Screen printing device

A technology of screen printing and carrying device, which is applied in the direction of screen printing machine, printing machine, printing machine, etc., can solve the problem of difficult circuit substrate clamping and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

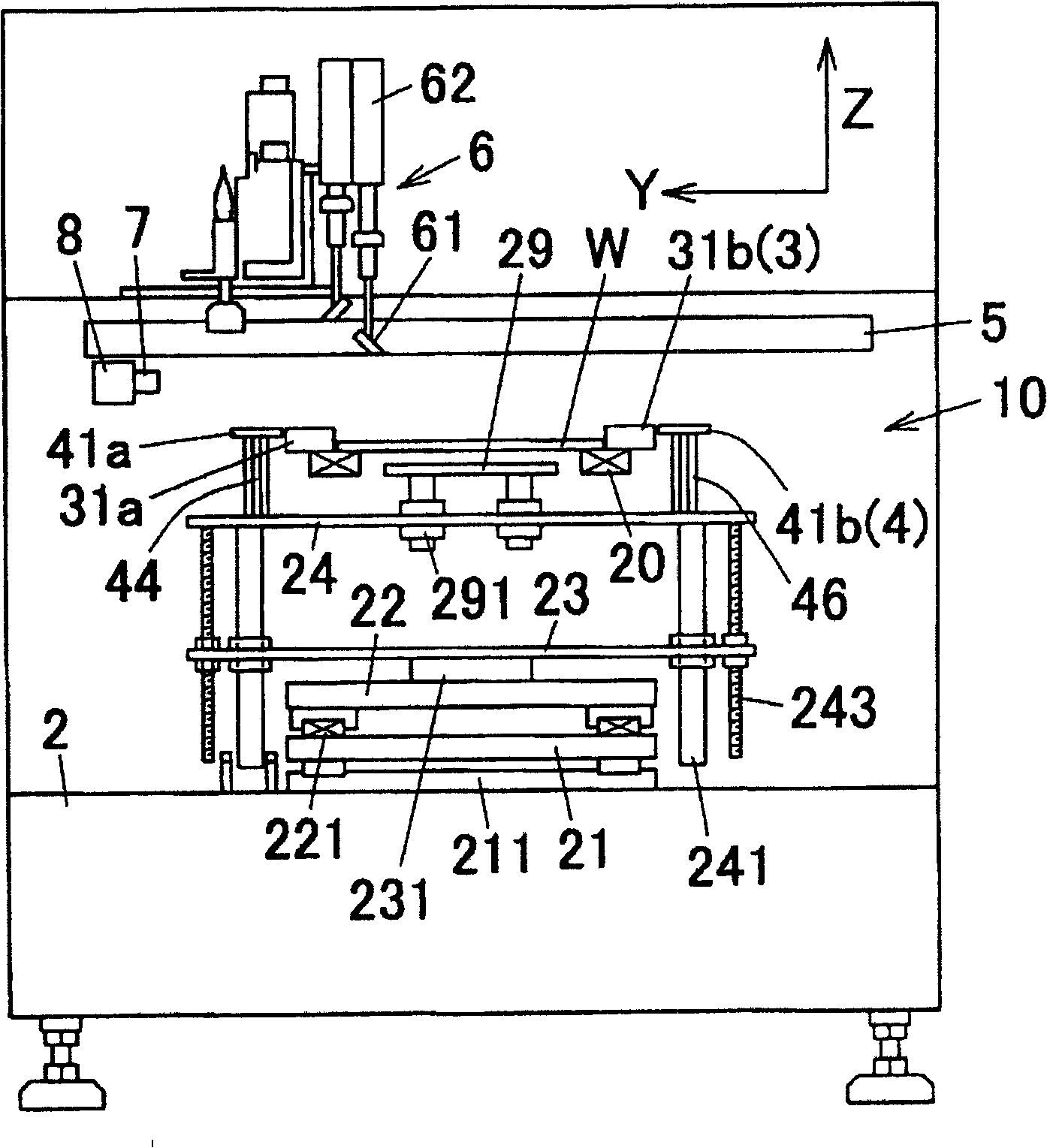

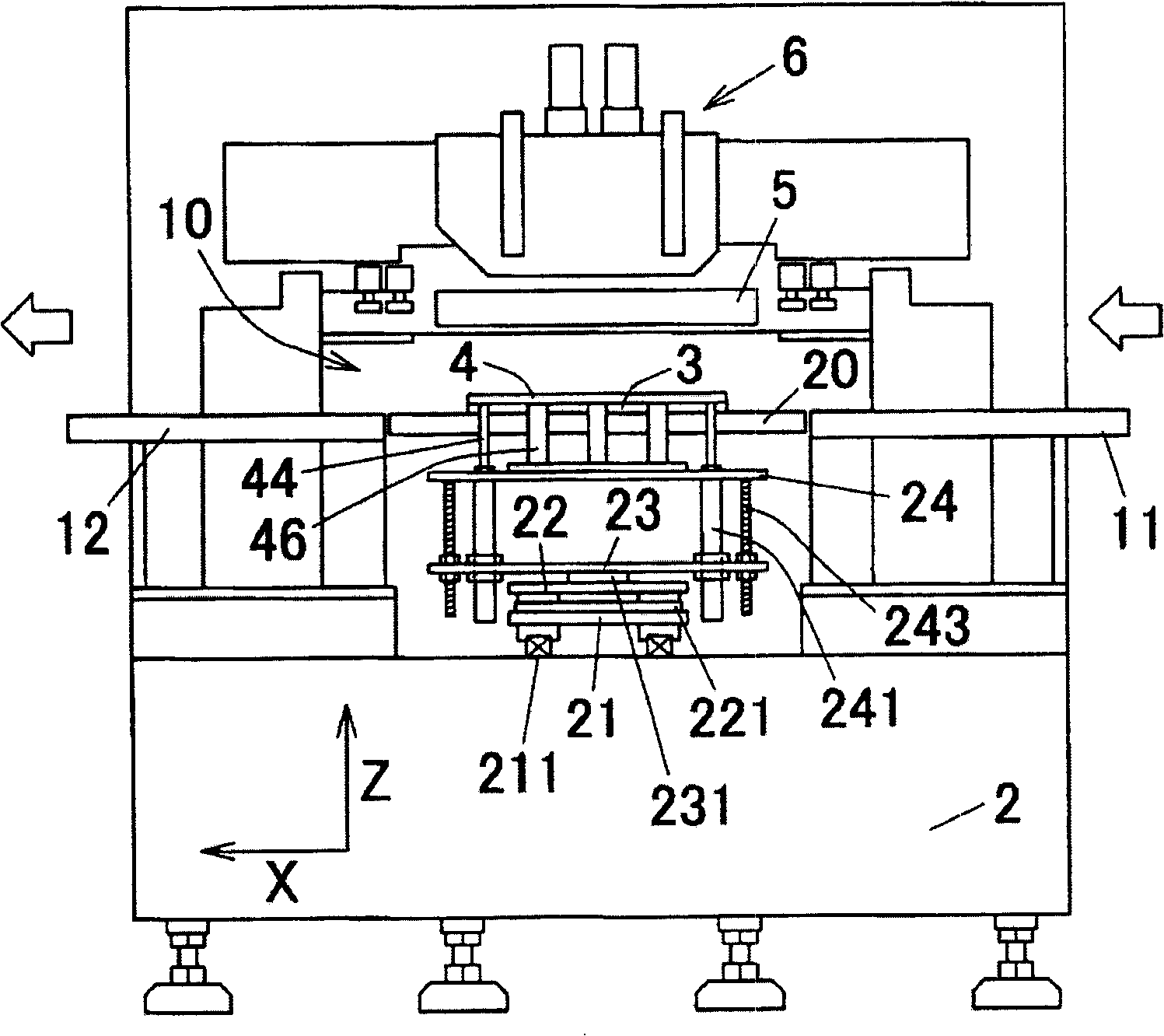

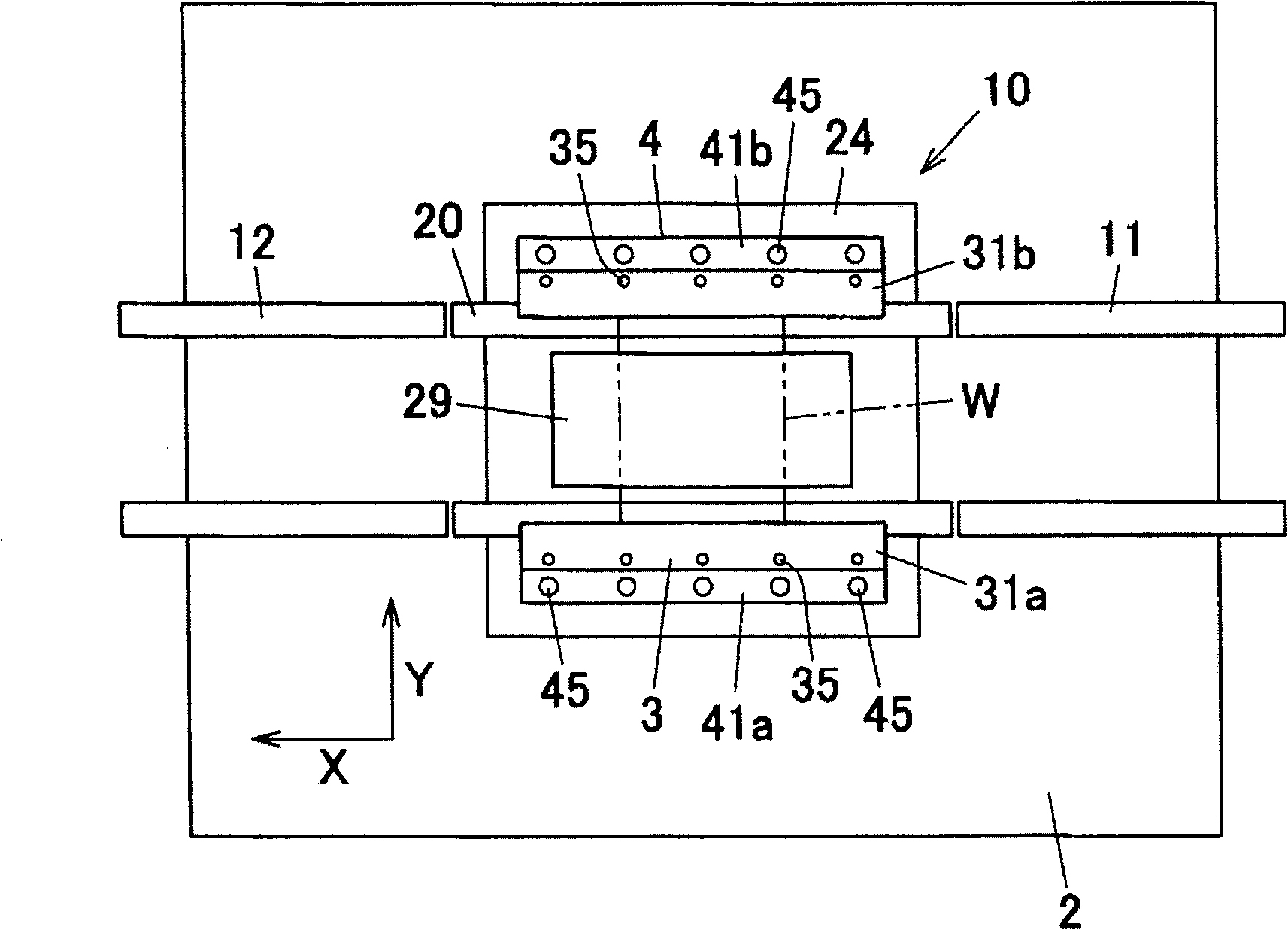

[0029] figure 1 It is a side view of a screen printing device according to an embodiment of the present invention, figure 2 is the front view of the device, image 3 is the top view of the device, Figure 4 It is a perspective view of the printing table 10 of the apparatus and its surroundings. As shown in the above figure, on the base 2 of the screen printing device (referred to as the printing device), a printing table 10 is provided, and on both sides of the printing table 10, along the X-axis direction (transport line) are provided with The substrate W is carried into the upstream conveyor belt 11 of the printing table 10 and carried out from the downstream conveyor belt 12 of the printing table 10 .

[0030] Moreover, the printing device also includes a clamp assembly 3 for clamping the circuit substrate W; a positioning assembly 4 for abutting against the upper surface of the circuit substrate W when clamping the circuit substrate W to position it; a mask assembly 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com