Oven with bent rail

A technology of curved rails and ovens, applied in general parts of printing machinery, printing, printing machines, etc., can solve problems such as no prevention, and achieve the effect of reducing internal stress concentration, reducing heat shrinkage, and correcting warpage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and embodiments.

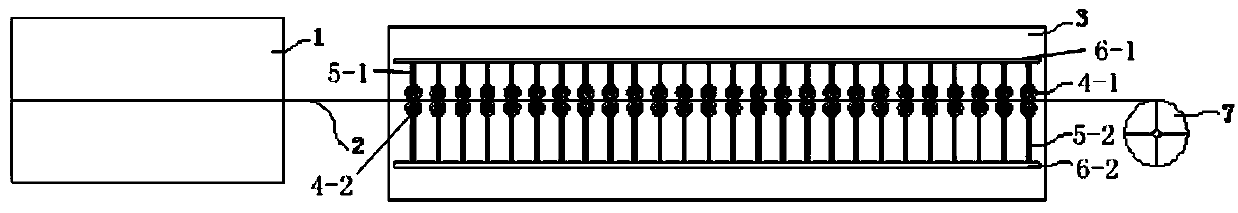

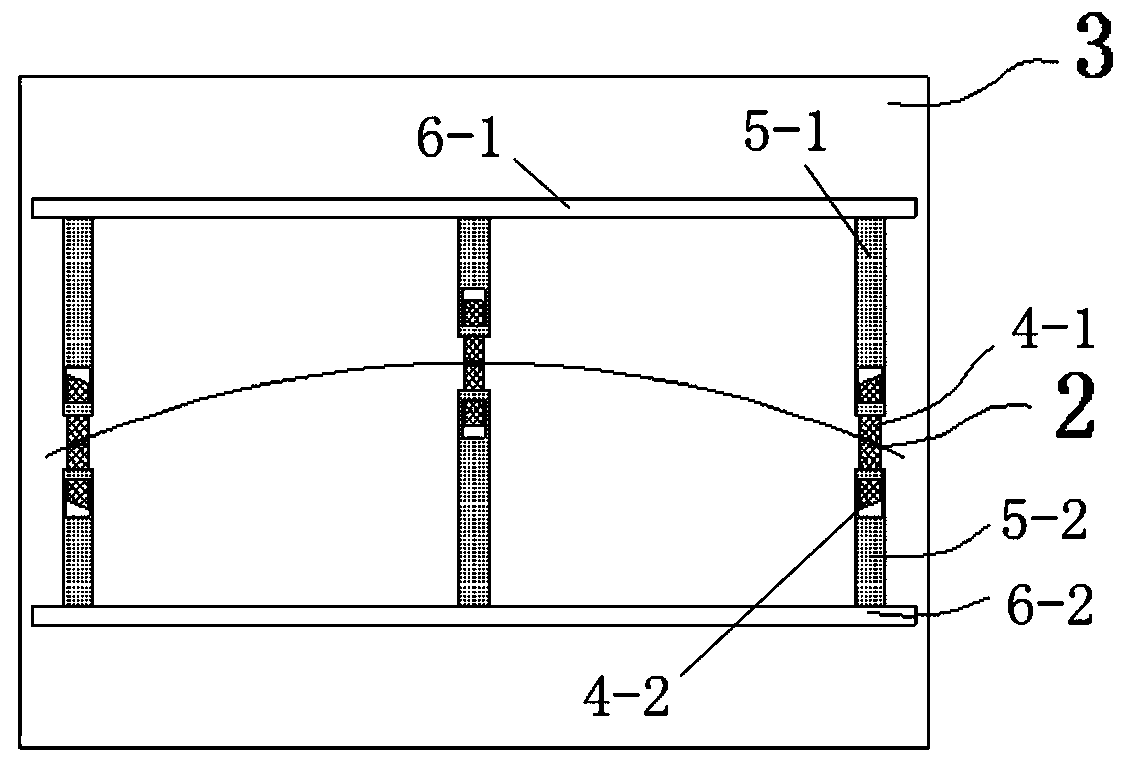

[0014] like figure 1 and figure 2 As shown, a kind of oven with curved track, the interior of oven 3 is provided with upper roller bracket fixing plate 6-1 and lower roller bracket fixing plate 6-2 arranged up and down oppositely, described upper roller bracket fixing plate 6- The lower side of 1 is provided with several rows of symmetrically arranged upper roller brackets 5-1 along the direction of the inlet and outlet of the oven 3, and the extension length of the upper roller brackets 5-1 is set incrementally from the middle row to the two sides rows, that is, by the oven 3 Viewed from the direction of the entrance and exit, several rows of upper roller brackets 5-1 are arranged in a concave arch shape in the middle; the upper side of the lower roller bracket fixing plate 6-2 is arranged symmetrically with the upper roller brackets along the direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com