Back water-coating device

A technology of back coating and adjustment device, applied to paper and other directions, can solve the problems of inability to precisely control the water absorption of paper, affecting the health of operators, and water mist pollution in the workshop, avoiding water mist pollution, simple structure and precise control. effect in place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

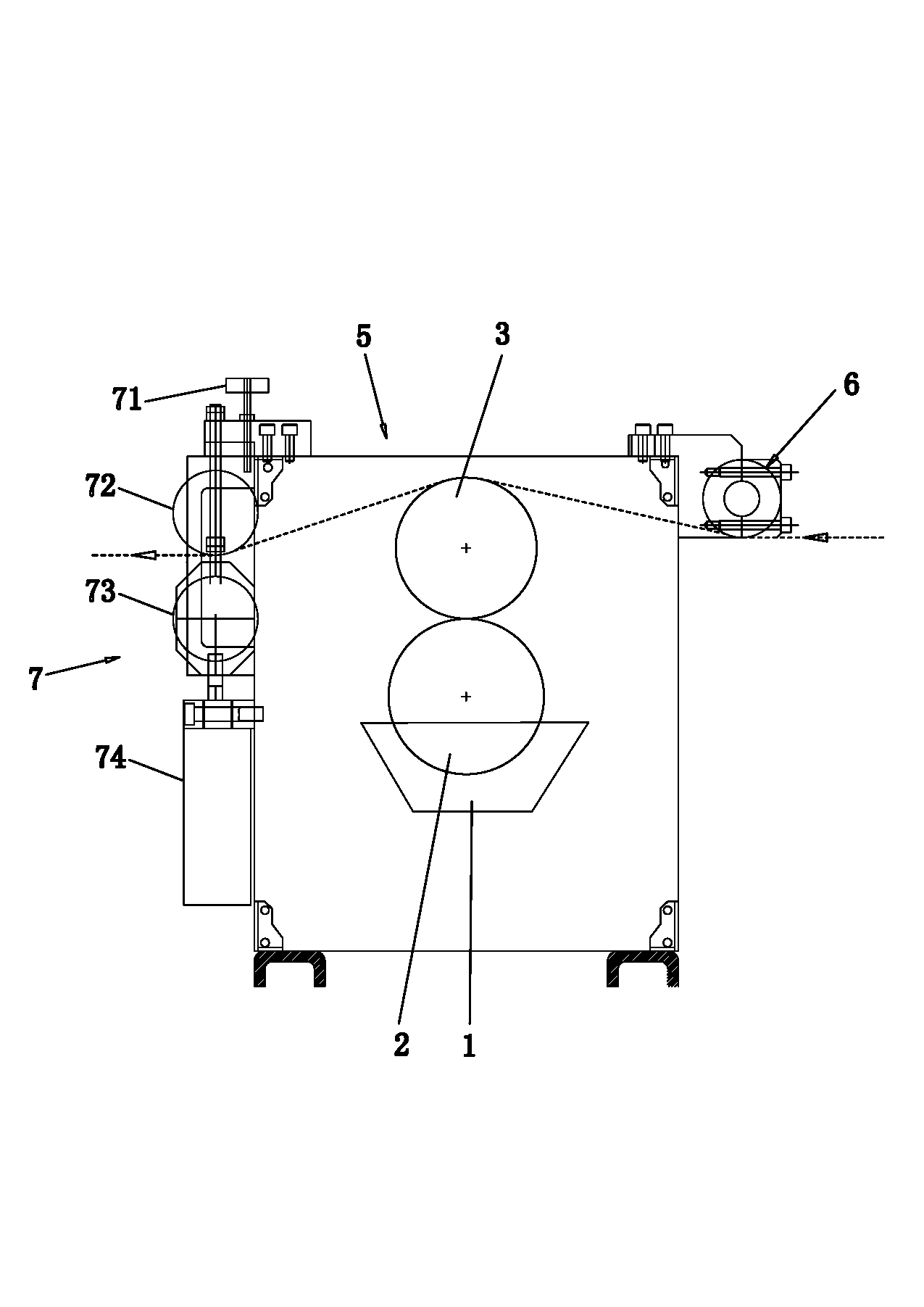

[0043] Such as figure 1 Shown, a kind of back coating water device, it comprises water tank 1, the metering roller 2 that contacts with the liquid level of water tank 1, the applicator roller 3 that applies water film on paper surface, and described metering roller 2 and described applicator The roller 3 is in contact, and also includes a motor for adjusting the rotation speed, and the motor is connected with the metering roller 2 and the applicator roller 3 .

[0044] There are two motors in this embodiment, and the two motors are respectively connected to the metering roller 2 and the applicator roller 3 . Two motors respectively drive the metering roller 2 and the applicator roller 3 through universal joints. When the speed reaches 400m / min~500m / min, the gap between the metering roller 2 and the applicator roller 3 will be filled with continuous , Uninterrupted water film, at this time, the air will not enter the gap between the metering roller 2 and the applicator roller...

Embodiment 2

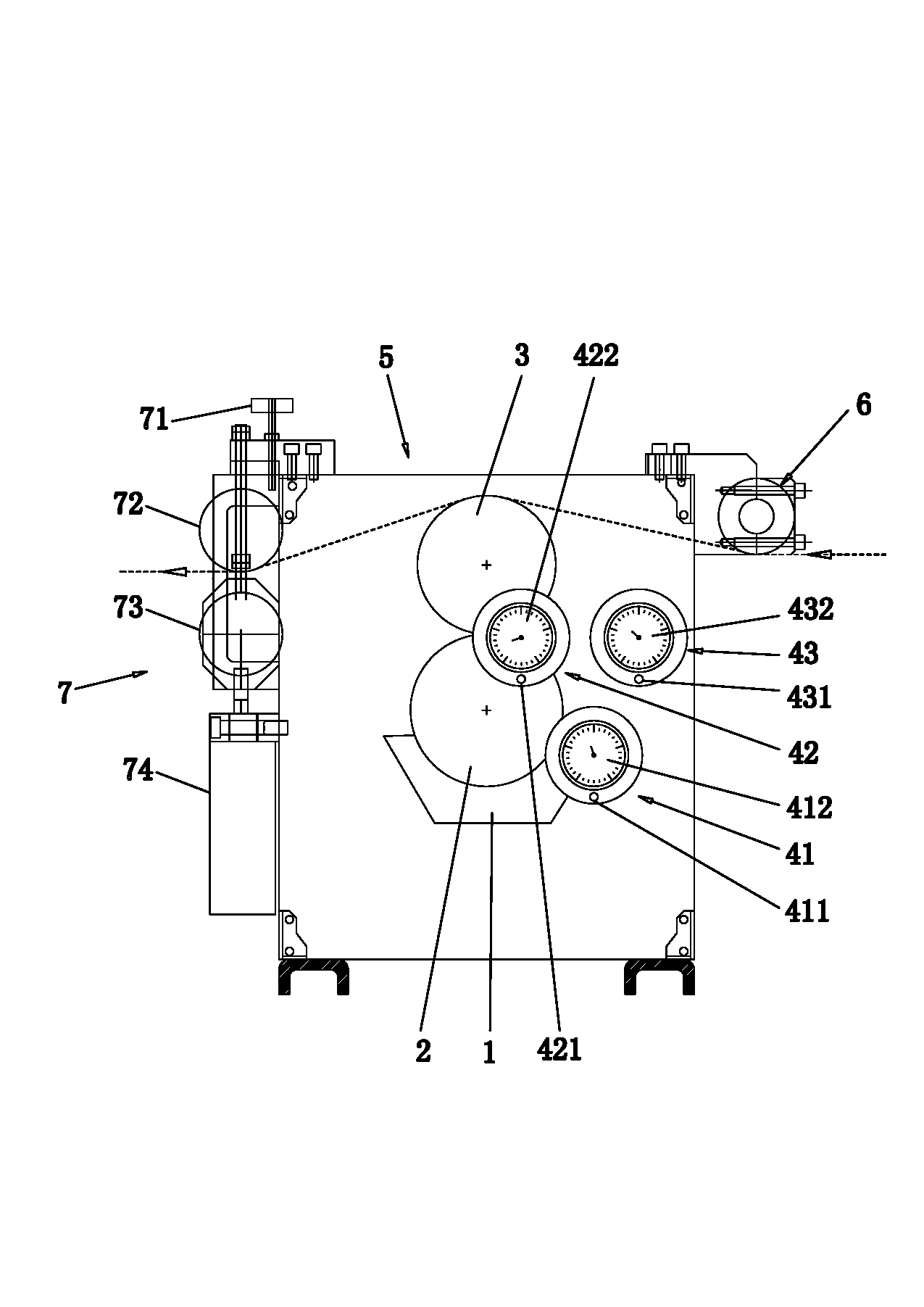

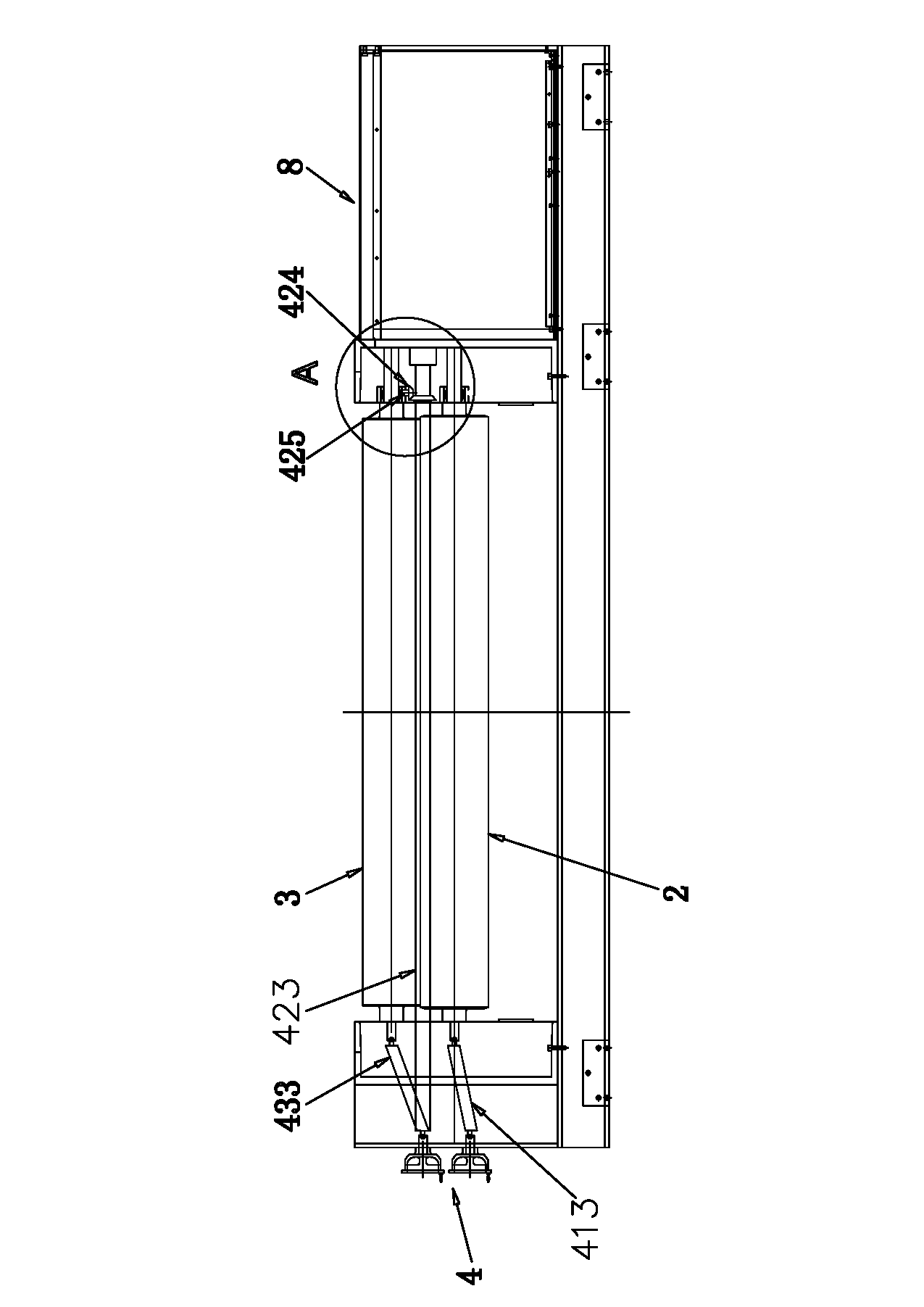

[0050] Such as Figure 2~6 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment also includes a compensation adjustment device 4, and the compensation adjustment device 4 includes a scissors difference adjustment device 41, a driving side adjustment device 42, and an operation side adjustment device 43, The scissor difference adjustment device 41 is connected to the metering roller 2 , the drive side adjustment device 42 is connected to the application roller 3 , and the operation side adjustment device 43 is connected to the application roller 3 .

[0051] Such as figure 2 , image 3 As shown, the scissors difference adjustment device 41 in this embodiment includes a first adjustment handle 411, a scissors difference adjustment table 412, and a scissors difference adjustment link 413. The first adjustment handle 411 is connected to the scissors difference adjustment link 413, and the scissors difference adjustment link 413 A rod 413 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com