Device for correcting automobile frame body

An automobile frame and body technology, which is applied in the field of automobile frame body correcting devices, can solve the problems of data deviation, unknown Z-axis deformation amount and deformation direction, difficult frame positioning and fixing, etc.

Inactive Publication Date: 2012-09-19

SHANGAHI SHOW KYOEL AUTOMOTIVE EQUIP

View PDF7 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Usual correcting machinery and tools (jacks, etc.) have the following disadvantages: 1. It is difficult to position and fix the frame

2. The deformation amount and deformation direction of the Z axis are unknown, and the workpiece needs to be turned over for reverse correction of deformation

3. Multiple clamping and fixing will cause deviations in the corrected data, resulting in repeated work

4. It is difficult to control the springback of the longitudinal beam after the correction force is released

5. Correction efficiency is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

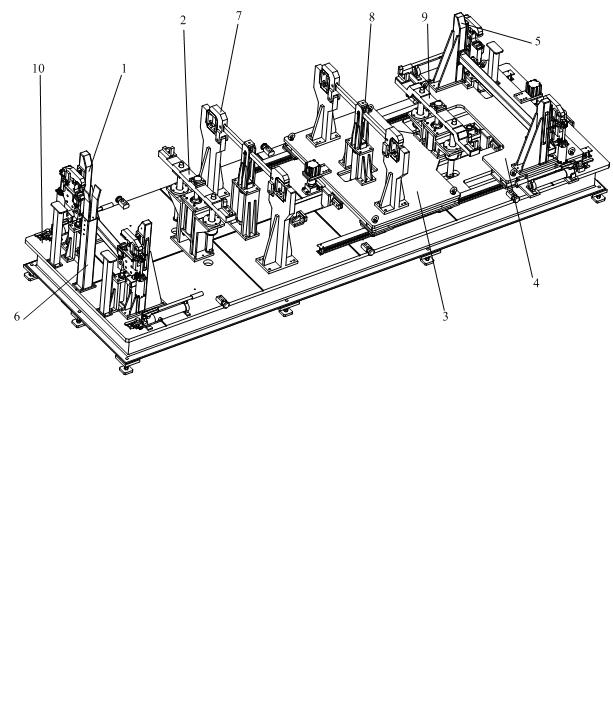

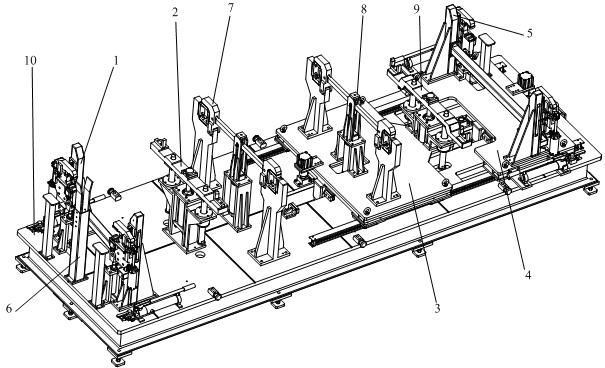

The invention discloses a device for correcting an automobile frame body, which comprises a front correction mechanism, a front jacking mechanism, a front slider, a rear slider, a rear correction mechanism, a guide column, a front clamping and positioning mechanism, a rear clamping and positioning mechanism, a rear jacking mechanism and a base plate, wherein the front correction mechanism and the guide column are arranged side by side, the front jacking mechanism is positioned behind the front correction mechanism, the front clamping and positioning mechanism is positioned behind the front jacking mechanism, the rear clamping and positioning mechanism is positioned on the front slider which is arranged behind the front clamping and positioning mechanism, the rear jacking mechanism is positioned behind the rear clamping and positioning mechanism, the rear correction mechanism is positioned on the rear slider which is arranged behind the rear jacking mechanism, and the front correction mechanism, the front jacking mechanism, the front slider, the rear slider, the rear correction mechanism, the guide column and the front clamping and positioning mechanism are all arranged on the base plate. The device can effectively correct buckling deformation ofthe head and tail parts of the automobile frame after welding.

Description

technical field [0001] The invention relates to a straightening device, in particular to a straightening device for an automobile frame body. [0002] Background technique [0002] Most of the welding of modern automobile frames adopts carbon dioxide shielded welding. Due to the different welding voltage, current, ambient temperature and personal operation methods, the deformation of individual frames will be out of tolerance. It is necessary to measure and correct the individual frames after welding. . Common rectifying machinery and tools (jack etc.) have following shortcoming: one, be difficult to vehicle frame is positioned and fixed. 2. The deformation amount and deformation direction of the Z axis are unknown, and the workpiece needs to be turned over for reverse correction of deformation. 3. Multiple clamping and fixing will cause deviations in the corrected data, resulting in repeated work. 4. It is difficult to control the springback of the longitudinal beam a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21D1/12

Inventor 田永鑫杨斌李育赐刘彪王正锋

Owner SHANGAHI SHOW KYOEL AUTOMOTIVE EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com