Patents

Literature

44results about How to "Correct warping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

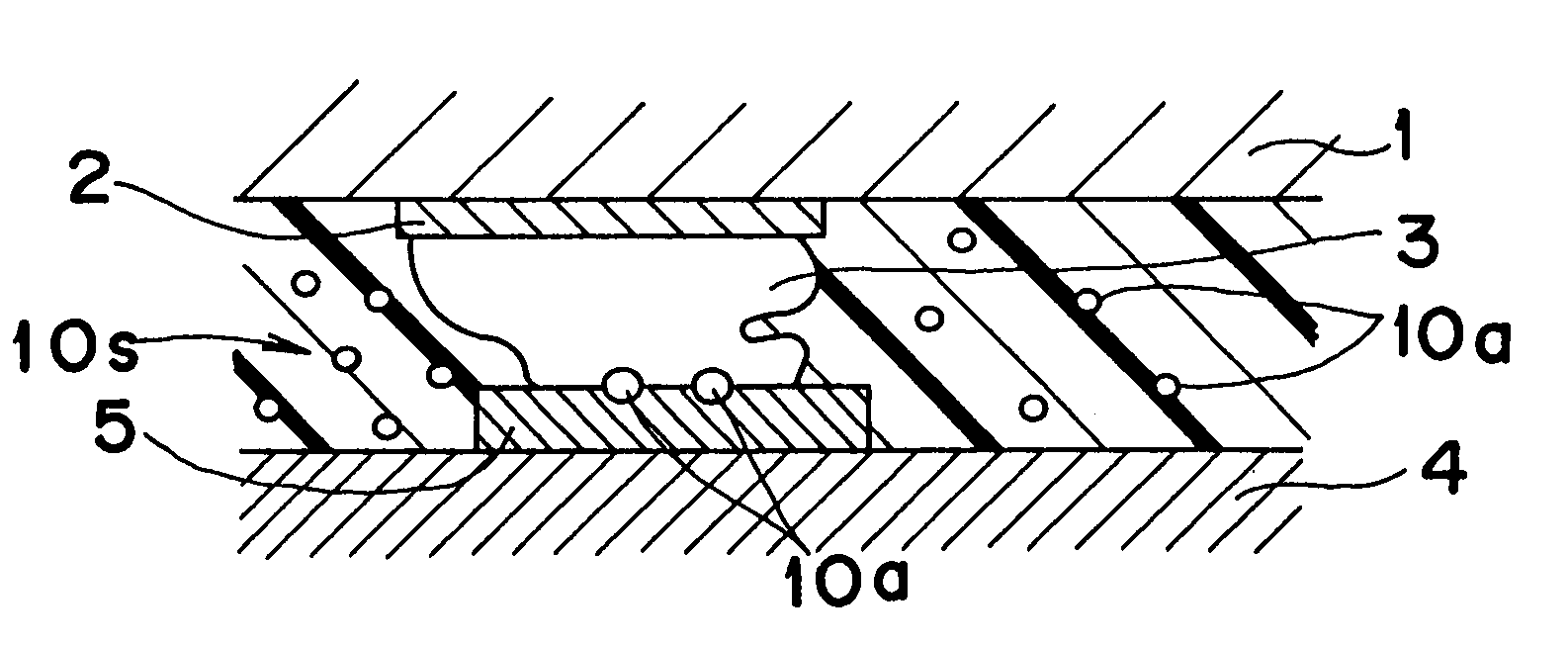

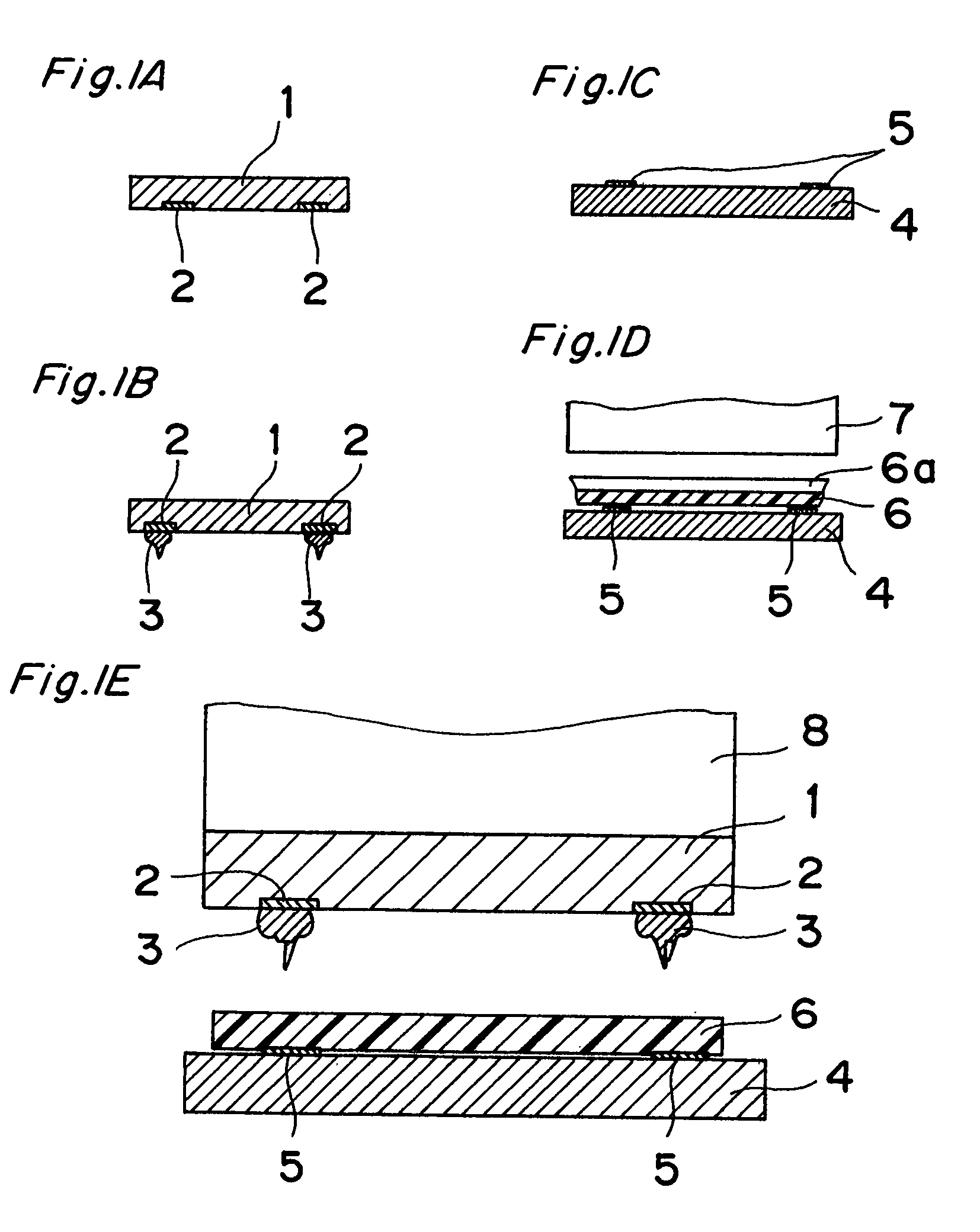

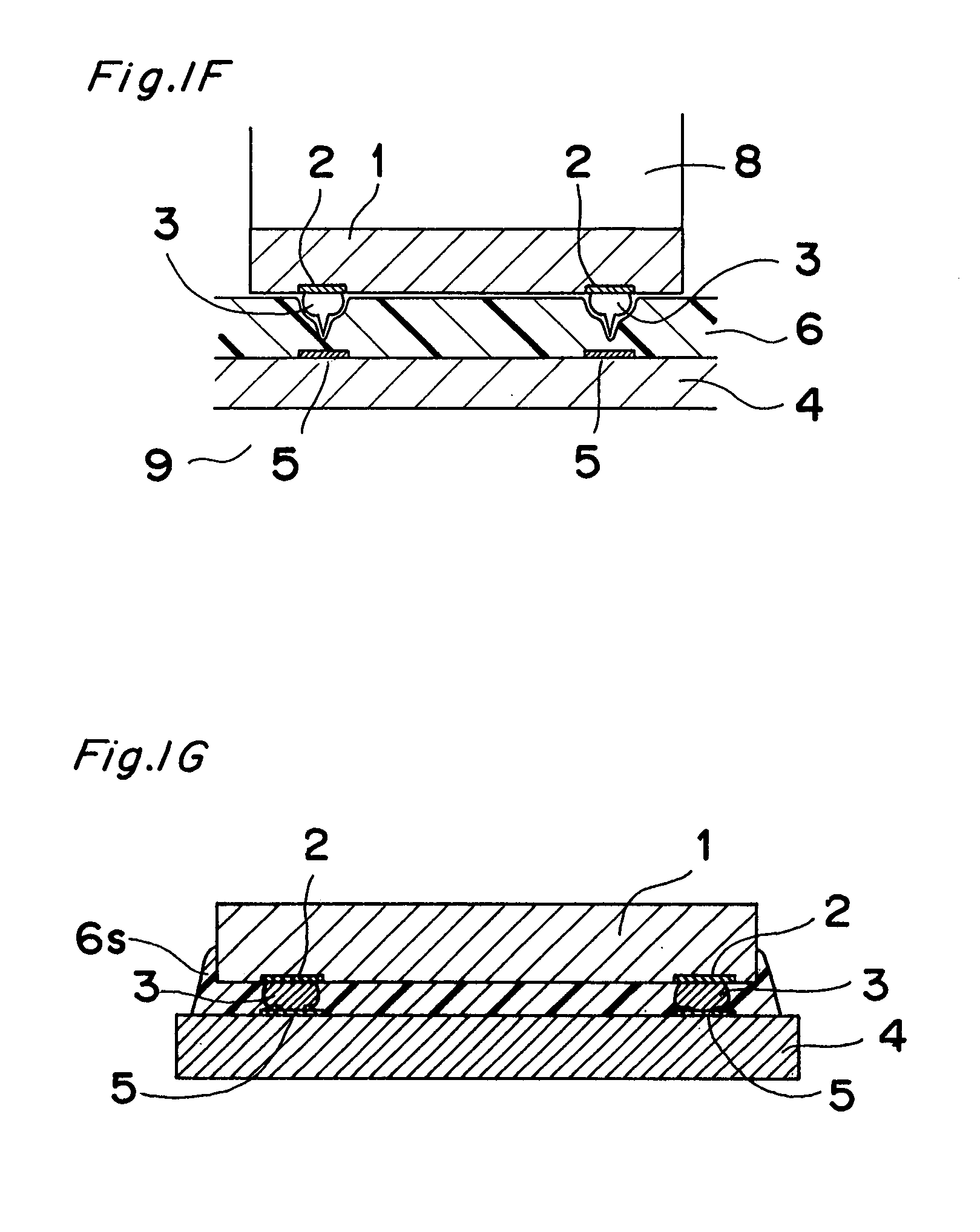

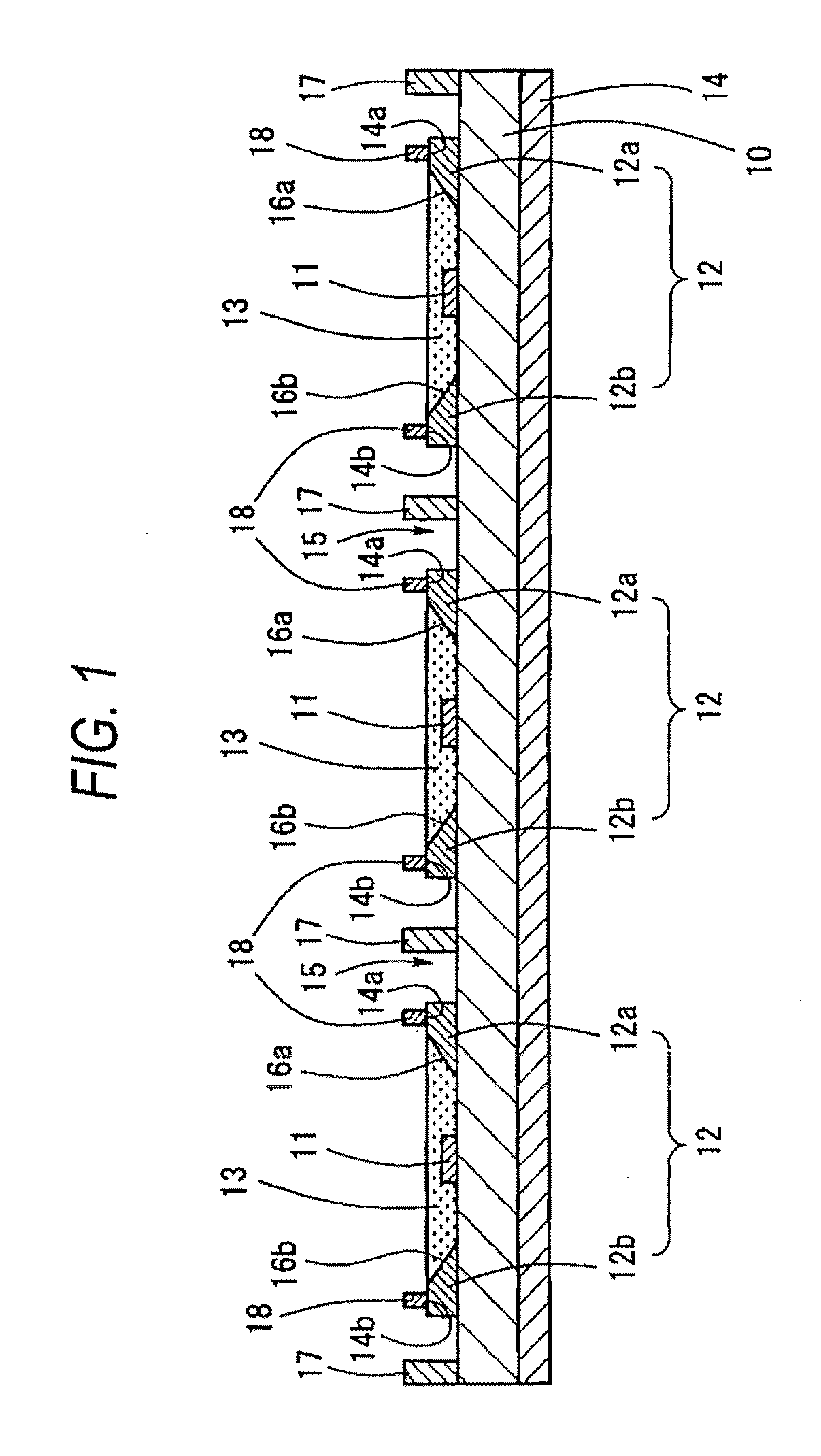

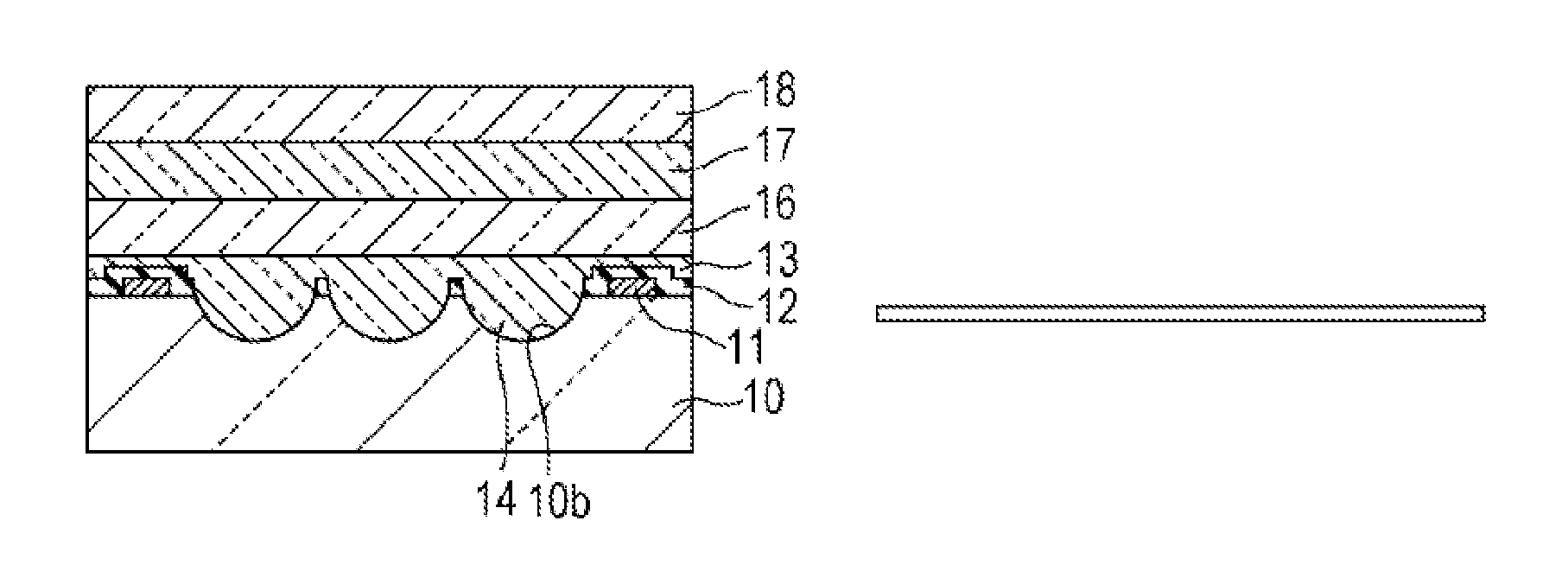

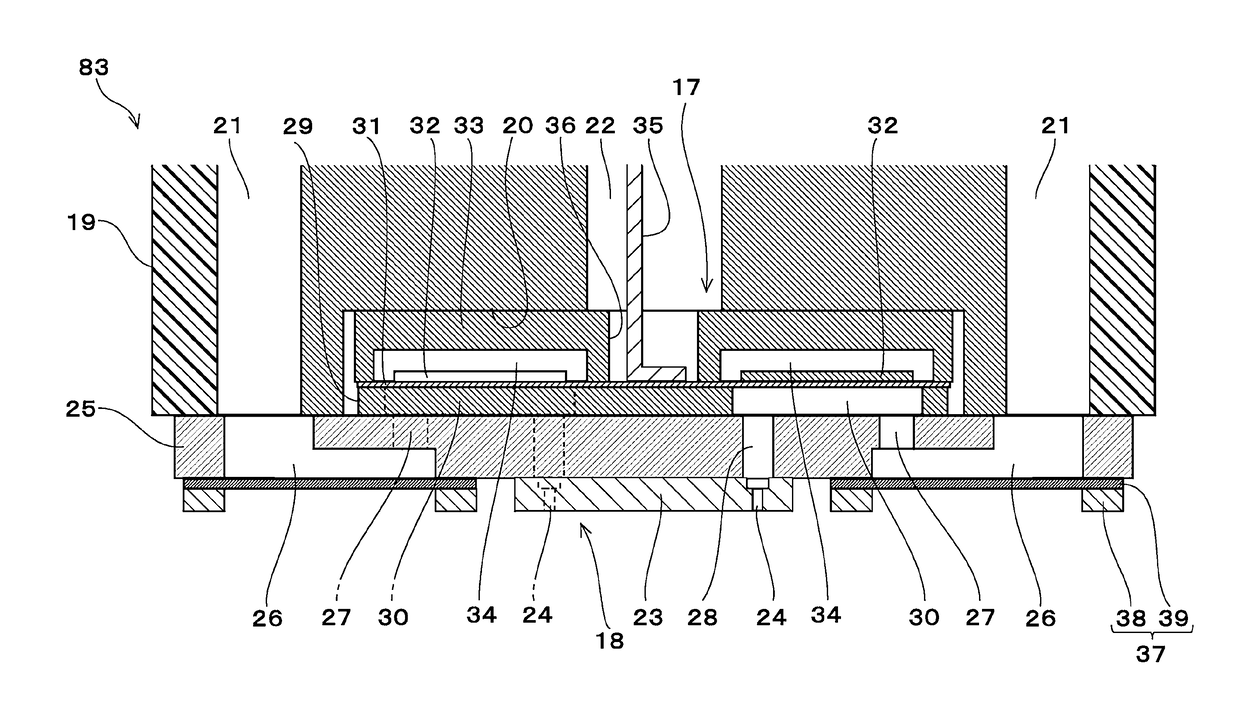

Method and device for mounting electronic component on circuit board

InactiveUS6981317B1Correct warpingPrinted circuit assemblingSemiconductor/solid-state device detailsElectronic componentElectrode

When mounting an IC chip on a circuit board, bumps are formed on electrodes of the IC chip, and the bumps and the electrodes of the circuit board are aligned in position with each other with interposition of an insulative thermosetting resin having no conductive particle between the electrodes of the circuit board and the bumps. The IC chip is pressed against the circuit board with a pressure force of not smaller than 20 gf per bump by a heated head so as to perform warp correction of the IC chip and the board, while the resin interposed between the IC chip and the circuit board is hardened to bond the IC chip and the circuit board together.

Owner:PANASONIC CORP

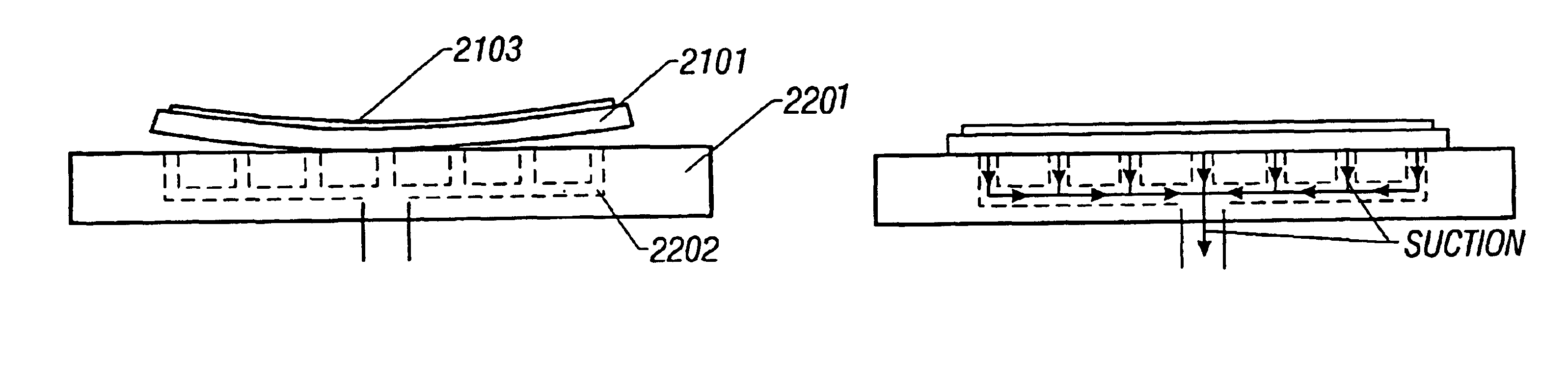

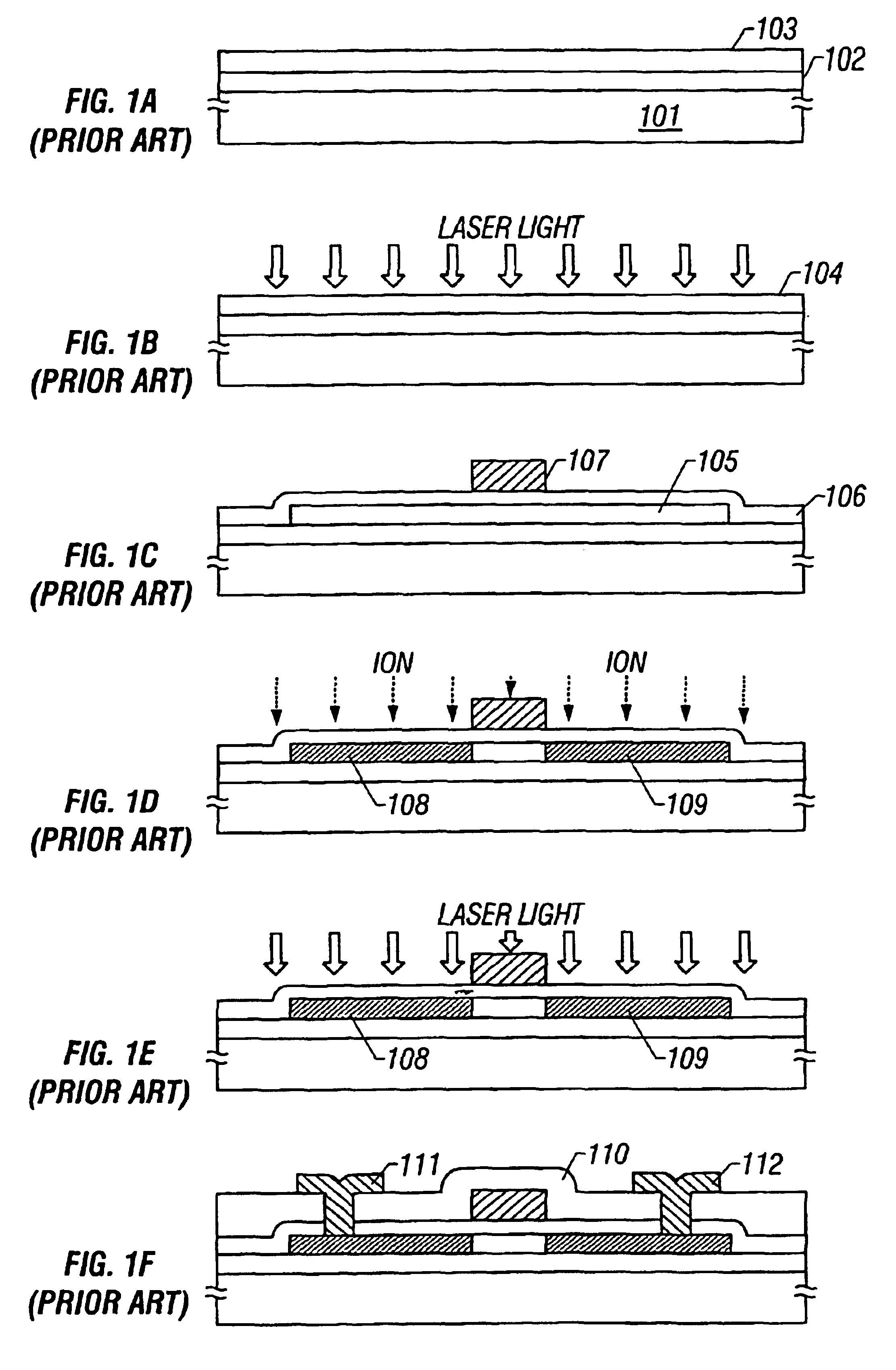

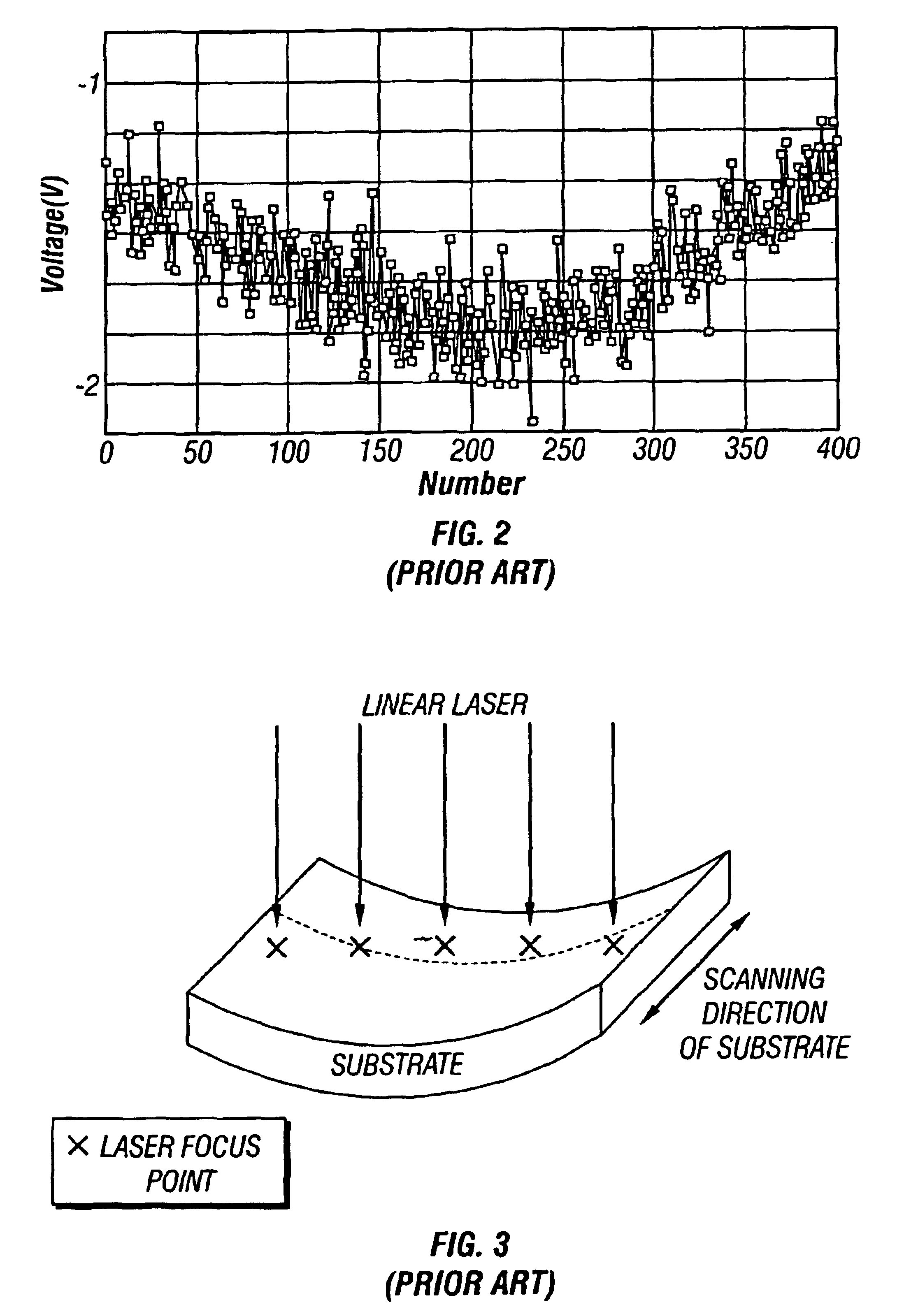

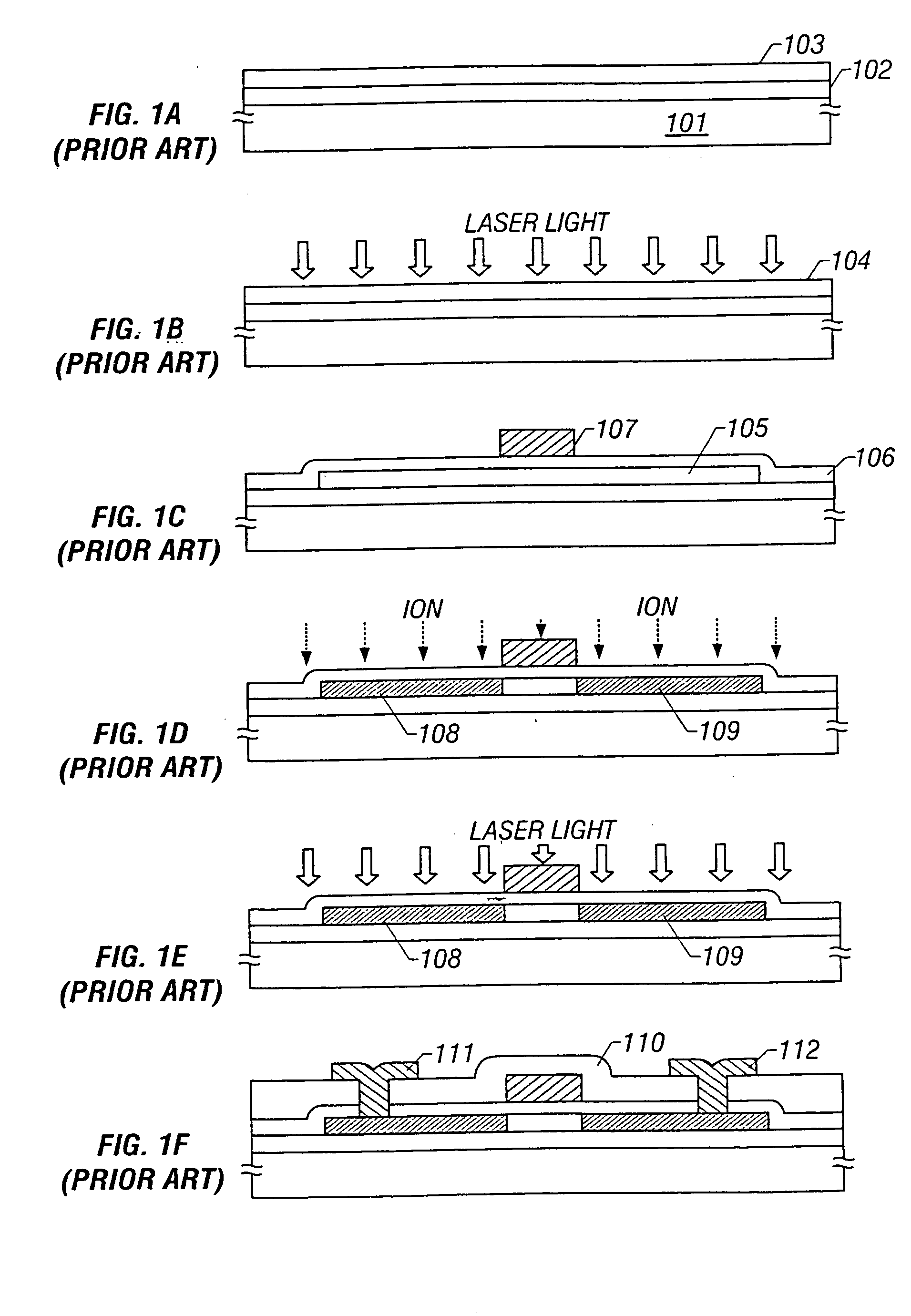

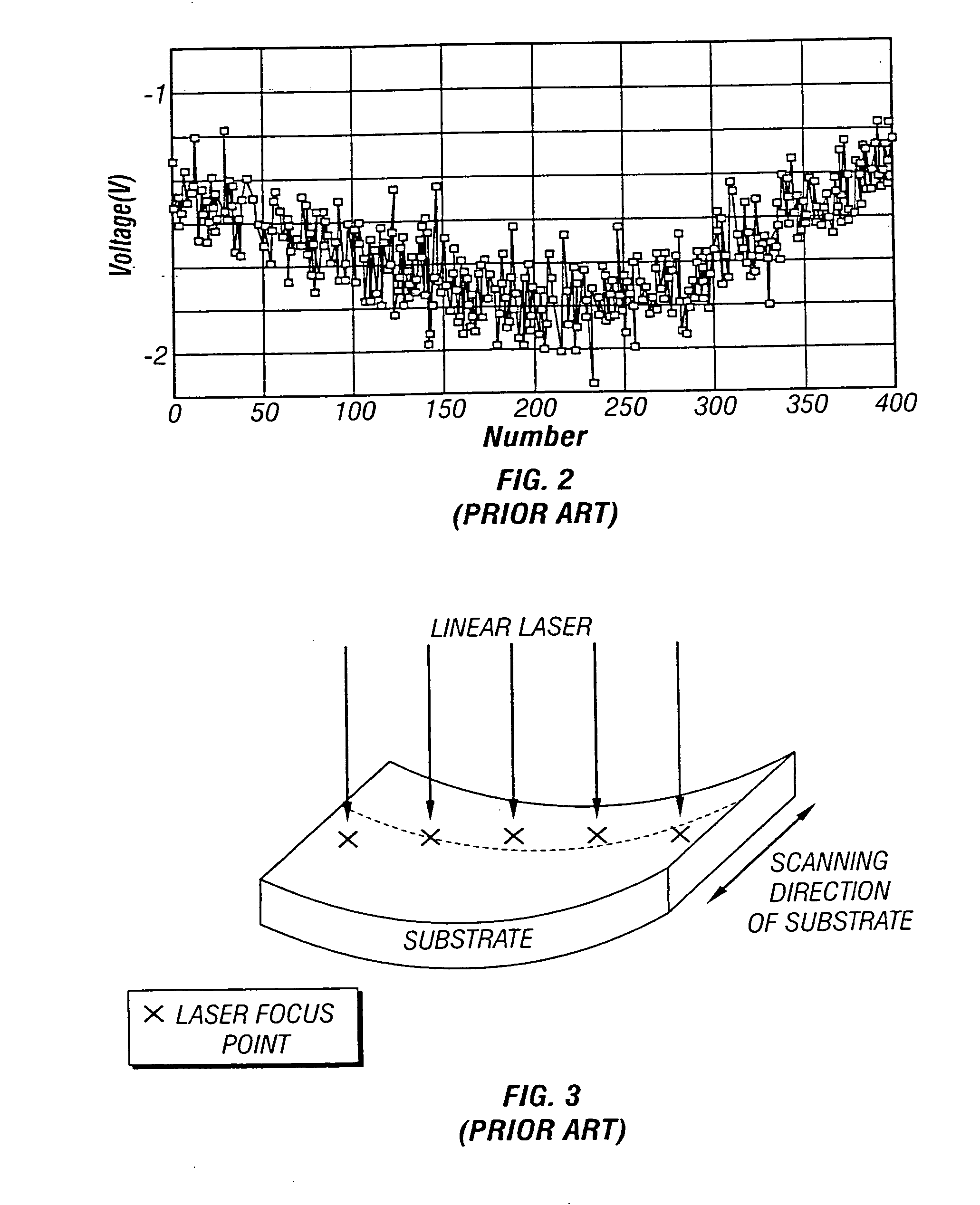

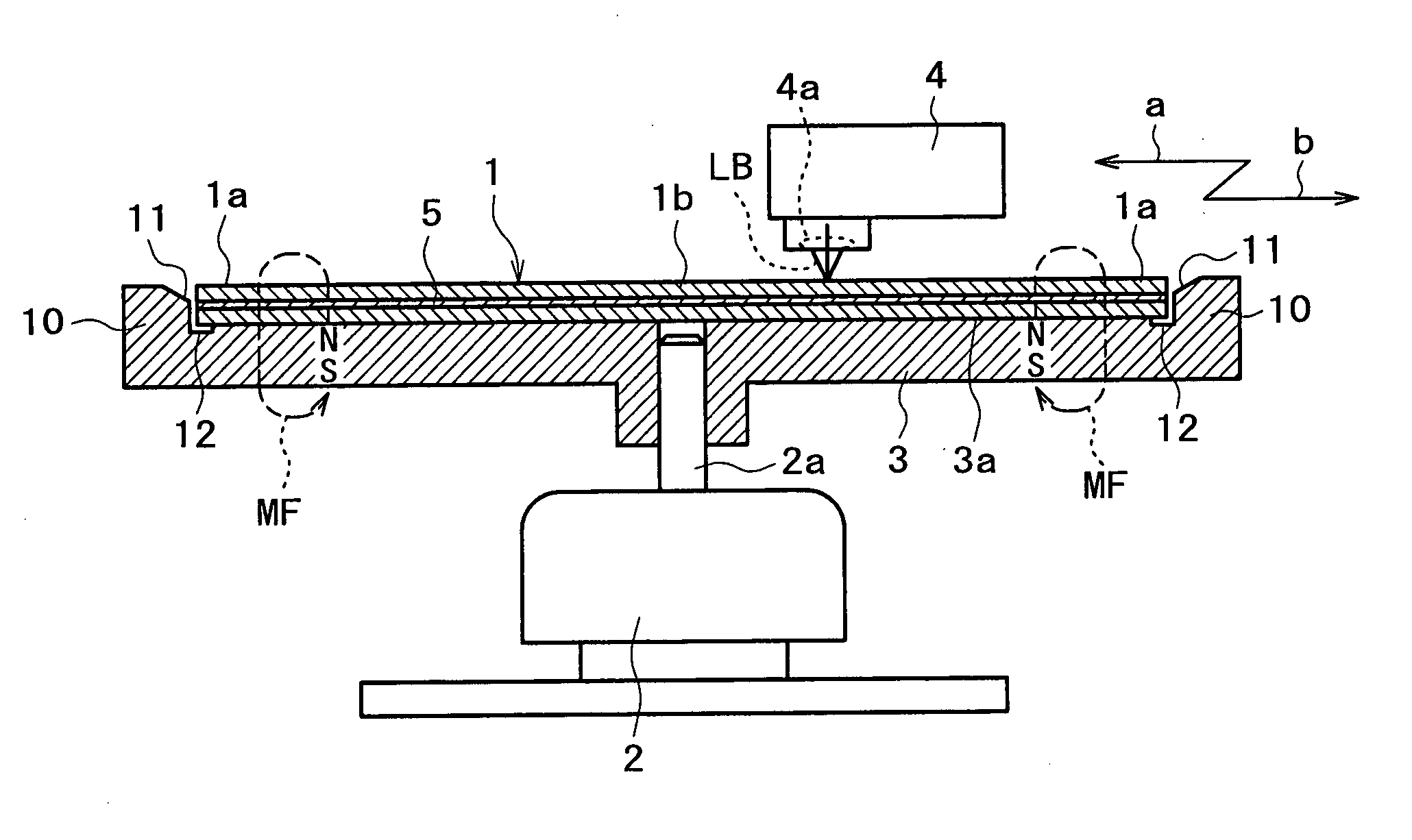

Method and apparatus for producing semiconductor device

InactiveUS6902616B1Correct warpingGood effectFrom gel statePolycrystalline material growthLiquid-crystal displayCrystallinity

A liquid crystal display device is manufactured by first forming a crystalline semiconductor film 2103, of silicon for example, over an insulating substrate 2101, such as glass. The substrate is warped in the process. The warpage is corrected by suction against a stage 2201. The film crystallinity is enhanced by scanning with a linear laser beam.

Owner:SEMICON ENERGY LAB CO LTD

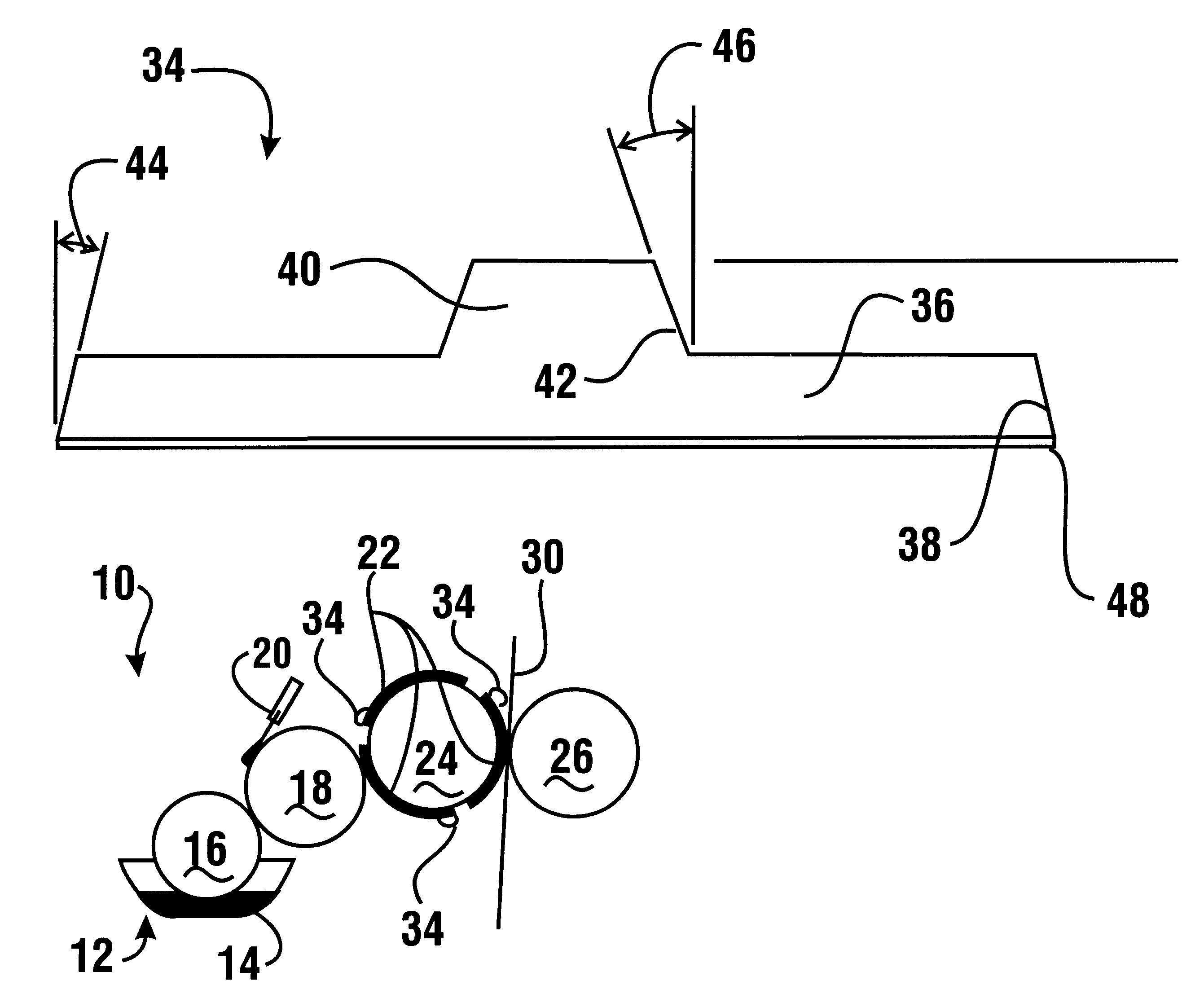

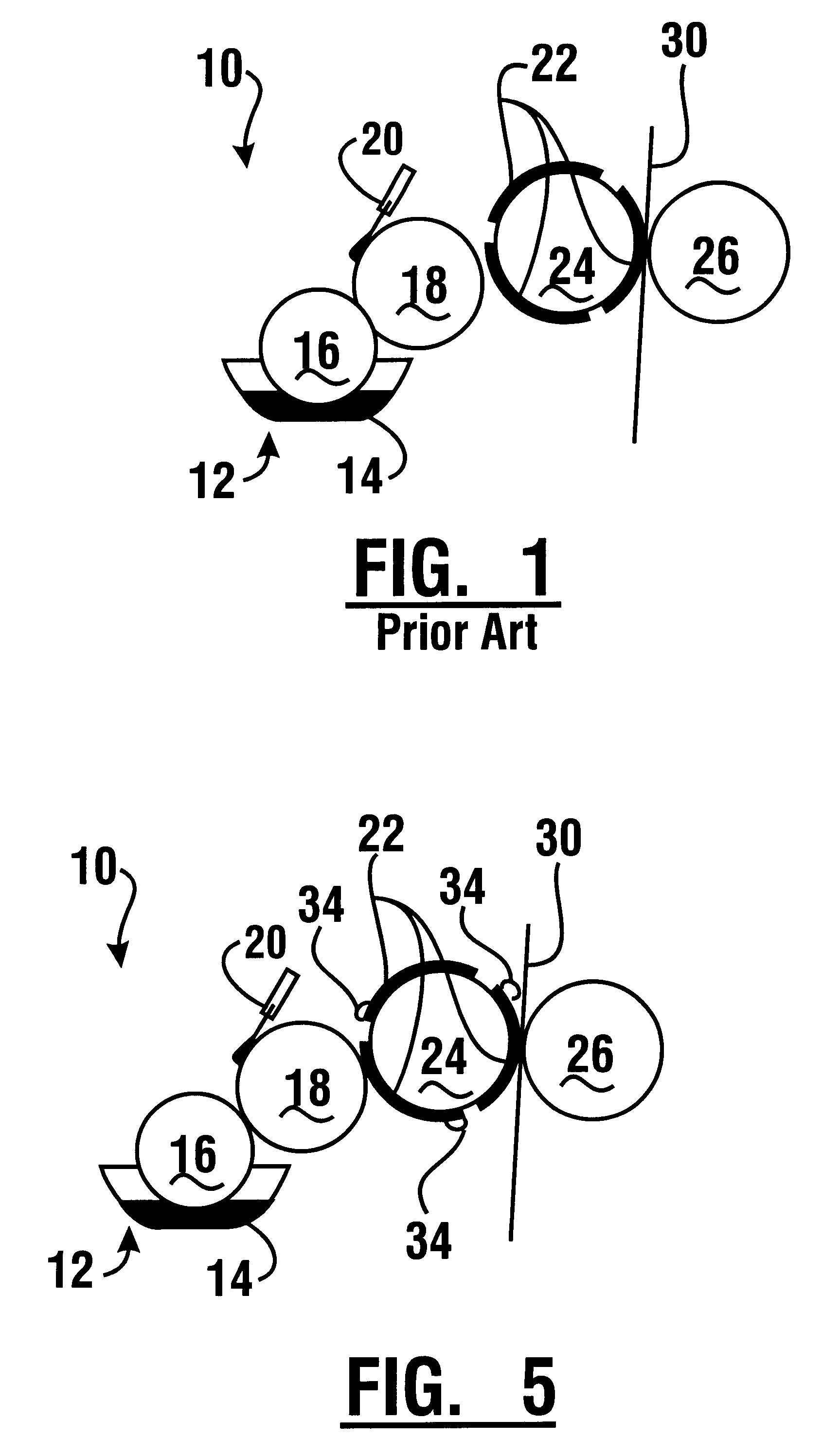

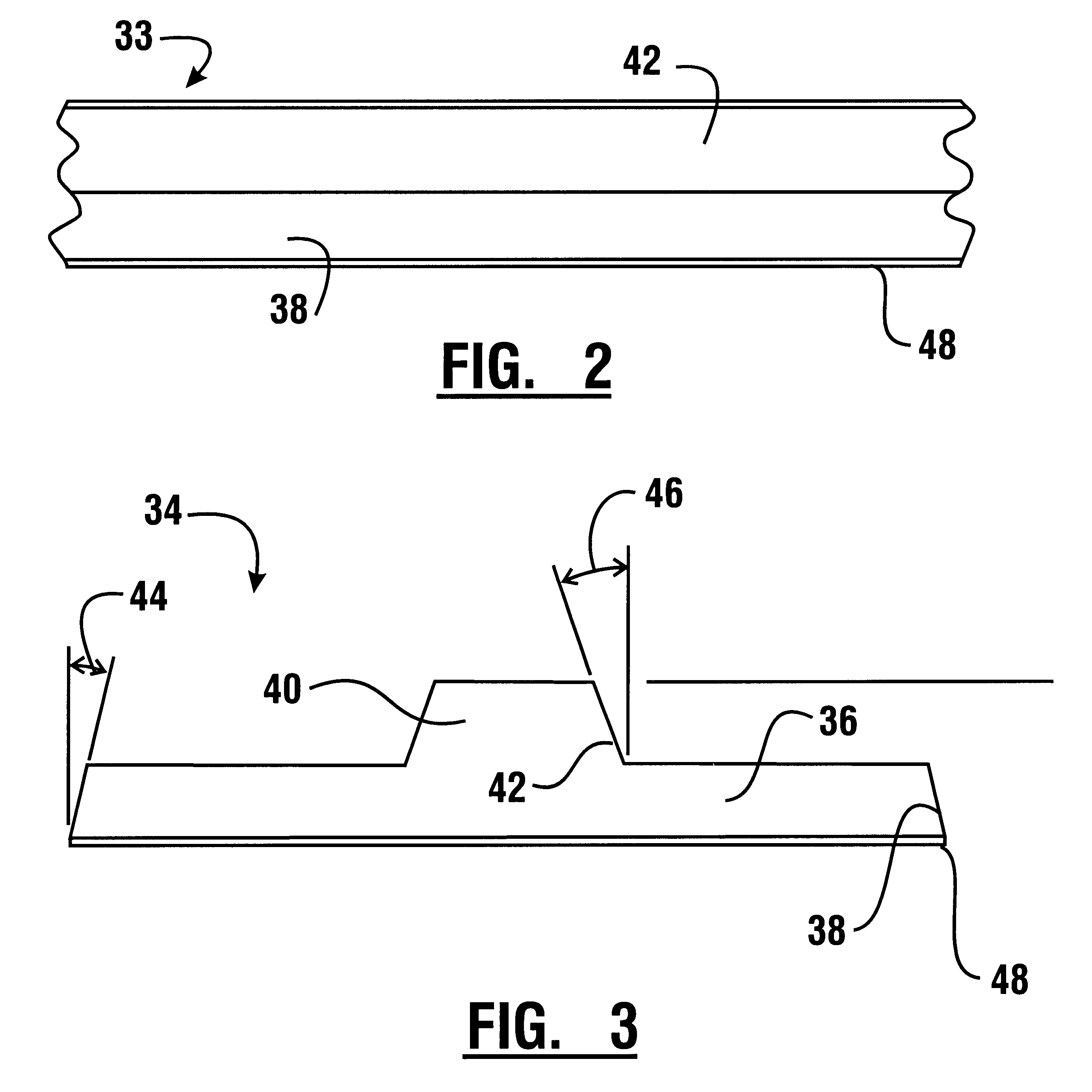

Flexographic printing apparatus and method

A pull band (34) is attached to a printing plate (22) in a flexographic printing operation to hold a flexible substrate (30) in a selected orientation for transfer of ink in a selected pattern. The pull band overcomes differences in friction between the printing plate and the substrate in areas of different amounts of ink to maintain the selected orientation. A specific length pull band may be selected and cut from a roll of pull band material. Pull bands may be attached parallel and perpendicular to the direction of rotation of the printing plate.

Owner:FEESLER DOUGLAS W

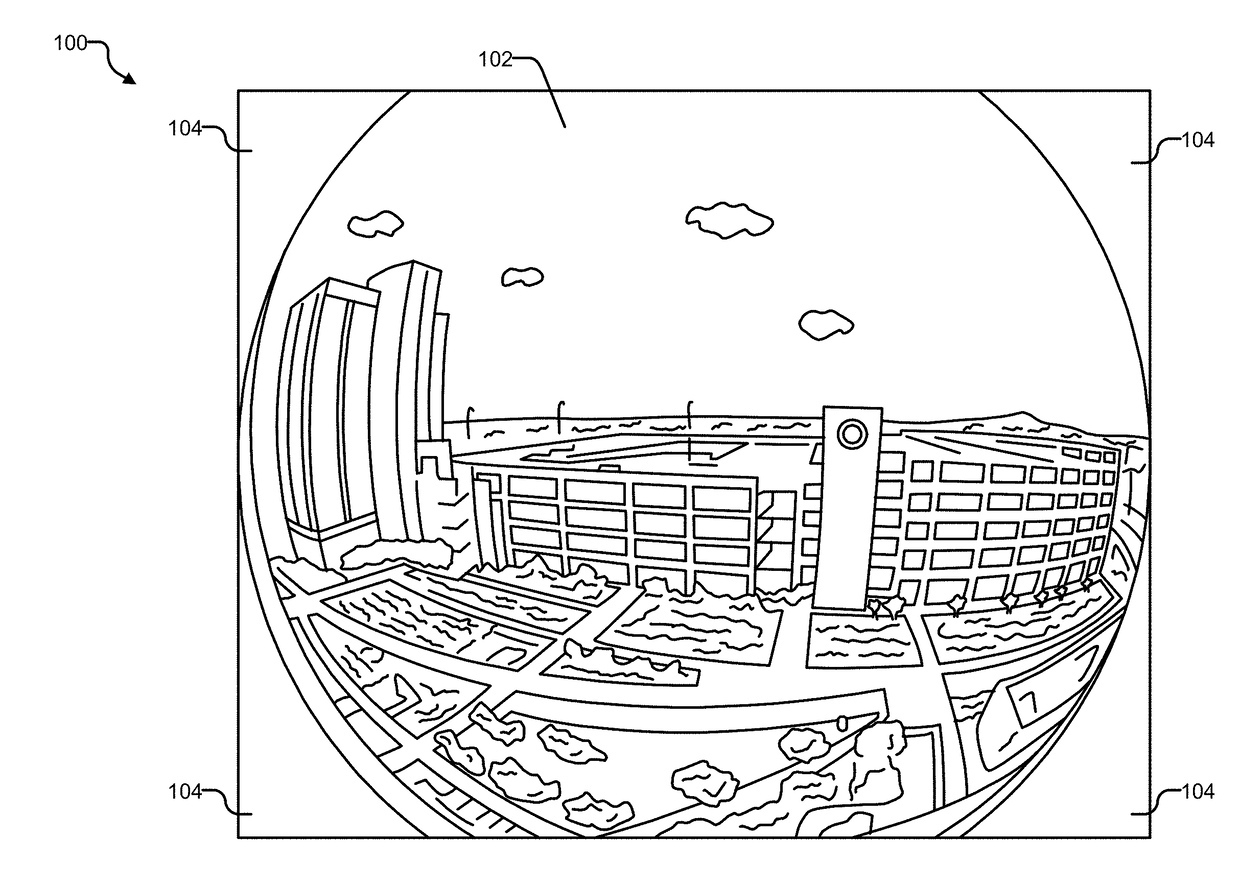

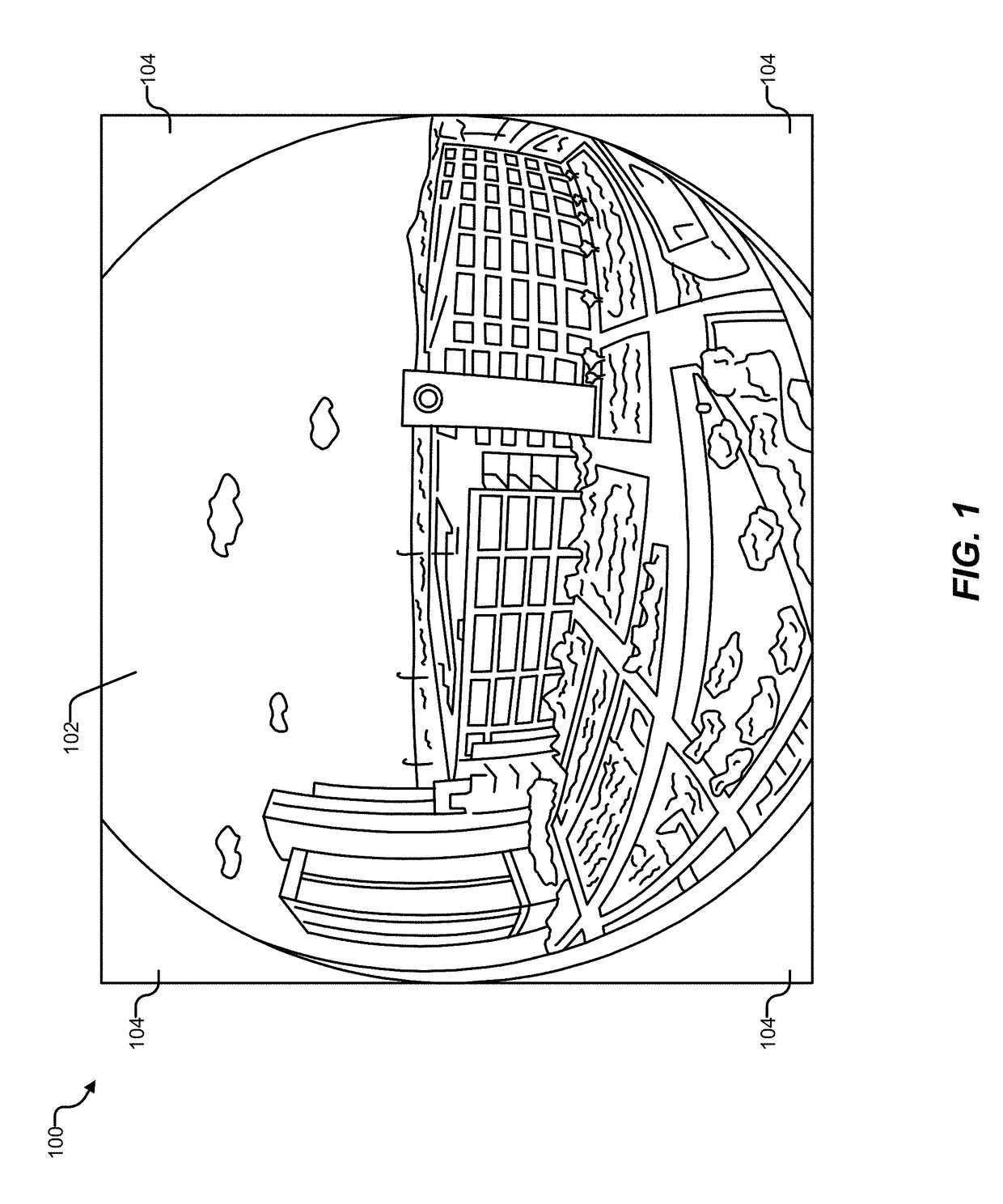

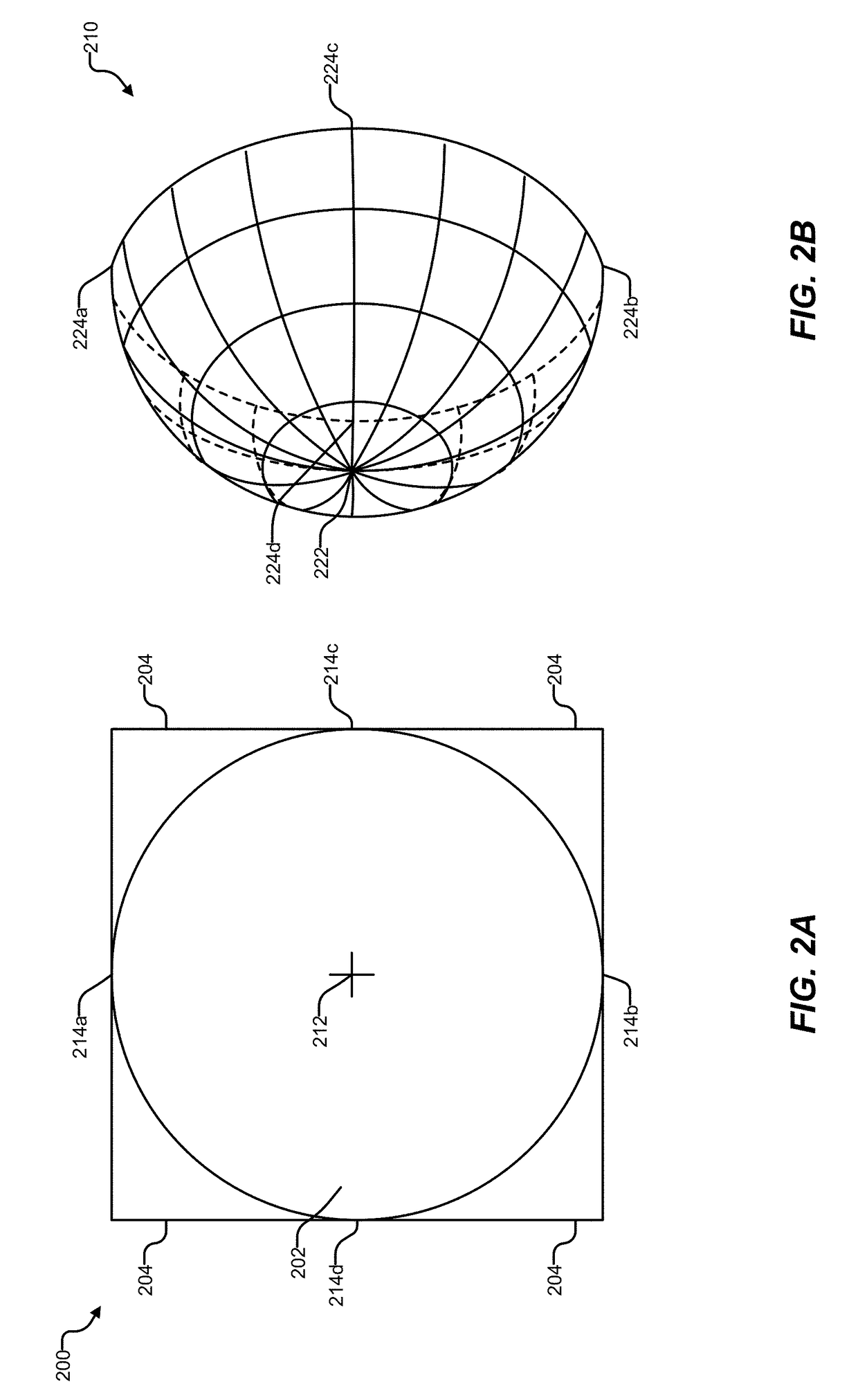

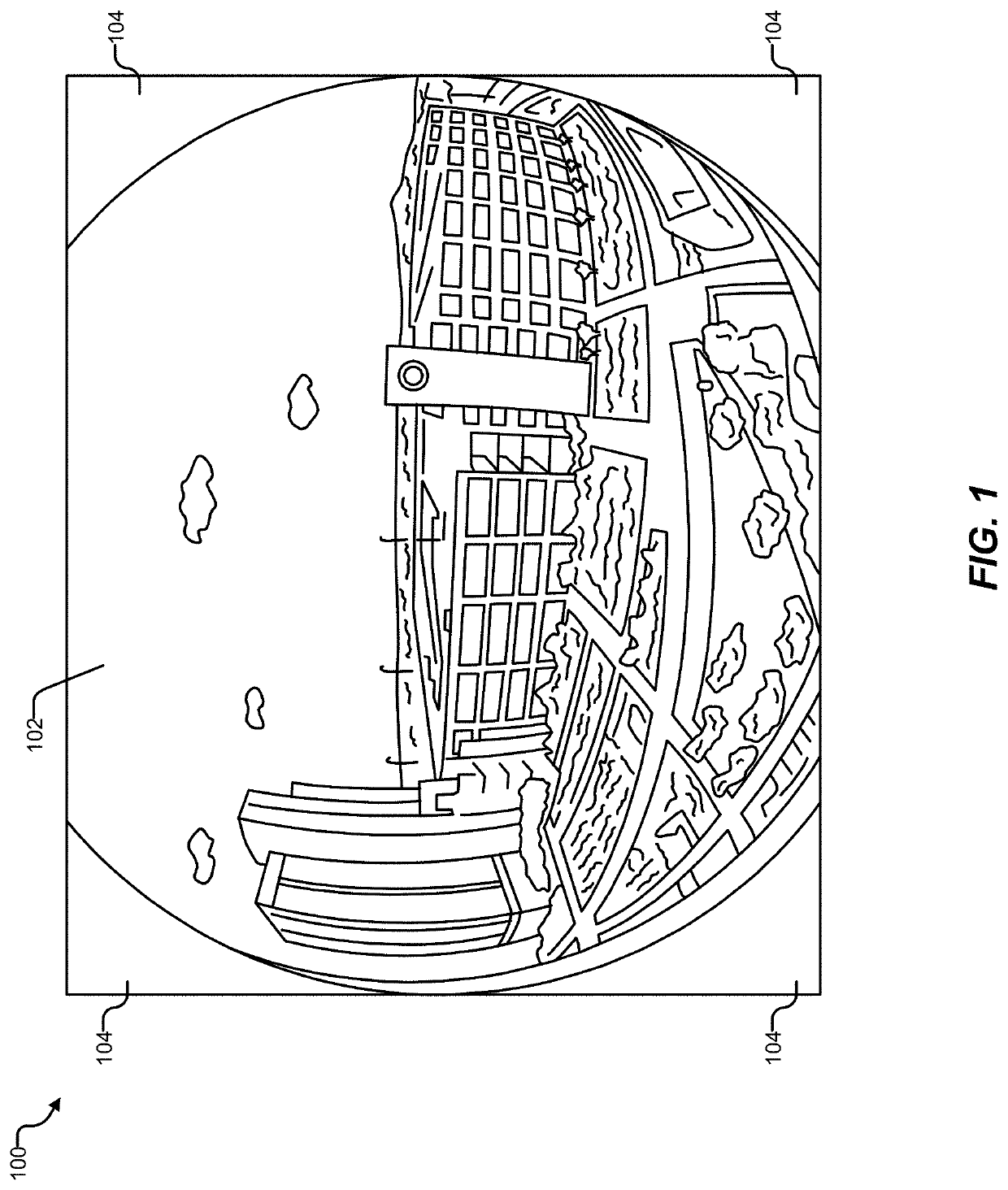

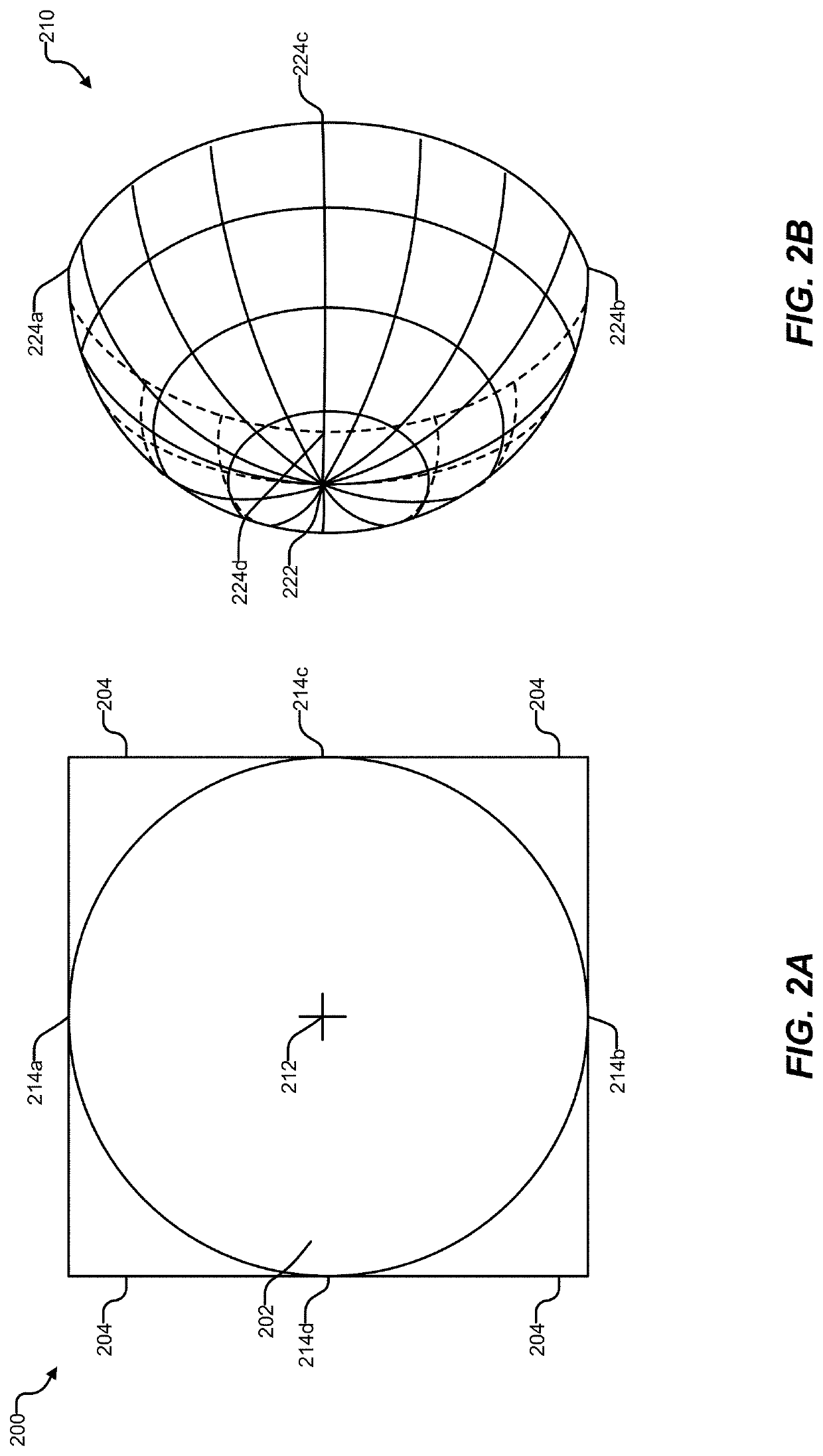

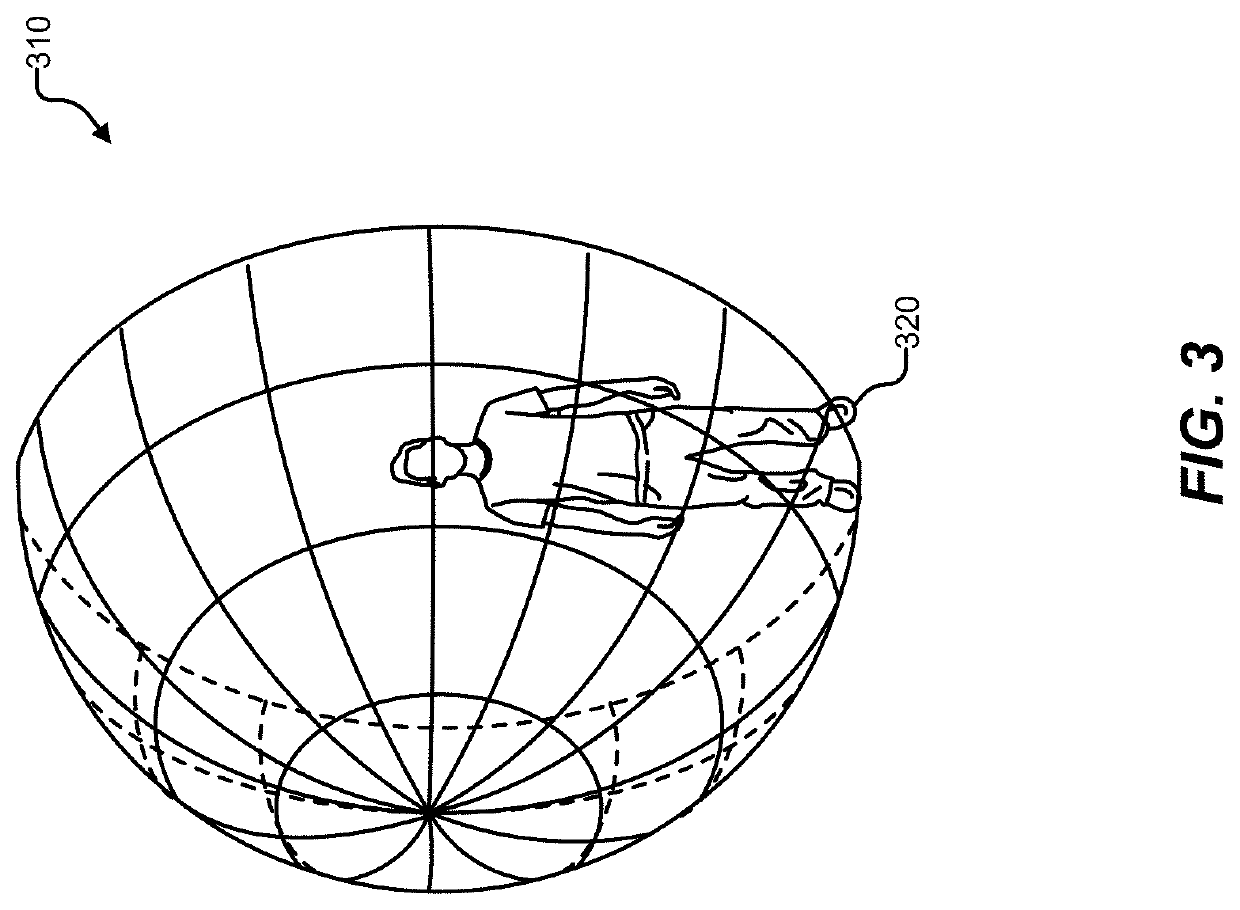

Fisheye rendering with lens distortion correction for 360-degree video

ActiveUS20170345136A1Correct warpingImage enhancementTelevision system detailsComputer graphics (images)Omnidirectional camera

In various implementations, provided are systems and methods for correcting the distortion present in a fisheye image, and rendering the image for display as 360-degree video. In various implementations, a computing device can receive 2-dimensional video data captured by an omnidirectional camera. The computing device can map an image from each video frame to a 3-dimensional hemispherical representation. In various implementations, this mapping can be executed using a polynomial model. The 3-dimensional hemispherical representation can then be used in a 360-degree video presentation, to provide a virtual reality experience.

Owner:QUALCOMM INC

Fabrication method for microlens array substrate

ActiveUS20140116986A1Reduce stressImprove stressOptical articlesNon-linear opticsEtching rateOptical path length

A microlens substrate will warp when an oxide film is formed and annealed before forming a mask in order to adjust the etching rate of wet etching. Accordingly, a film exerting a stress that cancels out this warping is formed upon a microlens. This film functions as an optical path length adjusting layer.

Owner:SEIKO EPSON CORP

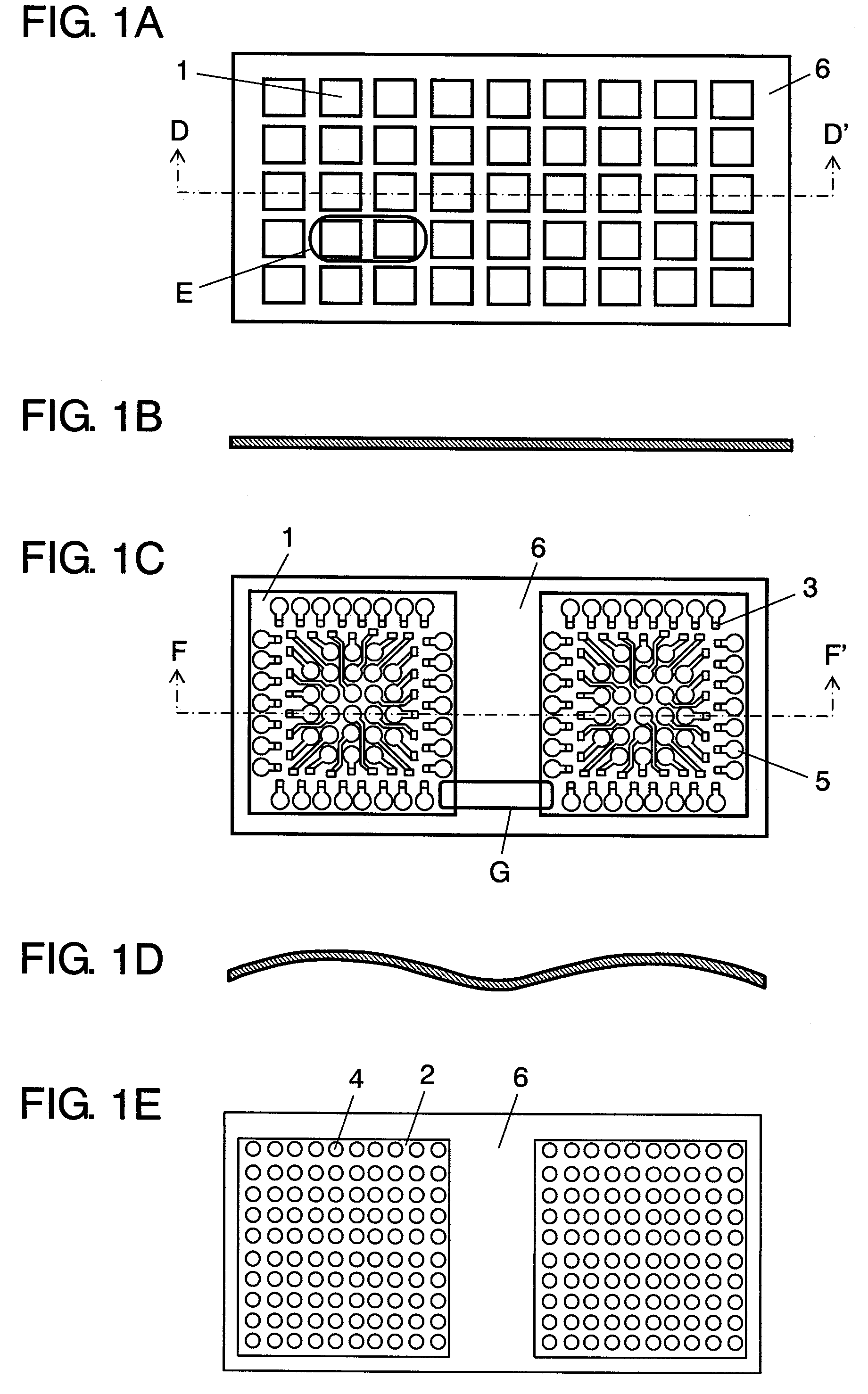

Wiring board, method for manufacturing same and semiconductor device

InactiveUS20090133915A1Reduce residual stressCorrect warpingSemiconductor/solid-state device detailsSolid-state devicesEngineeringProtection layer

A wiring board which includes a product portion configured with at least one layer of electrically insulating base, a wiring pattern formed on the surface or inner portion of the electrically insulating base, and a wiring protection layer which is formed on the surface of the board and has an opening. Warping over the entire wiring board can be reduced since this wiring board has a warp-correcting portion warped in a direction different from that of the product portion.

Owner:PANASONIC CORP

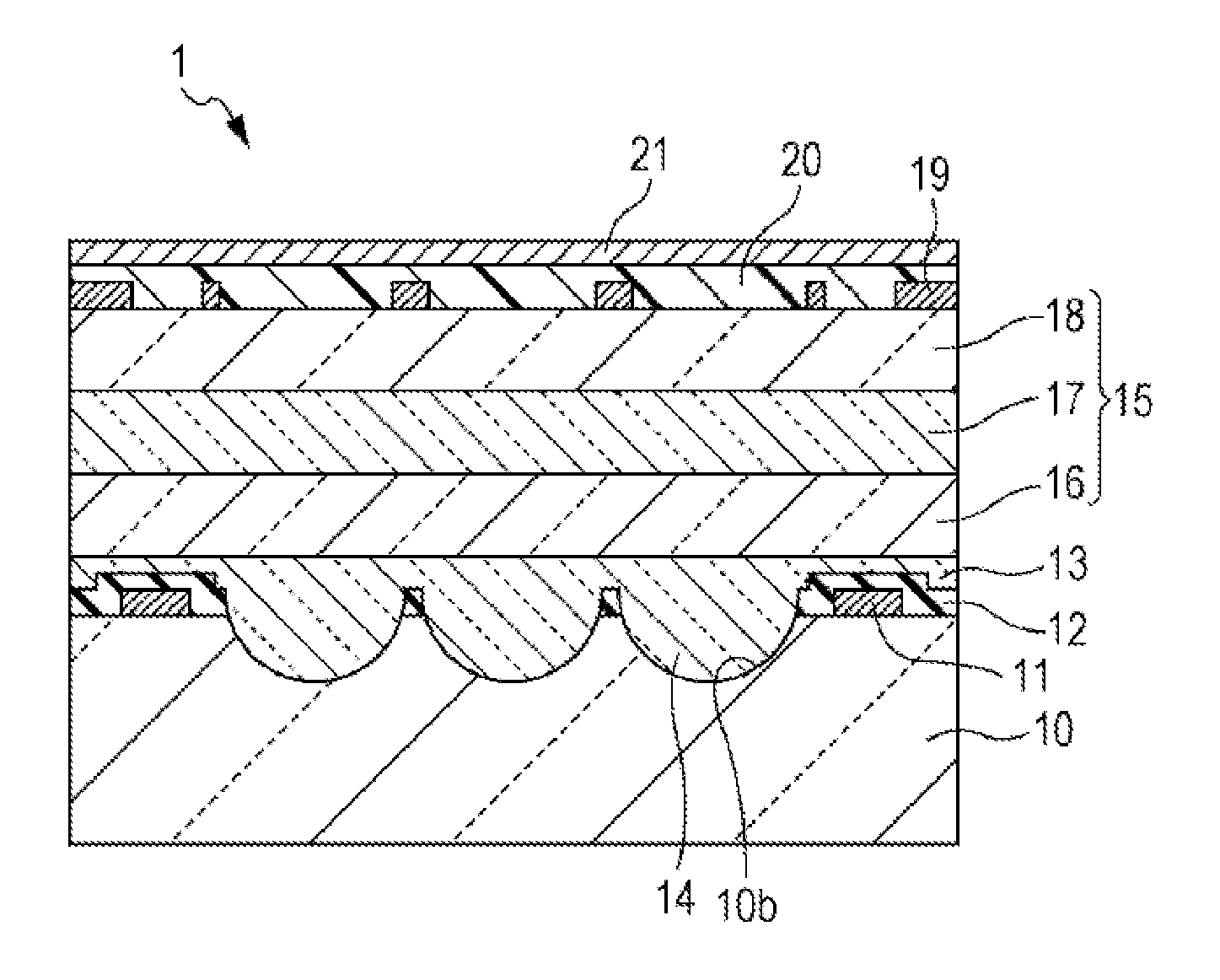

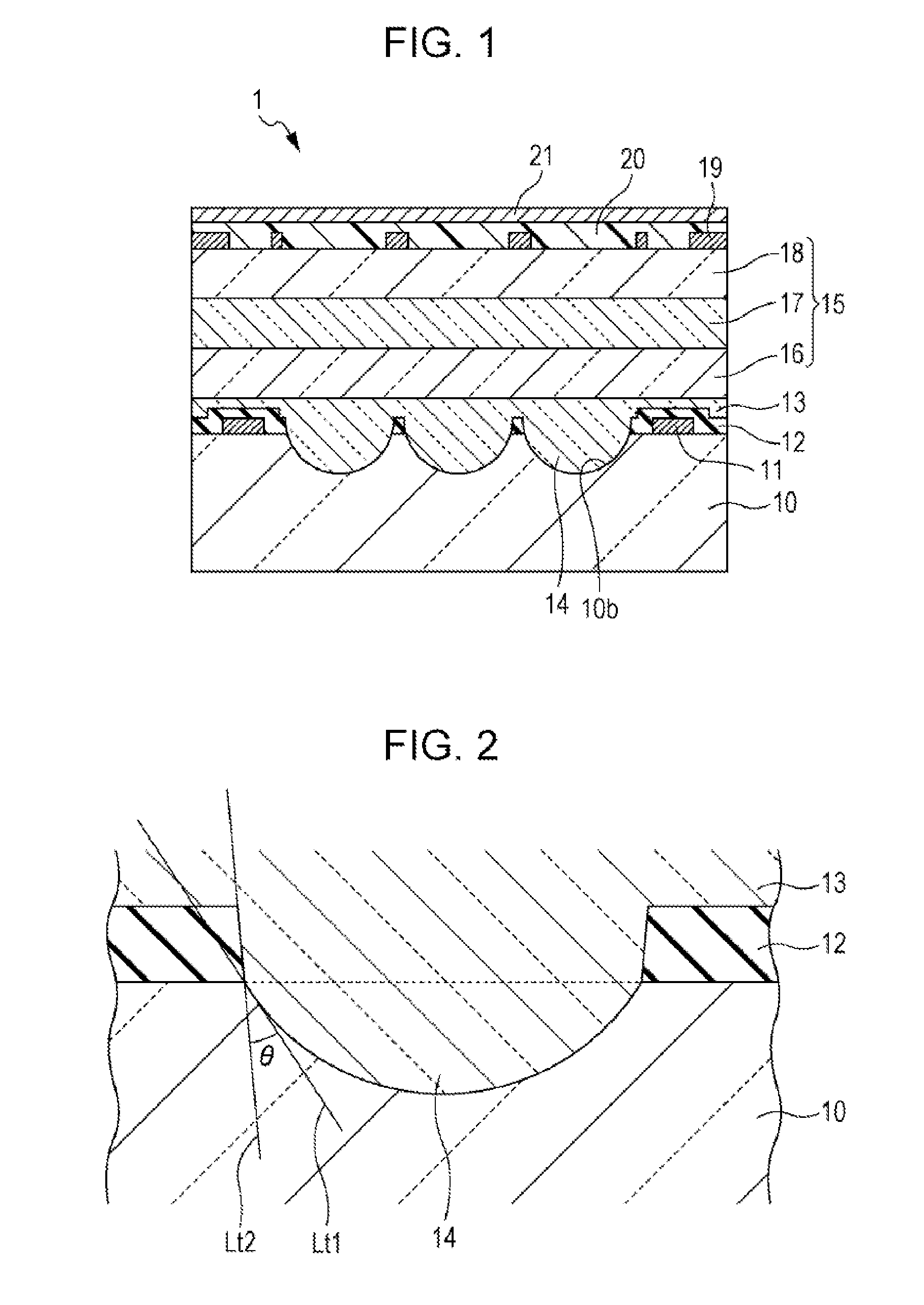

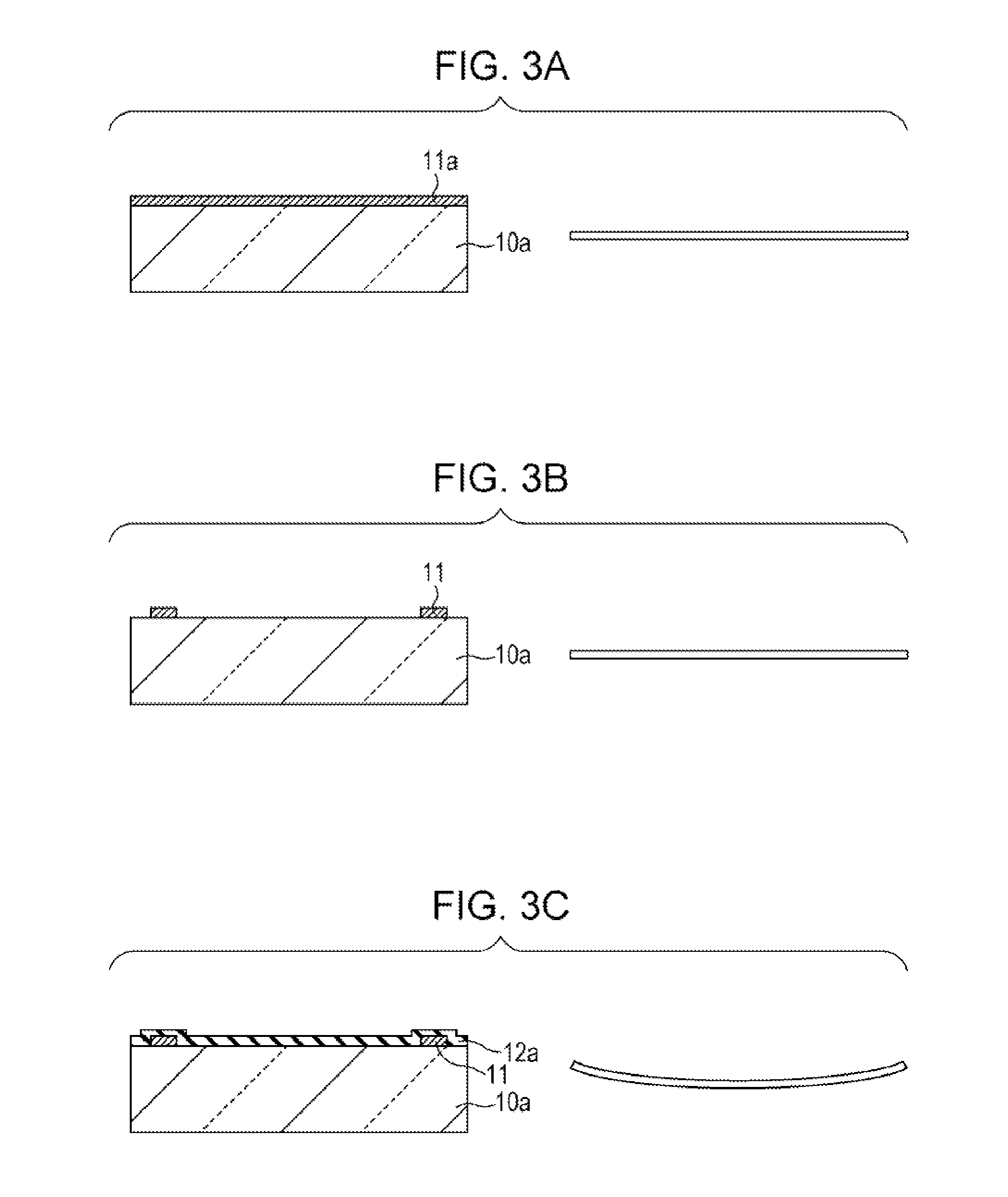

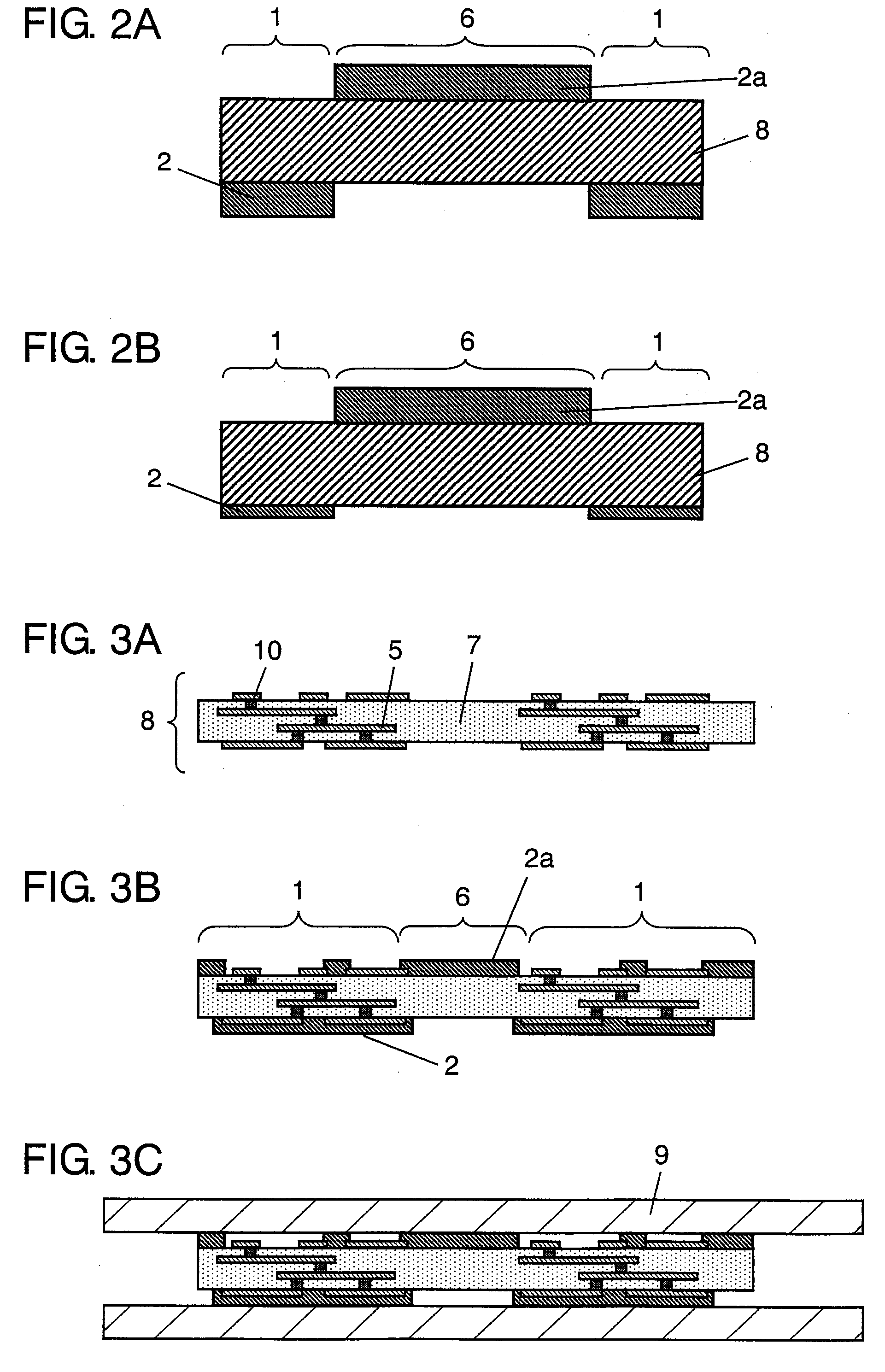

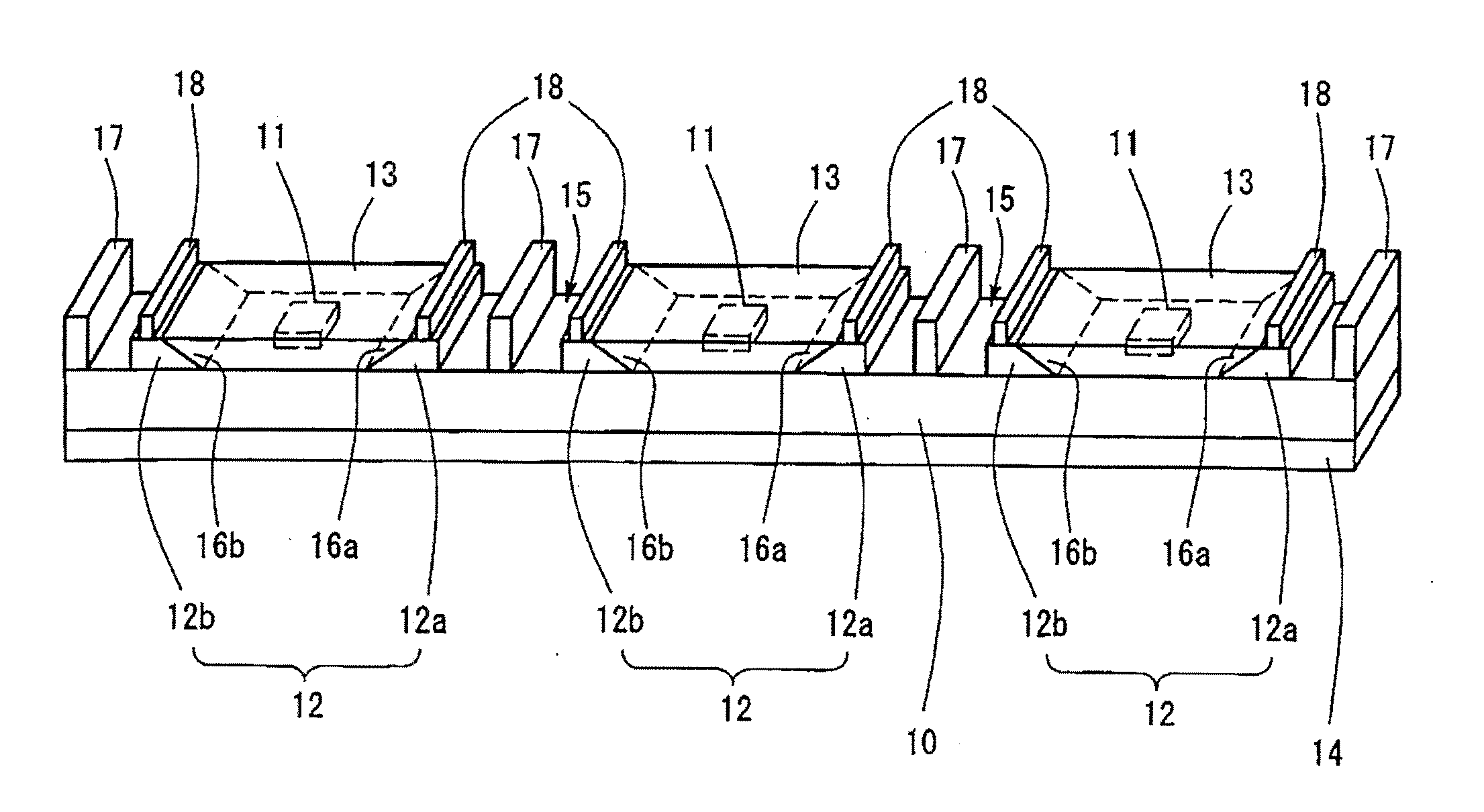

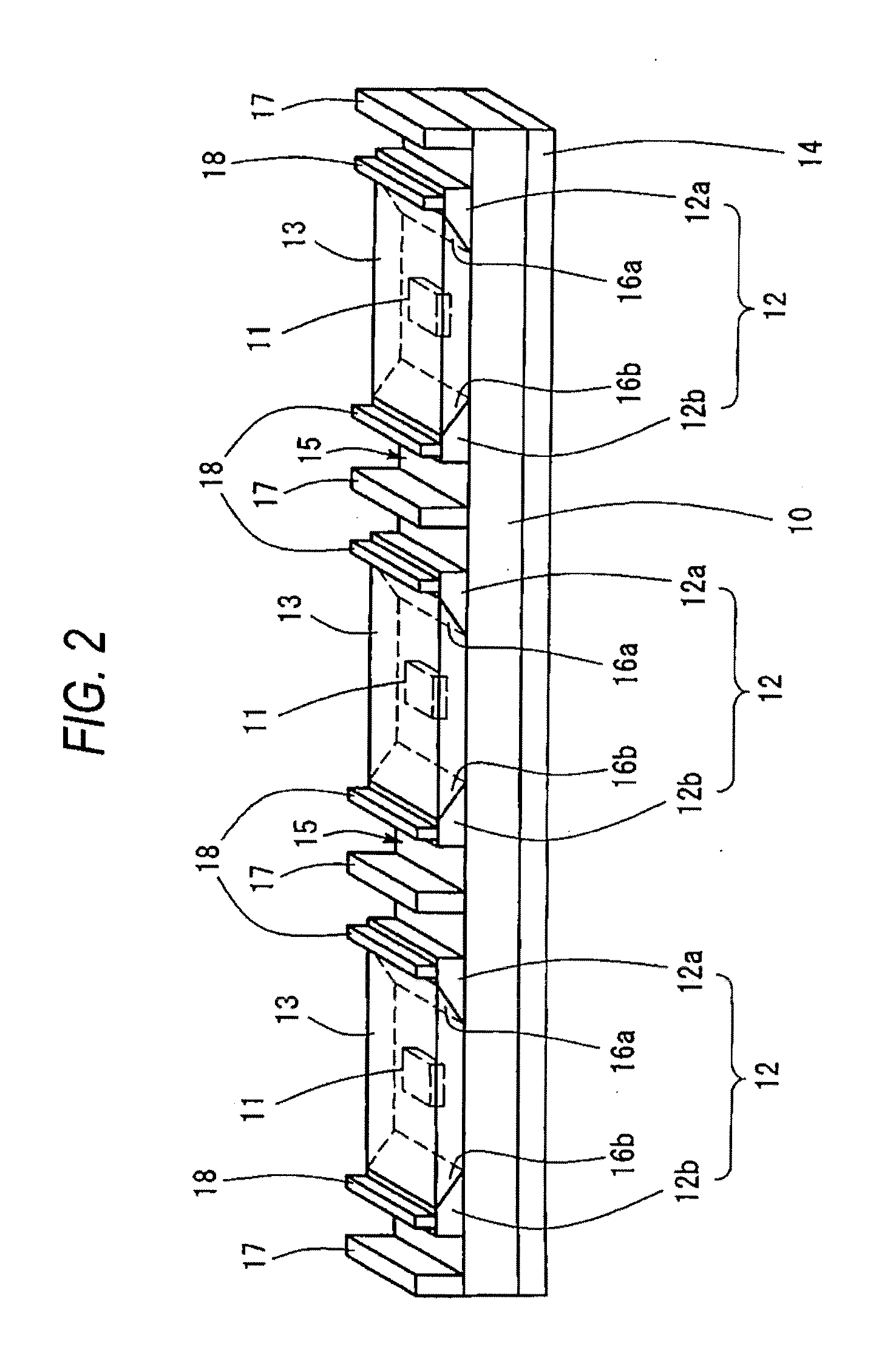

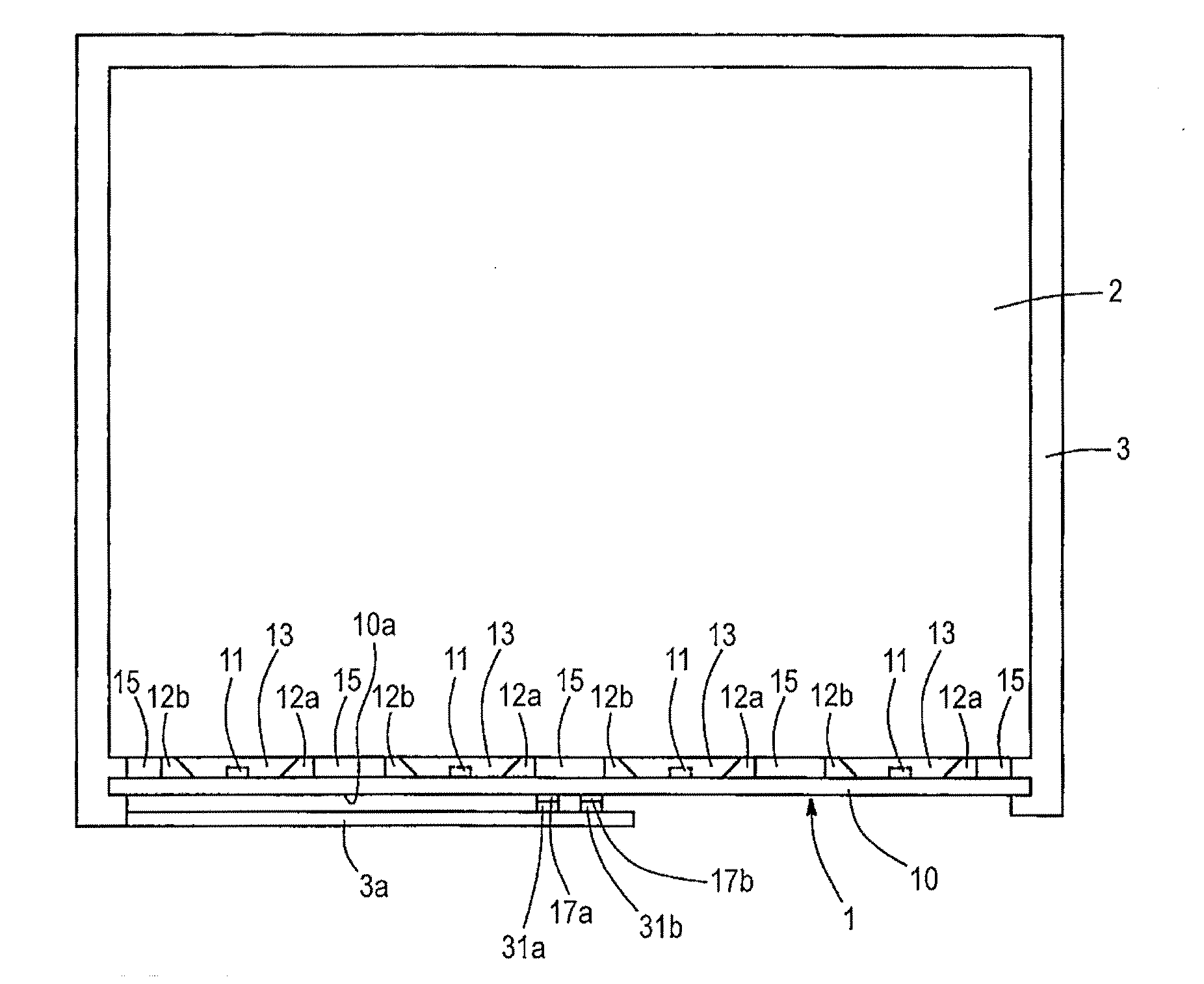

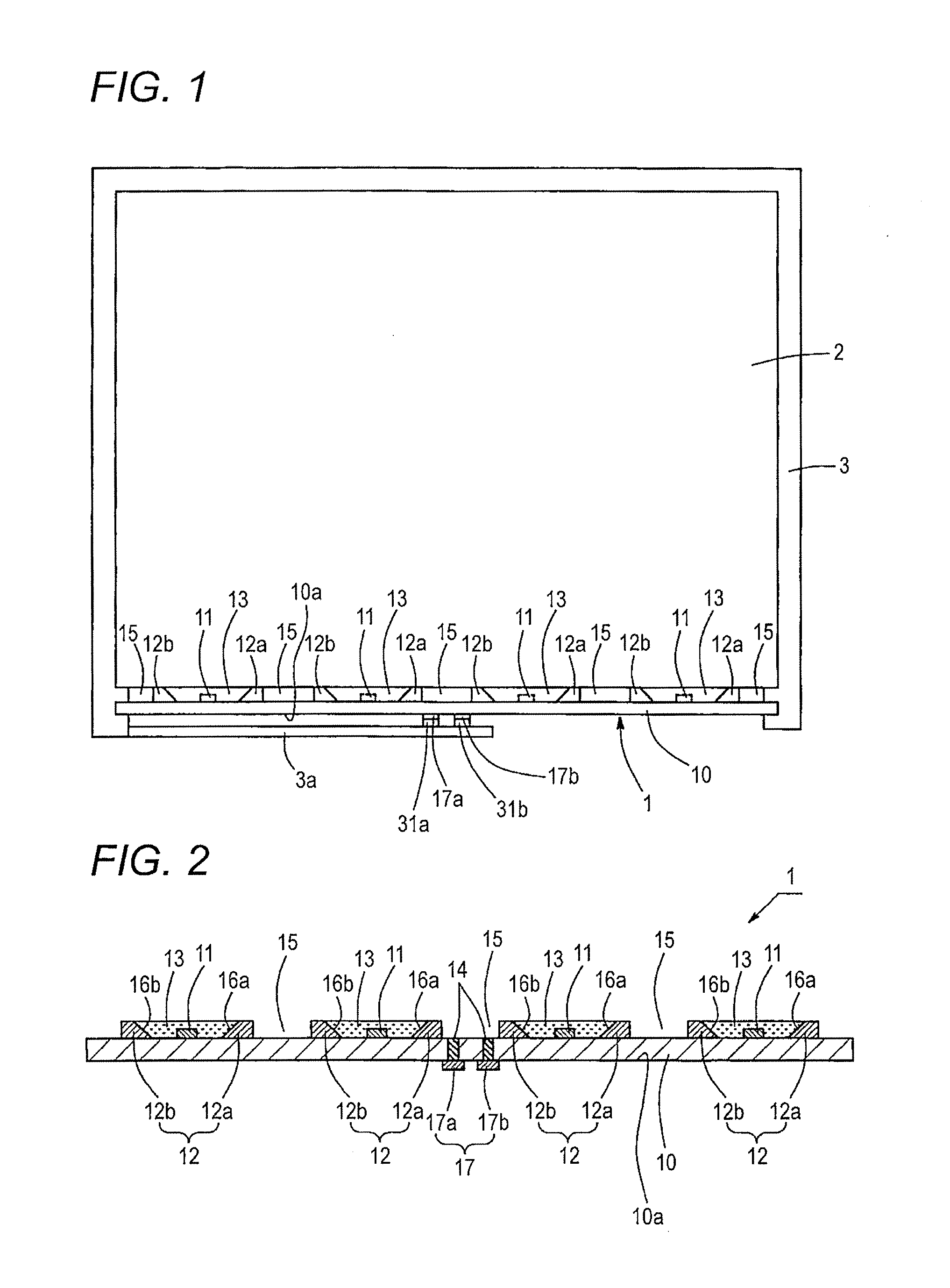

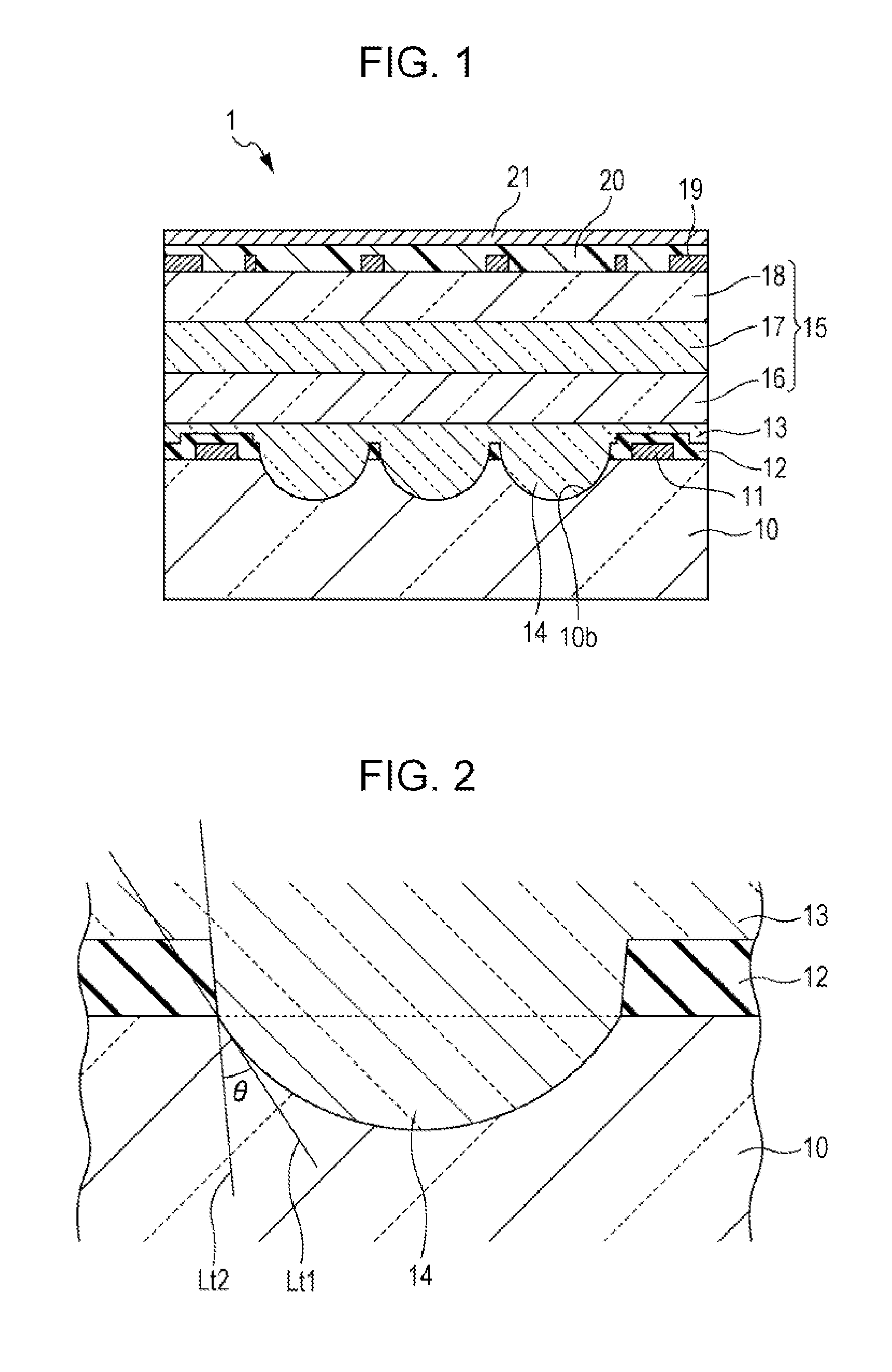

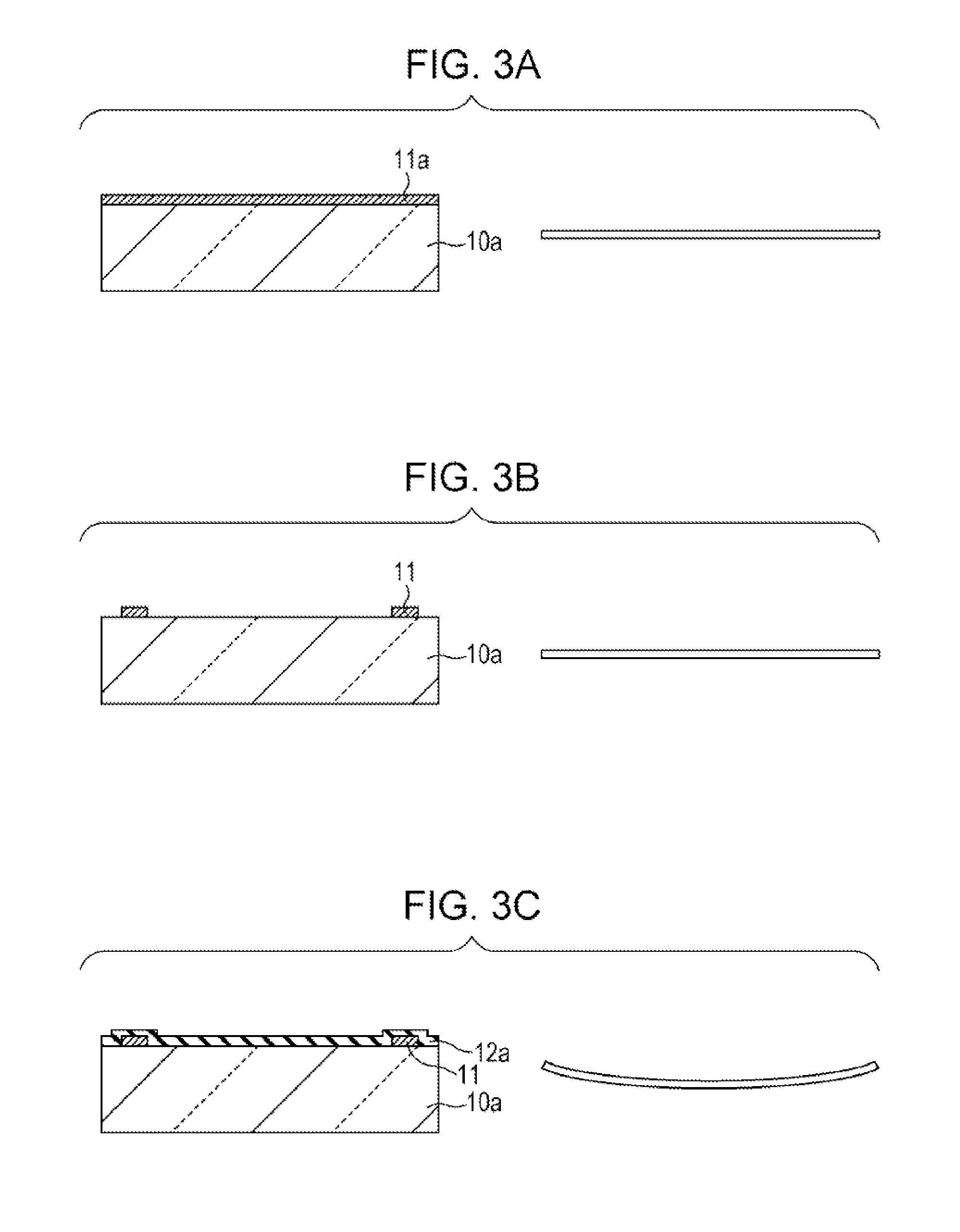

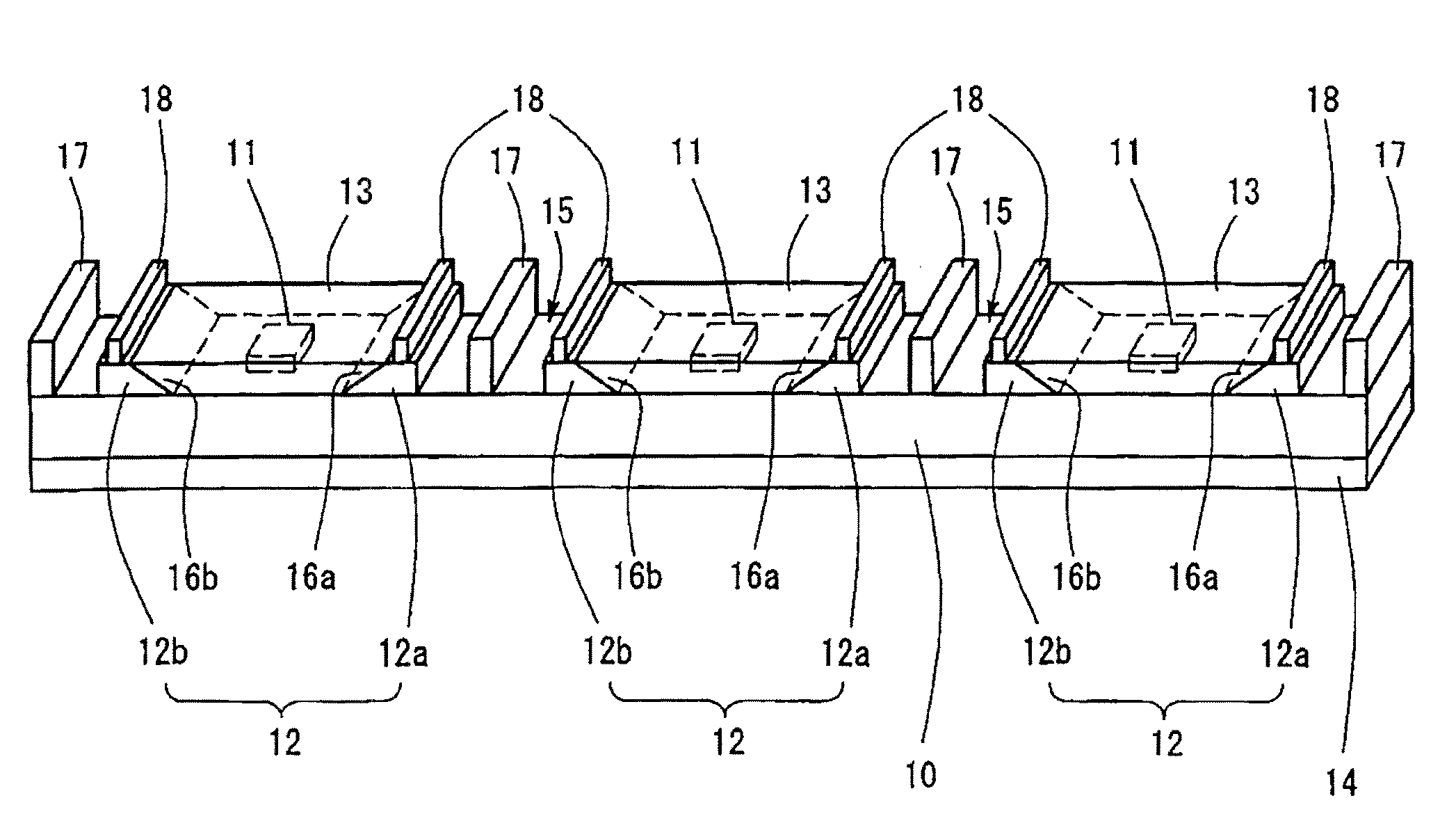

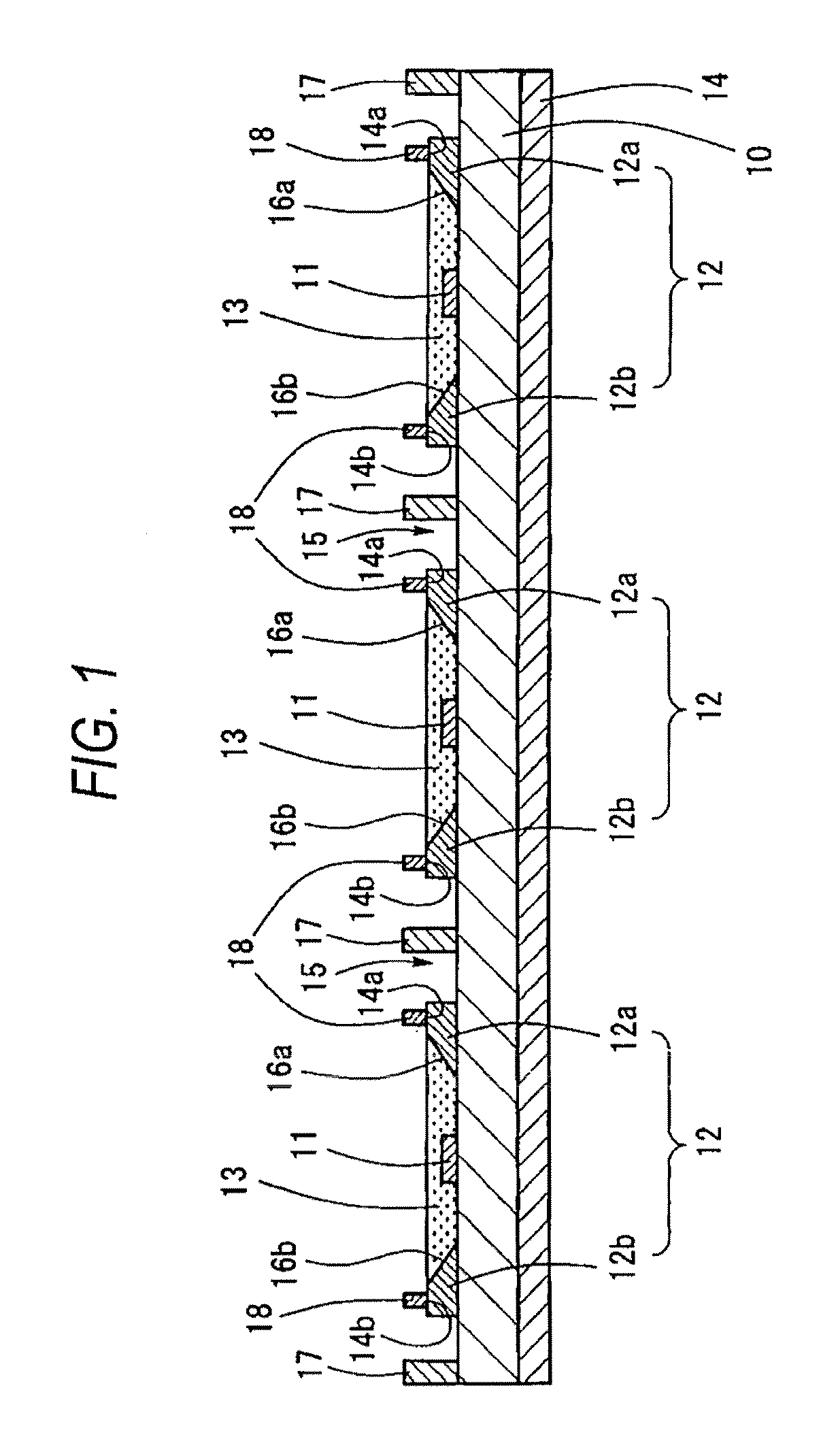

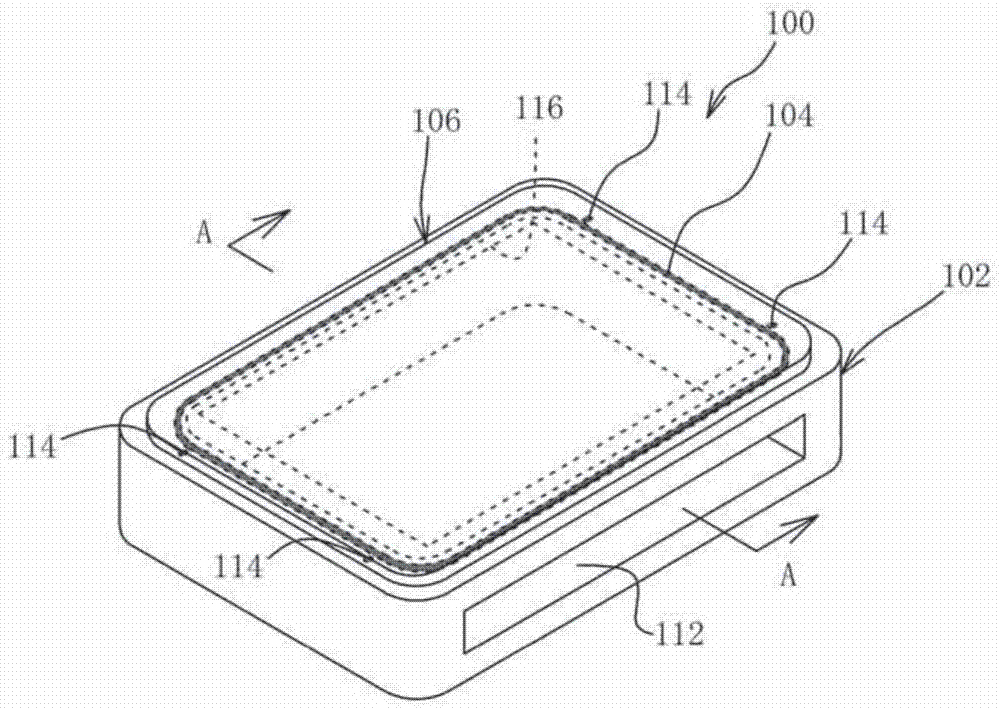

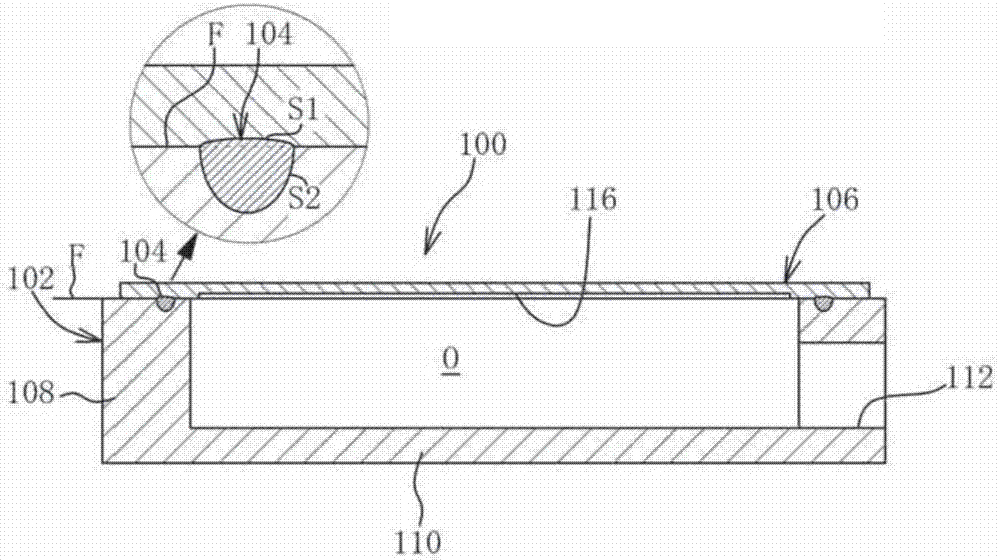

Linear light source device and planar light source device

InactiveUS20130070479A1Heat suppressionCorrect warpingLighting support devicesElongate light sourcesOptoelectronicsLight source

A linear light source device comprises a wiring substrate in a rectangular shape and a wiring pattern formed thereon, a plurality of light emitting elements arranged on the wiring substrate in a longitudinal direction of the wiring substrate and connected with the wiring pattern on the wiring substrate, reflectors, each of which includes two parts having slope surfaces on one side and the other side facing each other in the longitudinal direction of each light emitting element, and which are separated from each other on the wiring substrate corresponding to the light emitting elements, respectively; and a sealing resin sealing the light emitting elements by burying a recession portion defined by a surface of the wiring substrate where the light emitting elements are arranged and the two slope surfaces, wherein the two parts of each of reflectors have convex portions on their upper surfaces, respectively.

Owner:TOYODA GOSEI CO LTD

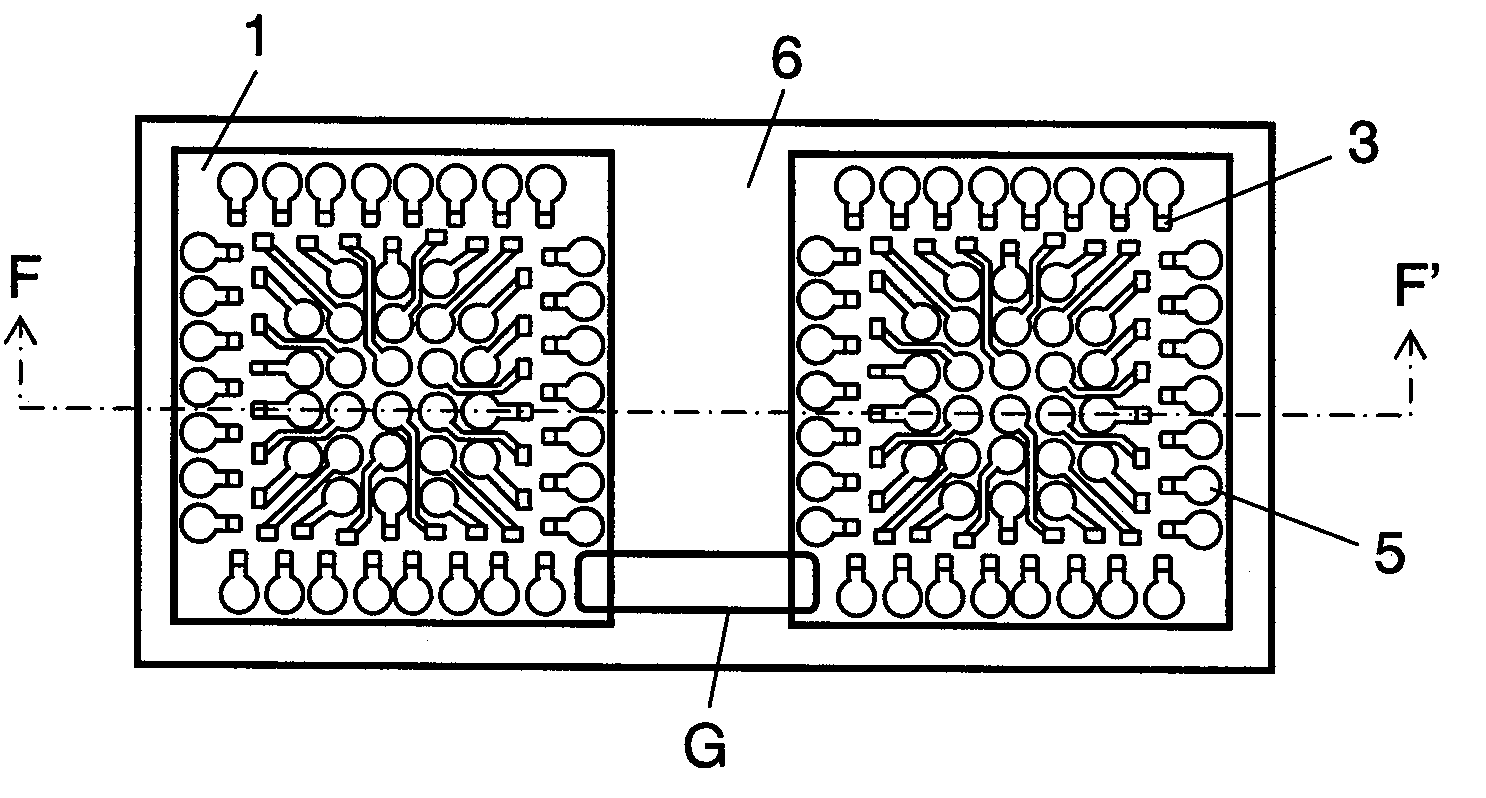

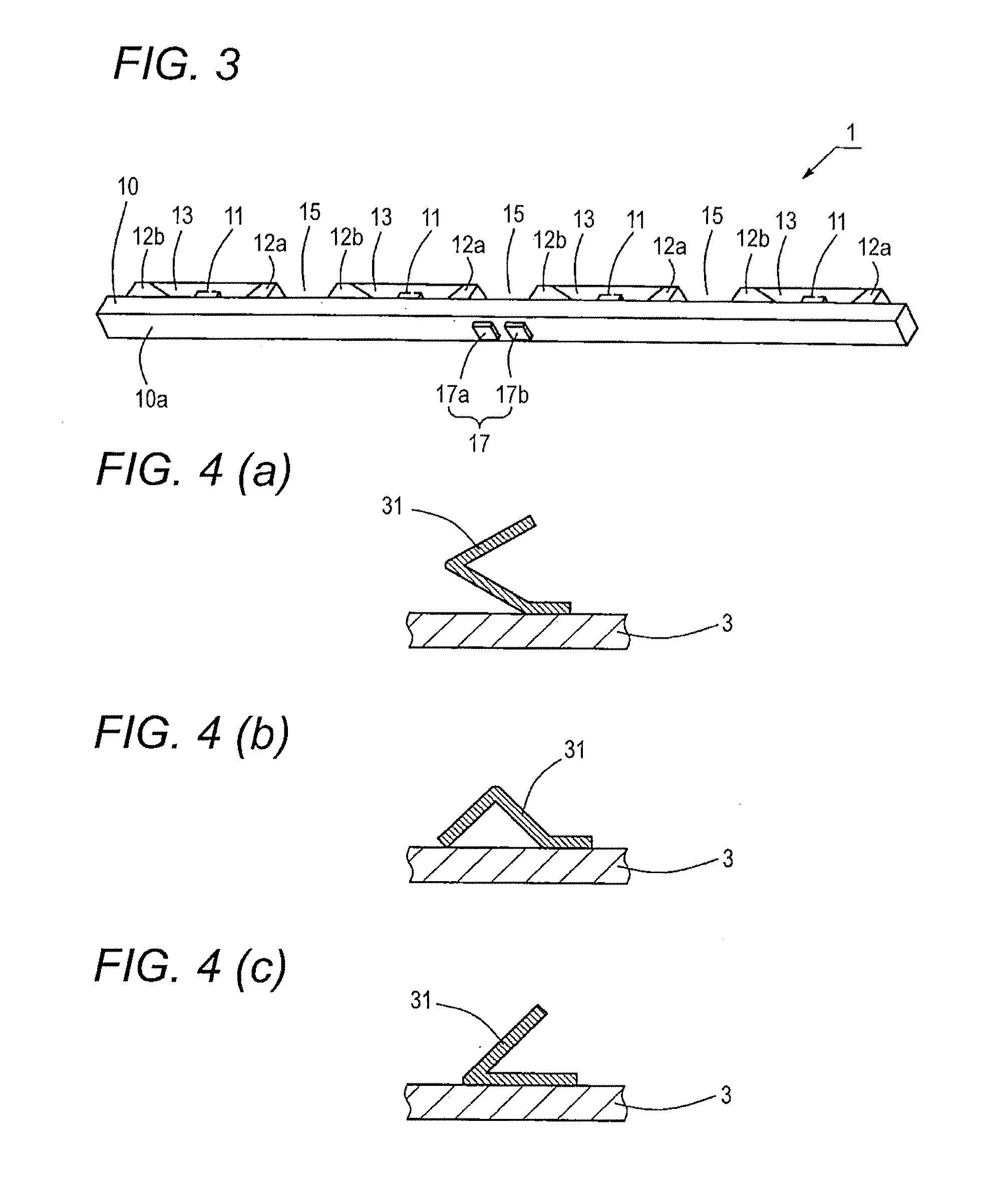

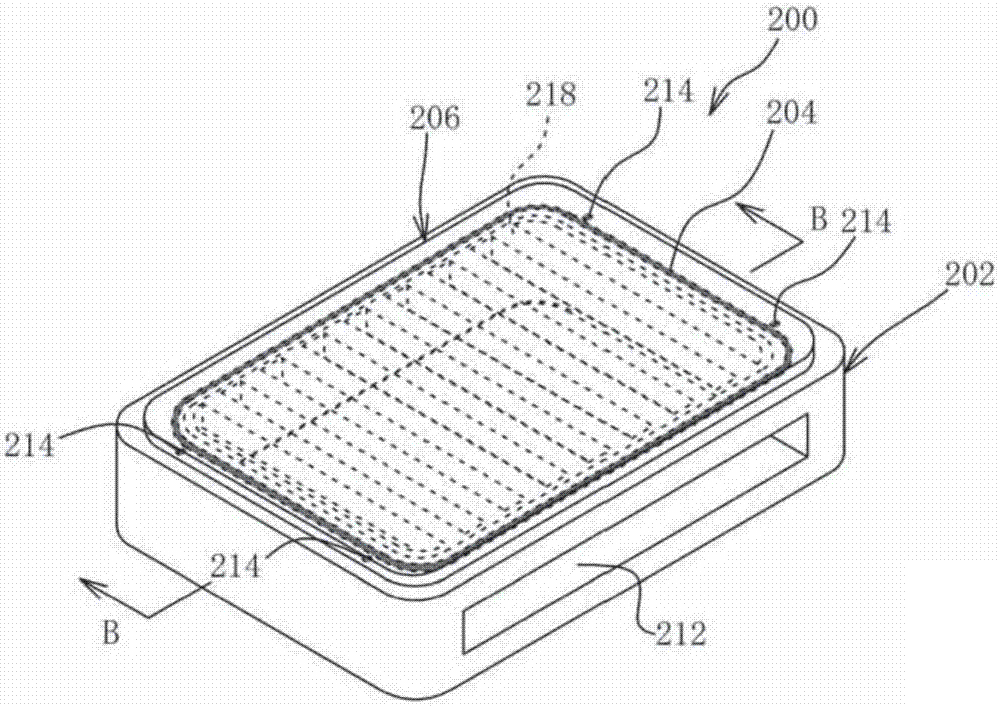

Linear light source device and planar light source device

ActiveUS20130077344A1Warpage suppressionIncrease brightnessMechanical apparatusLight guides for lighting systemsLight guideOptoelectronics

A linear light source device comprises a wiring substrate in a rectangular shape and having a wiring pattern formed thereon, a plurality of light emitting elements arranged on the wiring substrate in a longitudinal direction of the wiring substrate and connected with the wiring pattern on the wiring substrate, and a sealing resin that seals the light emitting elements, wherein the linear light source device is to be arranged on a side surface of a light guiding plate to form a planar light source device, and an external connection terminal is arranged on a surface of the wiring substrate that is opposite to a surface of the wiring substrate where the light emitting element are arranged and in a central portion in the longitudinal direction of the wiring substrate, and connected with the wiring pattern.

Owner:TOYODA GOSEI CO LTD

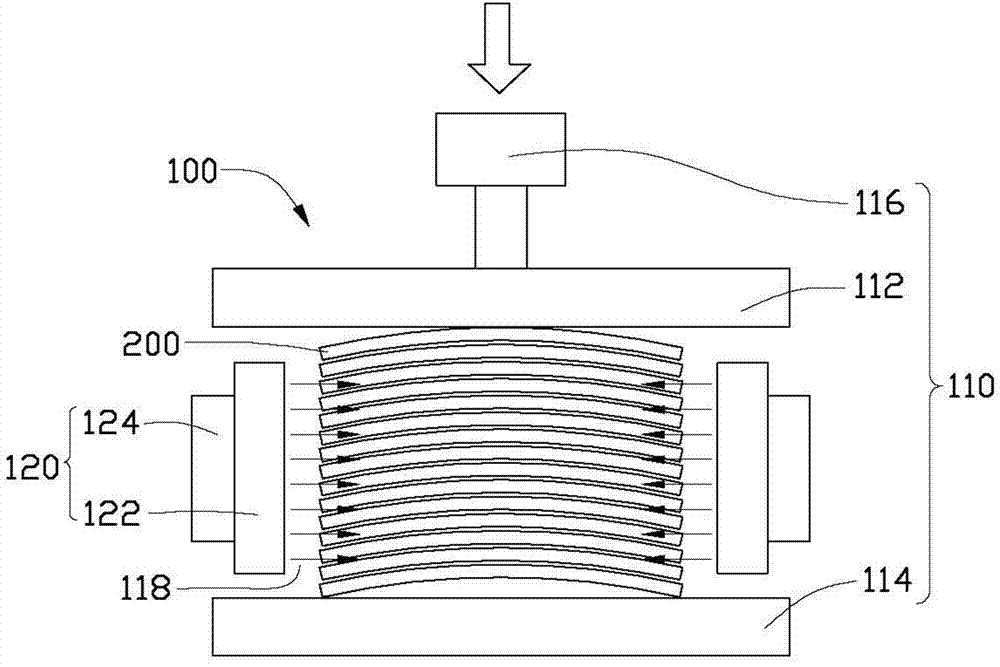

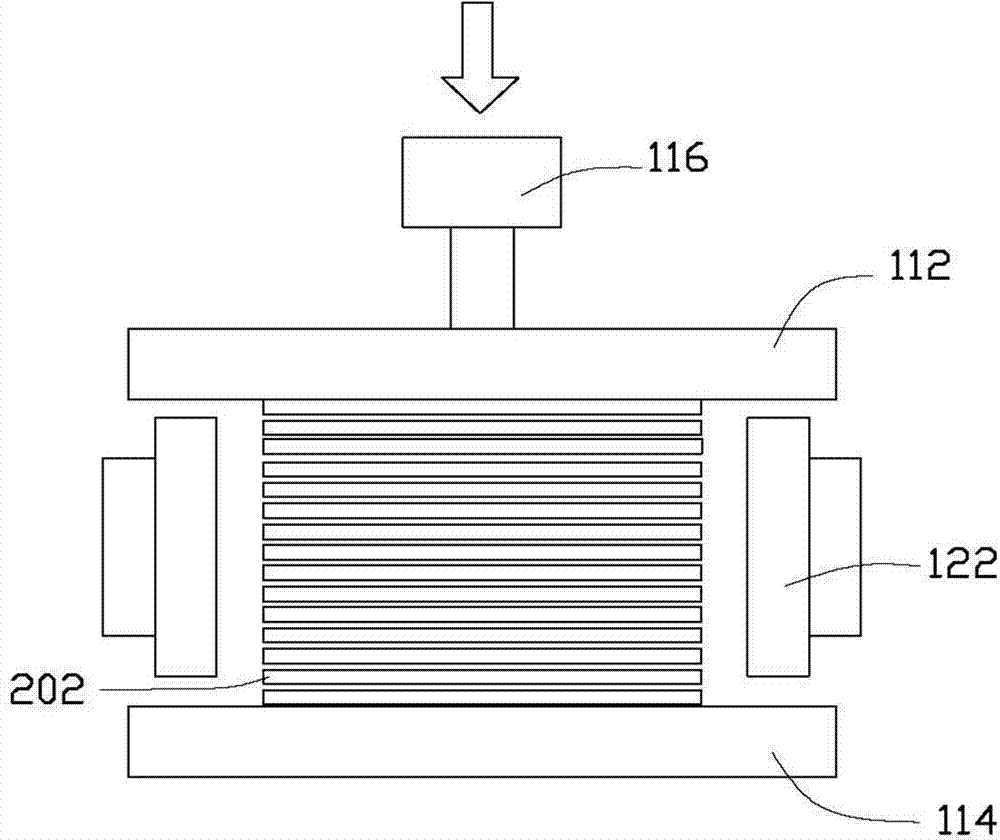

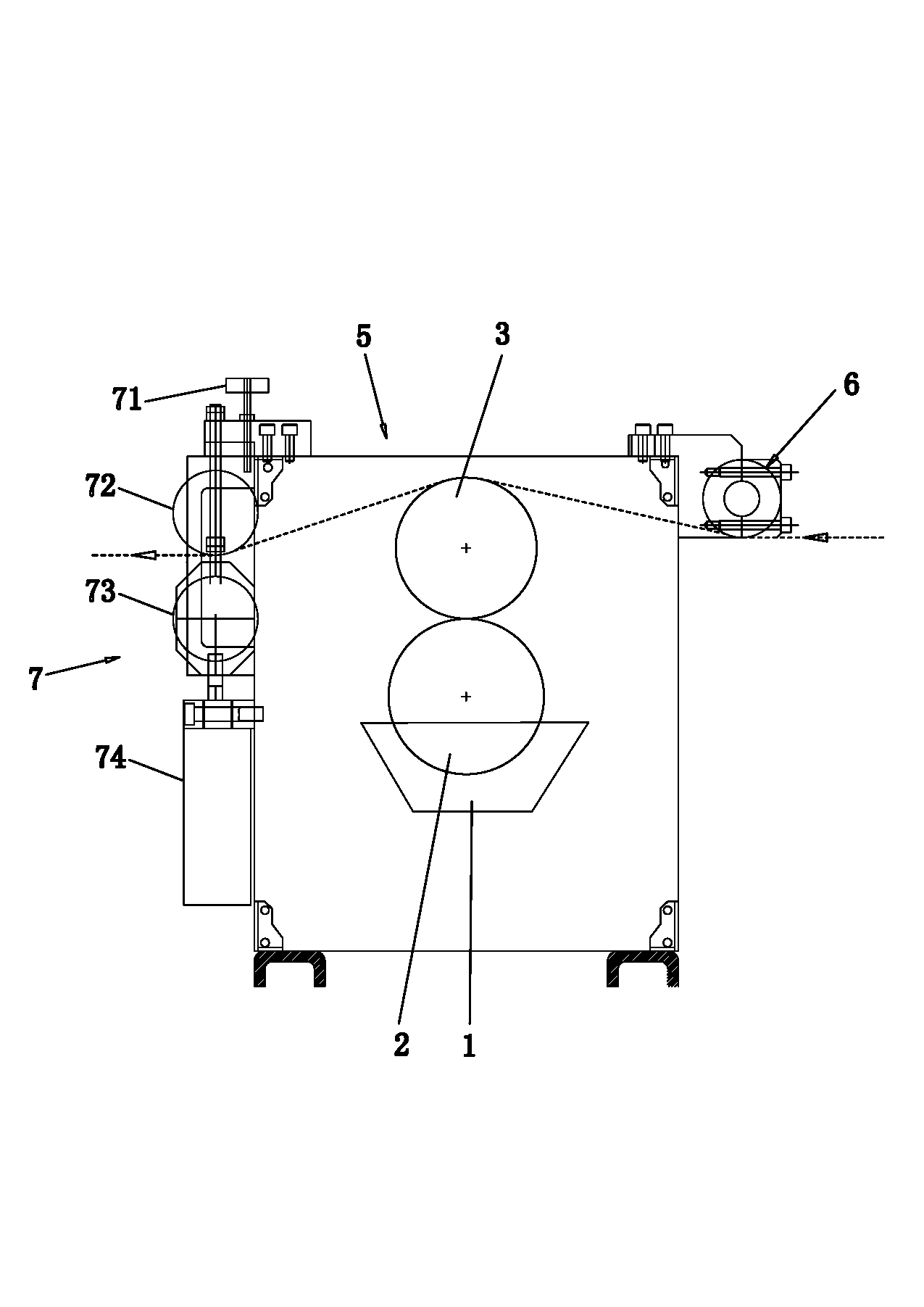

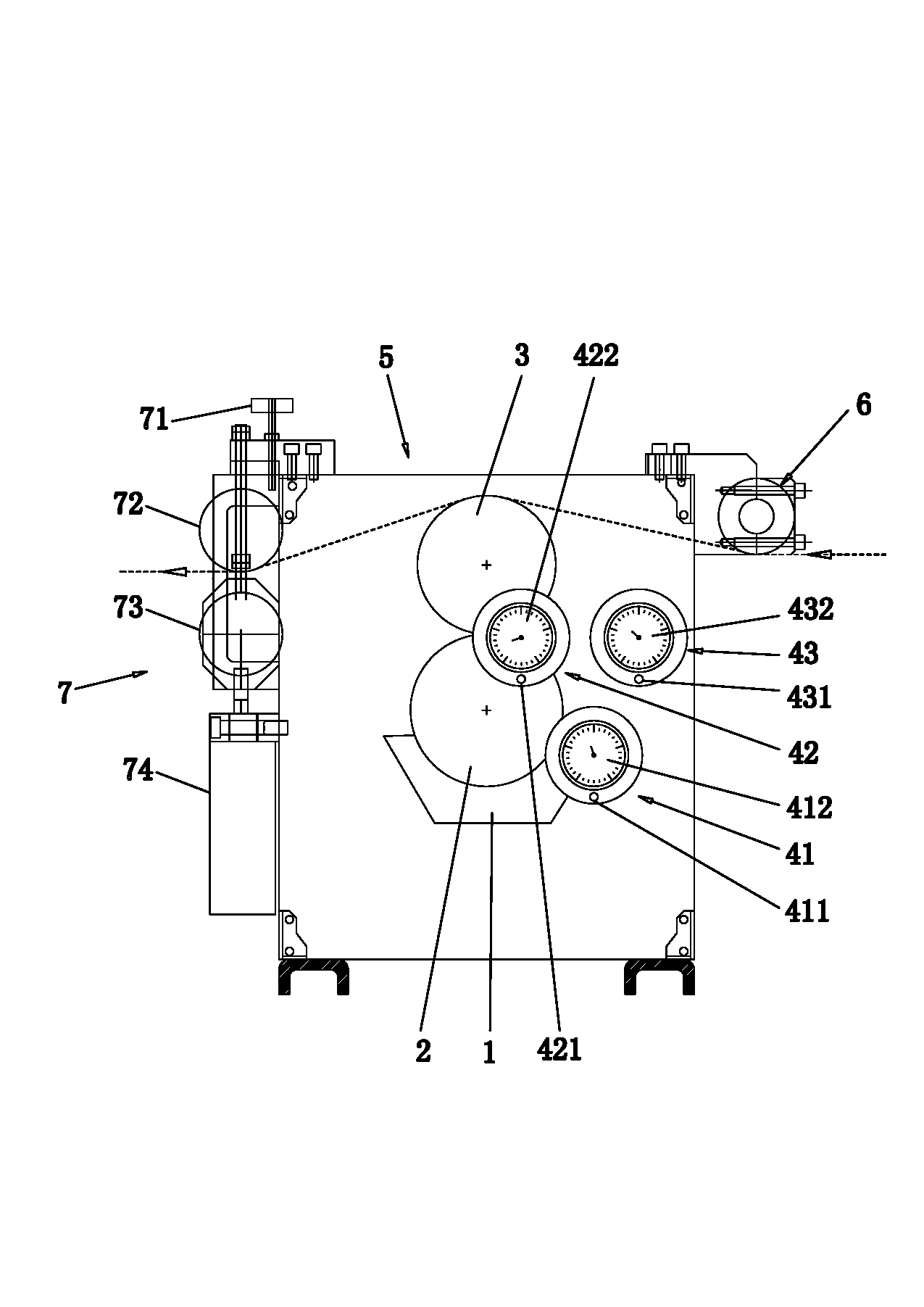

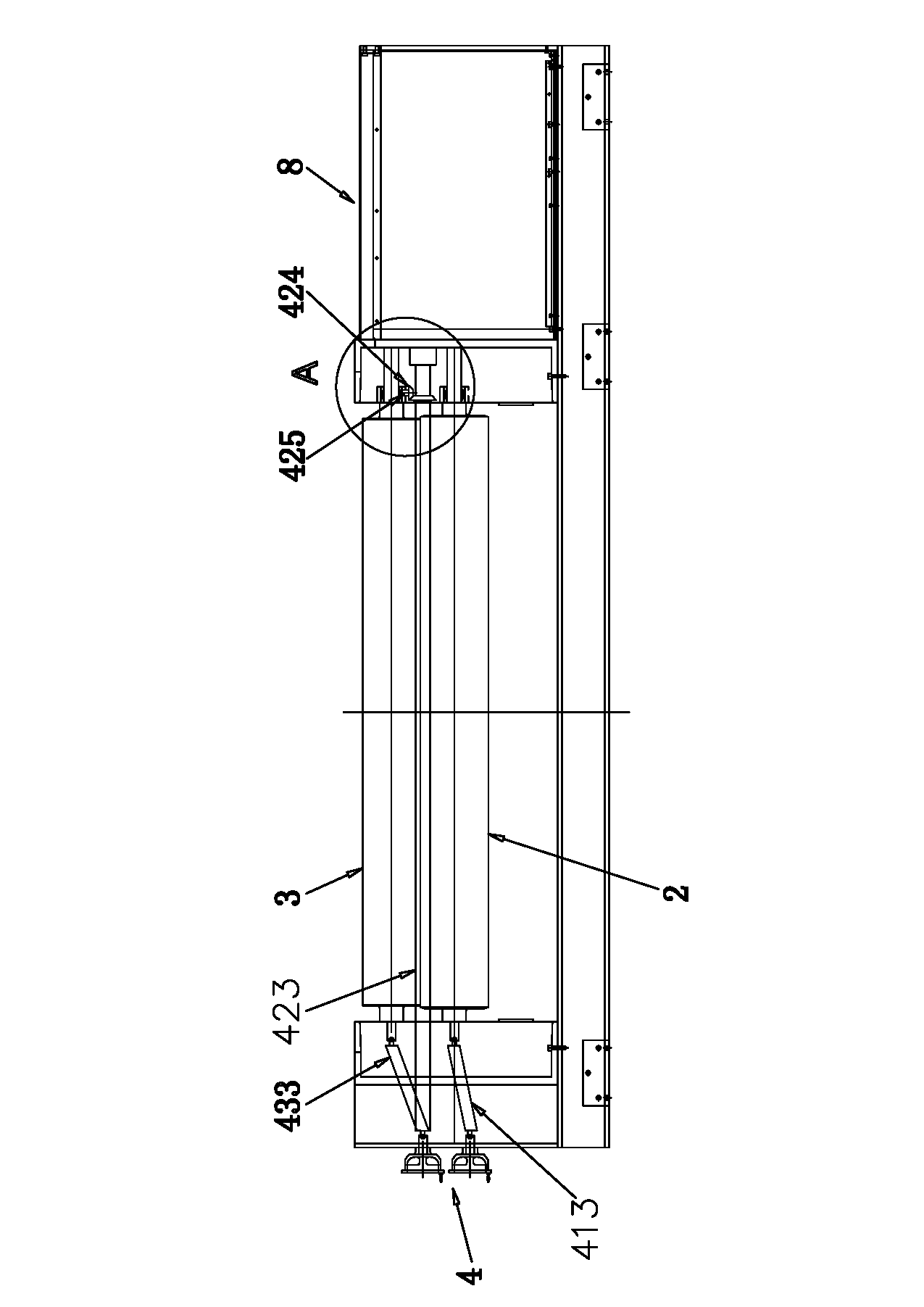

Light guide plate warping correction method, and device thereof

A light guide plate warping correction method comprises the following steps: placing a warping light guide plate between an upper platen and a lower platen; stitching the upper platen, the warping light guide plate and the lower platen through utilizing an oil hydraulic cylinder against the upper platen; and winding a coin surrounding the light guide plate, wherein there is a gap between the coil and the light guide plate, an electromagnetic wave is generated after energizing the coil, the electromagnetic wave traverses through the gap and heats the warping light guide plate, and the oil hydraulic cylinder still stitches the upper platen, the warping light guide plate and the lower platen when the warping light guide plate is heated by the electromagnetic wave in order to correct the warping light guide plate. A light guide plate warping correction device comprises a holder composed of the upper platen, the lower platen and the oil hydraulic cylinder, and a heater comprising the coil.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

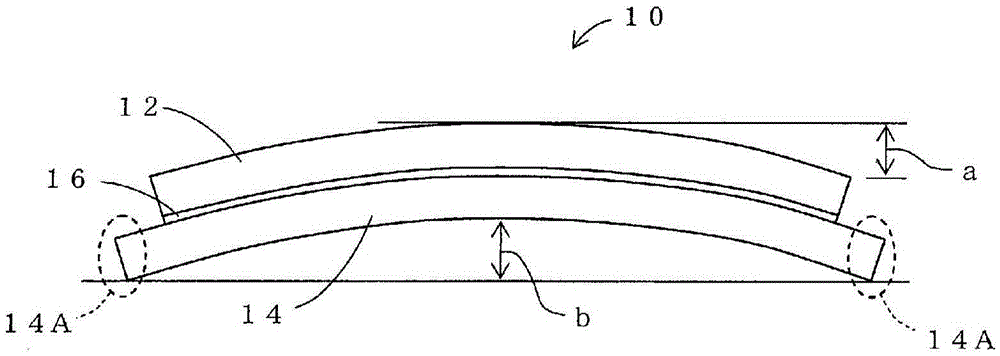

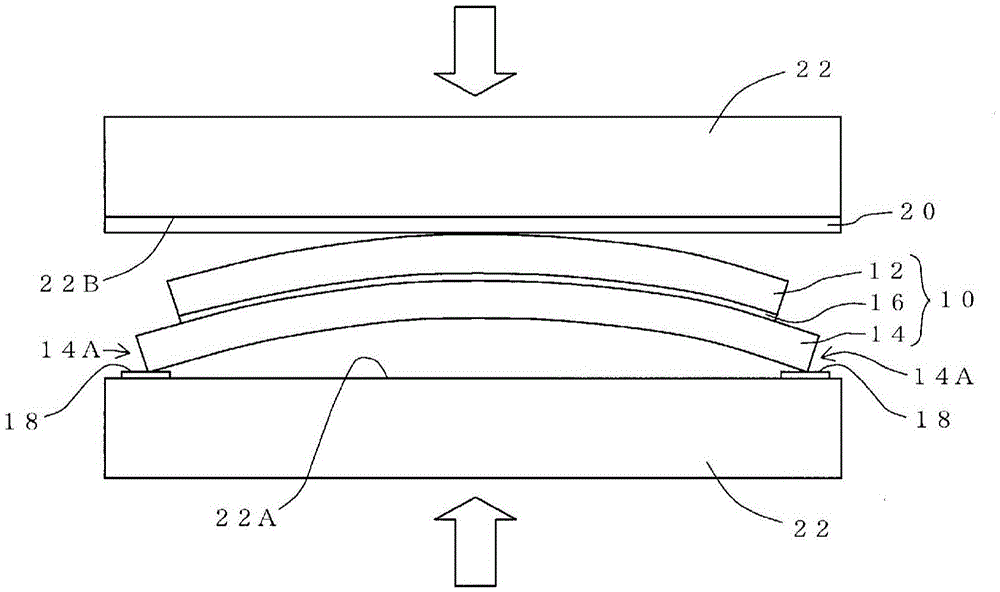

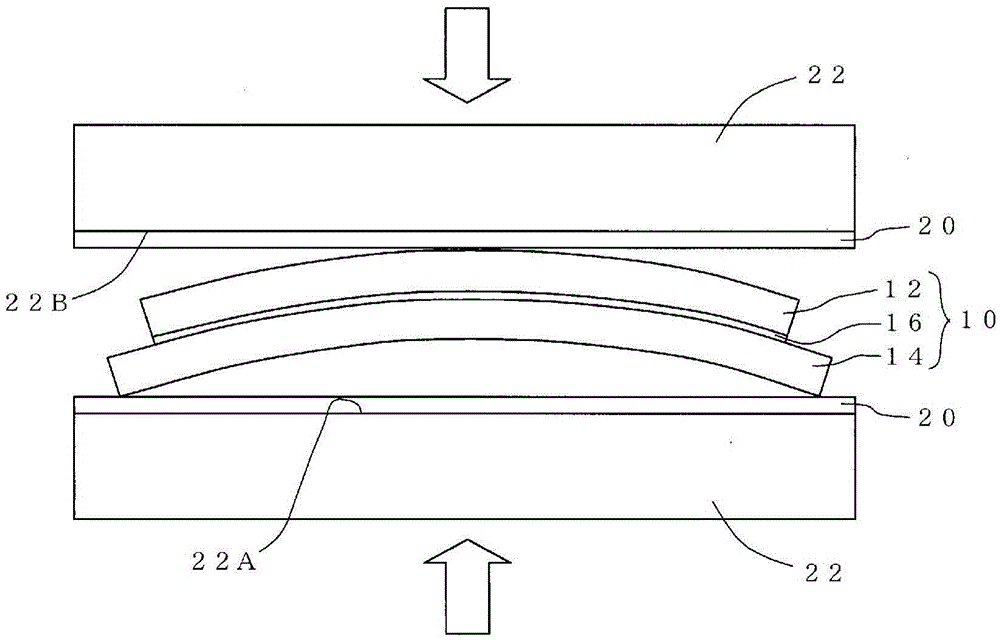

Warp correction method for sputtering target with backing plate

InactiveCN105531396ACorrect warpingIncrease productivityElectric discharge tubesVacuum evaporation coatingEngineeringCorrection method

Provided is a simple warp correction method which can correct warping in a warped sputtering target with a backing plate (BP). A pressing device is provided with an upper pressing surface (22B) and a lower pressing surface (22A) opposing each other in the vertical direction, and this warp correction method involves: an arrangement step for arranging the BP-attached sputtering target (10) on the lower pressing surface (22A) with the target (12) side up, and for arranging spacers (18) between the lower pressing surface (22A) and the outside edges (14A) of the backing plate (14) of the BP-attached target (10); and, after the arrangement step, a pressing step for pressing the BP-attached target (10) in the vertical direction by means of the pressing device. The target (12) is a composite comprising metal oxides and / or carbon dispersed in the matrix metal.

Owner:TANAKA PRECIOUS METAL IND

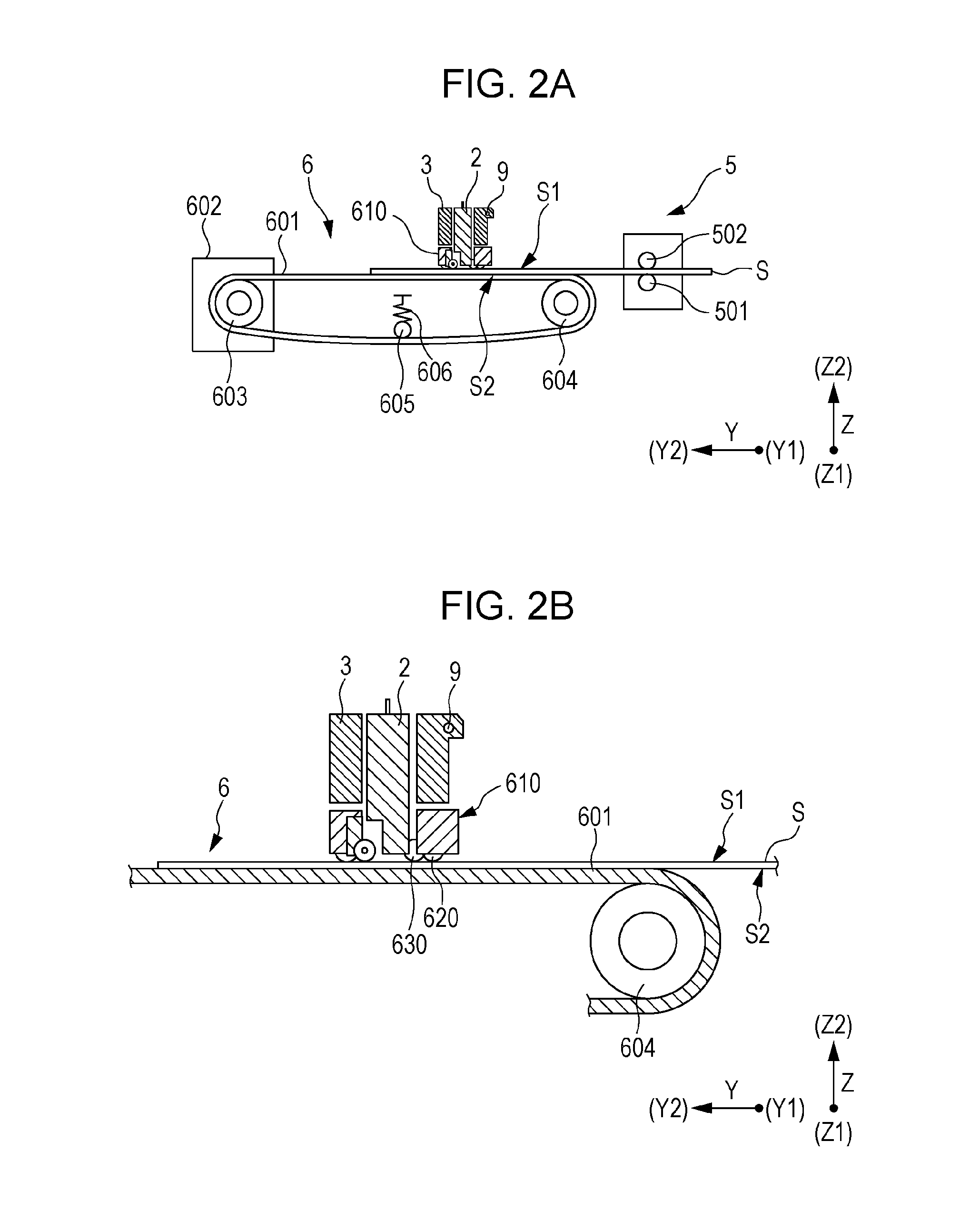

Screen printing device

A screen printing apparatus of the invention comprises: a supporting device supporting a circuit substrate from below; a clamp, from both sides, holding the side surface of the circuit substrate supported by the supporting device; a circuit substrate pressing device for pressing the circuit substrate from above, which is supported on the supporting device and maintaining the circuit substrate in a warp and then straightened state along an up-and-down direction. The circuit substrate pressing device holds the circuit substrate to move the same along a holding direction of the clamp. According to the invention, via the circuit substrate pressing device pressing the circuit substrate, a warp of the circuit substrate can be straightened and the circuit substrate can be maintained in this state.

Owner:YAMAHA MOTOR CO LTD

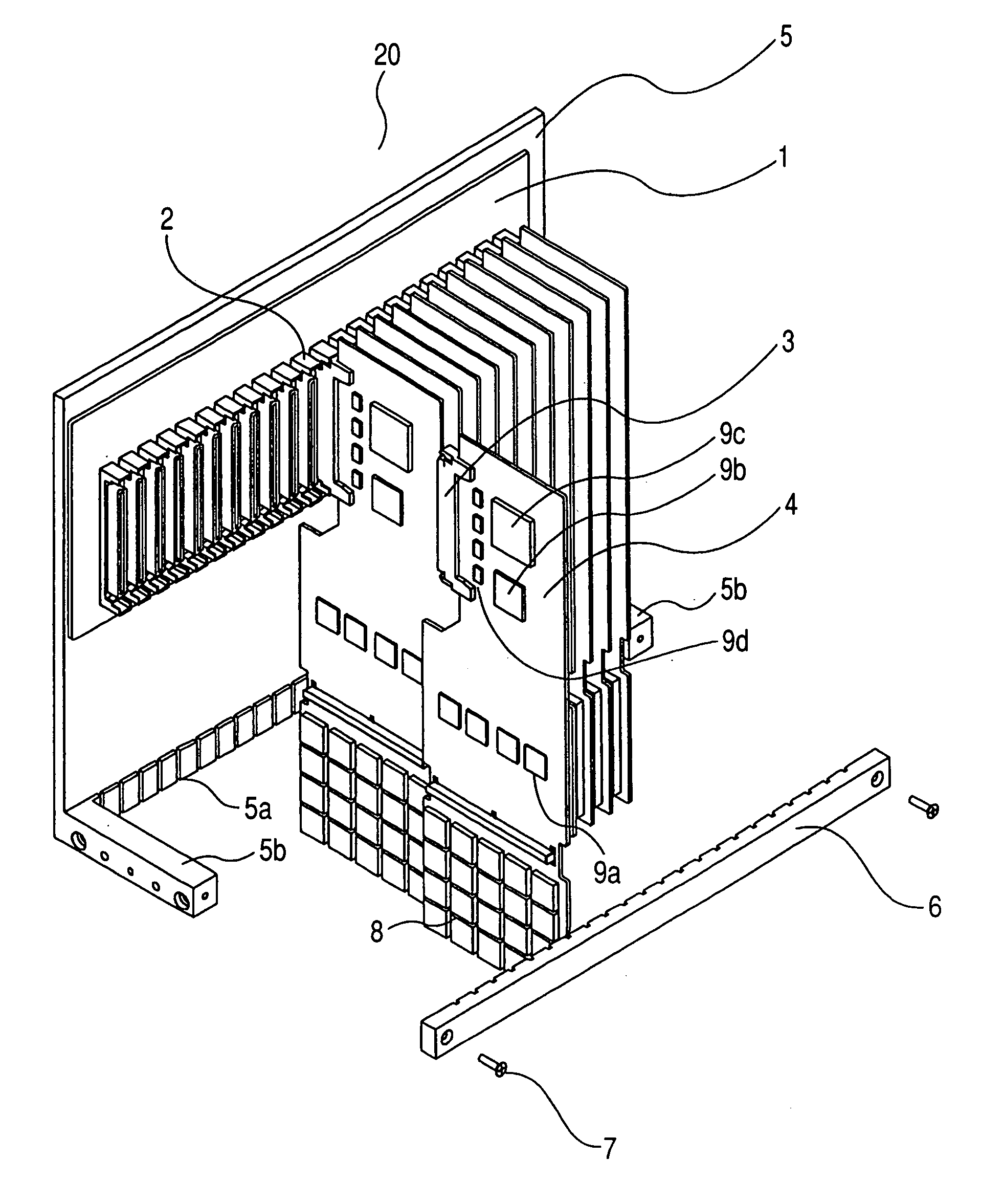

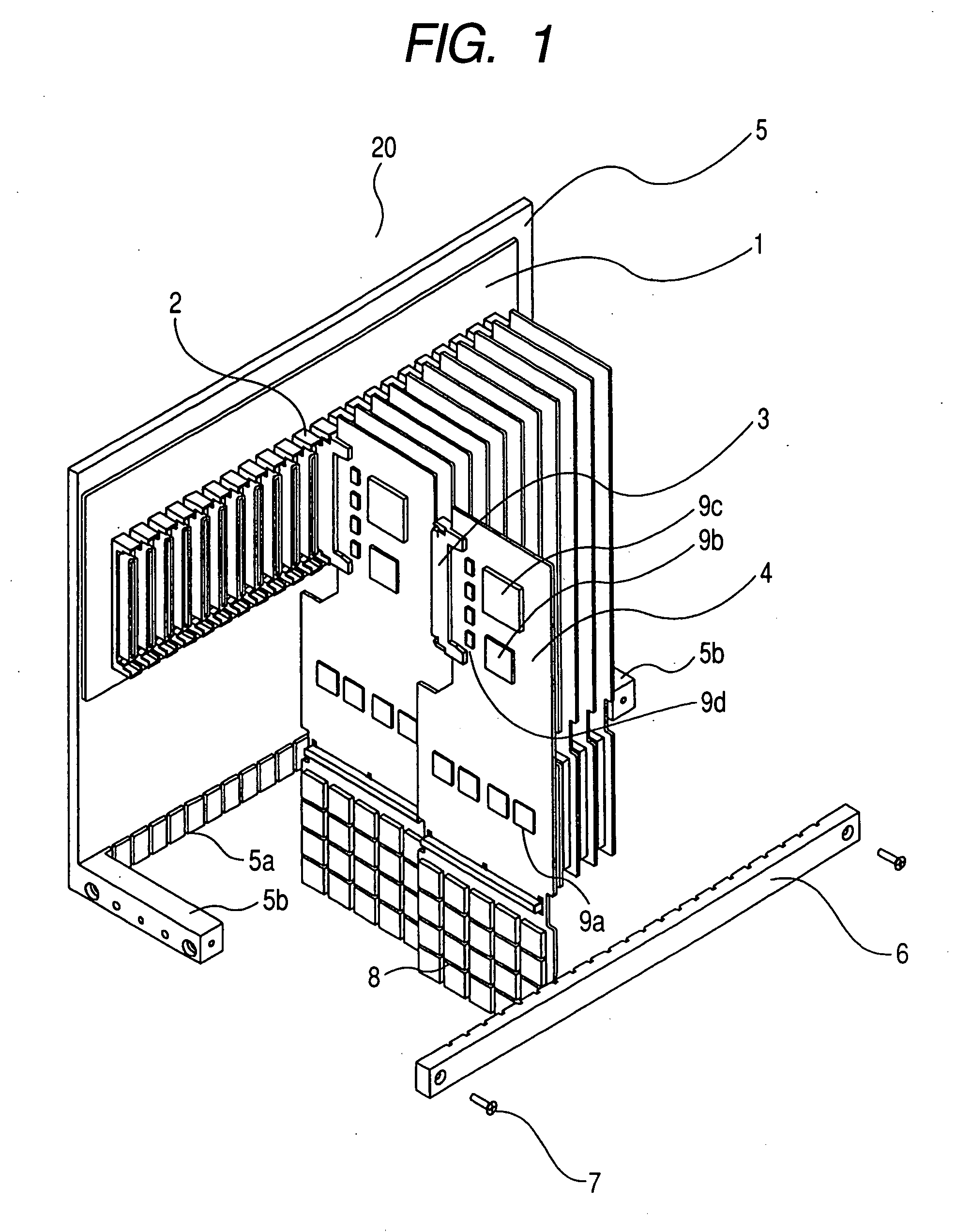

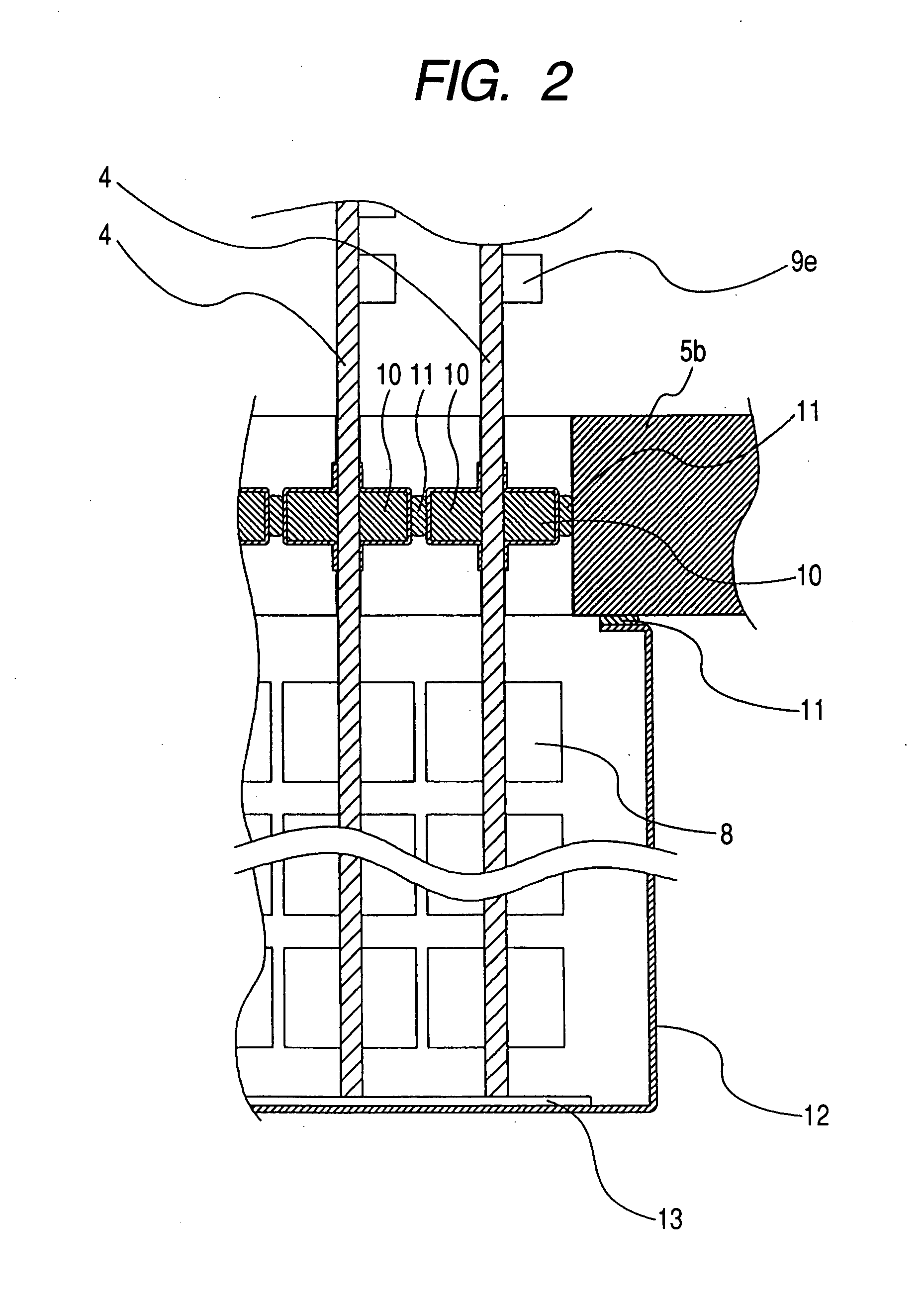

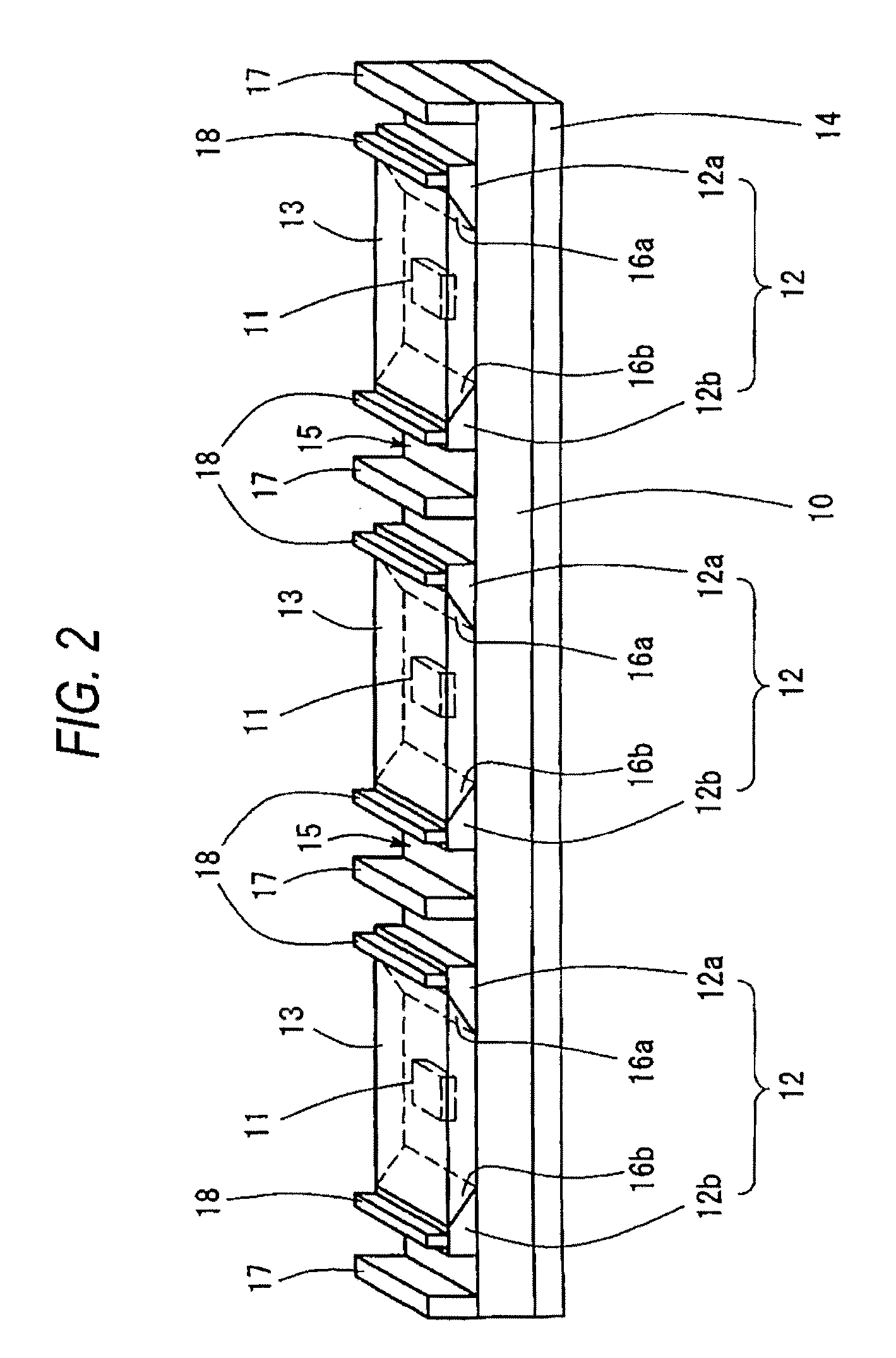

Structure for mounting printed board and nuclear medicine diagnosis system

InactiveUS20080007895A1Protection from vibrationCorrect warpingSubstation/switching arrangement detailsClamping/extracting meansDevice materialEngineering

The present invention is provided a structure for mounting a printed board in which each connector that is attached to each of a plurality of sub printed boards, which are juxtaposed to one another with respect to a main printed board secured to a metal backboard, is inserted into each of a plurality of connectors that are juxtaposed to one another on the main printed board so that the sub printed boards are mounted on the main printed board by the connector connections. Parts of both ends of an area in proximity to a semiconductor-device mounted area on each of the sub printed boards ate pinched between a first metal frame and a second metal frame so that each of the sub printed boards are secured.

Owner:HITACHI LTD

Fabrication method for microlens array substrate

ActiveUS9234988B2Improve stressRelieve pressureOptical articlesNon-linear opticsOptical path lengthMicro lens array

A microlens substrate will warp when an oxide film is formed and annealed before forming a mask in order to adjust the etching rate of wet etching. Accordingly, a film exerting a stress that cancels out this warping is formed upon a microlens. This film functions as an optical path length adjusting layer.

Owner:SEIKO EPSON CORP

Linear light source device and planar light source device

InactiveUS9022633B2Prevent degradationConduction of heat to the light guiding plate from the light emitting elements can be suppressedMechanical apparatusLighting support devicesOptoelectronicsLight source

A linear light source device comprises a wiring substrate in a rectangular shape and a wiring pattern formed thereon, a plurality of light emitting elements arranged on the wiring substrate in a longitudinal direction of the wiring substrate and connected with the wiring pattern on the wiring substrate, reflectors, each of which includes two parts having slope surfaces on one side and the other side facing each other in the longitudinal direction of each light emitting element, and which are separated from each other on the wiring substrate corresponding to the light emitting elements, respectively; and a sealing resin sealing the light emitting elements by burying a recession portion defined by a surface of the wiring substrate where the light emitting elements are arranged and the two slope surfaces, wherein the two parts of each of reflectors have convex portions on their upper surfaces, respectively.

Owner:TOYODA GOSEI CO LTD

Method and apparatus for producing semiconductor device

InactiveUS20050214991A1Good effectCorrect warpingPolycrystalline material growthFrom solid stateFlat glassDevice material

An amorphous silicon film is formed on a flat glass substrate, and then crystallized by heating to obtain a crystalline silicon film. The glass substrate is placed on a stage having a convex U-shaped curved surface. The glass substrate is heated for a desired period of time at a temperature close to a strain point of the glass substrate, and then is cooled. Also, an amorphous silicon film formed on a glass substrate is crystallized into a crystalline silicon film by heating and then the glass substrate is mounted on a stage having a flat surface in such a manner that the lower surface of the glass substrate is in close contact with the flat surface of the stage by pressing the upper surface of the glass substrate. Then, a linear laser beam is irradiated on the crystalline silicon film in a scanning manner.

Owner:SEMICON ENERGY LAB CO LTD

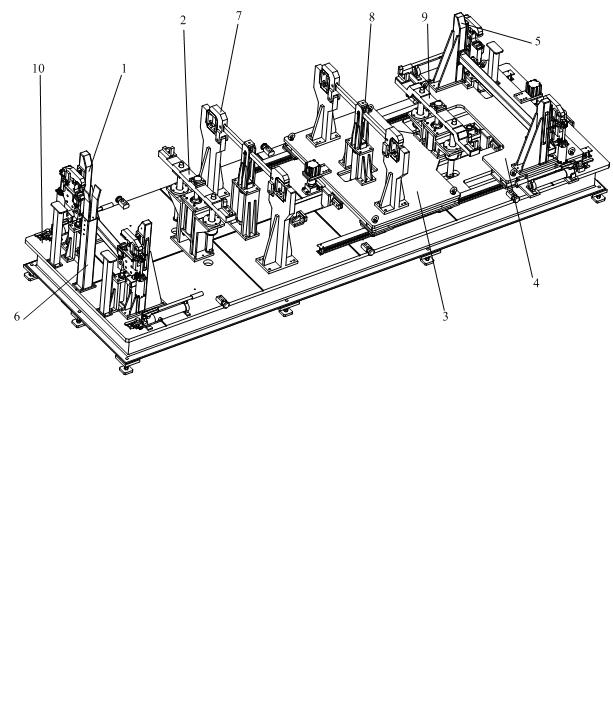

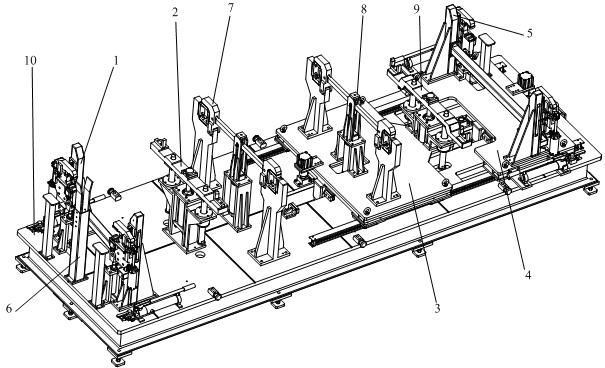

Device for correcting automobile frame body

The invention discloses a device for correcting an automobile frame body, which comprises a front correction mechanism, a front jacking mechanism, a front slider, a rear slider, a rear correction mechanism, a guide column, a front clamping and positioning mechanism, a rear clamping and positioning mechanism, a rear jacking mechanism and a base plate, wherein the front correction mechanism and the guide column are arranged side by side, the front jacking mechanism is positioned behind the front correction mechanism, the front clamping and positioning mechanism is positioned behind the front jacking mechanism, the rear clamping and positioning mechanism is positioned on the front slider which is arranged behind the front clamping and positioning mechanism, the rear jacking mechanism is positioned behind the rear clamping and positioning mechanism, the rear correction mechanism is positioned on the rear slider which is arranged behind the rear jacking mechanism, and the front correction mechanism, the front jacking mechanism, the front slider, the rear slider, the rear correction mechanism, the guide column and the front clamping and positioning mechanism are all arranged on the base plate. The device can effectively correct buckling deformation ofthe head and tail parts of the automobile frame after welding.

Owner:SHANGAHI SHOW KYOEL AUTOMOTIVE EQUIP

Liquid ejecting head, liquid ejecting apparatus, and method of manufacturing liquid ejecting head

ActiveUS20150273826A1Increase in sizeImprove liquid qualityInking apparatusWriting implementsLiquid jetEngineering

Owner:SEIKO EPSON CORP

Fisheye rendering with lens distortion correction for 360-degree video

ActiveUS10699389B2Correct warpingImage enhancementTelevision system detailsComputer graphics (images)Radiology

In various implementations, computing systems and computer-implemented methods can be used for correcting the distortion present in a fisheye image, and rendering the image for display as 360-degree video. In various implementations, a computing device can receive 2-dimensional video data captured by an omnidirectional camera. The computing device can map an image from each video frame to a 3-dimensional hemispherical representation. In various implementations, this mapping can be executed using a polynomial model. The 3-dimensional hemispherical representation can then be used in a 360-degree video presentation, to provide a virtual reality experience.

Owner:QUALCOMM INC

Back water-coating device

InactiveCN103184714ACorrect warpingAvoid wastingPaper/cardboardElectric machineryProcess engineering

The invention relates to the technical field of coating equipment, and particularly relates to a back water-coating device. The back water-coating device comprises a water tank, a metering roller in contact with the liquid level of the water tank, a coating roller for coating a water film on a paper surface and a motor used for adjusting the rotating speed, wherein the metering roller is in contact with the coating roller; and the motor is connected with the metering roller and the coating roller. The metering roller of the device transfers water in the water tank onto the coating roller which coats the water film on a non-coating side of paper; the water film slightly permeates into the surface of the non-coating side of the paper; and the paper is oppositely pulled back in the warping direction, thereby achieving an object of correcting the warping of the paper. The rotating speed of the metering roller is adjusted by adjusting the rotating speed of the motor; the quantity of the water coated on the surface of the paper can be accurately controlled according to different requirements; and the control is accurate. The device is simple in structure, prevents water mist pollution and keeps the plant environment clean.

Owner:GUANGDONG QIAOSHENG ANTI COUNTERFEITING MATERIALS CO LTD

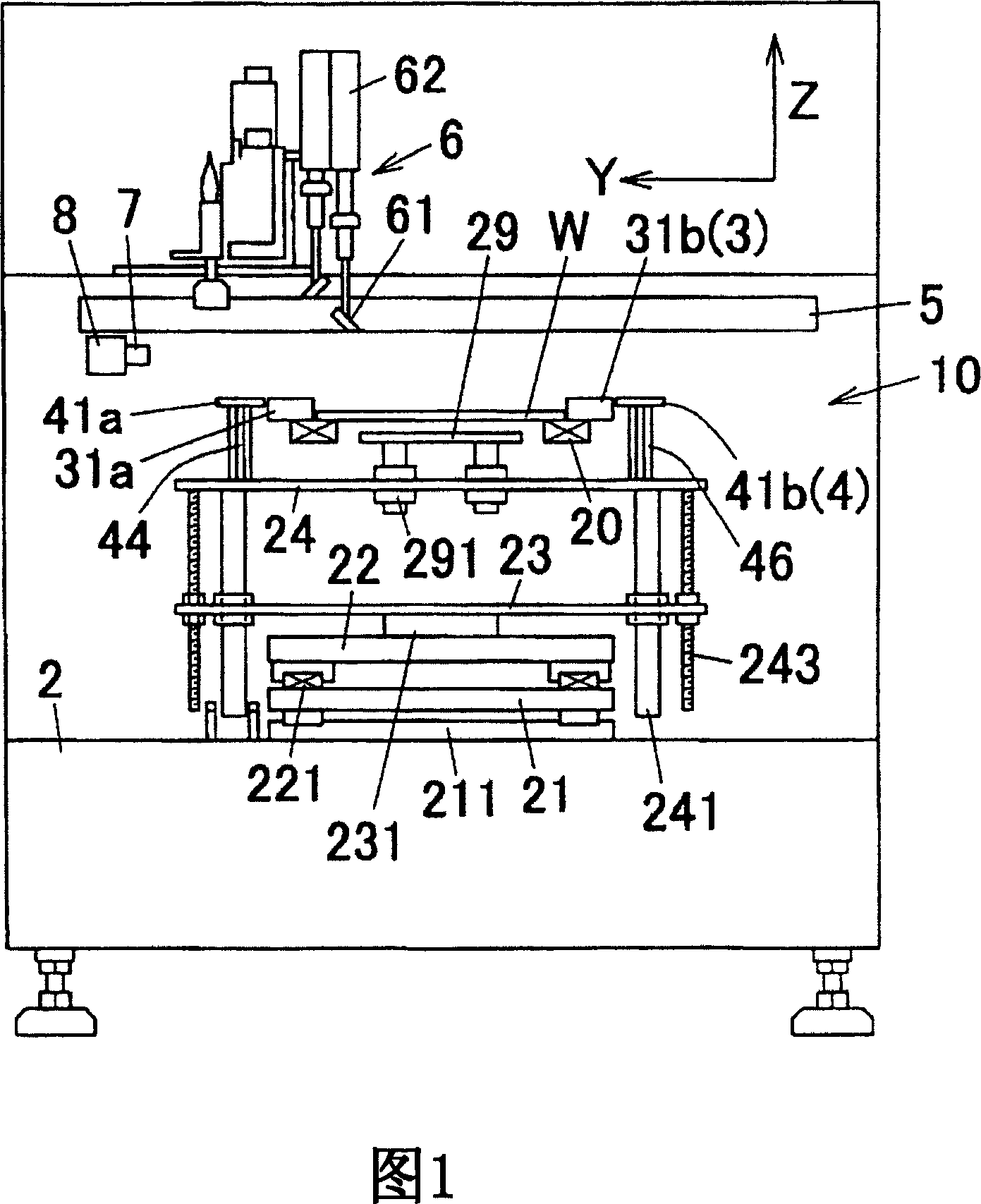

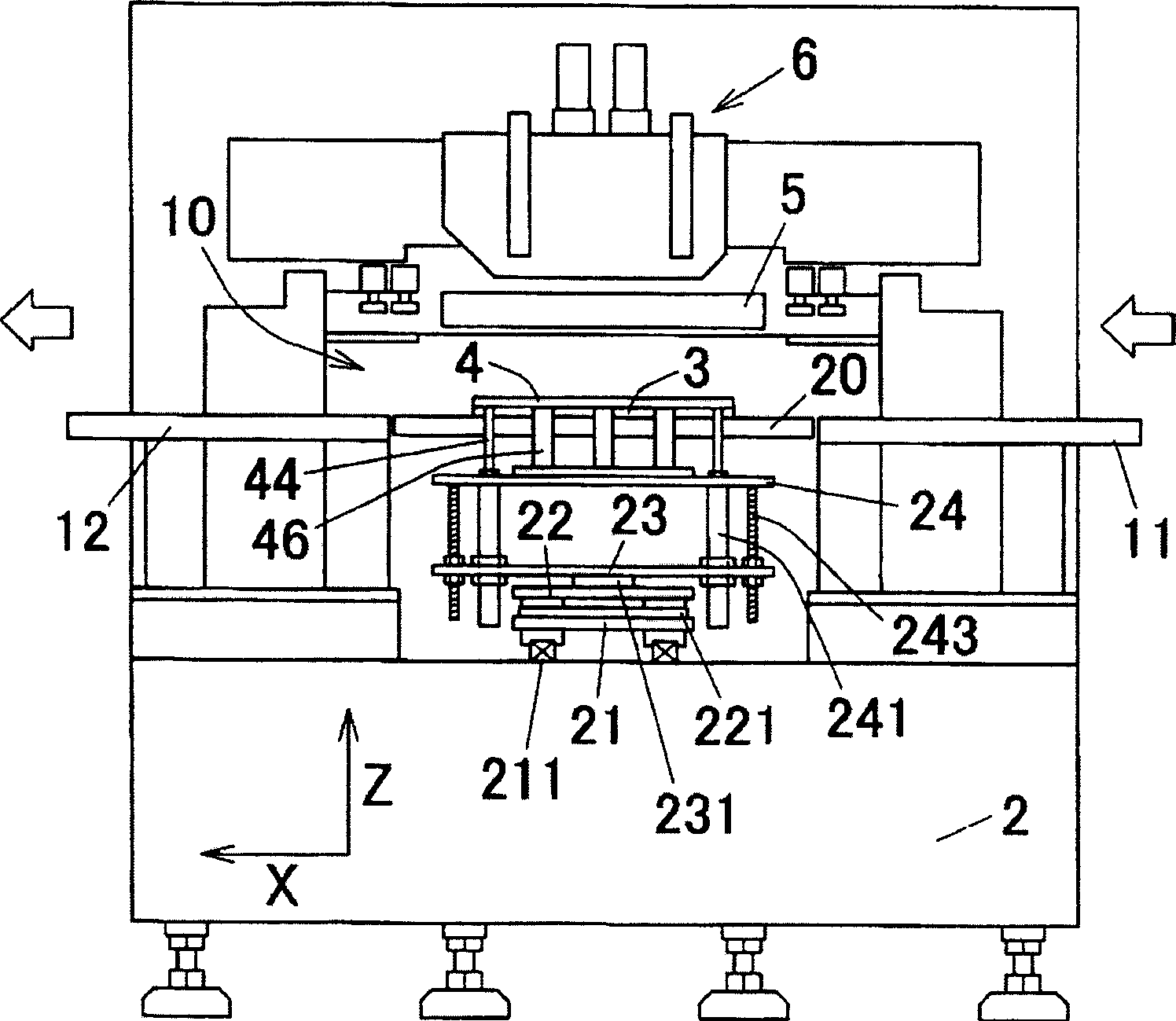

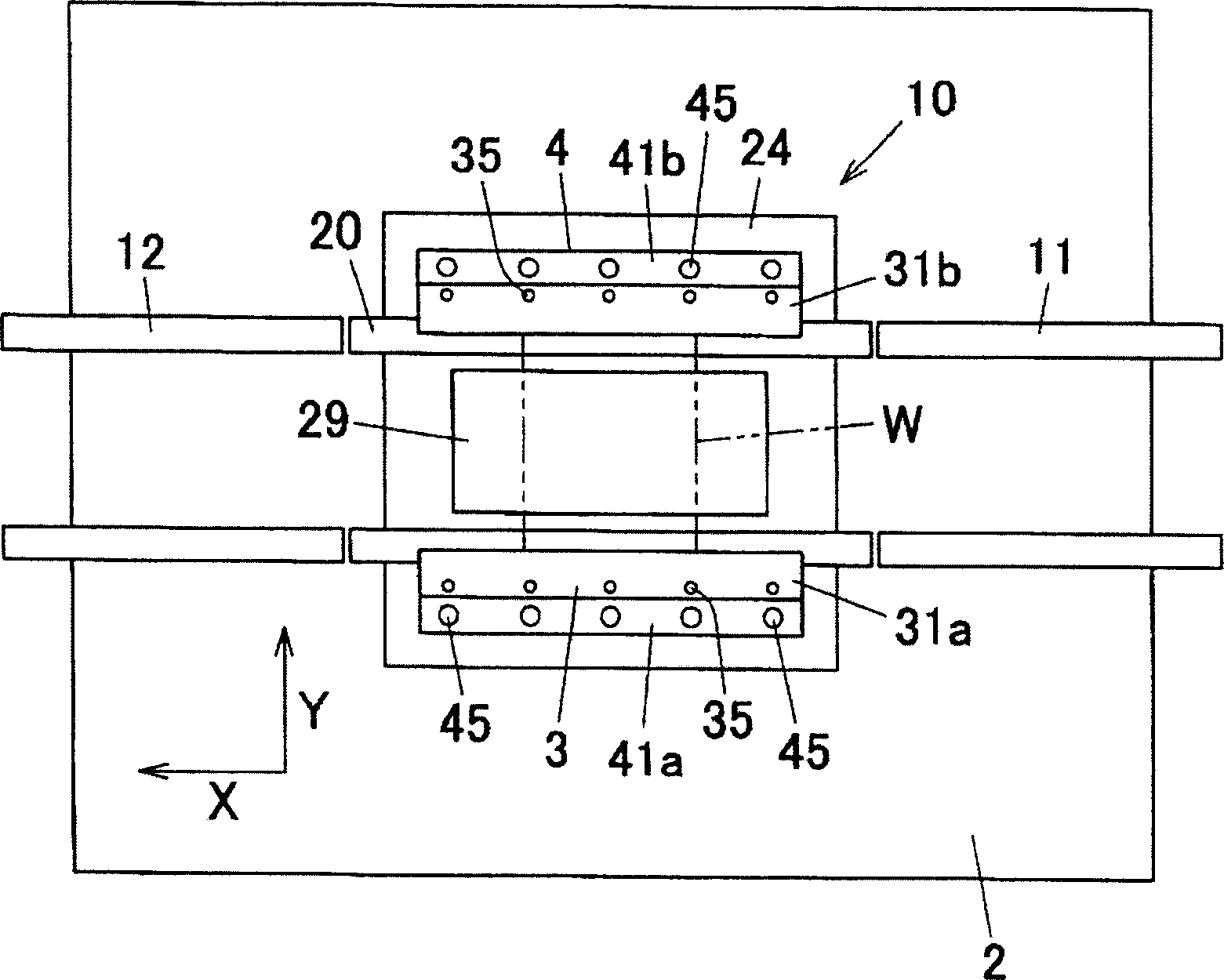

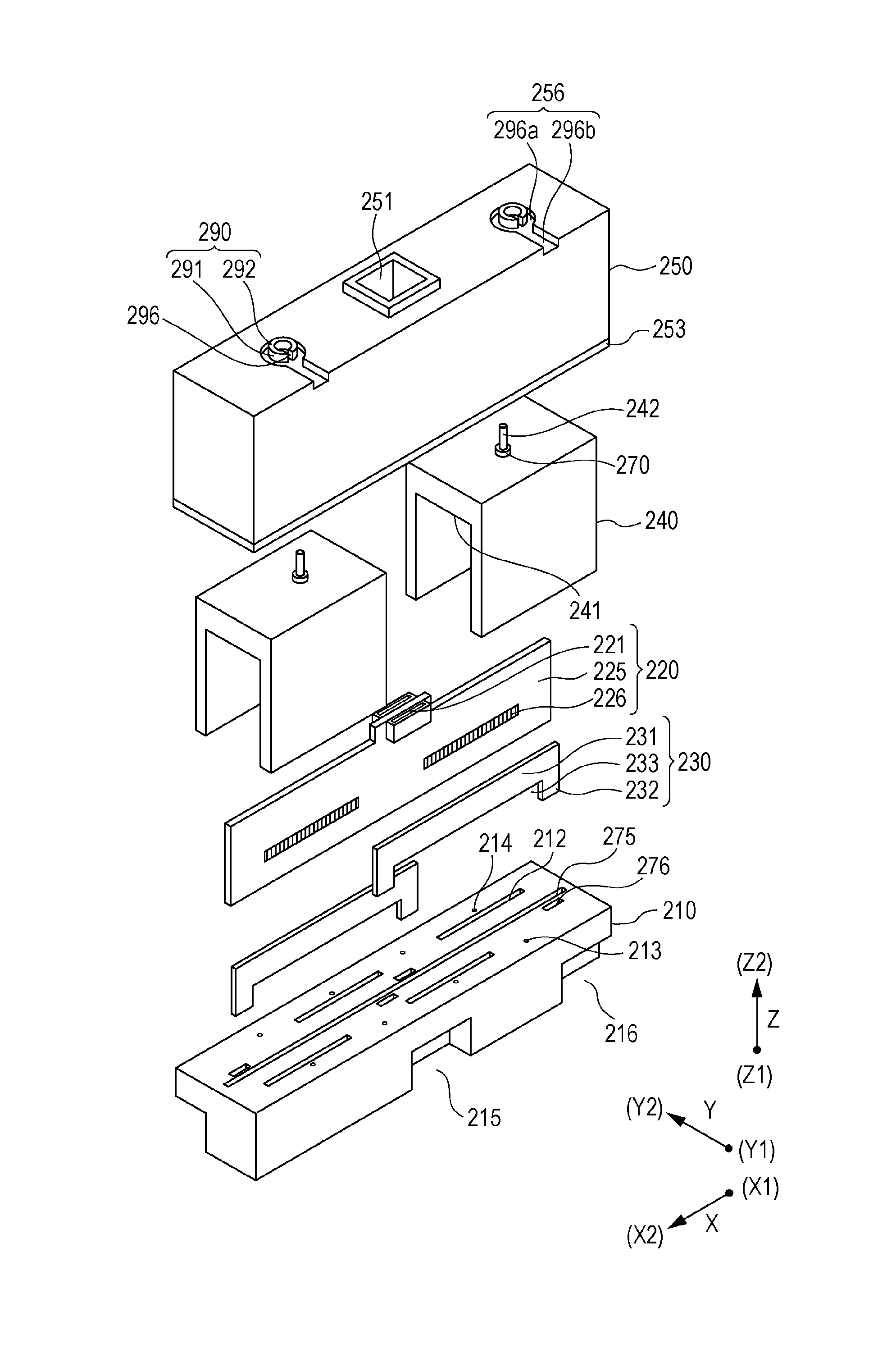

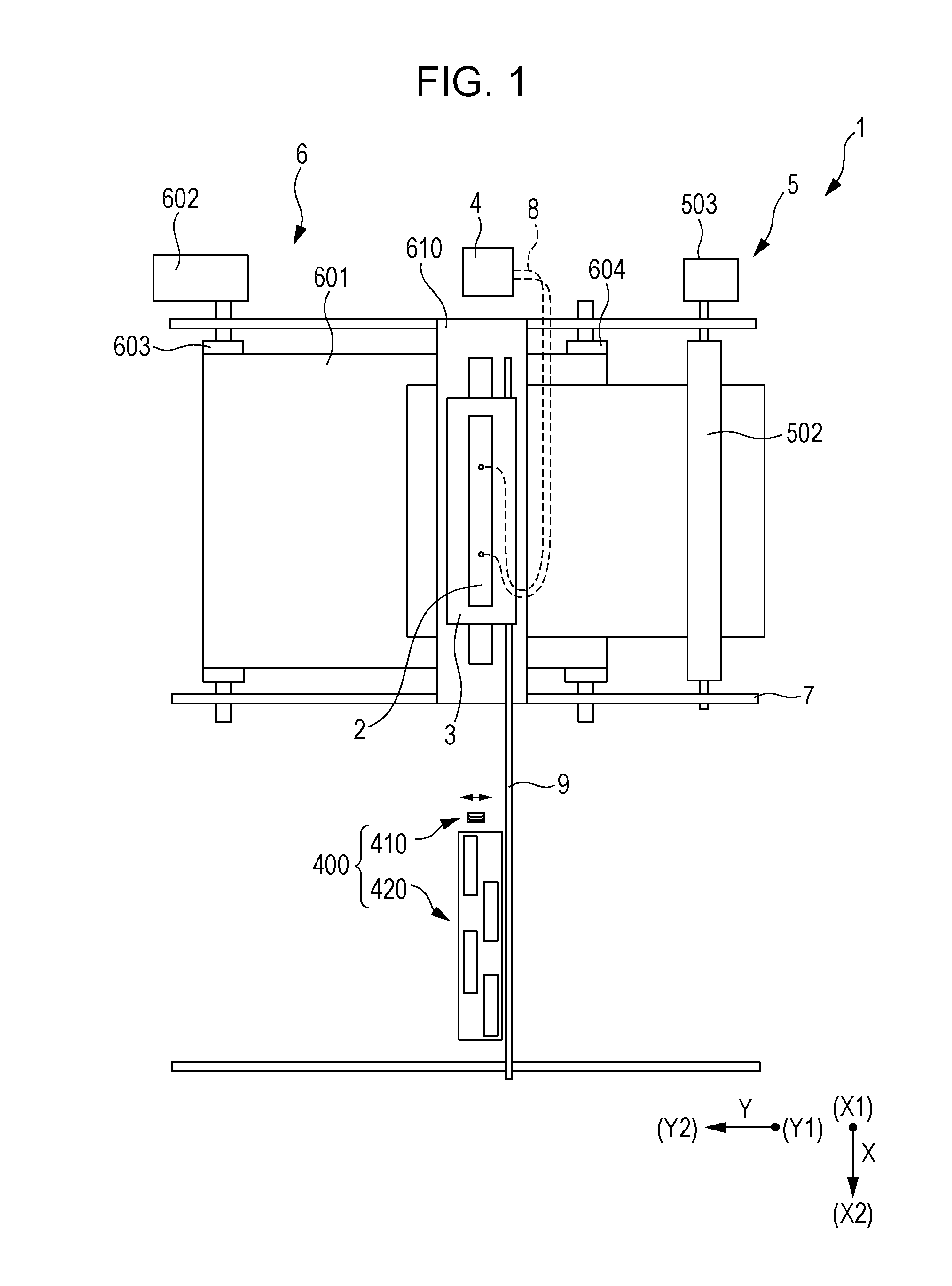

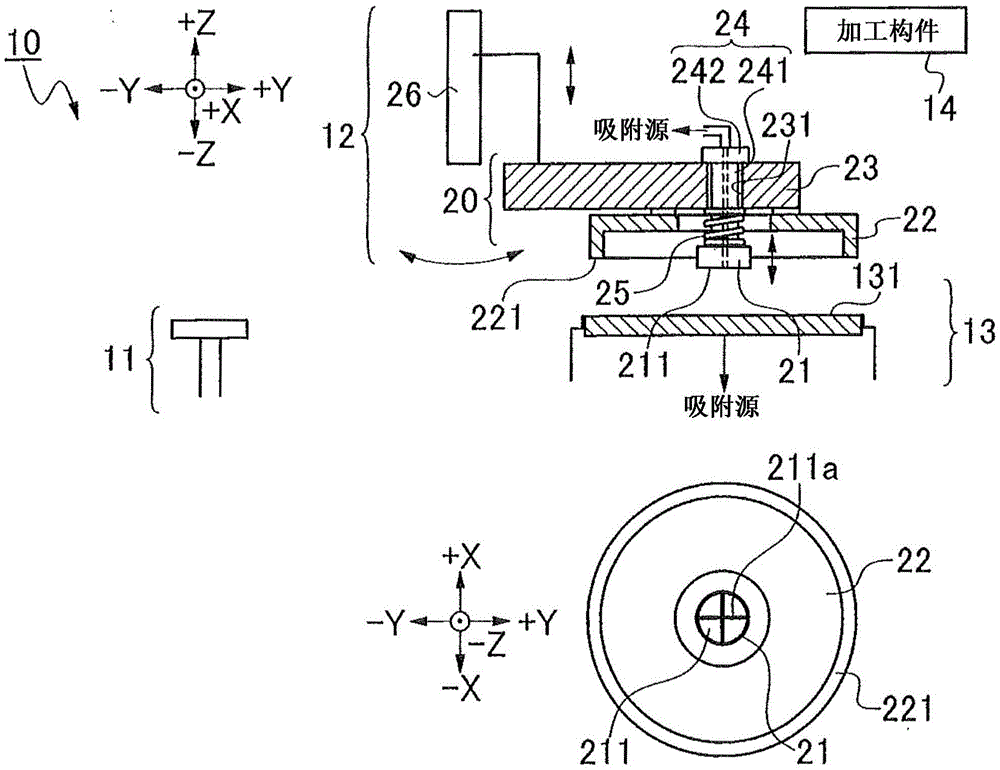

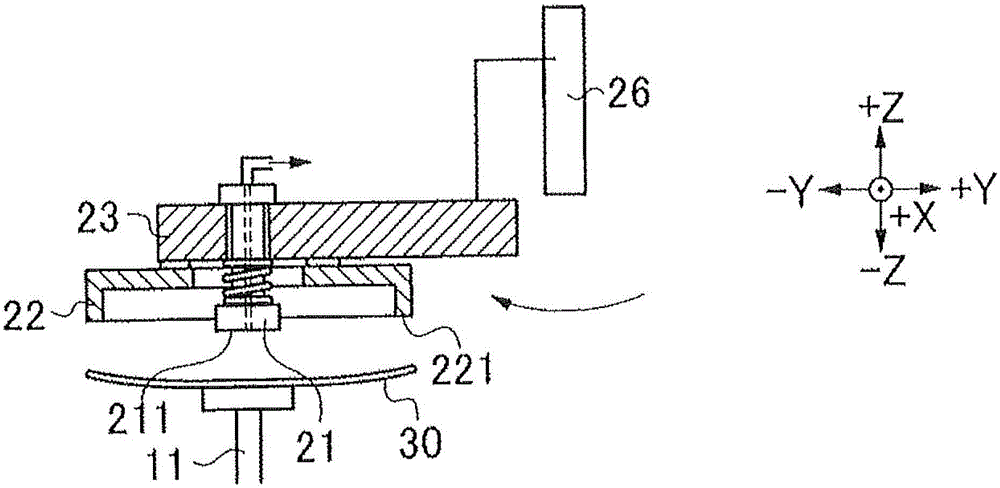

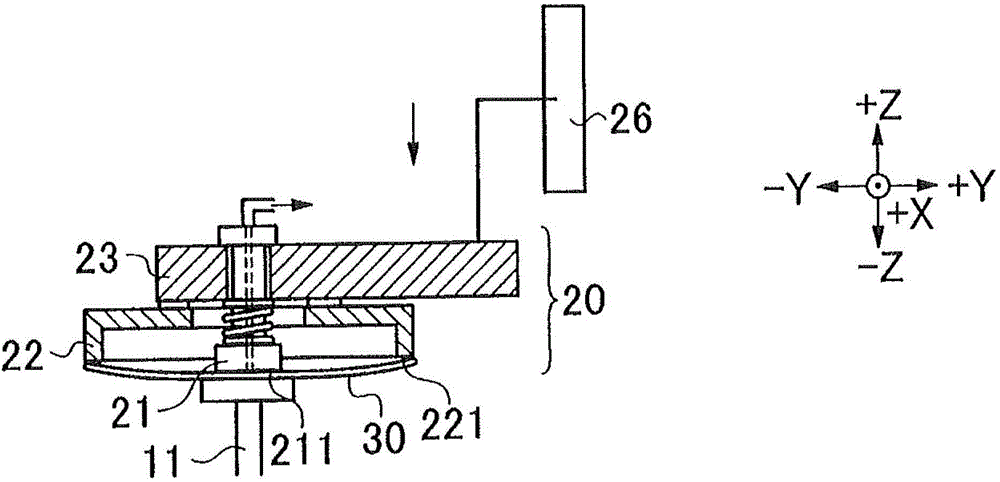

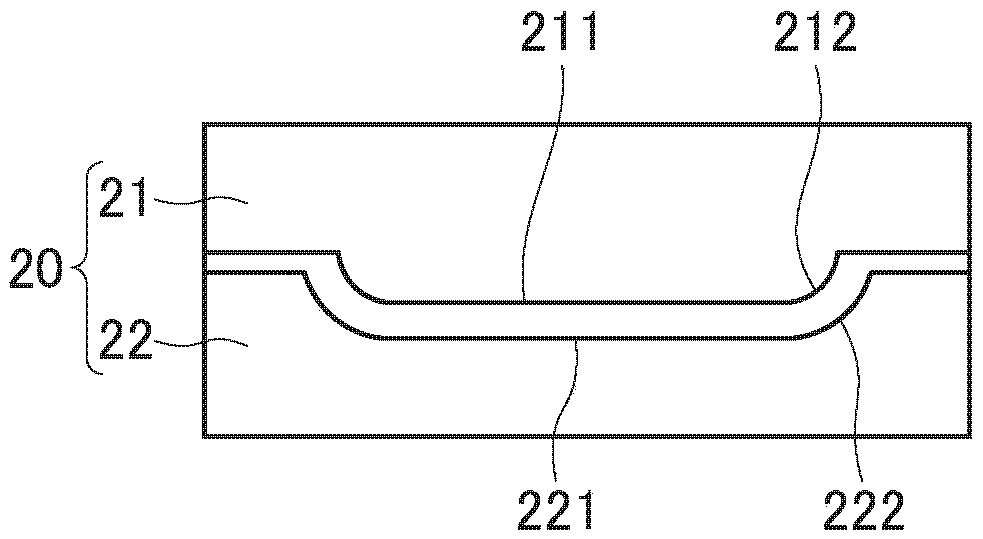

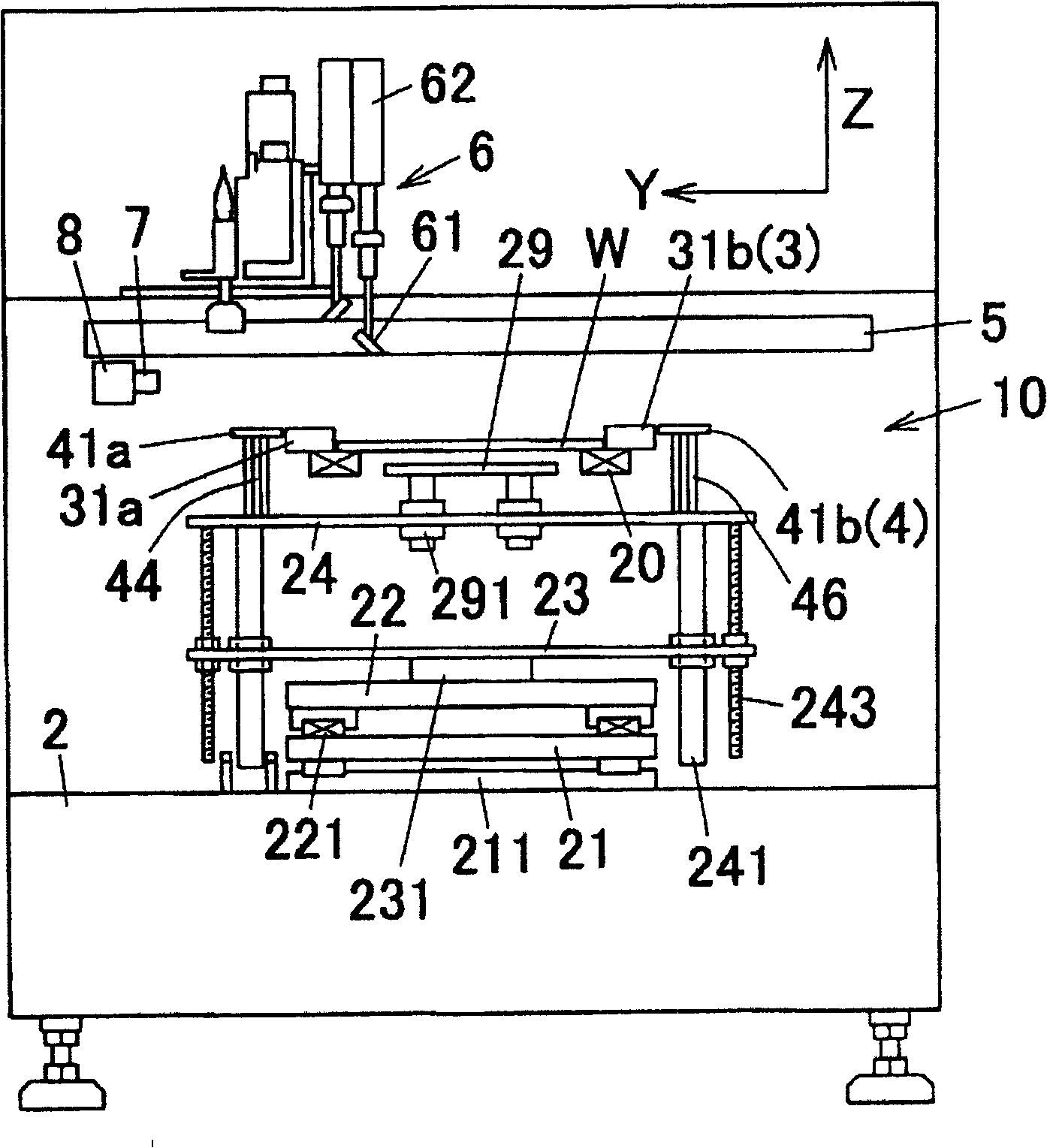

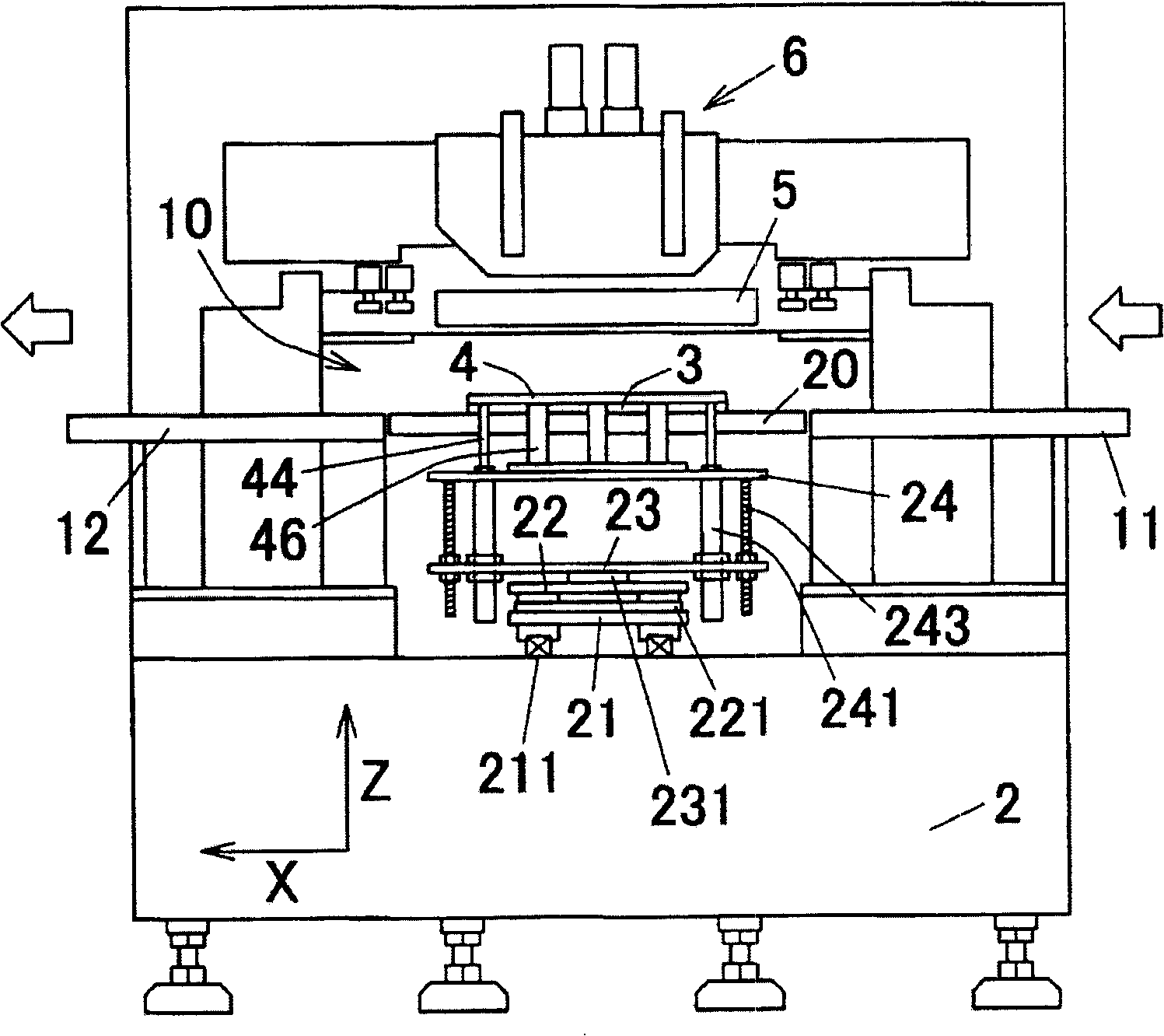

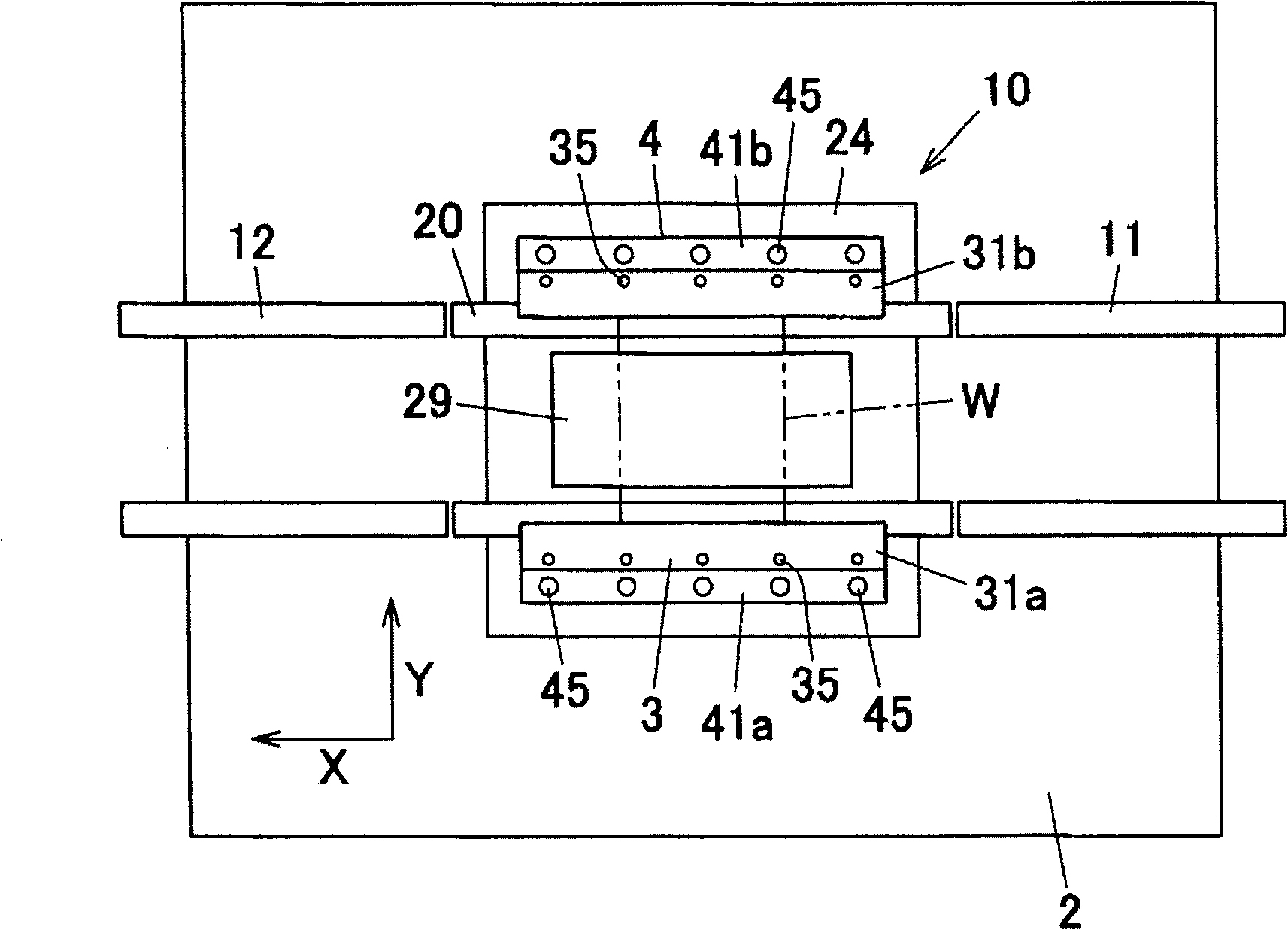

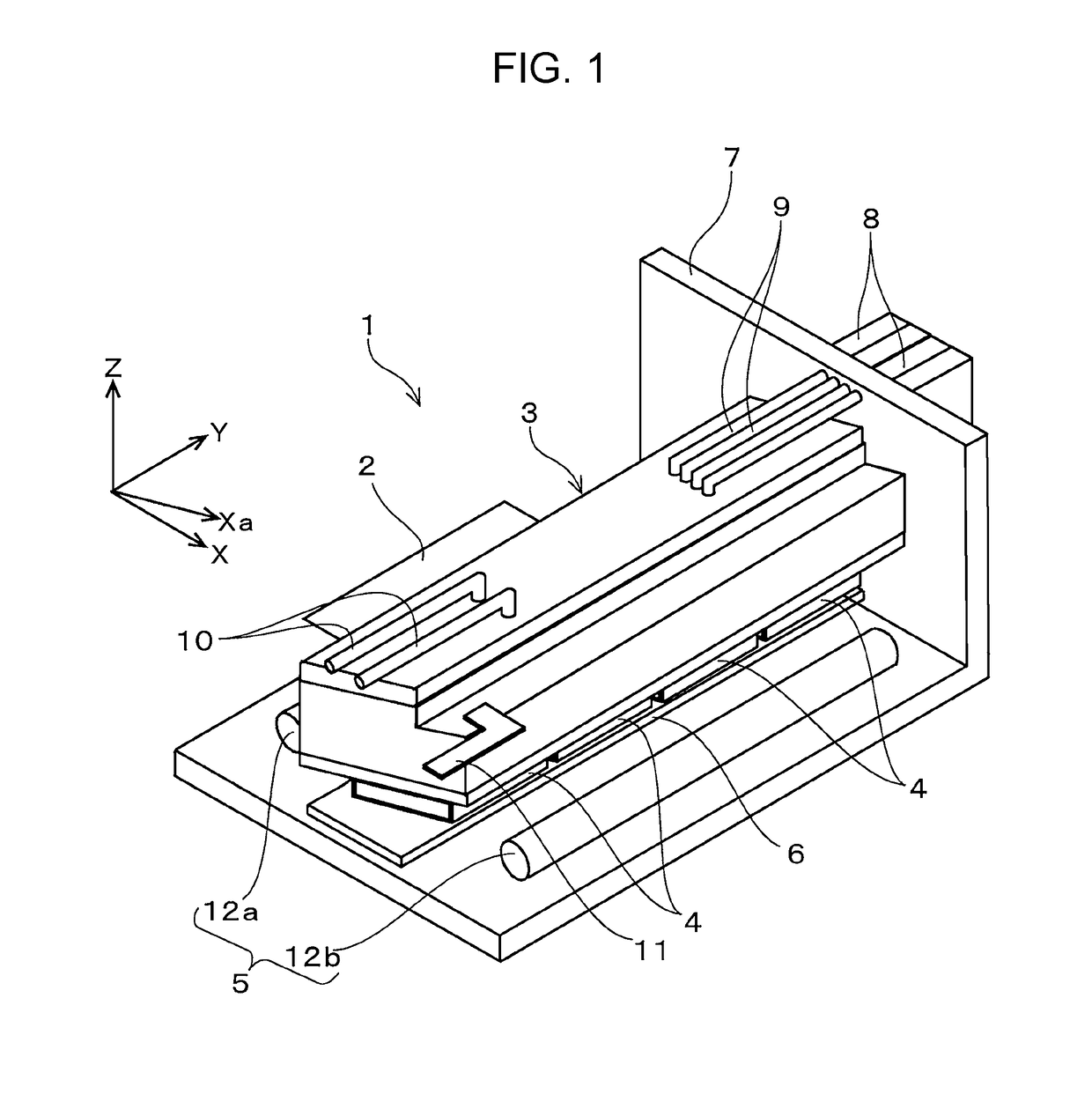

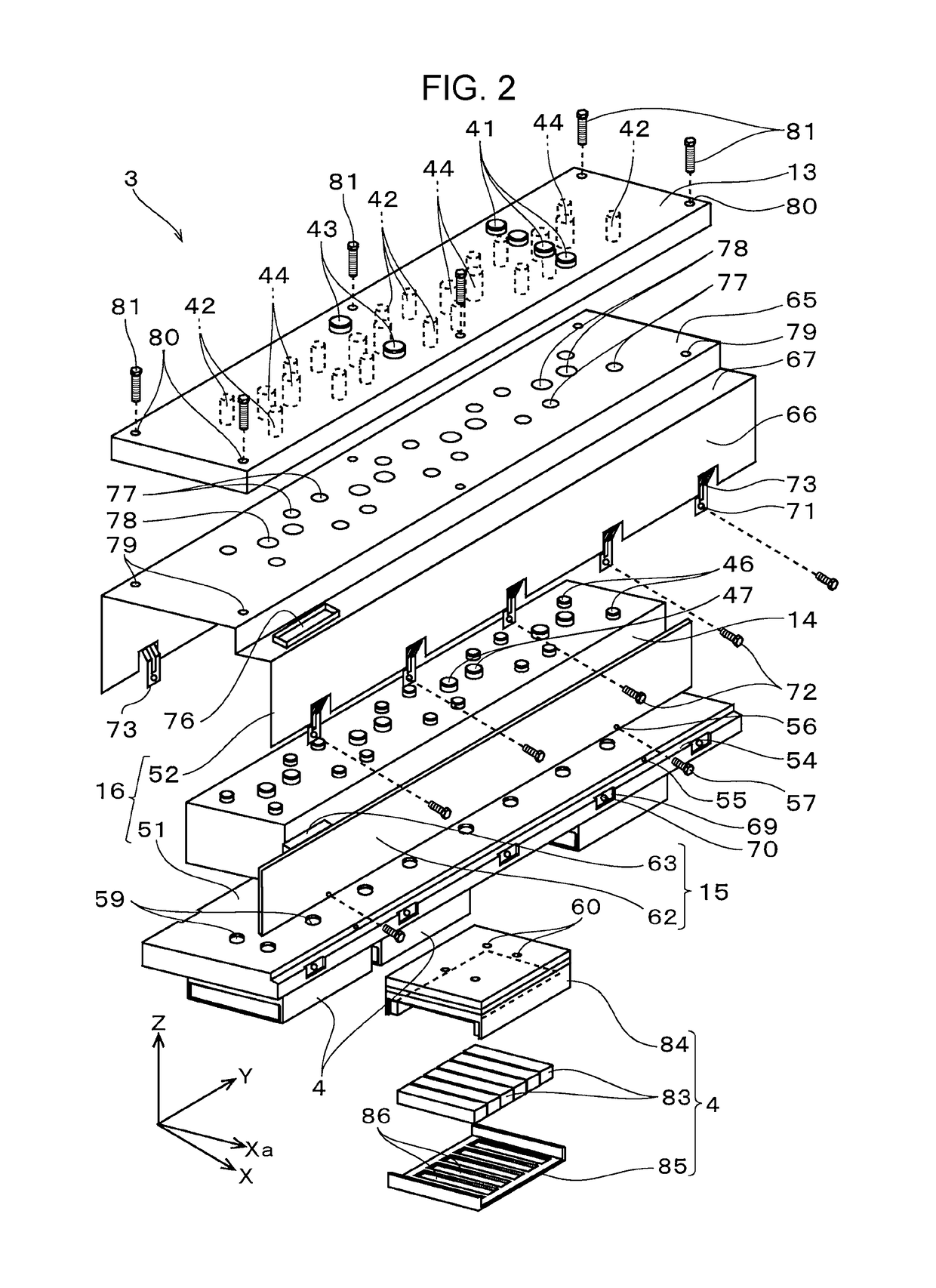

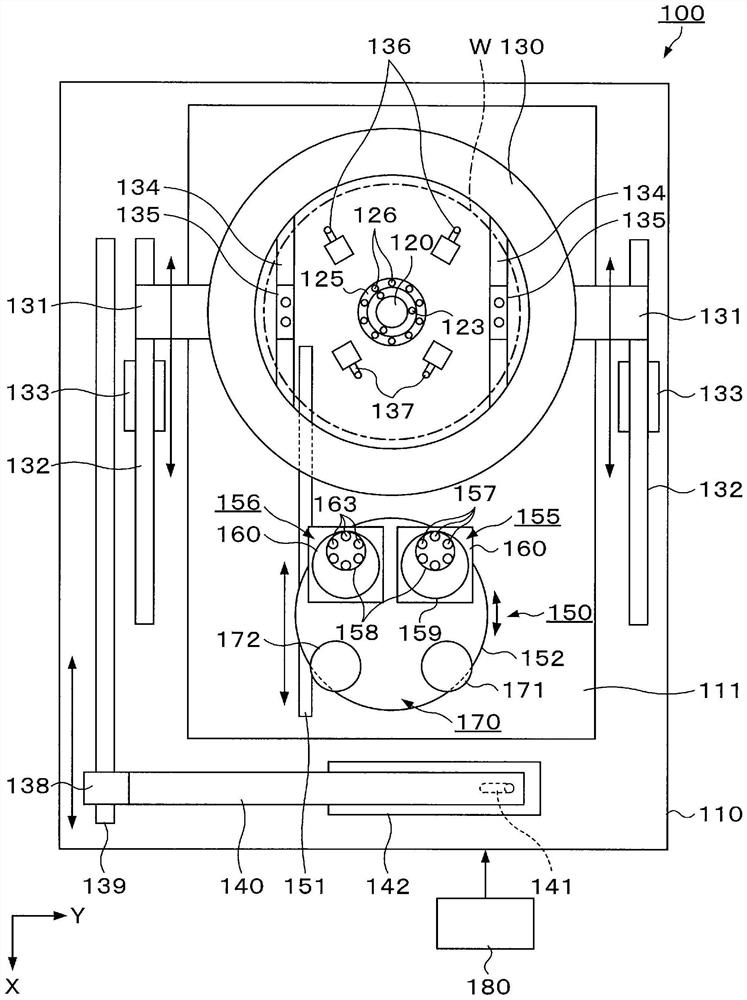

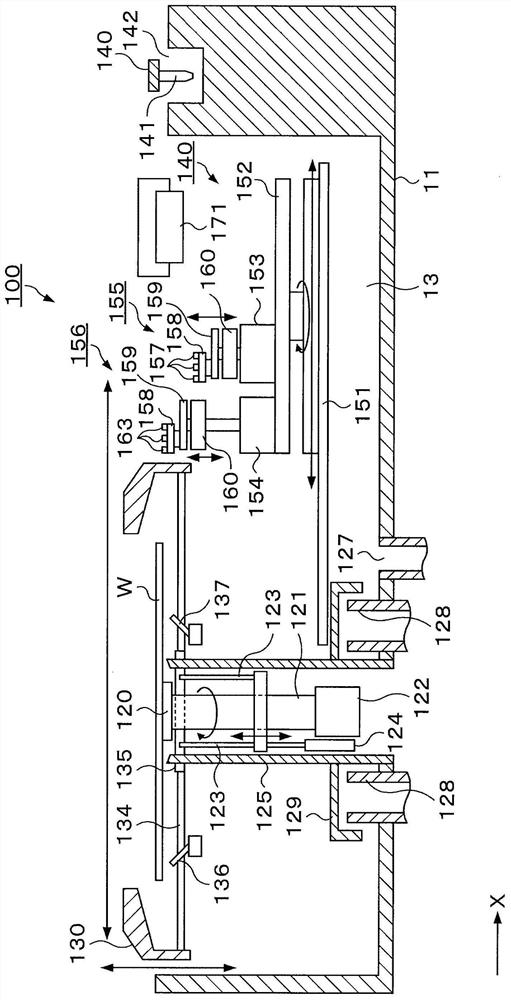

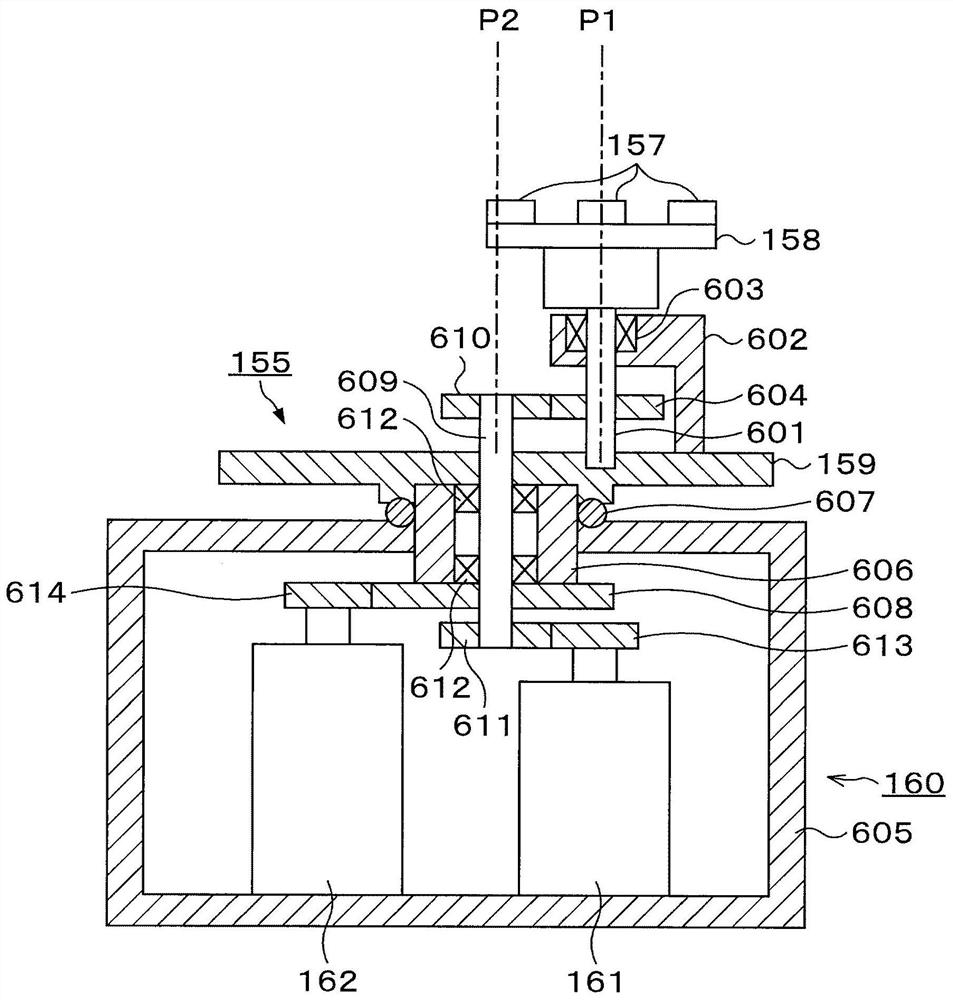

Processing Device

ActiveCN104647204AWill not complicate the structureCorrect warpingWork carriersGrinding work supportsEngineeringMechanical engineering

The present invention provides a processing device which can correct the warping of a workpiece without complicating the structure of the device, and can keep the workpiece on a chuck workbench reliably. A conveying pad (21) possesses an absorption surface (211) of absorbing and keeping the central part of the workpiece, a pressing part (22) possesses an annular pressing surface (211) with an internal diameter greater than the external diameter of the conveying pad (21), and a forwarding and withdrawing part penetrates a hole (231) and a shaft (24) and enables the conveying pad (21) to forward and withdraw along a direction vertical with the absorption surface (211) between a position of the absorption surface (211) protruding towards the pressing surface (221) and the position at which the absorption surface (211) and the pressing surface (221) are located in a same plane. A lifting component (26) enables a keeping mechanism (20) keeping the workpiece to move towards the direction of the chuck workbench (13), thereby pressing the workpiece against the chuck workbench (13). Therefore, the forwarding and withdrawing part acts, so that the absorption surface (211) is positioned in the plane same with the pressing surface (221), the warping of the workpiece is corrected, and the chuck workbench (13) keeps the workpiece.

Owner:DISCO CORP

method for producing 3D protective glass

A method for producing a 3D protective glass, comprises the steps of a glass forming step and a chemical strengthening treatment step, wherein the glass forming step includes a heating step of heatinga flat glass material to a transition temperature Tg [DEG C] or more of the glass material, applying a bending in a thickness direction to at least a portion of a peripheral portion of the glass material using a pair of dies including a punch and a die, and a cooling step of cooling the glass material below the temperature of Tg after the heating step; the chemical strengthening treatment step isa step of performing a chemical strengthening treatment on the glass material after the glass forming step; and the cooling step includes the steps of: recording the control temperature of the die asa control temperature T1 [ DEG C]; when the control temperature of the die is recorded as the control temperature T2 [DEG C], and setting at least one of the T2 and the T1 to be equal to or lower than the Tg of the glass material, wherein the T2 is greater than the T1 and the (T2-T1) is maintained at 10 DEG C or higher.

Owner:ASAHI GLASS CO LTD

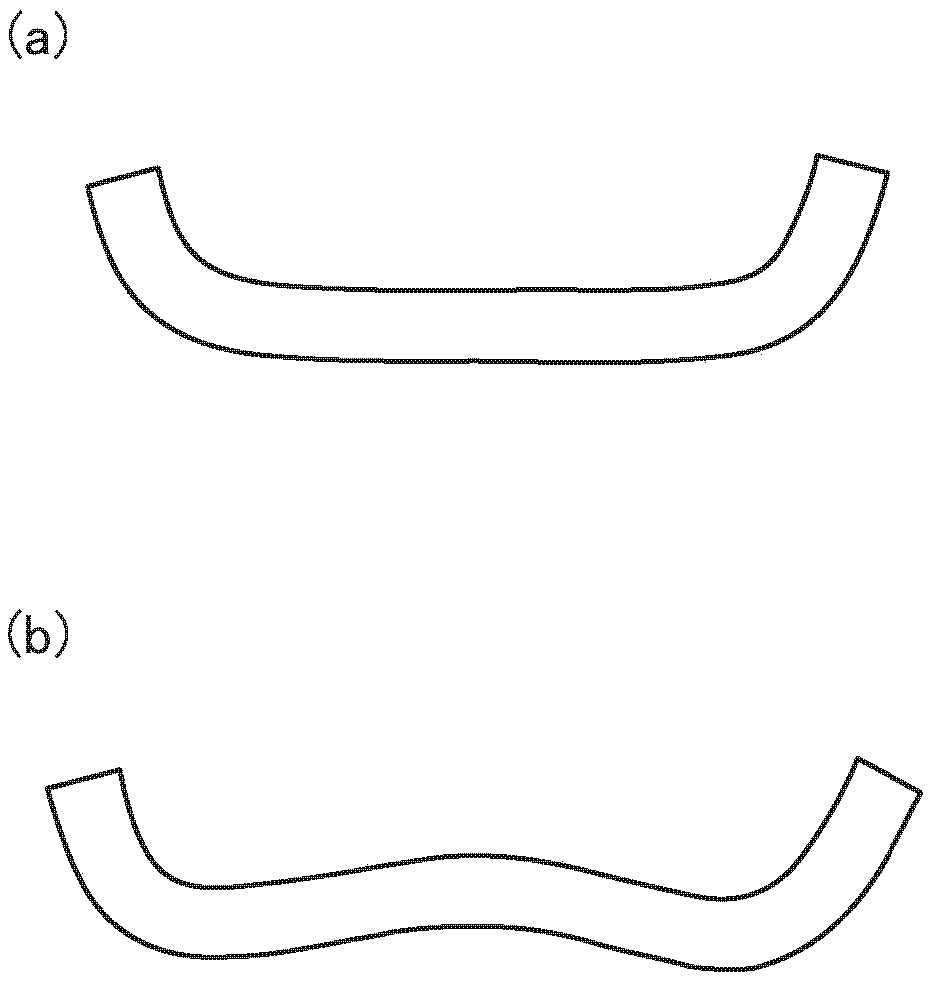

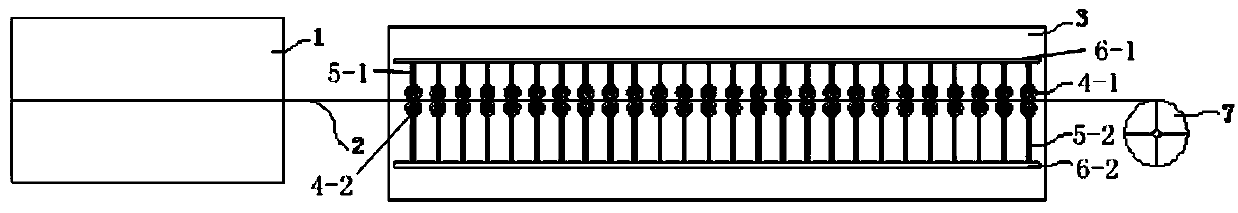

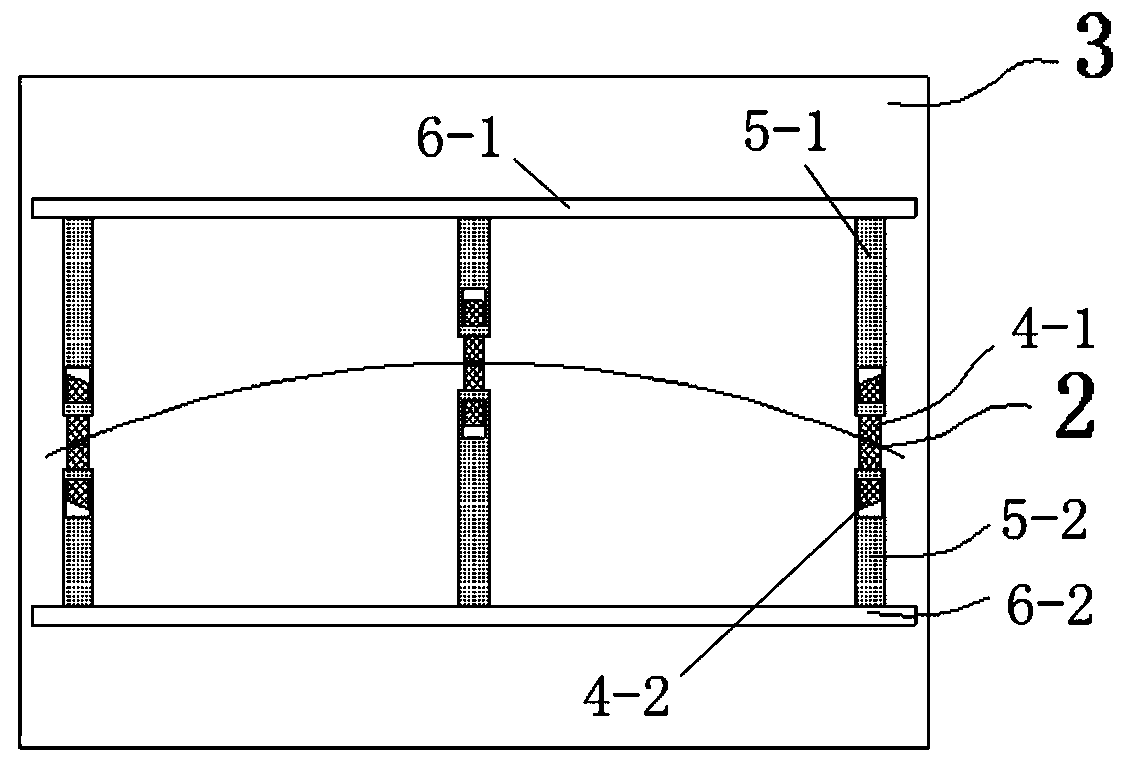

Oven with bent rail

InactiveCN110370799AReduce concentrationReduce heat shrinkagePrinting press partsFlexible circuitsPulp and paper industry

The invention belongs to the technical field of flexible circuit board ink baking devices, and in particular, relates to an oven with a bent rail. An upper roller bracket fixed plate and a lower roller bracket fixed plate are arranged in the oven; multiple rows of upper roller brackets are symmetrically arranged on the lower side of the upper roller bracket fixed plate in an oven access port direction, and the extension lengths of the upper roller brackets are gradually increased from middle row to two side rows; lower roller brackets matched with the upper roller brackets of the upper rollerbracket fixed plate are symmetrically arranged on the upper side of the lower roller bracket fixed plate in the oven access port direction, and the extension lengths of the lower roller brackets are gradually reduced from middle row to two side rows; and rollers rotated in the oven access port direction are arranged at the end parts of free ends of the upper roller brackets and at the end parts offree ends of the lower roller brackets. Under a concave-convex cooperation effect of the upper roller brackets and the lower roller brackets, flexible circuit boards are baked in a reverse warping state for drying ink to achieve a warp correcting effect.

Owner:江苏上达半导体有限公司

Screen printing device

Owner:YAMAHA MOTOR CO LTD

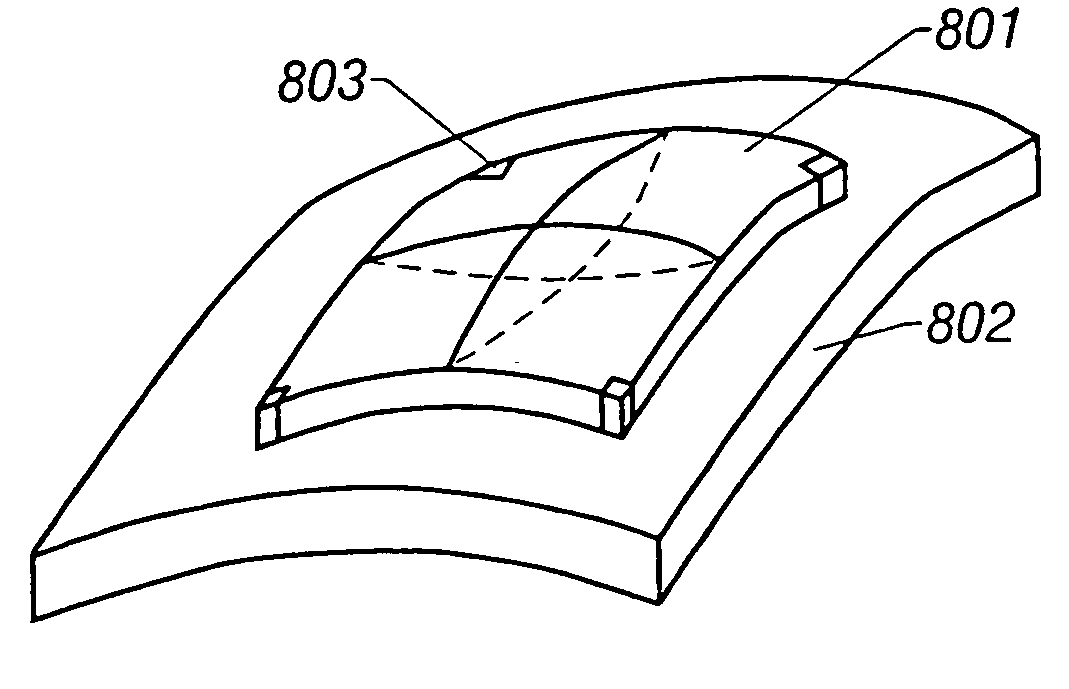

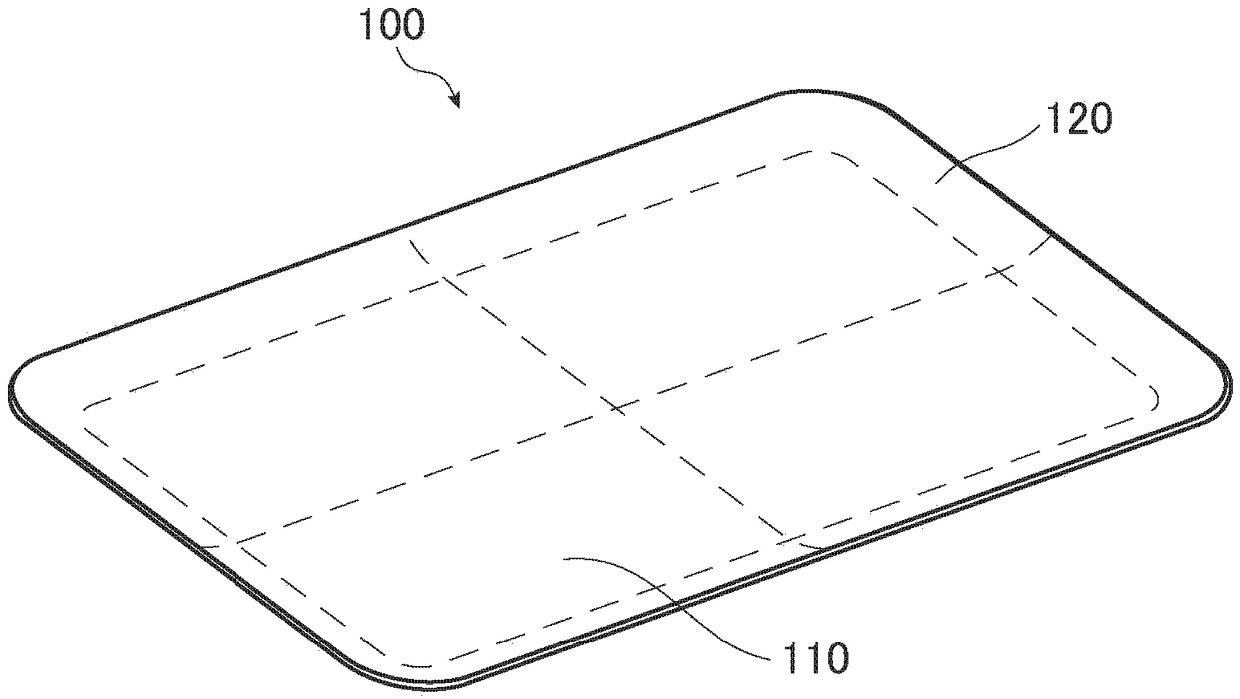

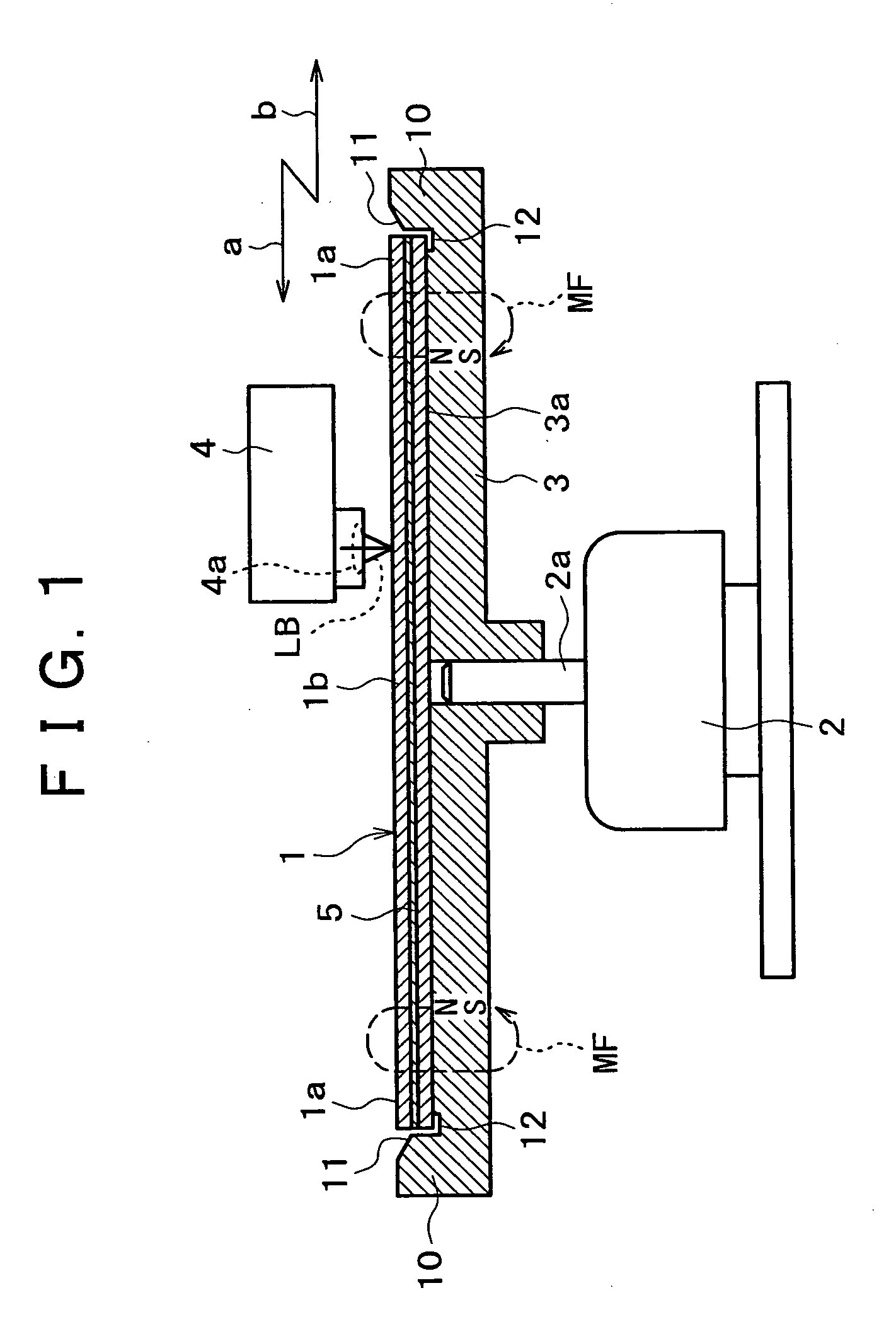

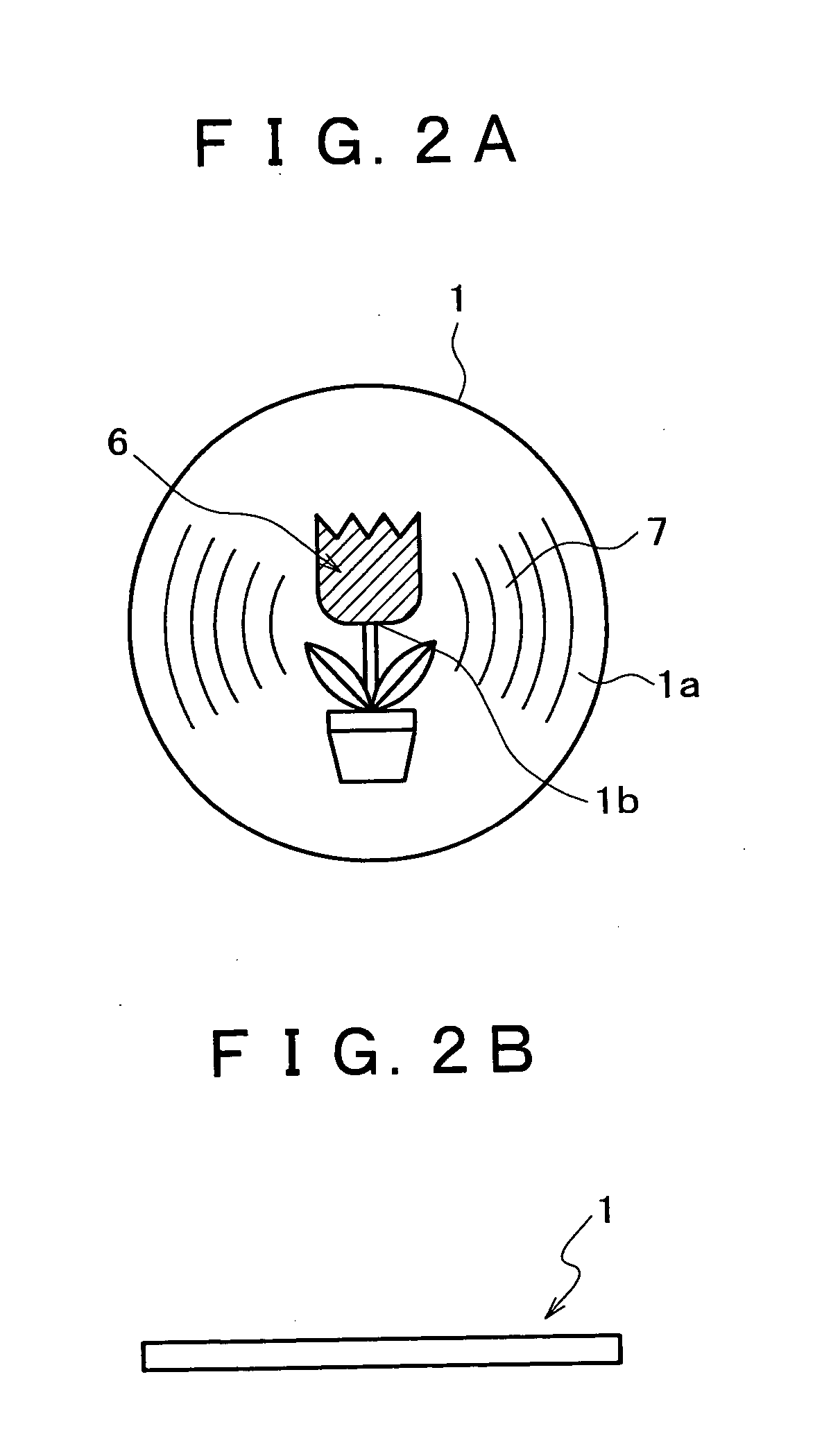

Optical disk medium, optical disk medium production method, turntable and optical disk apparatus

InactiveUS20050046689A1High densityEliminate warpingRecording apparatusDuplicating/marking methodsMagnetic tension forceEngineering

An optical disk that is prevented from being warped when it is driven to rotate by a turntable includes a disk substrate formed as a metal substrate made of a magnetic substance. When the optical disk is mounted on a disk receiving face of the turntable, the metal substrate is attracted to the disk receiving face of the turntable by the magnetic force, thereby to correct any warping of the optical disk medium with a high degree of accuracy.

Owner:SONY CORP

Liquid ejecting head and manufacturing method for liquid ejecting head

A liquid ejecting head includes a liquid ejecting unit that has a nozzle surface to which the nozzle is open, a base member to which the liquid ejecting unit is fixed, and a cover member that is attached to the base member and on which a laminated member is laminated, in which the cover member has a fixing portion to which the laminated member is fixed and a fragile portion that has lower rigidity than the fixing portion, and is attached to the base member by fixing the fragile portion to the base member.

Owner:SEIKO EPSON CORP

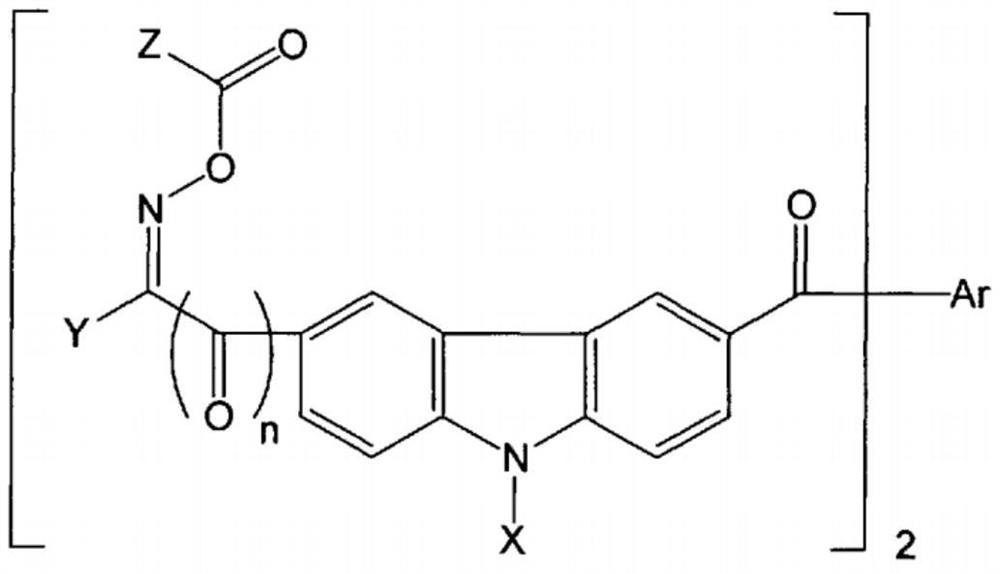

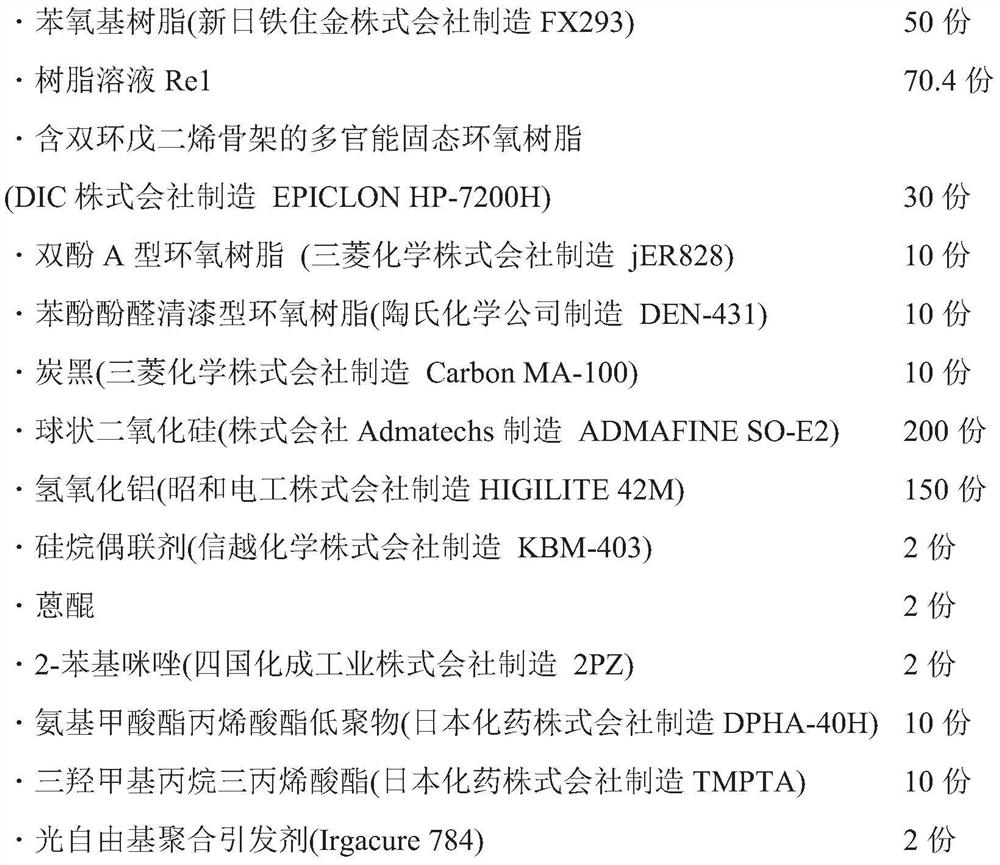

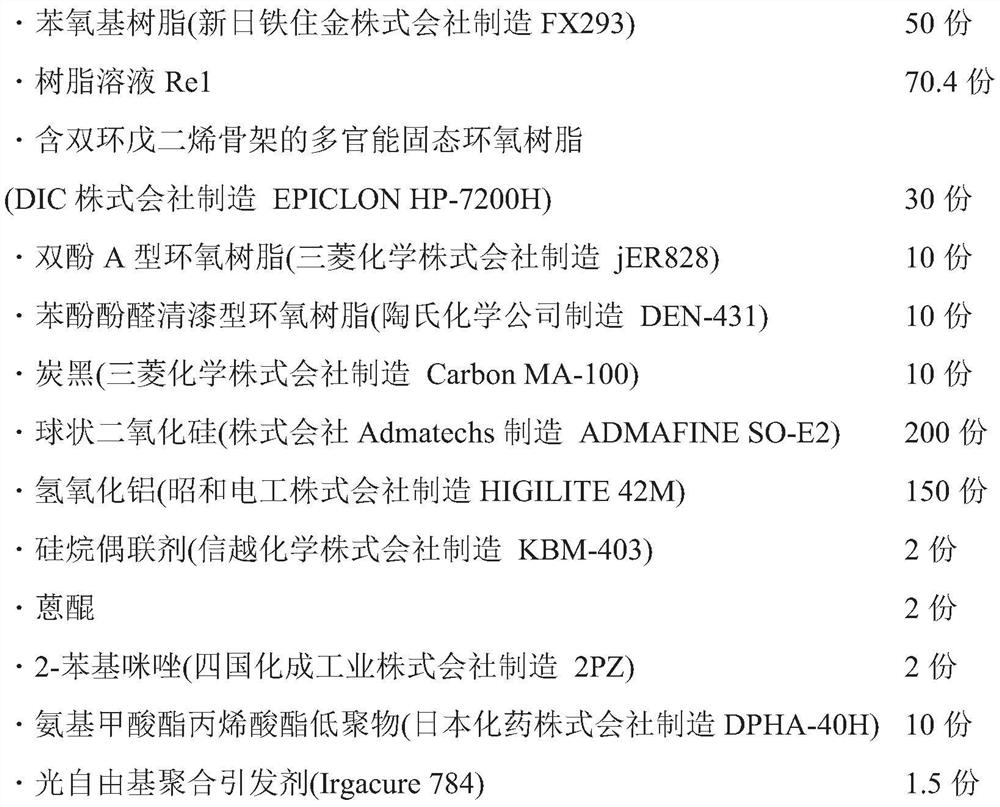

Sealing materials for semiconductors

ActiveCN109415493BCorrect warpingCorrection correction amountSemiconductor/solid-state device detailsSolid-state devicesWaferingPhysical chemistry

Provided is a sealing material for semiconductors capable of reducing warpage of semiconductor wafers and semiconductor packages, especially wafers or packages in fan-out wafer-level packaging (FO-WLP). A semiconductor sealing material comprising at least a thermosetting component (A) and an active energy ray-curable component (B), characterized in that it is resistant to 150°C in an environment not exposed to active energy rays. Sealing material for semiconductors after heat treatment for 10 minutes, at 25°C, at 1J / cm 2 When irradiated with ultraviolet light including a wavelength of 351 nm, the calorific value α (J / g) at this time satisfies 1≦α (J / g).

Owner:TAIYO HLDG CO LTD

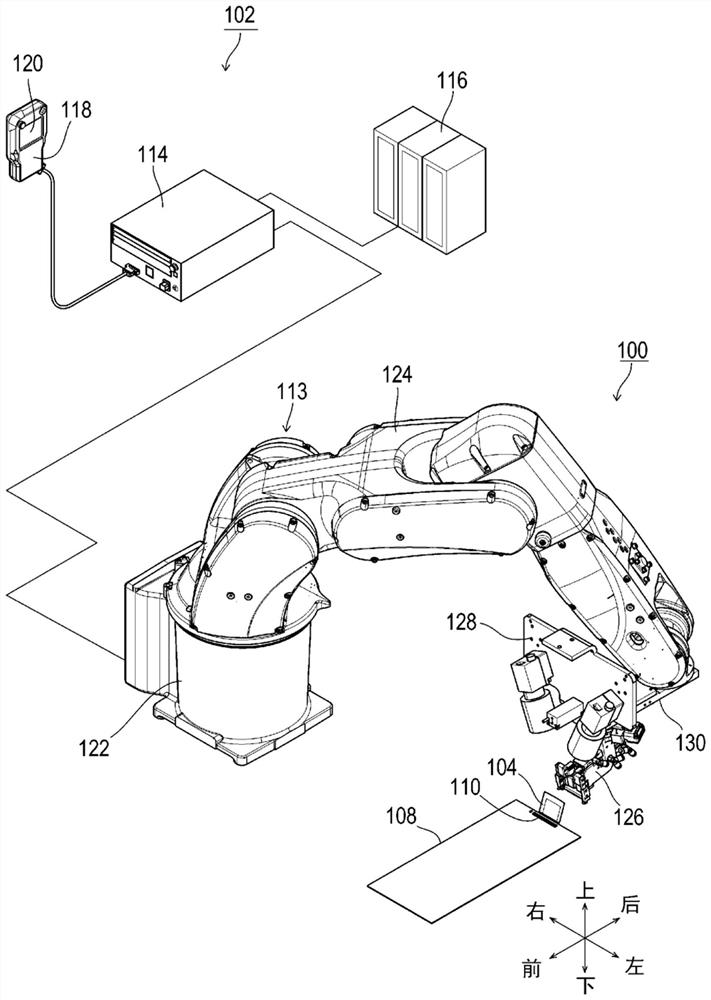

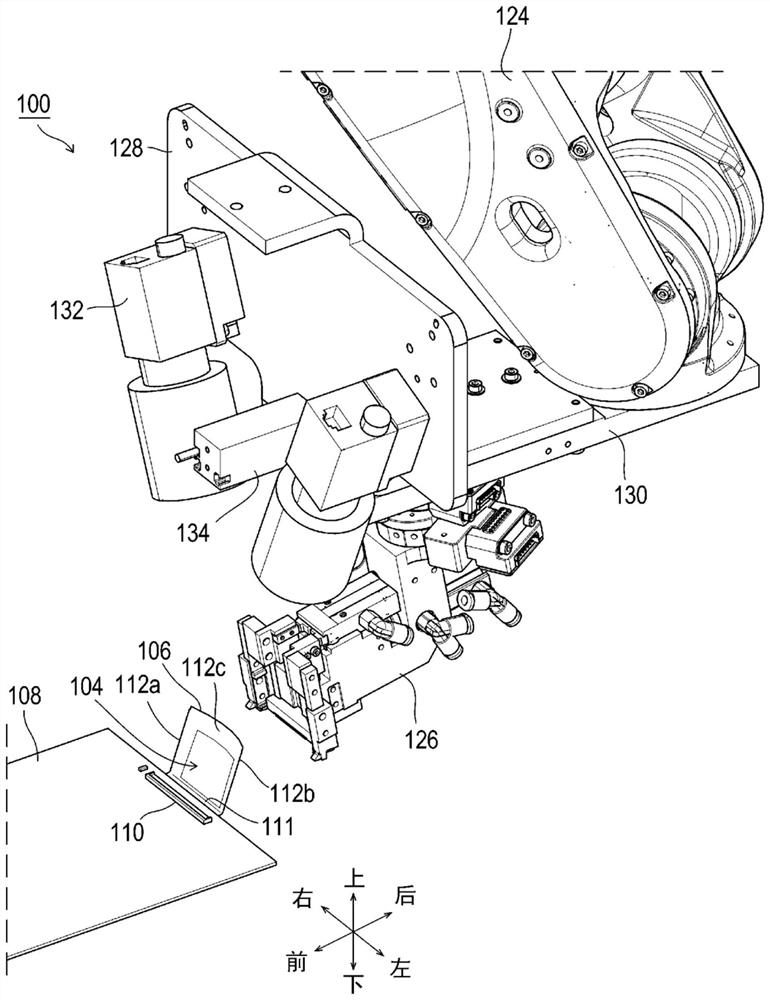

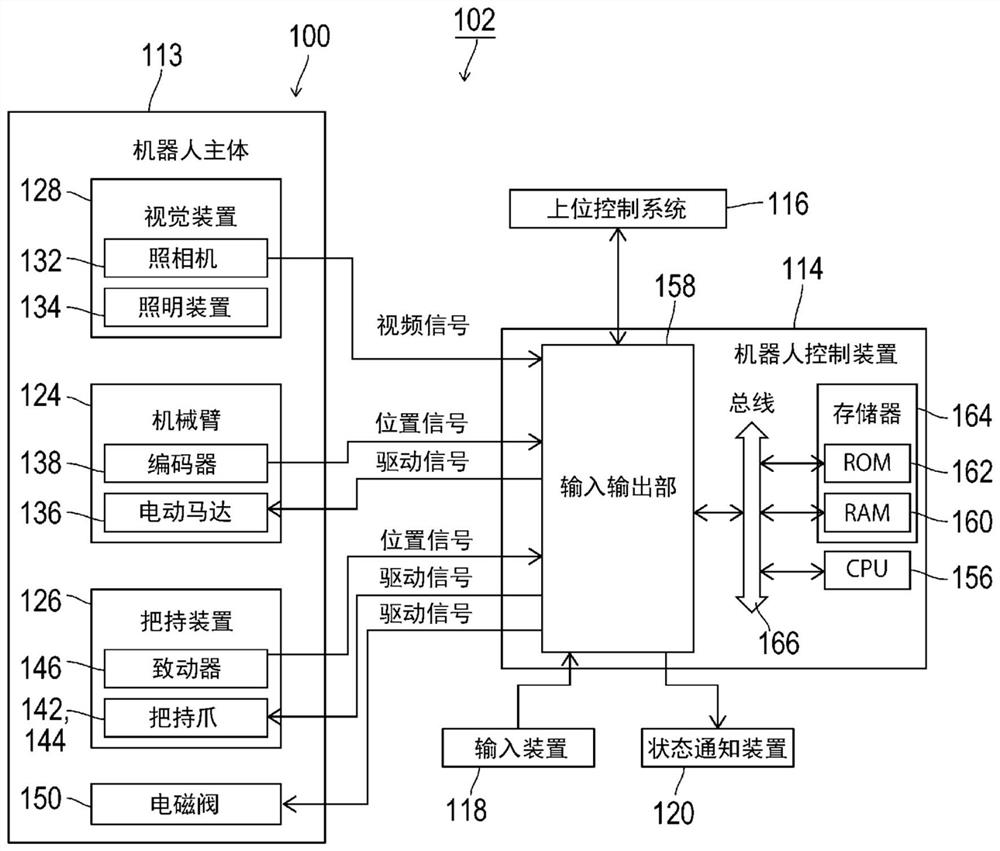

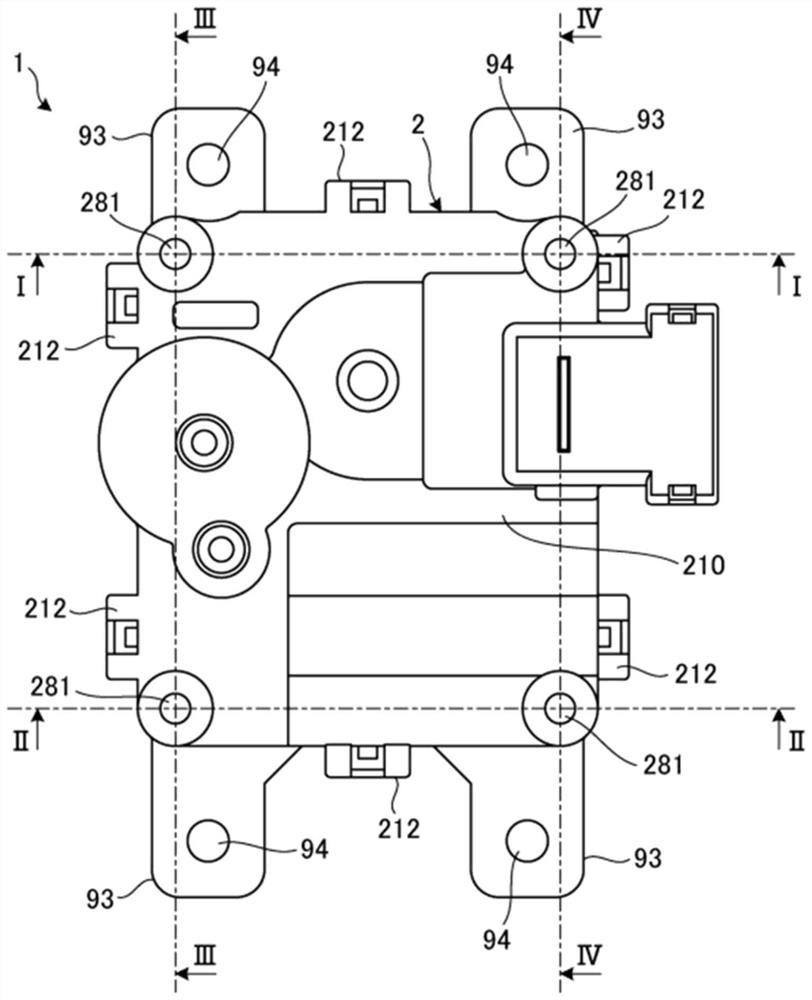

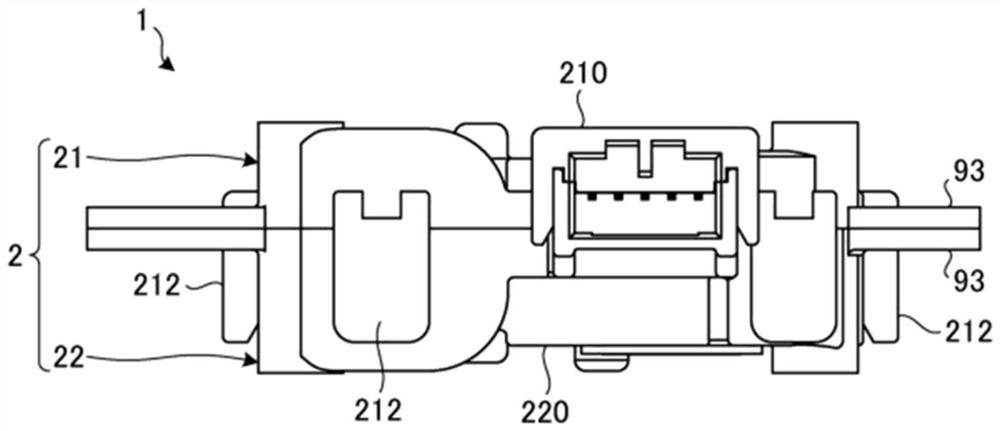

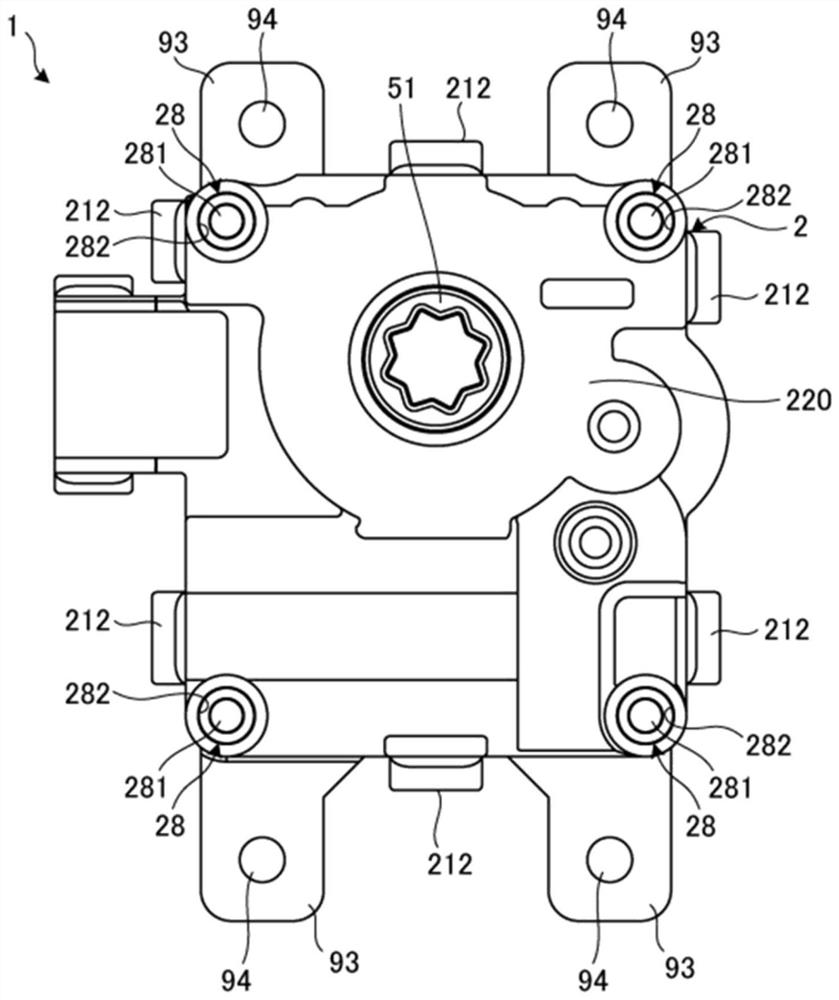

Electronic equipment assembling device and electronic equipment assembling method

ActiveCN114512882ACorrect warpingCoupling device engaging/disengagingFixed connectionsStructural engineeringRobot control

The invention provides an electronic equipment assembling device and an electronic equipment assembling method which can correct warping of a cable and reliably perform connection work of a plurality of cables with different width sizes. The electronic equipment assembling apparatus includes a robot control device that controls the operation of a gripping device that grips a flat and flexible cable having a free tip and a robot arm that moves the gripping device with respect to a circuit board that is a connection target of the tip of the cable, the gripping device having a suction unit that sucks the gripping device, and the robot arm that moves the gripping device with respect to the circuit board to which the tip of the cable is to be connected. A suction member provided on the lower surface and holding one surface of the cable in a suction manner; and a gripping claw which is located on the outer side of the suction part in the width direction and holds the cable in a manner of clamping the cable in the width direction, a first inclined surface is formed on the inner side of the gripping claw in the width direction, the first inclined surface is inclined from the bottom of the gripping claw in a manner that the gripping width becomes larger toward the upward direction, and a second inclined surface is formed on the bottom of the gripping claw. When the gripping claw is in a horizontal state, the second inclined surface is inclined with the front higher than the rear.

Owner:NACHI-FUJIKOSHI

Rotary device

Owner:MINEBEA CO LTD

Substrate warpage correcting method, computer storage medium, and substrate warpage correction device

PendingCN111801772ACorrect warpingSemiconductor/solid-state device manufacturingGrinding headsEngineeringMechanical engineering

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com