Structure for mounting printed board and nuclear medicine diagnosis system

a printed board and structure technology, applied in the direction of standard structures, electrical apparatus construction details, orthogonal pcbs mounting, etc., can solve the problems of low location accuracy of printed boards, backlash produced, and inability to achieve the location accuracy required for semiconductor devices, and achieve high location accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

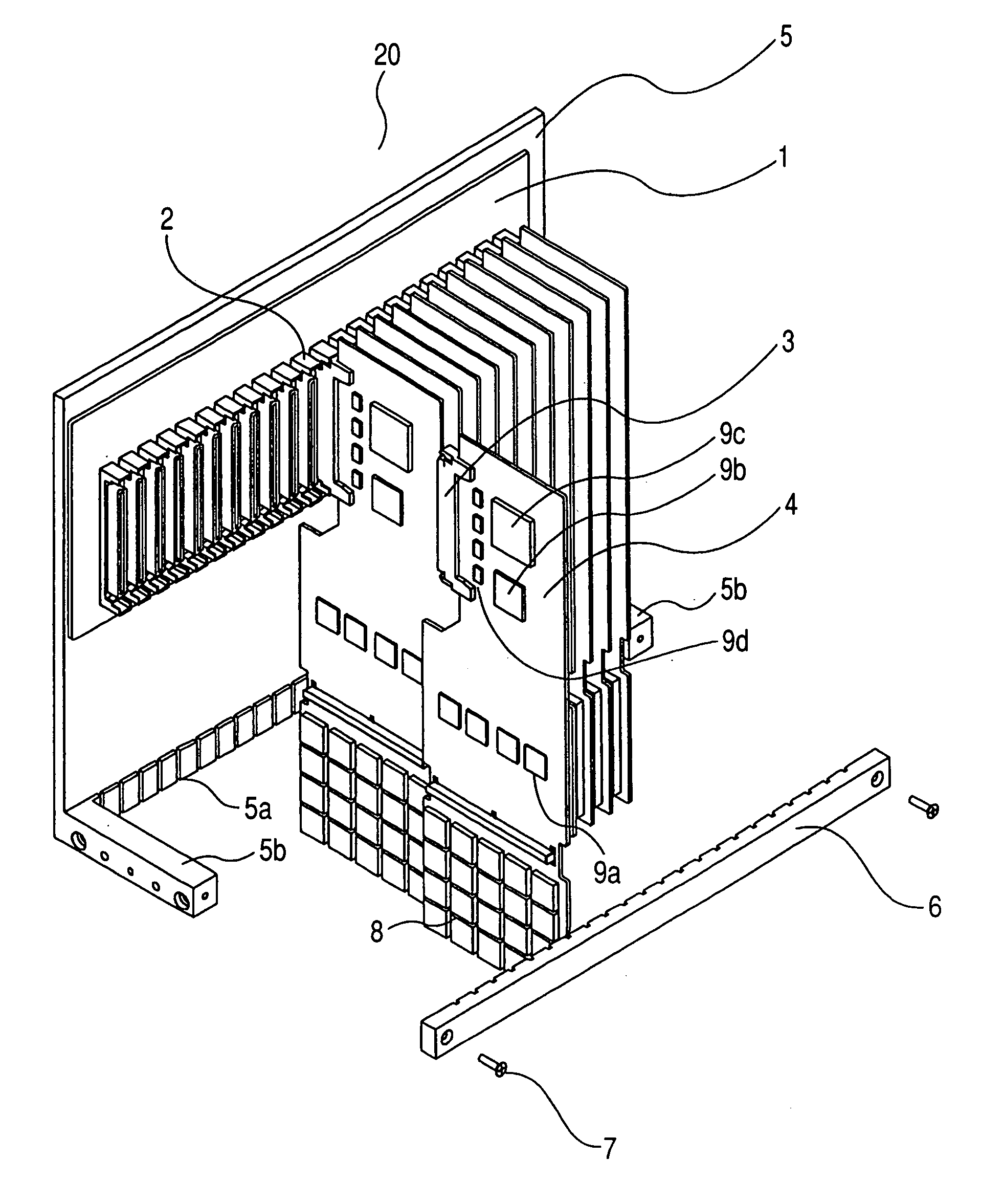

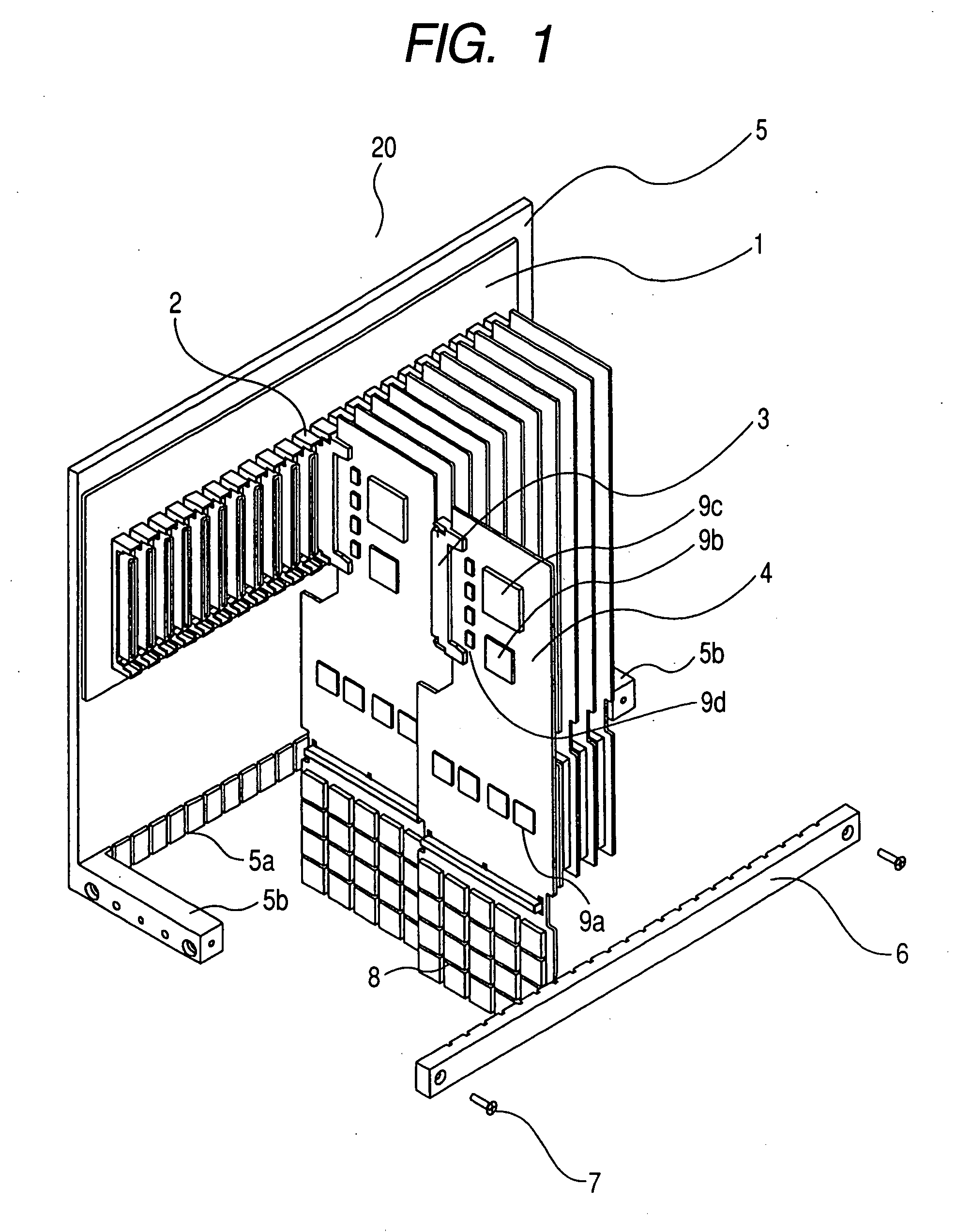

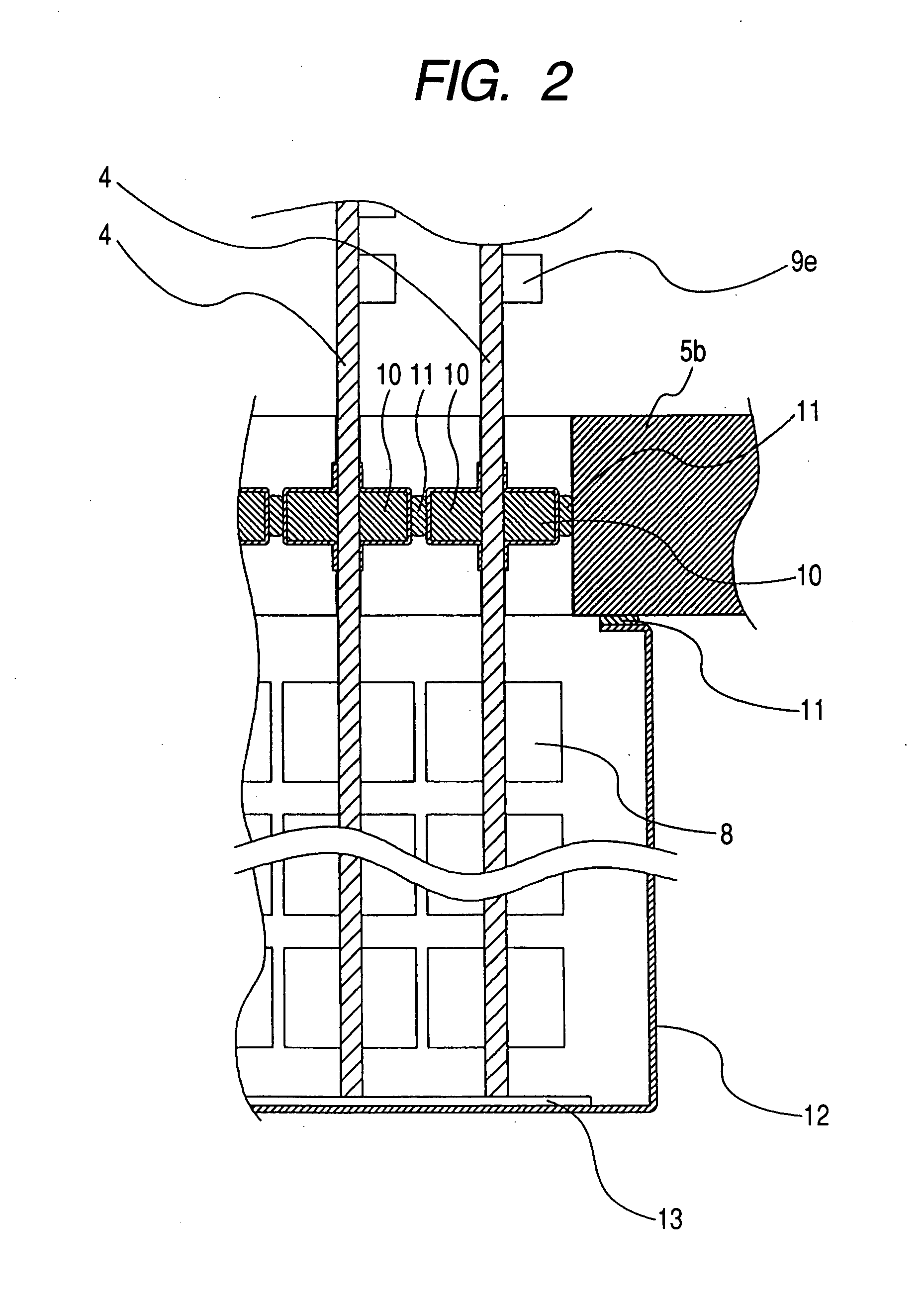

[0022] The structure for mounting a printed board according to a first embodiment of the present invention will be described with reference to FIGS. 1 through 3. FIG. 1 is a perspective view schematically illustrating the structure for mounting a printed board (the positioning of a printed board and the electromagnetic shielding structure thereof) according to the first embodiment of the present invention. FIG. 2 is a partially sectional view of a plurality of sub printed boards viewed from the board width direction, the plurality of sub printed boards being juxtaposed to one another in the structure for mounting a printed board according to the first embodiment of the present invention. FIG. 3 is a diagram of a sub printed board viewed from the element mounting side, the sub printed board being based on the structure for mounting a printed board according to the first embodiment of the present invention.

[0023]FIG. 1 partially illustrates electronic apparatus in which a multiplicit...

second embodiment

[0032] Next, a second embodiment of a nuclear medicine diagnosis system (for example, a PET system or a SPECT system), which has the structure for mounting a printed board according to the present invention, will be described with reference to FIG. 1.

[0033] The nuclear medicine diagnosis system (for example, a PET system or a SPECT system) according to the present invention includes: the sub printed board described in the first embodiment, which corresponds to the joint substrate described in JP-A-2005-106805 (the patent document 3); and the main printed board 1 described in the first embodiment, which is used as a top plate in this embodiment.

[0034]FIG. 1 is a diagram illustrating a basis configuration of an observation unit (detector unit) 20 that forms a camera in the PET system and the SPECT system. As a nuclear medicine diagnosis system, the PET system includes a camera (imaging unit), a data processor, and a display unit. A subject is imaged by use of the camera with the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com