollerbracket fixed plate are symmetrically arranged on the upper side of the lower roller bracket fixed plate in the oven access port direction, and the extension lengths of the lower roller brackets are gradually reduced from middle row to two side rows; and rollers rotated in the oven access port direction are arranged at the end parts of free ends of the upper roller brackets and at the end parts offree ends of the lower roller brackets. Under a concave-convex cooperation effect of the upper roller brackets and the lower roller brackets, flexible circuit boards are baked in a reverse warping state for drying ink to achieve a warp correcting effect.

Owner:江苏上达半导体有限公司

Power cable

InactiveCN107293368AImprove heat resistanceReduce heat shrinkageClimate change adaptationInsulated cablesPower cableInsulation layer

The invention discloses a power cable comprising a supporting core, single core bodies, and an insulation layer. The supporting core and the single core bodies are disposed in the insulation layer. The supporting core is disposed on the central position of the insulation position, and the number of the single core bodies is more than one. The single core bodies are in a circular arrangement, and are disposed in an annular cavity formed by the supporting core and the insulation layer. Each of the single core bodies comprises a hollow conductive layer, an insulation medium filler, and an insulation medium protection sleeve. The insulation medium filler is disposed in the hollow conductive layer, and the periphery of the insulation medium protection sleeve is provided with wrinkled textures. The outer side of the insulation layer is provided with an inner sheath, the outer side of which is provided with a fireproof layer. The outer side of the fireproof layer is provided with a steel wire armor layer in a single-stranded and twisted way, and the steel wire armor layer adopts galvanized circular steel wires. The outer side of the steel wire armor layer is provided with an outer sheath. The thermal shrinkage problem of the cable is effectively solved, and at the same time, mechanical damages of underground machinery construction and subterranean animals are prevented.

Owner:杨攀

Flame-retardant polycarbonate resin composition, sheet and film using same, and manufacturing method for each

ActiveUS20180208763A1Improve flame retardant performanceHeat suppressionPolymer scienceFluoropolymer

The present invention provides a polycarbonate resin composition containing a polycarbonate resin (A), a flame retardant (B), and a fluoropolymer (C), said polycarbonate resin composition being characterized in that the fluidity of the fluoropolymer (C), as measured using a Koka flow tester (under the conditions of a measurement temperature of 400° C., a measurement load of 0.98 MPa, and a die hole diameter of 2.1 mm), is 0.1×10−3 cm3 / sec or greater. The present invention also provides a sheet and a film.

Owner:MITSUBISHI GAS CHEM CO INC +1

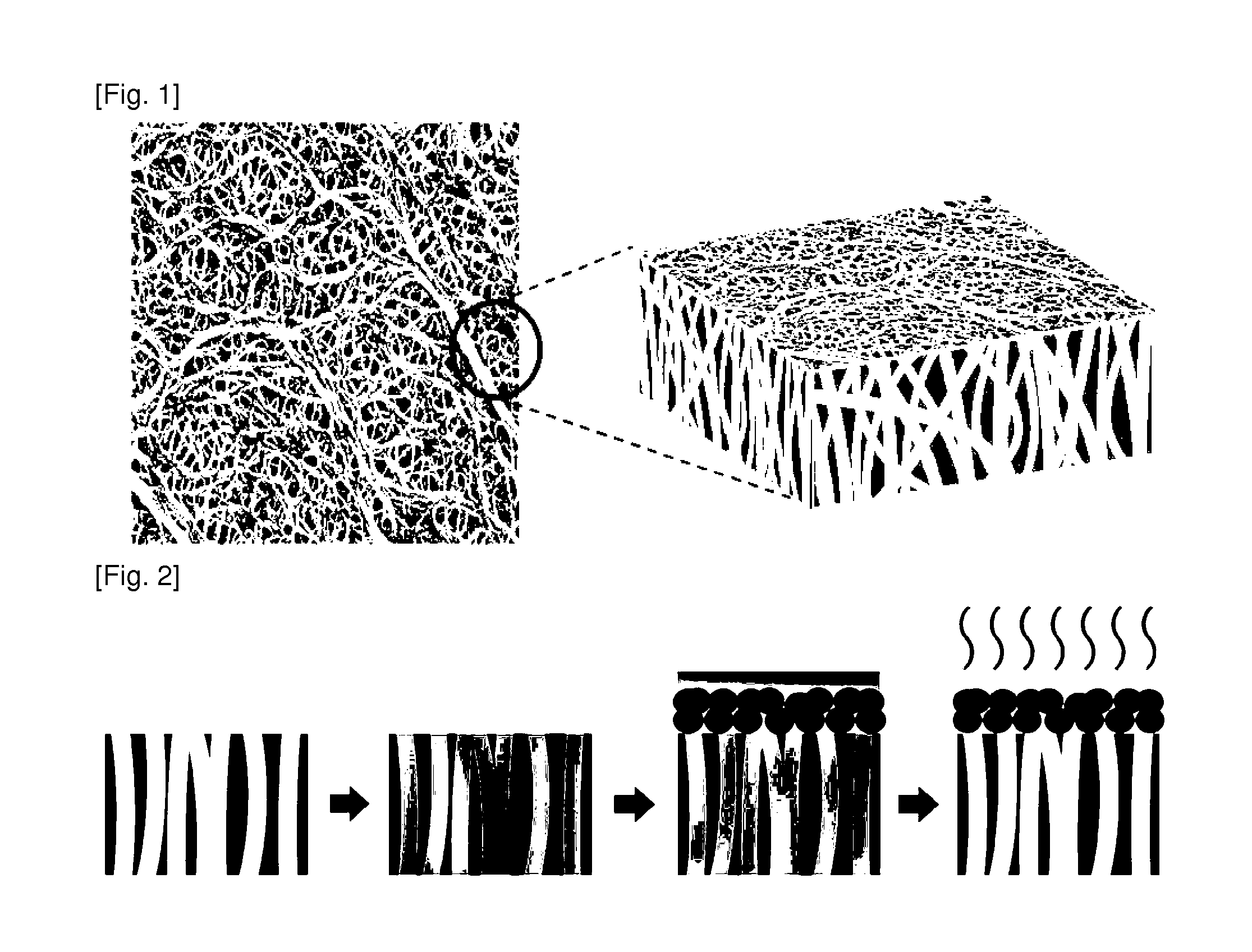

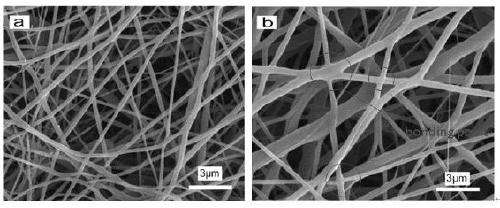

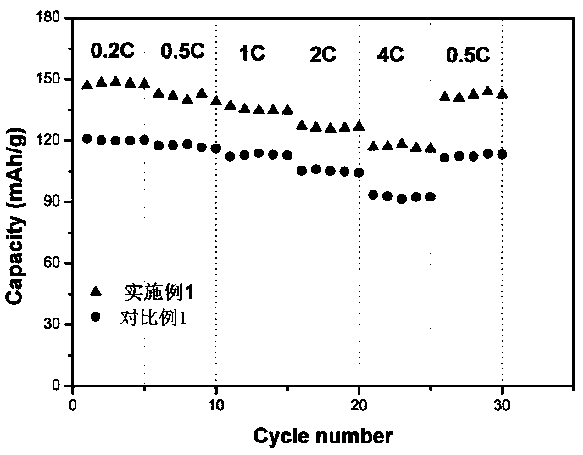

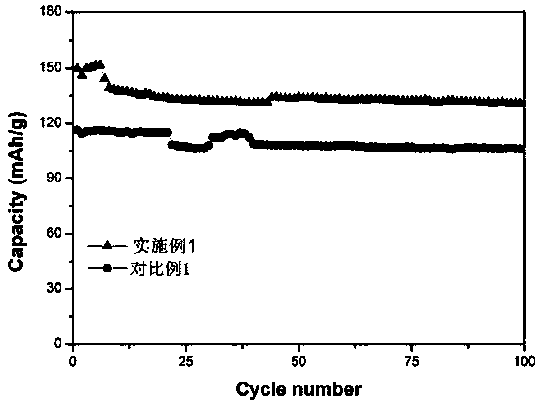

Modified polyimide nanofiber membrane as well as preparation and application thereof

PendingCN109763259AEnhanced high temperature flame retardancyImprove mechanical propertiesFilament/thread formingNon-woven fabricsPorosityLithium-ion battery

The invention discloses a modified polyimide nanofiber membrane. The nanofiber membrane is prepared from a solution containing the following raw materials in percentage by mass: 0.01%-0.5% of sulfonated graphene oxide, 5%-20% of modified polyimide and the balance of an organic solvent by spinning. The nanofiber membrane has higher porosity and uniform pore size distribution, and has good high-temperature stability and electrochemical stability. On the other hand, the nanofiber membrane has good liquid absorption and wettability and can fully contact with an electrolyte; besides, the nanofibermembrane has the characteristics of high ionic conductivity and low interface contact resistance, so that the nanofiber membrane can be used as a separator in preparation of a lithium ion battery, cycle performance of the lithium ion battery is improved, and use safety of the battery is effectively improved.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

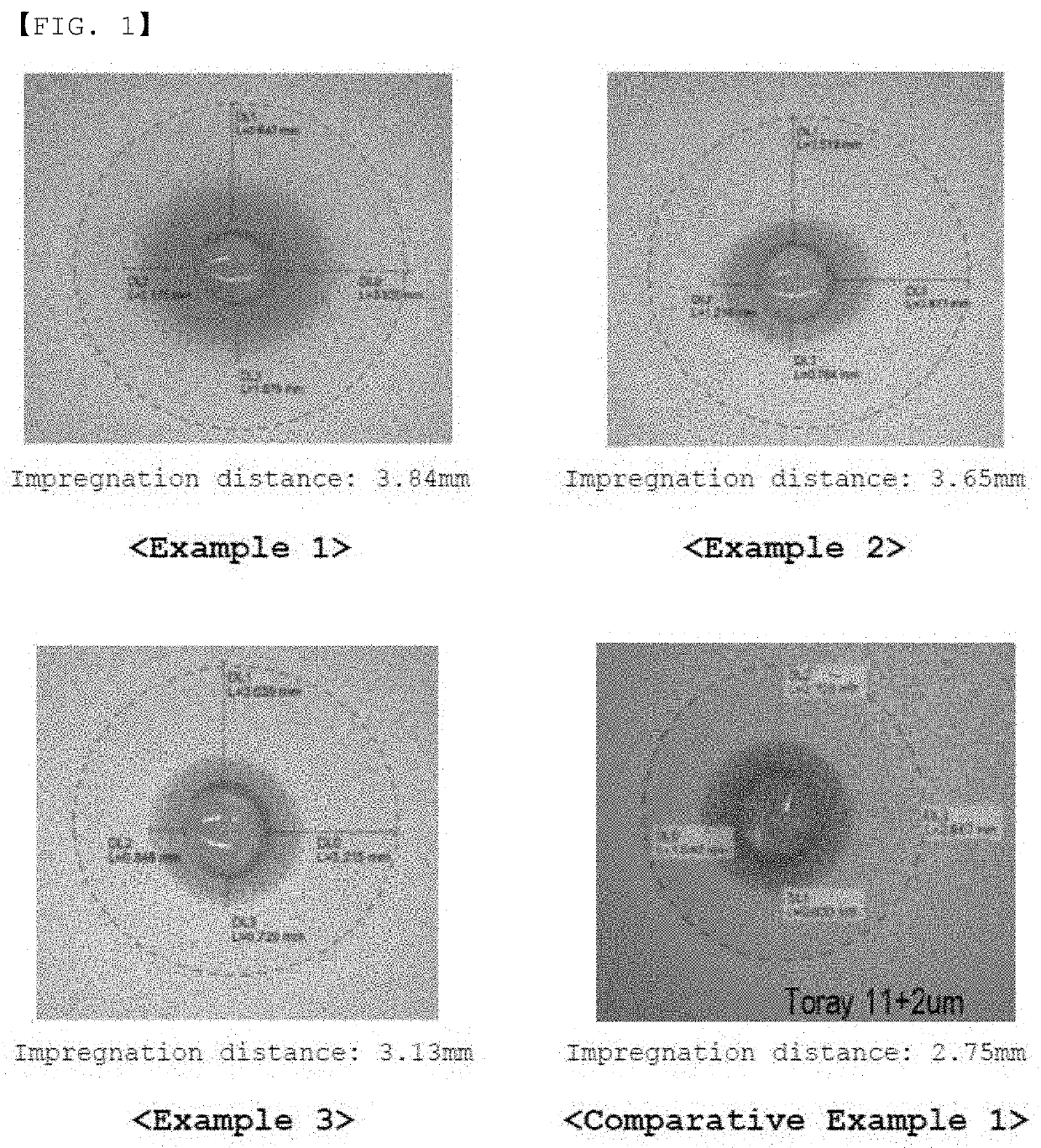

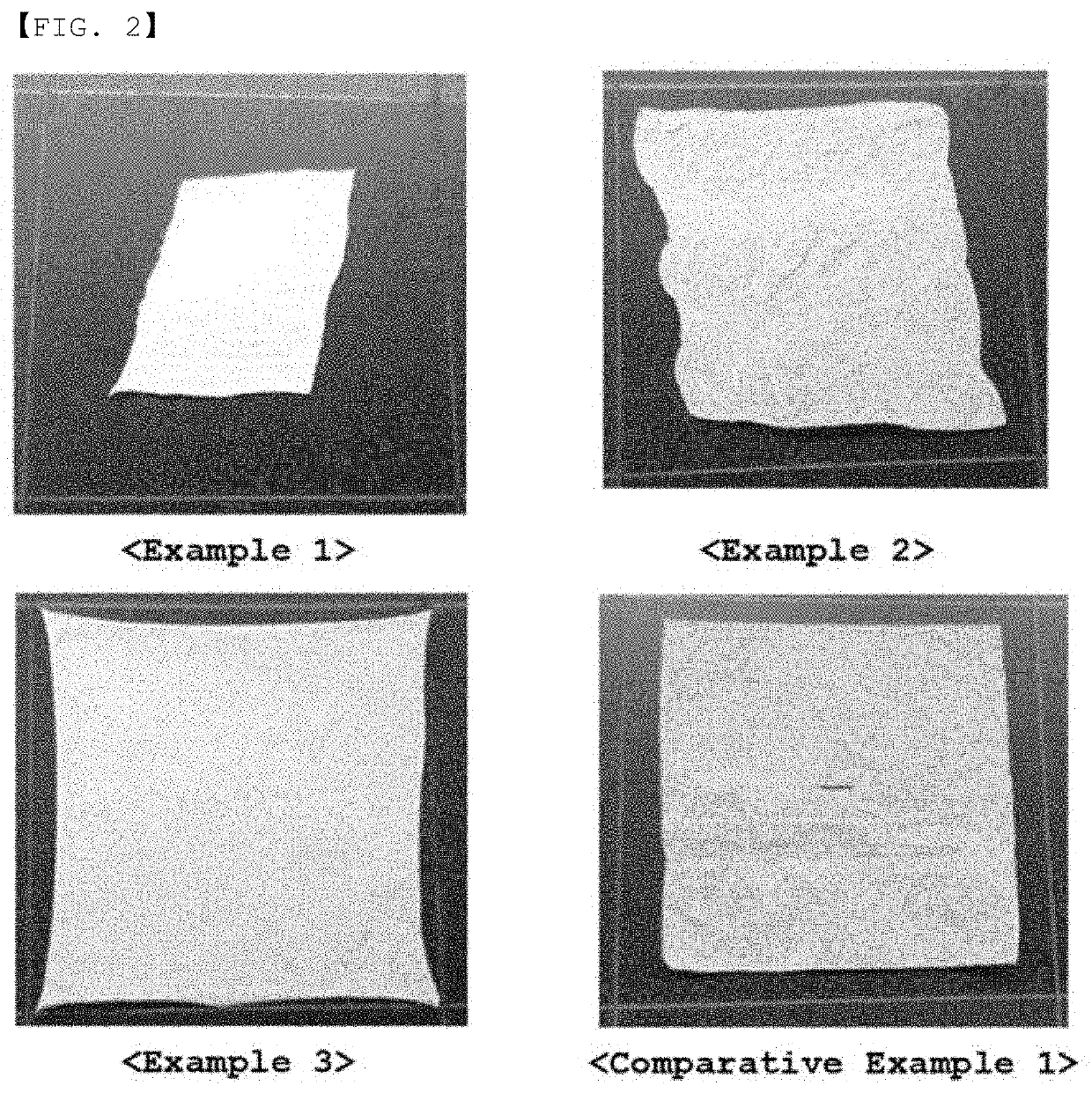

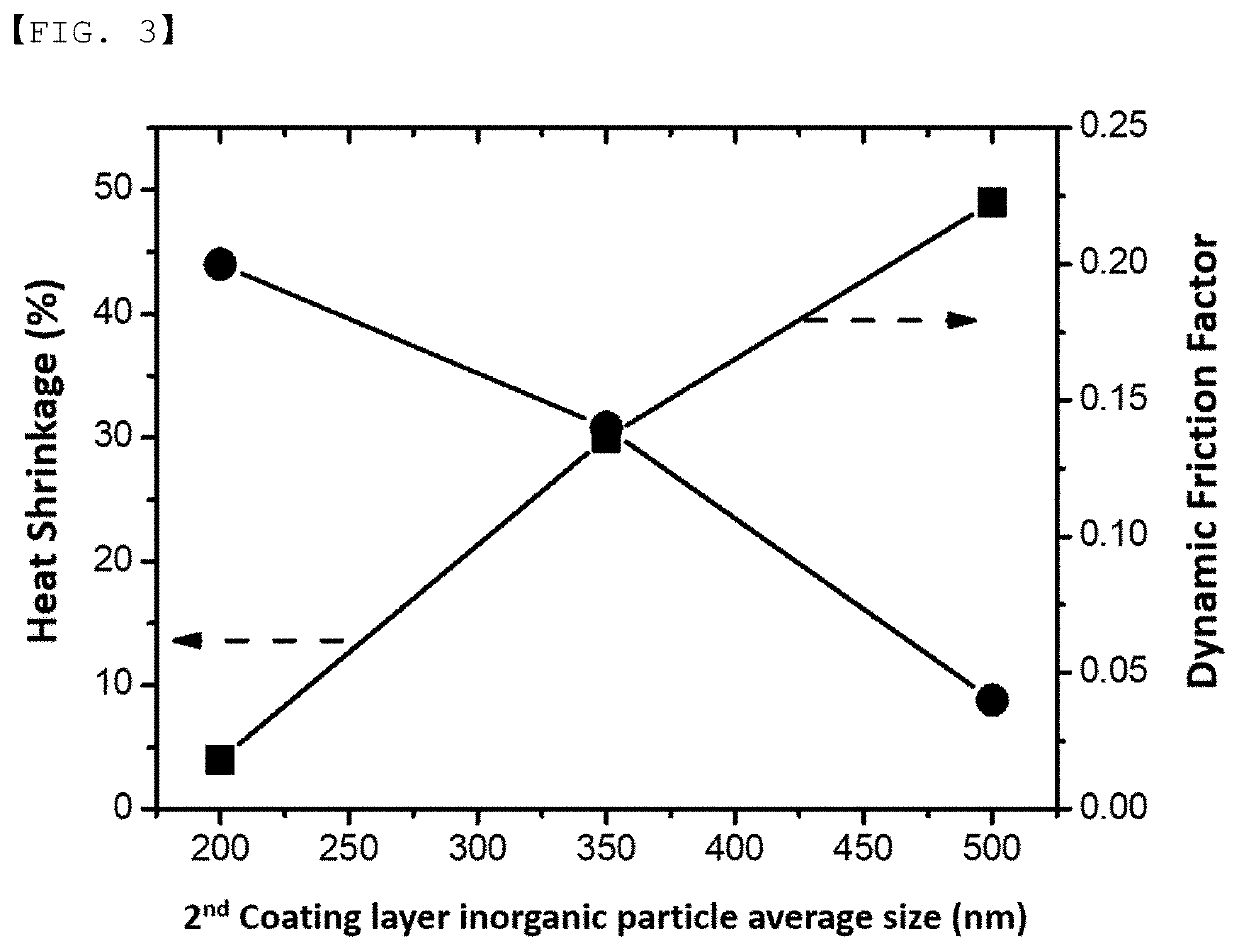

Separator comprising dual coating layers and secondary battery comprising the same

PendingUS20210050577A1Reduce heat shrinkageExcellent impregnationCell seperators/membranes/diaphragms/spacersLi-accumulatorsPolymer sciencePolyolefin

A separator having a polyolefin substrate, first coating layer including first inorganic particles on at least one surface of the polyolefin substrate and a second coating layer including second inorganic particles on a surface of the first coating layer opposite the polyolefin substrate, An average particle size of the first inorganic material particles of the first coating layer is greater than an average particle size of the second, inorganic material particles of the second coating layer. The first inorganic particles of the first coating layer are 900 nm or more based on. D50, and the second inorganic particles of the second coating layer are 10 nm or more and 500 nm or less based on D50.

Owner:LG ENERGY SOLUTION LTD

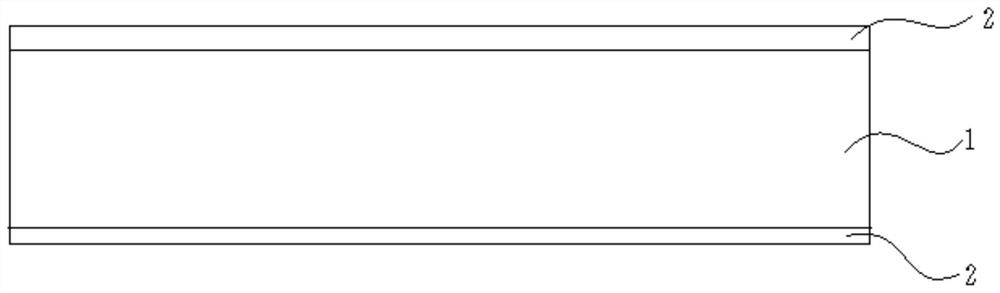

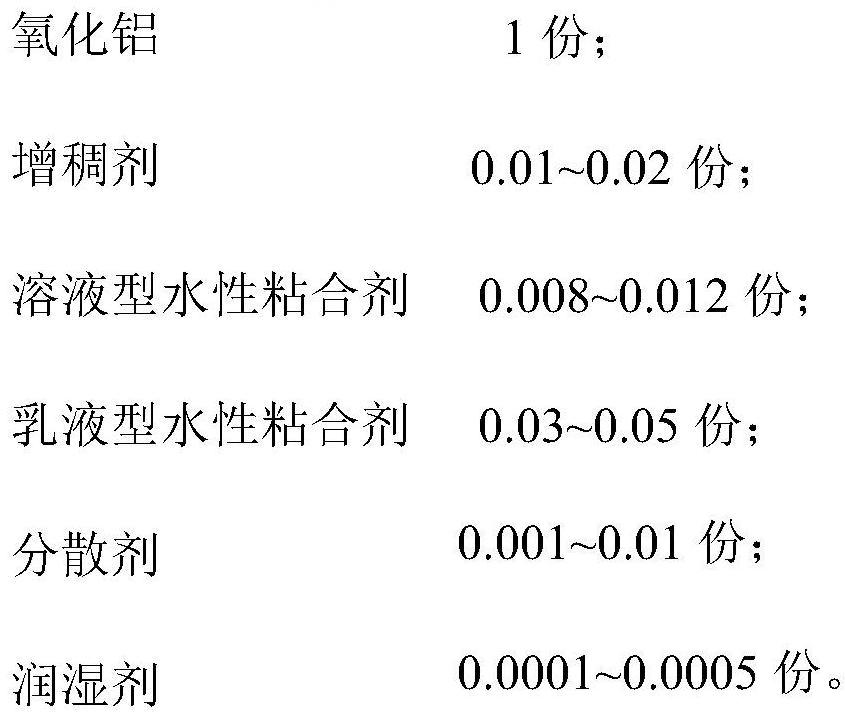

Lithium ion battery diaphragm, lithium ion battery and preparation method of lithium ion battery diaphragm

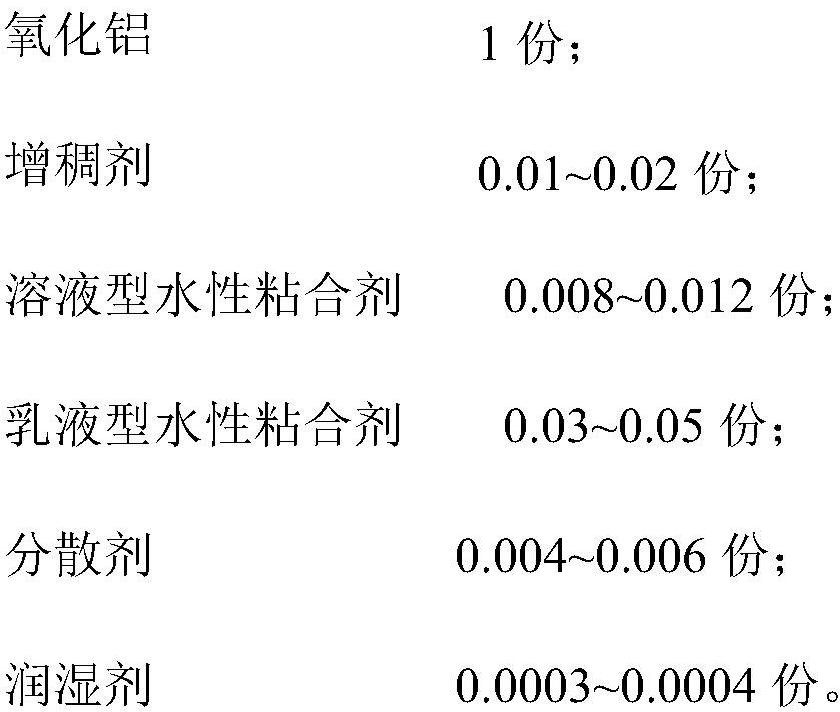

PendingCN113594633AImprove securityGood heat shrinkabilitySecondary cellsCell component detailsCeramic coatingAdhesive

The invention provides a lithium ion battery diaphragm, a lithium ion battery and a preparation method of the lithium ion battery diaphragm. The lithium ion battery diaphragm comprises a base membrane and a ceramic coating covering the surface of the base membrane, and the ceramic coating comprises the following raw materials in parts by weight: 1 part of aluminum oxide; 0.01 to 0.02 part of a thickening agent; 0.008 to 0.012 part of a solution type water-based adhesive; 0.03 to 0.05 part of an emulsion type water-based adhesive; 0.001 to 0.01 part of a dispersing agent; and 0.0001 to 0.0005 part of a wetting agent. The lithium ion battery diaphragm disclosed by the invention has relatively good thermal shrinkage performance and puncture strength, and the safety of the battery is improved.

Owner:SUZHOU GREEN POWER NEW ENERGY MATERIALS CO LTD

Glass substrate for flat panel display

InactiveUS20140309098A1High Tg and strain pointExcellent devitrification resistanceGlass forming apparatusNon-linear opticsDevitrificationShrinkage rate

A flat panel display glass substrate includes a glass comprising, in mol %, 55-80% SiO2, 3-20% Al2O3, 3-15% B2O3, and 3-25% RO (the total amount of MgO, CaO, SrO, and BaO). The contents in mol % of SiO2, Al2O3, and B2O3 satisfy a relationship (SiO2+Al2O3) / (B2O3)=7.5-17. The strain point of the glass is 665° C. or more. The devitrification temperature of the glass is 1250° C. or less. The substrate has a heat shrinkage rate of 75 ppm or less. The rate of heat shrinkage is calculated from the amount of shrinkage of the substrate measured after a heat treatment which is performed at a rising and falling temperature rate of 10° C. / min and at 550° C. for 2 hours by the rate of heat shrinkage (ppm)={the amount of shrinkage of the substrate after the heat treatment / the length of the substrate before the heat treatment}×106.

Owner:AVANSTRATE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com