3D printed high-transparency zirconia ceramic crown material

A zirconia ceramic, 3D printing technology, applied in the field of 3D printing, can solve the problems of poor product quality stability, high elongation at break, easy fragility, etc., to improve quality stability, moderate elongation at break, good antibacterial function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

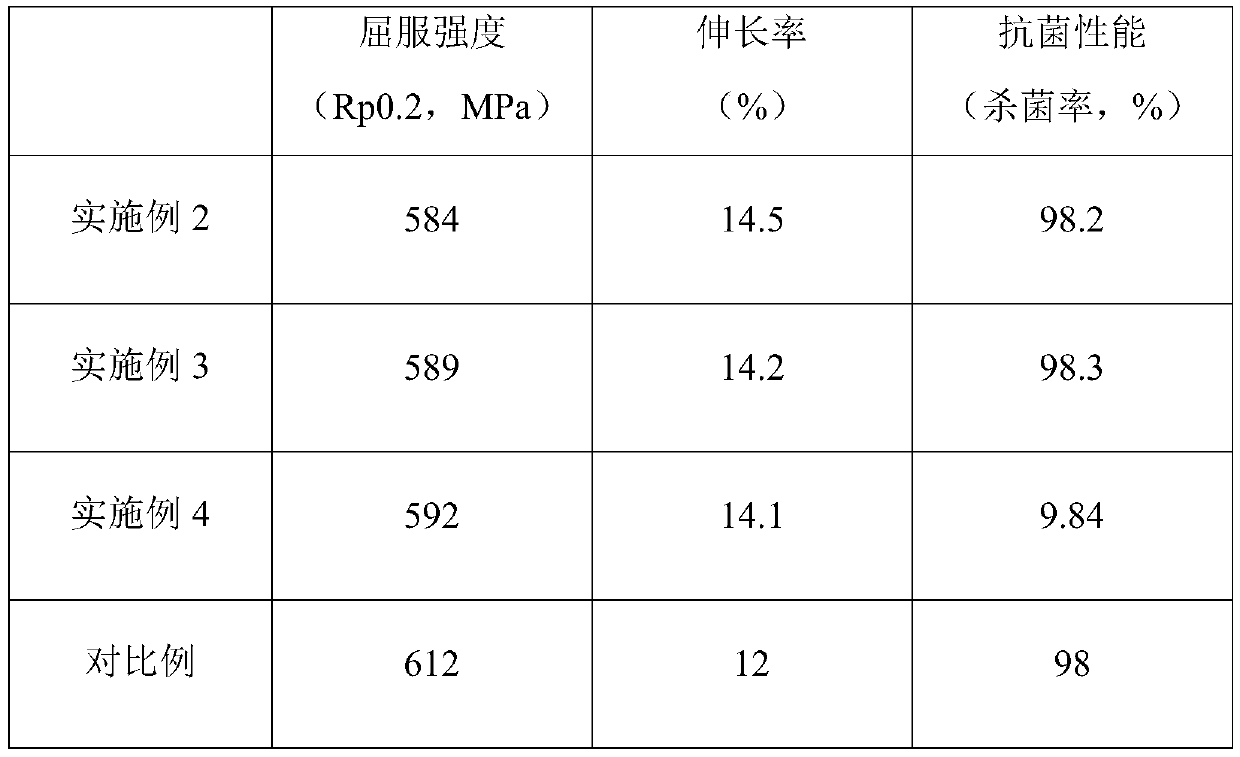

Examples

Embodiment 1

[0065] A 3D printing high-transparency zirconia ceramic dental crown material is made of raw materials including the following parts by weight:

[0066] Zirconia 170~195 parts,

[0067] Ethylene-vinyl acetate copolymer 240-270 parts,

[0068] 160-175 parts of hexanediol diacrylate,

[0069] Carboxyl silica microspheres 30-37 parts,

[0070] 10-14 parts of nano-titanium dioxide,

[0071] Aluminum oxide fiber 15-20 parts,

[0072] Edge graphene oxide 9-12 parts,

[0073] Photoinitiator 1.2~1.5 parts,

[0074] Dispersant 5-7 parts.

[0075] Preferably, the 3D printed high-transparency zirconia ceramic dental crown material is made of raw materials including the following parts by weight:

[0076] Zirconia 183 parts,

[0077] Ethylene-vinyl acetate copolymer 255 parts,

[0078] 168 parts of hexanediol diacrylate,

[0079] Carboxyl silica microspheres 34 parts,

[0080] Nano titanium dioxide 12 parts,

[0081] Aluminum oxide fiber 17 parts,

[0082] Edge graphene oxide...

Embodiment 2

[0094] A 3D printing high-transparency zirconia ceramic dental crown material is made of raw materials including the following parts by weight:

[0095] Zirconia 170 parts,

[0096] Ethylene-vinyl acetate copolymer 240 parts,

[0097] 160 parts of hexanediol diacrylate,

[0098] Carboxyl silica microspheres 30 parts,

[0099] Nano titanium dioxide 10 parts,

[0100] Aluminum oxide fiber 15 parts,

[0101] Edge graphene oxide 9 parts,

[0102] 1.2 parts of photoinitiator,

[0103] Dispersant 5 parts.

[0104] In this embodiment, the particle size of the carboxyl silica microspheres is 150-250 nm.

[0105] In this embodiment, the relative content of carboxyl groups in the edge graphene oxide is 32.5%.

[0106] In this embodiment, the ethylene-vinyl acetate copolymer is a transparent ethylene-vinyl acetate copolymer with a VA content of 25, a transparent ethylene-vinyl acetate copolymer with a VA content of 32, and a transparent ethylene-vinyl acetate copolymer with a VA co...

Embodiment 3

[0117] A 3D printing high-transparency zirconia ceramic dental crown material is made of raw materials including the following parts by weight:

[0118] Zirconia 195 parts,

[0119] Ethylene-vinyl acetate copolymer 270 parts,

[0120] 175 parts of hexanediol diacrylate,

[0121] Carboxyl silica microspheres 37 parts,

[0122] Nano titanium dioxide 14 parts,

[0123] 20 parts of alumina fiber,

[0124] Edge graphene oxide 12 parts,

[0125] 1.5 parts of photoinitiator,

[0126] Dispersant 7 parts.

[0127] In this embodiment, the particle size of the carboxyl silica microspheres is 220-300 nm.

[0128] In this embodiment, the relative content of carboxyl groups in the edge graphene oxide is 37.5%.

[0129] In this embodiment, the ethylene-vinyl acetate copolymer is a transparent ethylene-vinyl acetate copolymer with a VA content of 25, a transparent ethylene-vinyl acetate copolymer with a VA content of 32, and a transparent ethylene-vinyl acetate copolymer with a VA con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com