Light guide plate warping correction method, and device thereof

A light guide plate and warping technology, which is applied in the field of light guide plates, can solve problems such as uneven light and shade, water absorption of light guide plate materials, residual stress release, etc., and achieve the effect of rapid correction of warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

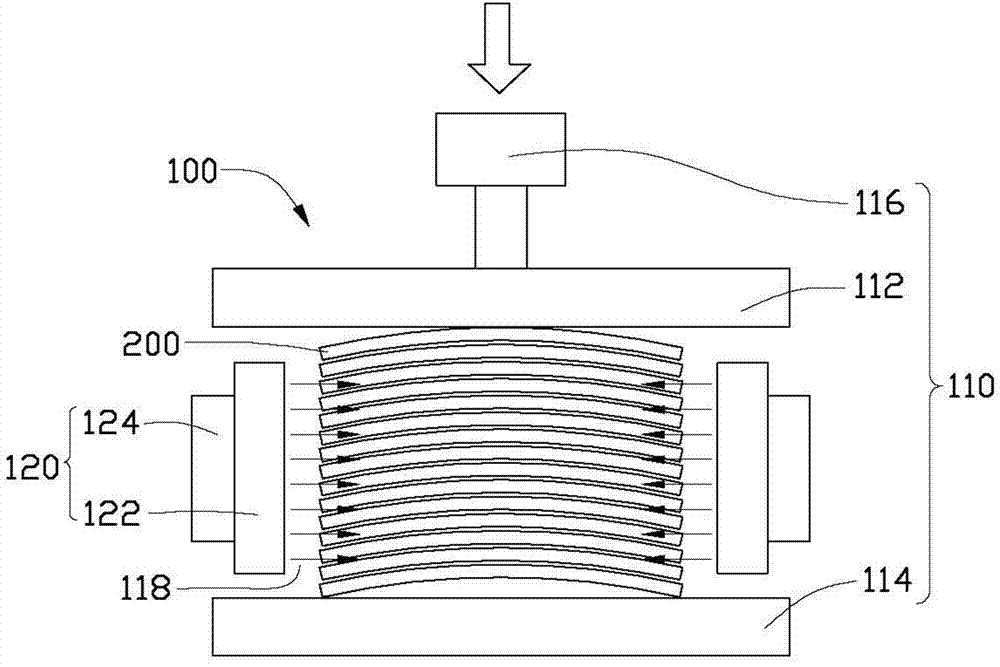

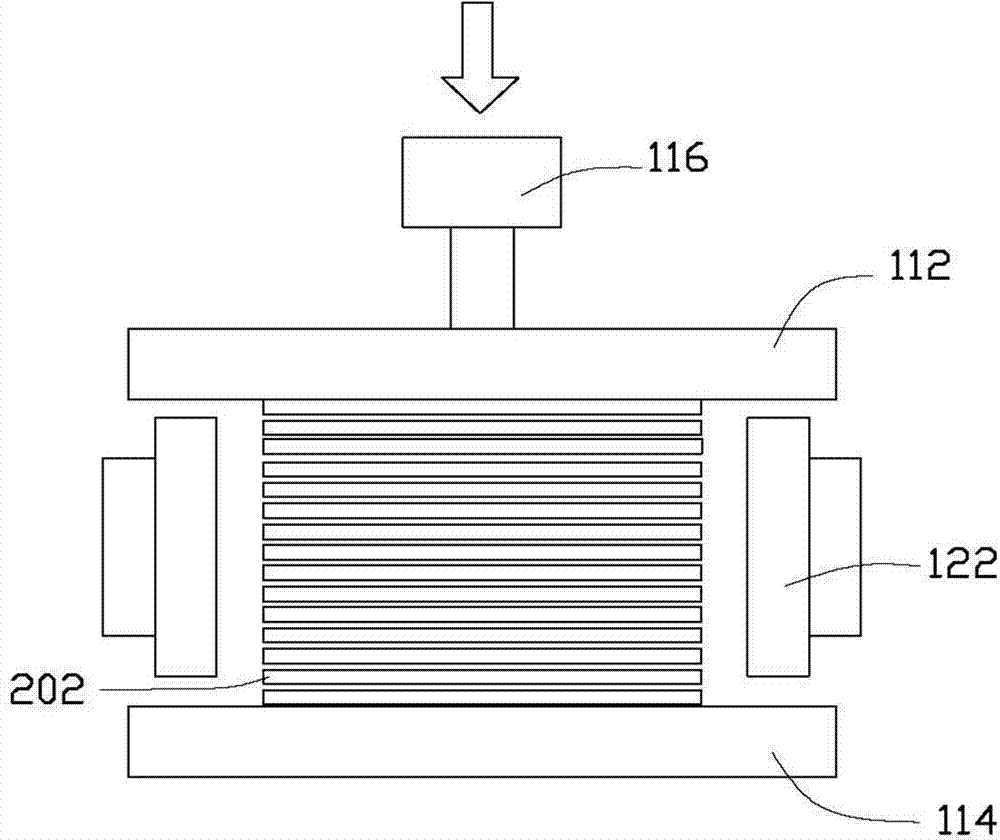

[0013] see figure 1 with figure 2 , the light guide plate warpage correction method and device provided in the embodiments of the present invention are described as follows.

[0014] The light guide plate warping correction device 100 includes a holding device 110 and a heating device 120 . The holding device 110 includes an upper pressing plate 112 , a lower pressing plate 114 and a hydraulic cylinder 116 . The upper pressing plate 112 and the lower pressing plate 114 are used to clamp the warped light guide plate 200 to be corrected ( figure 1 ) in between. The warped light guide plate 200 to be corrected may include one light guide plate or a plurality of laminated light guide plates, and this embodiment is a plurality of laminated light guide plates. The hydraulic cylinder 116 is in contact with the upper pressing plate 112 and is used for exerting a pressing force on the upper pressing plate 112 to press the upper pressing plate 112 , the light guide plate 200 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com