Substrate warpage correcting method, computer storage medium, and substrate warpage correction device

A substrate and warpage technology, applied in the fields of substrate warpage correction, computer storage media and substrate warpage correction devices, can solve problems such as inability to perform exposure with high precision, inability to transfer heat, and wafer warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

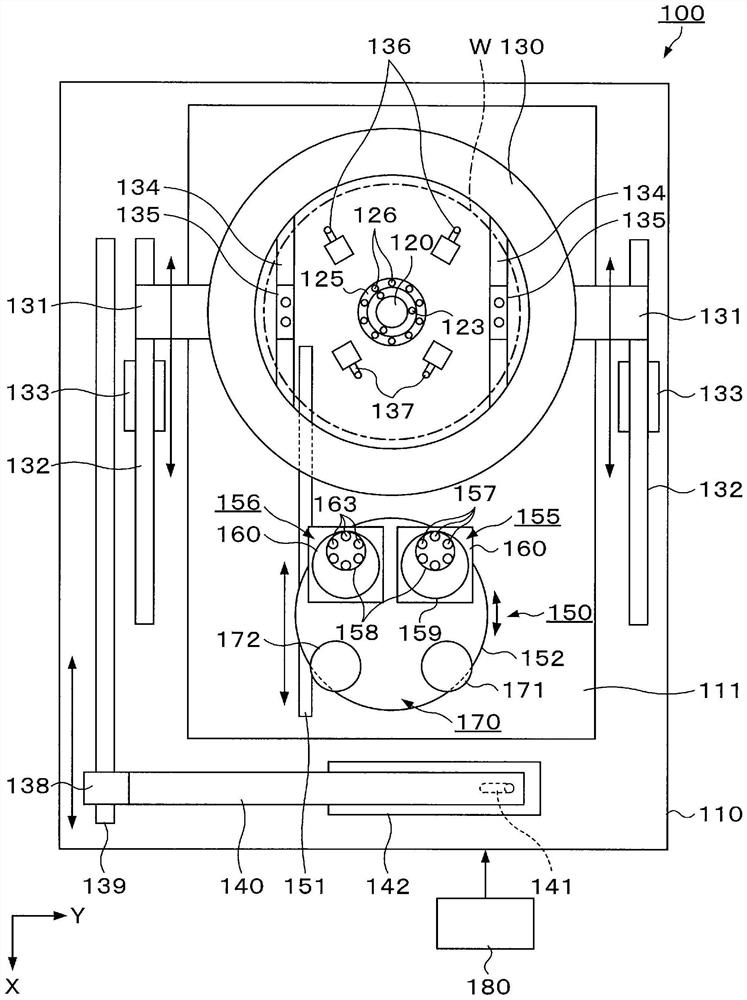

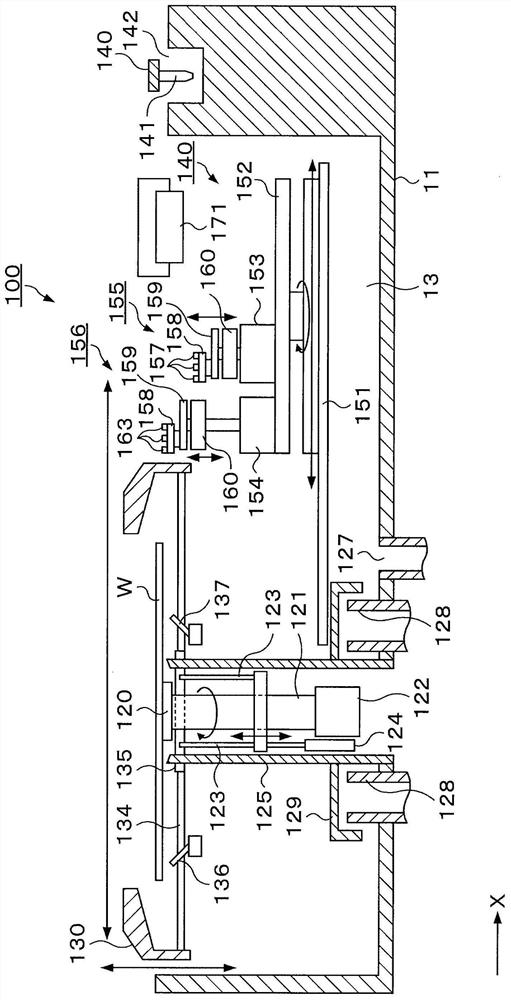

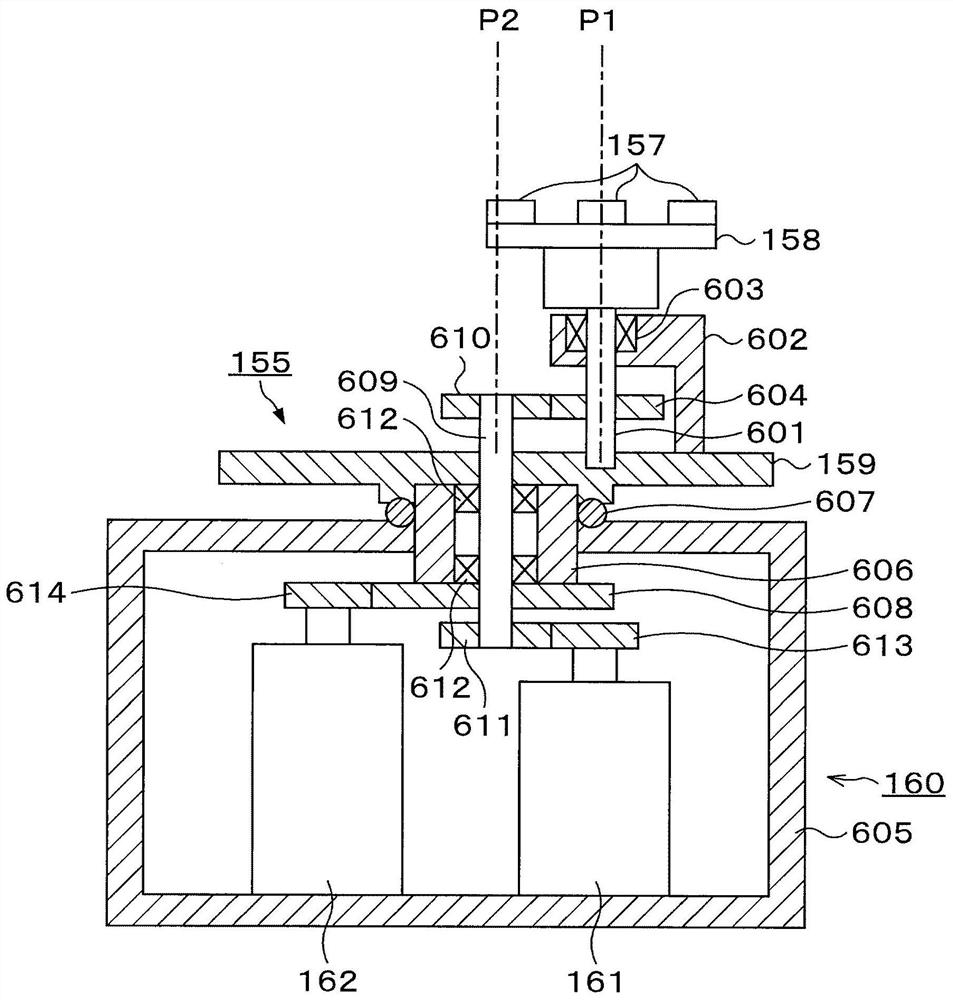

no. 1 approach

[0100] Figure 8 It is an explanatory diagram of a wafer W to be processed in the present embodiment. The vertical axis represents the warpage amount, which is the distance from the reference plane in each area of the wafer W before the surface roughening treatment, and the value of this area is positive in the area of the wafer W closer to the front side than the reference plane. In addition, the horizontal axis of the figure represents the respective positions of the above regions, and the center of the wafer W is taken as a reference point.

[0101] As the wafer W to be processed, when Figure 8 When it is determined that the wafer W has an inverted U-shape in cross-sectional view and the center of which protrudes most on the front side, in the warpage correction method of this embodiment, the wafer W is processed, for example, as follows: .

[0102] (Get the amount of warpage)

[0103] The control unit 180 of the surface roughening treatment apparatus 100 extracts ...

no. 2 approach

[0119] Figure 9 with Figure 10 is a diagram showing another example of the wafer W, Figure 9 It is a plan view of the wafer W, and the distance from the reference plane of each region in the wafer W is expressed in shades, and the larger the amount of protrusion from the front side of the reference plane, the darker the color. Figure 10 yes means Figure 9 A graph showing the relationship between the distance from the reference plane and the position of the region in each region of the wafer W in the portion of the solid line L shown in .

[0120] Figure 9 with Figure 10 The illustrated wafer W has a protruding shape toward the front side, and the area with a large amount of protrusion protruding toward the front side is not the central portion of the wafer W, specifically, the area A surrounded by dotted lines.

[0121] The wafer processing of the first embodiment is performed on a wafer W as a processing object such as Figure 8 The process shown is performed whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com