Lithium ion battery diaphragm, preparation method and lithium ion battery

A technology for lithium batteries and diaphragms, which is applied in the field of preparation and diaphragms for lithium batteries. It can solve the problems of unresolved battery safety issues, aggravated battery thermal runaway, and inability to maintain the original form, so as to avoid continuous expansion of thermal runaway and facilitate large-scale industrialization. Production, low heat shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In the second aspect, in some embodiments, a method for preparing the above-mentioned separator for lithium batteries is provided, comprising the following steps:

[0048] (a) Coating the surface of the high molecular polymer membrane or the polytetrafluoroethylene microporous membrane with an adhesive, or soaking the high molecular polymer membrane or the polytetrafluoroethylene microporous membrane in the adhesive;

[0049] (b) Adhering the film with the adhesive on the surface to another film, compacting and drying to obtain the lithium battery separator.

[0050] The above method is simple, practical and easy to implement, that is, one of the sub-membranes is first coated with an adhesive or soaked in the adhesive, and then the film is adhered to the other sub-membrane, compacted and then dried to obtain the obtained product. The separator for the lithium battery described above, and the prepared separator has the advantages of good safety performance, excellent ele...

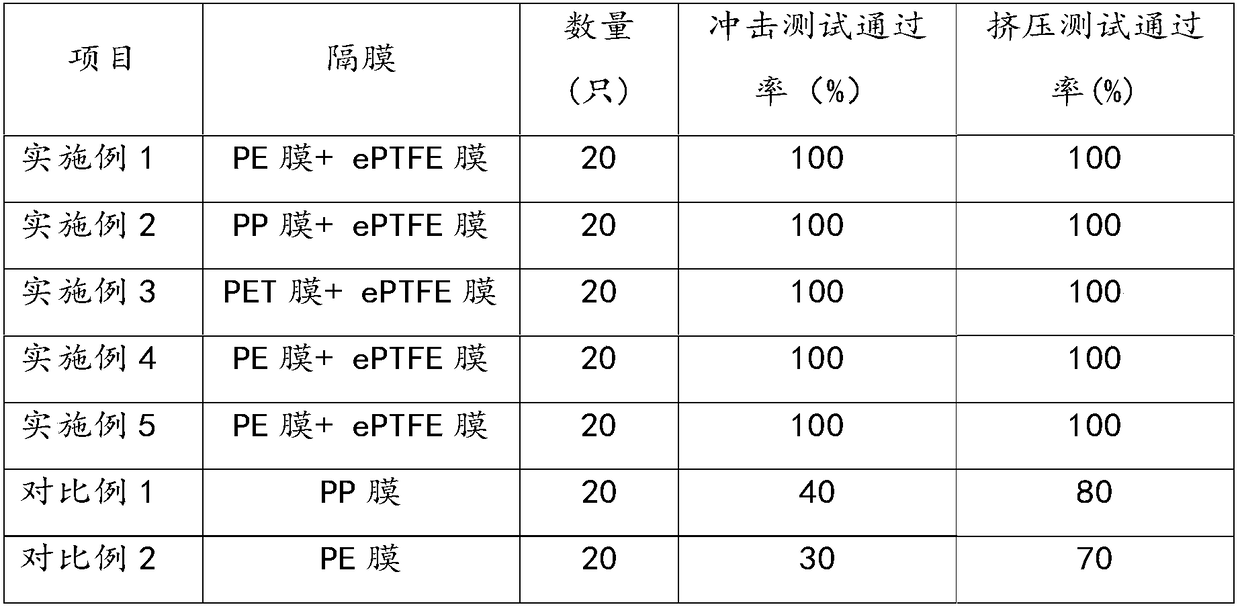

Embodiment 1

[0070] A diaphragm for a lithium battery has a double-layer film structure, including a high molecular polymer film and a polytetrafluoroethylene microporous film, and an adhesive is coated between the high molecular polymer film and the polytetrafluoroethylene microporous film.

[0071] Wherein, the polymer film is PE film, the polytetrafluoroethylene microporous film is ePTFE film, and the binder is PVDF-HFP solution.

[0072] The preparation method of described diaphragm for lithium battery comprises the following steps:

[0073] (a) Soak the polytetrafluoroethylene microporous membrane in ethanol, take it out after soaking for 5 minutes, then soak it in the PVDF-HFP solution with a mass percentage content of 2%, take it out after soaking for 30 minutes;

[0074] (b) Paste the soaked ePTFE membrane directly on the PE membrane;

[0075] (c) After being compacted, vacuum-dry at 60° C. for 30 minutes, and take out after complete drying to obtain a separator for lithium batter...

Embodiment 2

[0077] A diaphragm for a lithium battery has a double-layer film structure, including a high molecular polymer film and a polytetrafluoroethylene microporous film, and an adhesive is coated between the high molecular polymer film and the polytetrafluoroethylene microporous film.

[0078] Wherein, the polymer film is PP film, the polytetrafluoroethylene microporous film is ePTFE film, and the binder is PVDF-HFP solution.

[0079] The difference between this embodiment and embodiment 1 is that the PE film is replaced by a PP film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com