Sealing materials for semiconductors

A sealing material and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid device components, electric solid devices, etc., to achieve the effect of correcting warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

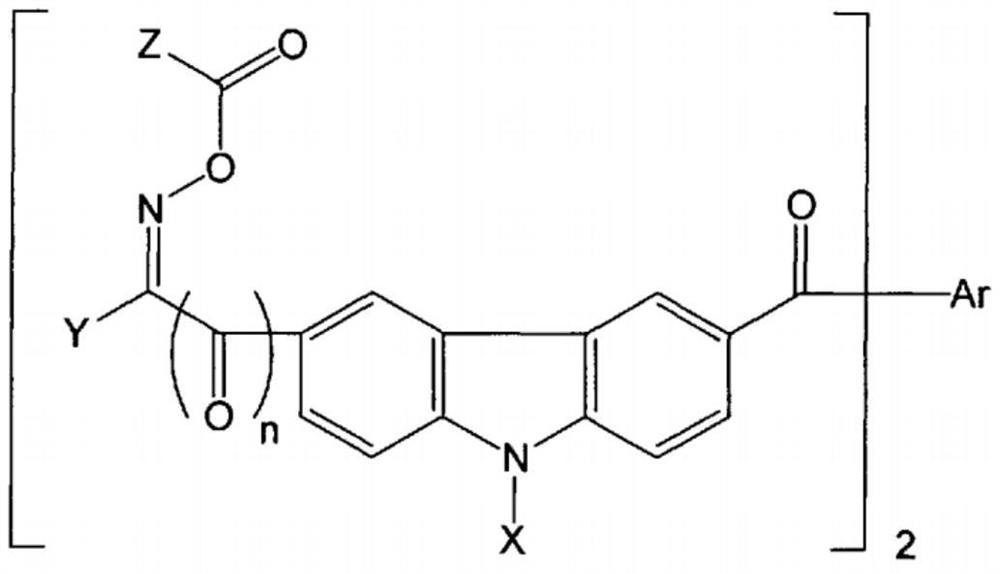

Method used

Image

Examples

Embodiment

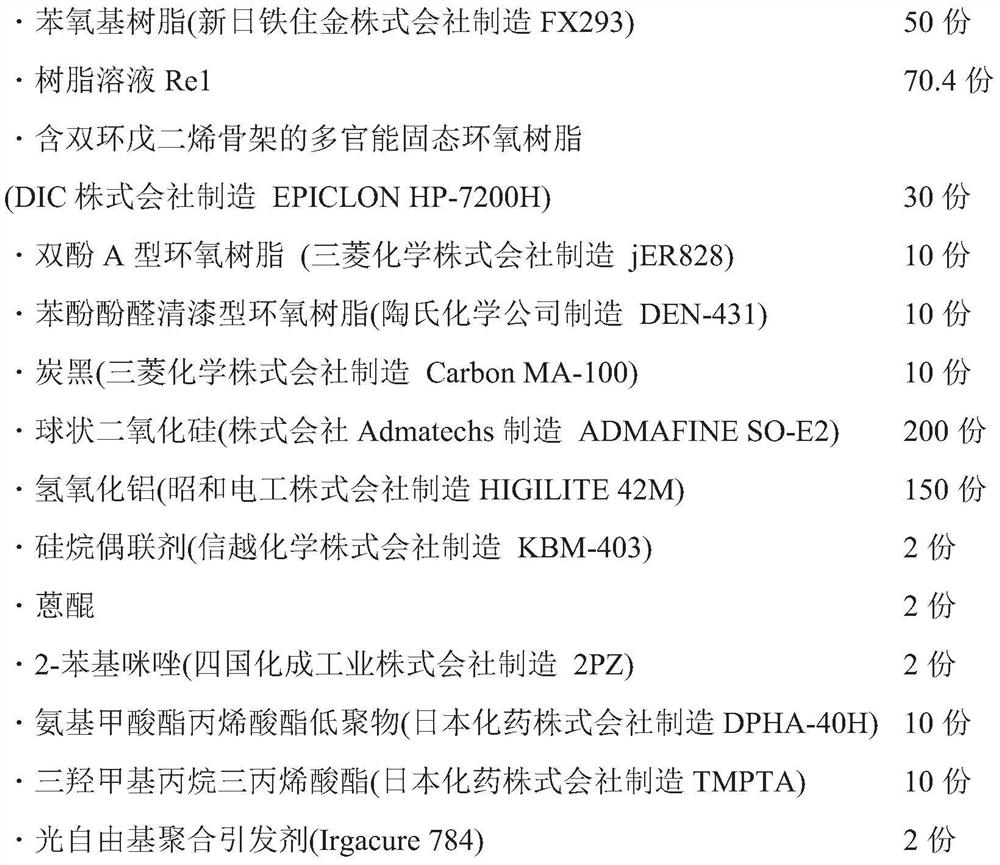

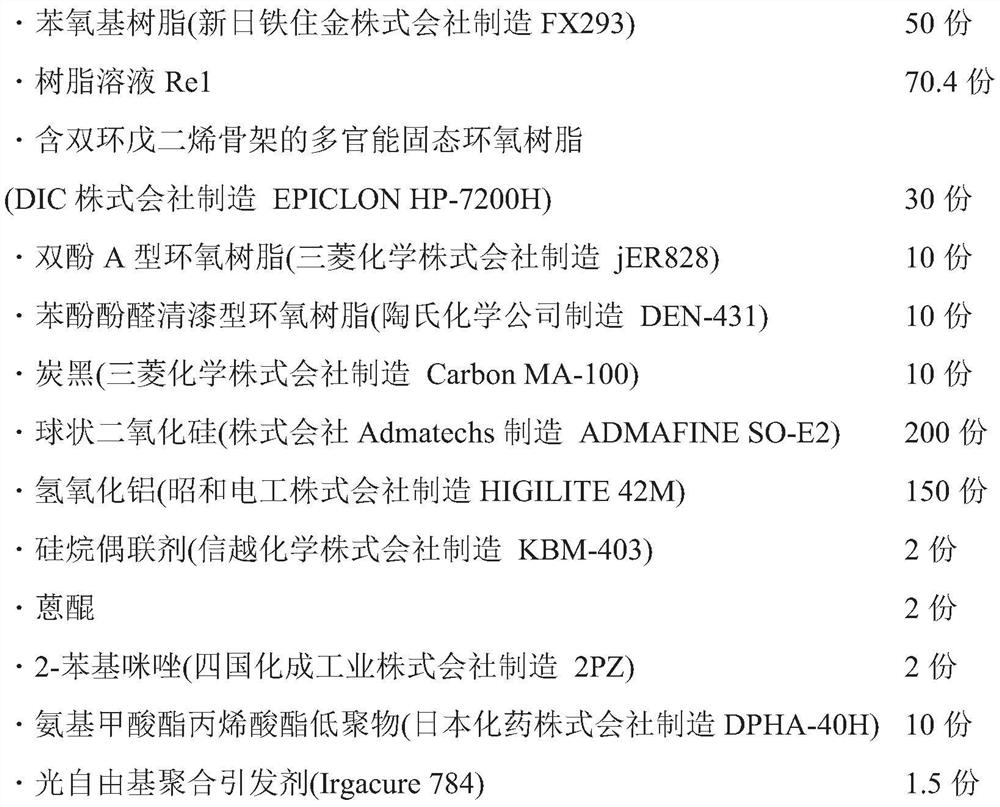

[0166] Hereinafter, the present invention will be described by way of examples, but the present invention is not limited by these examples. In addition, unless otherwise stated, "part" and "%" mean a mass part. In addition, unless otherwise specified, the preparation of the sealing material for semiconductors and the subsequent measurement were performed in an environment not exposed to active energy rays.

[0167]

[0168] 119.4 parts of novolak type cresol resin (manufactured by Showa Denko Co., Ltd., Shonol CRG951, OH equivalent: 119.4) and potassium hydroxide 1.19 were put into an autoclave equipped with a thermometer, a nitrogen introduction device and an alkylene oxide introduction device, and a stirring device. part and 119.4 parts of toluene, nitrogen replacement was carried out in the system under stirring, and the temperature was raised by heating. Next, slowly add 63.8 parts of propylene oxide dropwise at 125°C to 132°C at a rate of 0 to 4.8kg / cm 2 React for 16 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com