Polyvinyl chloride film suitable for coating of hot melt pressure sensitive adhesive and preparation method of polyvinyl chloride film

A technology of polyvinyl chloride film and hot-melt pressure-sensitive adhesive, applied in the field of polyvinyl chloride film, can solve the problems of large thickness deviation of the adhesive, doping with bubbles, reducing production efficiency, etc., and achieve excellent high temperature resistance characteristics and improve high temperature resistance performance. , the effect of increasing temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

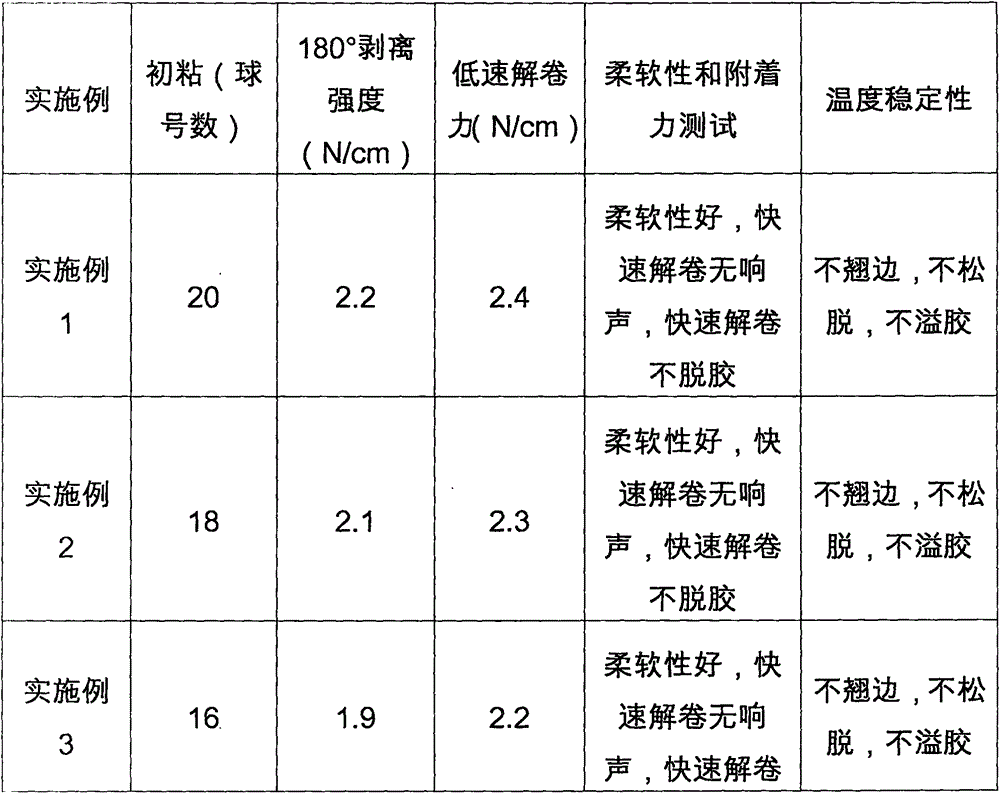

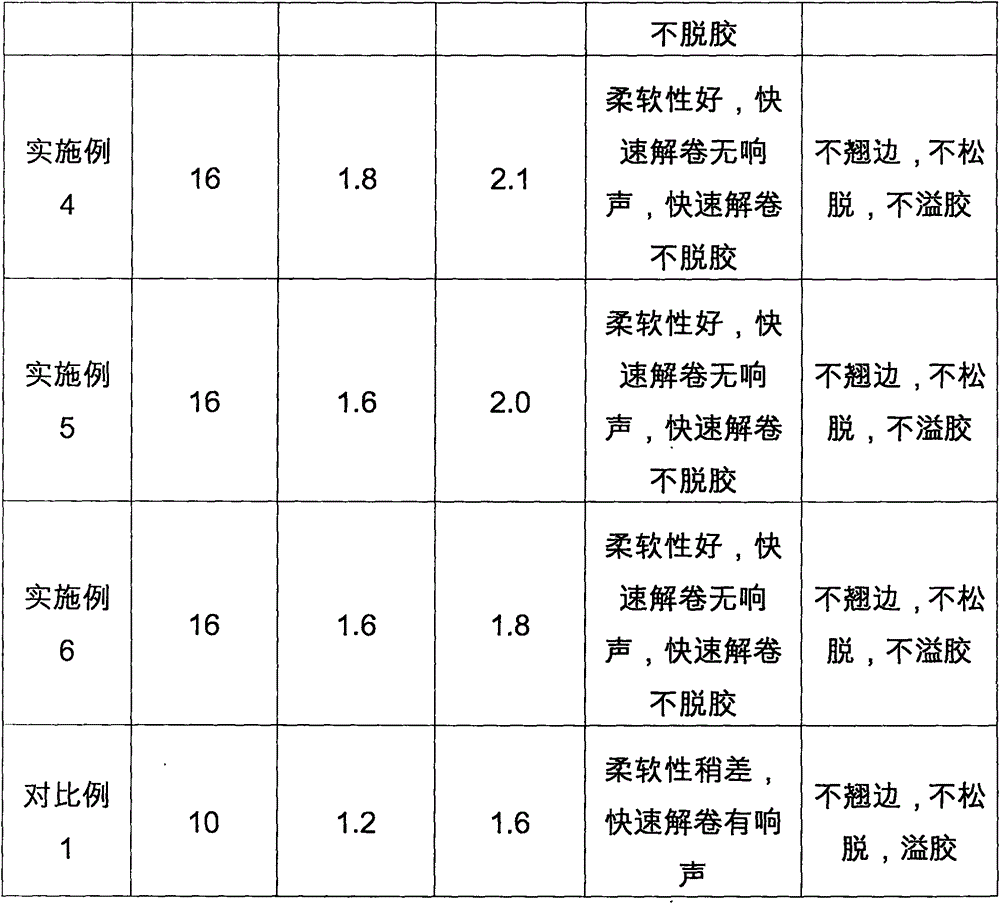

Examples

Embodiment 1

[0041] A preparation method for a polyvinyl chloride film suitable for hot-melt pressure-sensitive adhesive coating. In terms of parts by mass, 100 parts of polyvinyl chloride resin with a polymerization degree of 1000-2000, 40 parts of ethylene adipate Ester, 2 parts of barium zinc stabilizer, 10 parts of calcium carbonate are stirred and mixed uniformly by a mixer, the resulting mixture is mixed by an open mill, and the obtained compounded rubber is extruded by an extruder and then rolled into a film by a calender, and the calendering temperature is at 190°C to obtain a polyvinyl chloride film;

[0042] The obtained polyvinyl chloride film enters the first thickness control unit, the embossing roller, the cooling system, the second thickness control unit, and the winding system in sequence to obtain a polyvinyl chloride film suitable for hot-melt pressure-sensitive adhesive coating.

Embodiment 2

[0044] A preparation method for a polyvinyl chloride film suitable for hot-melt pressure-sensitive adhesive coating. In terms of parts by mass, 100 parts of polyvinyl chloride resin with a polymerization degree of 1000-2000, 60 parts of propylene glycol adipate, 6 parts of calcium-zinc stabilizer and 25 parts of kaolin are mixed evenly by a mixer, the resulting mixture is mixed by an open mill, and the obtained compounded rubber is extruded by an extruder and then rolled into a film by a calender, and the calendering temperature is 195°C , to obtain a polyvinyl chloride film;

[0045] The obtained polyvinyl chloride film enters the first thickness control unit, the embossing roller, the cooling system, the second thickness control unit, and the winding system in sequence to obtain a polyvinyl chloride film suitable for hot-melt pressure-sensitive adhesive coating.

Embodiment 3

[0047] A preparation method for a polyvinyl chloride film suitable for hot-melt pressure-sensitive adhesive coating, in terms of parts by mass, 100 parts of polyvinyl chloride resin with a degree of polymerization of 2000-3000, 45 parts of nitrile rubber powder, 3 1 part of organotin stabilizer, 12 parts of kaolin, 2 parts of green color masterbatch for PVC (manufacturer is Dongguan Hanling Plastic Co., Ltd.) are stirred and mixed evenly through a mixer, and the resulting mixture is mixed through an open mill to obtain a mixed rubber material. After being extruded by an extruder, it is calendered by a calender to form a film at a calendering temperature of 200°C to obtain a polyvinyl chloride film;

[0048] The obtained polyvinyl chloride film enters the first thickness control unit, the embossing roller, the cooling system, the second thickness control unit, and the winding system in sequence to obtain a polyvinyl chloride film suitable for hot-melt pressure-sensitive adhesive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com