Patents

Literature

96results about "OLED parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

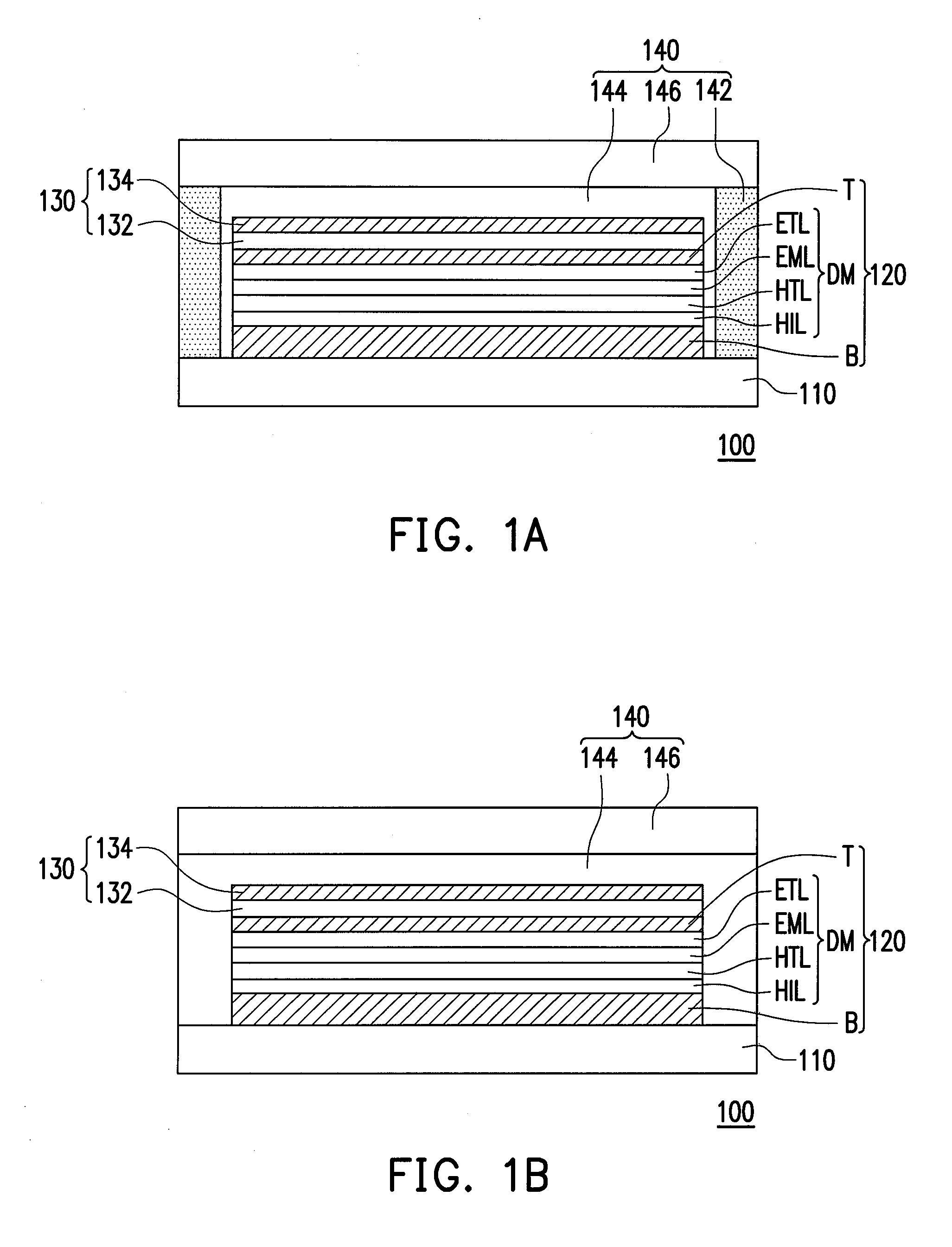

White Organic Light Emitting Device

ActiveUS20130069077A1Avoid introducingImprove efficiencyOLED parametersSolid-state devicesDopantOrganic light emitting device

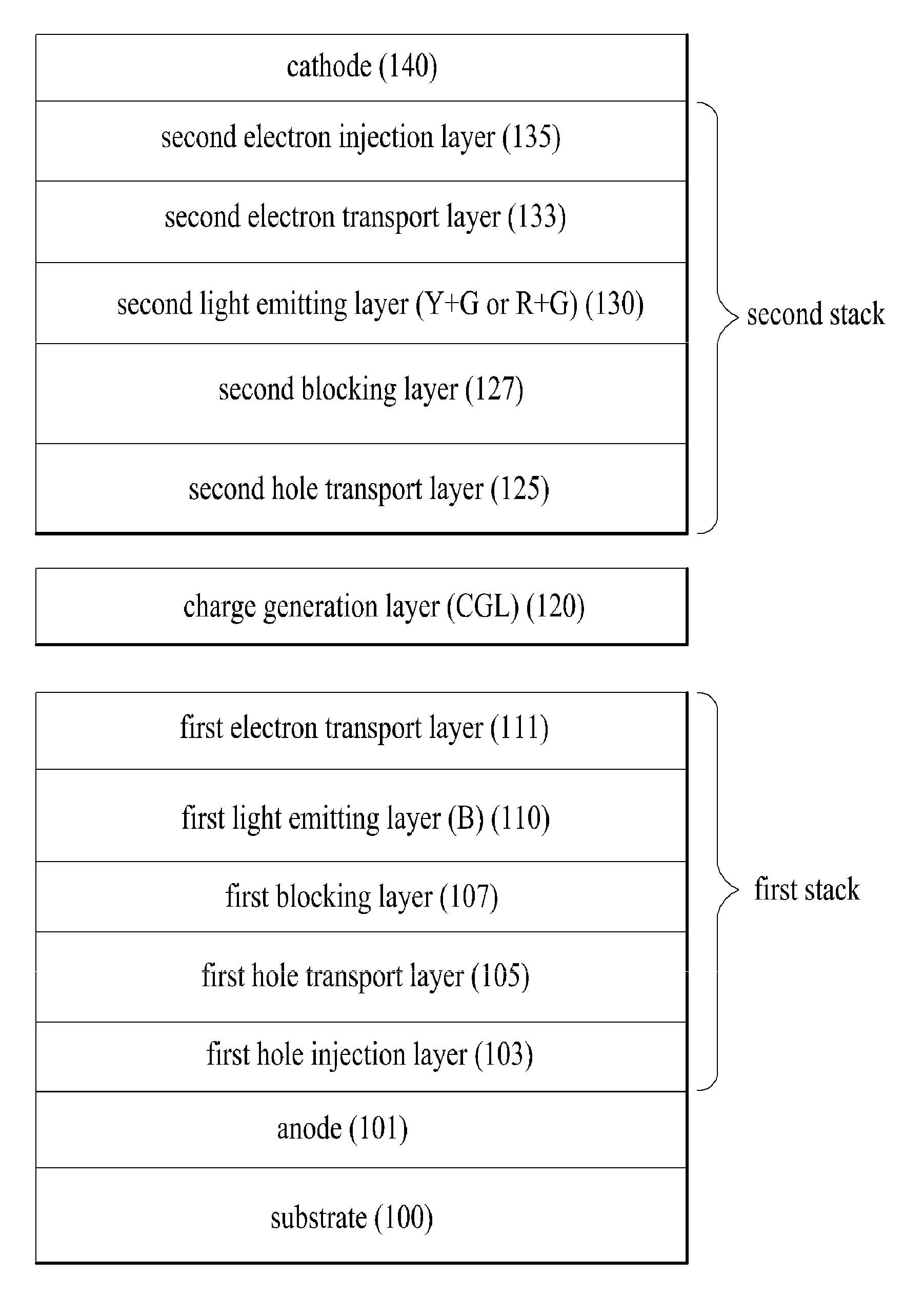

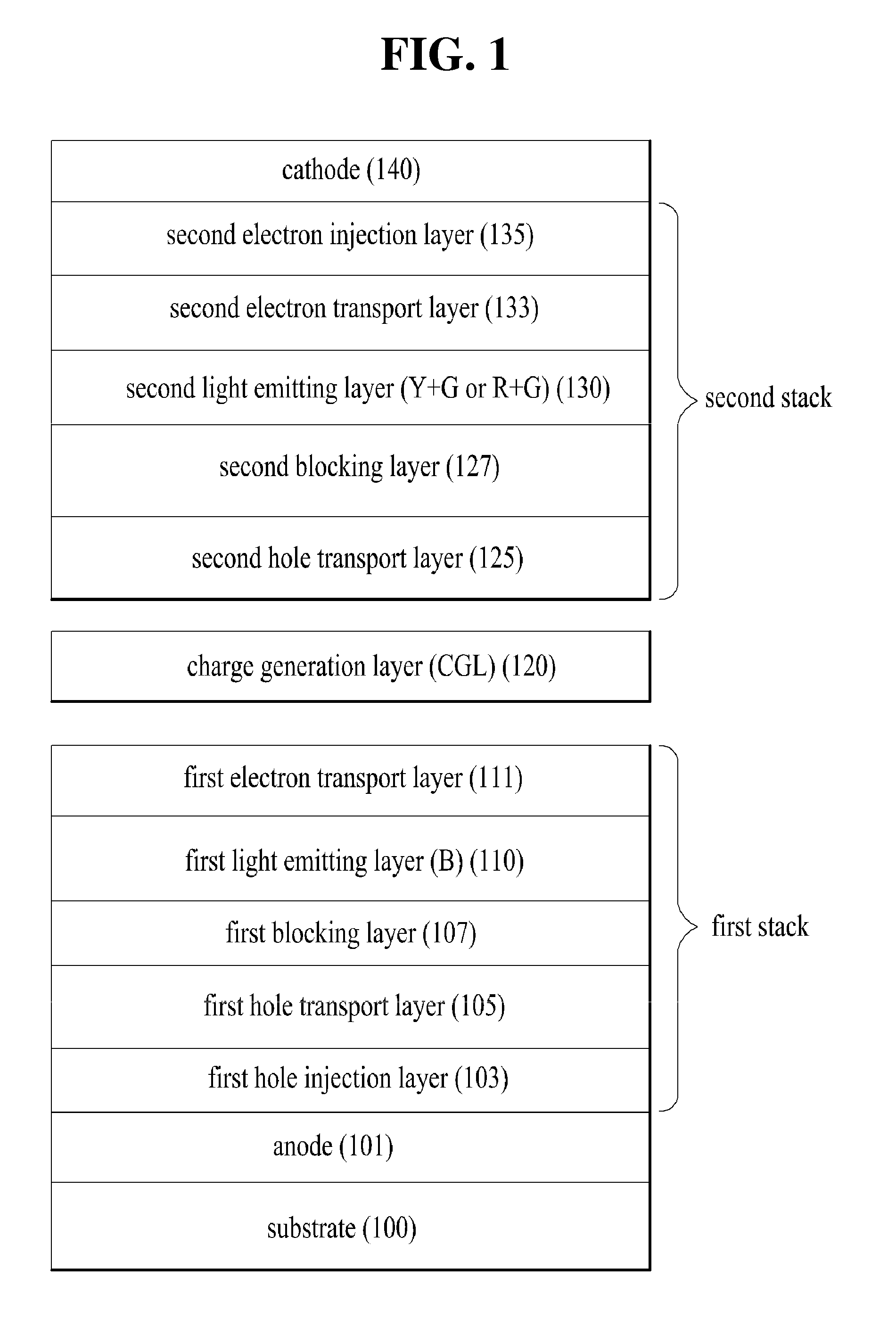

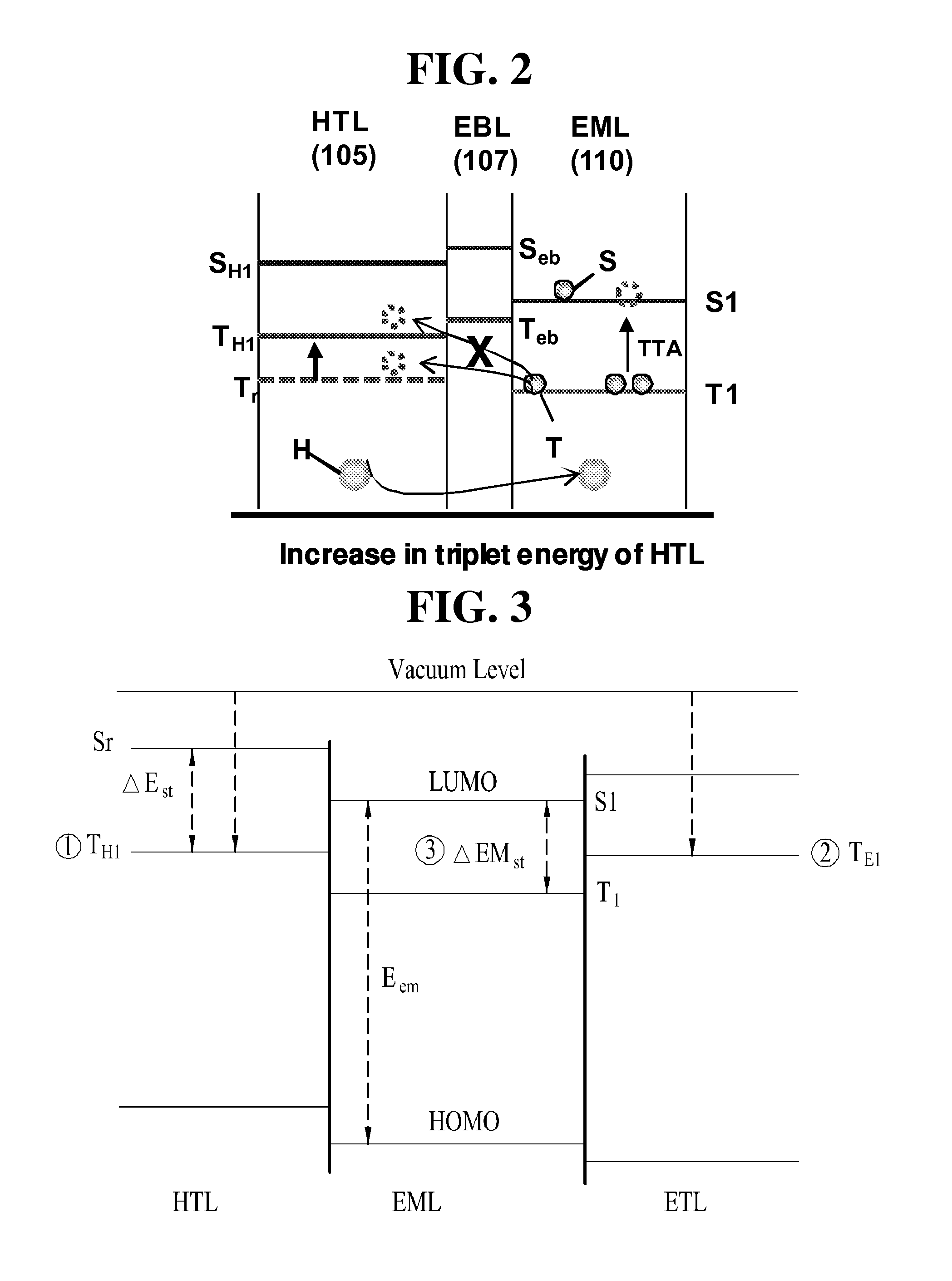

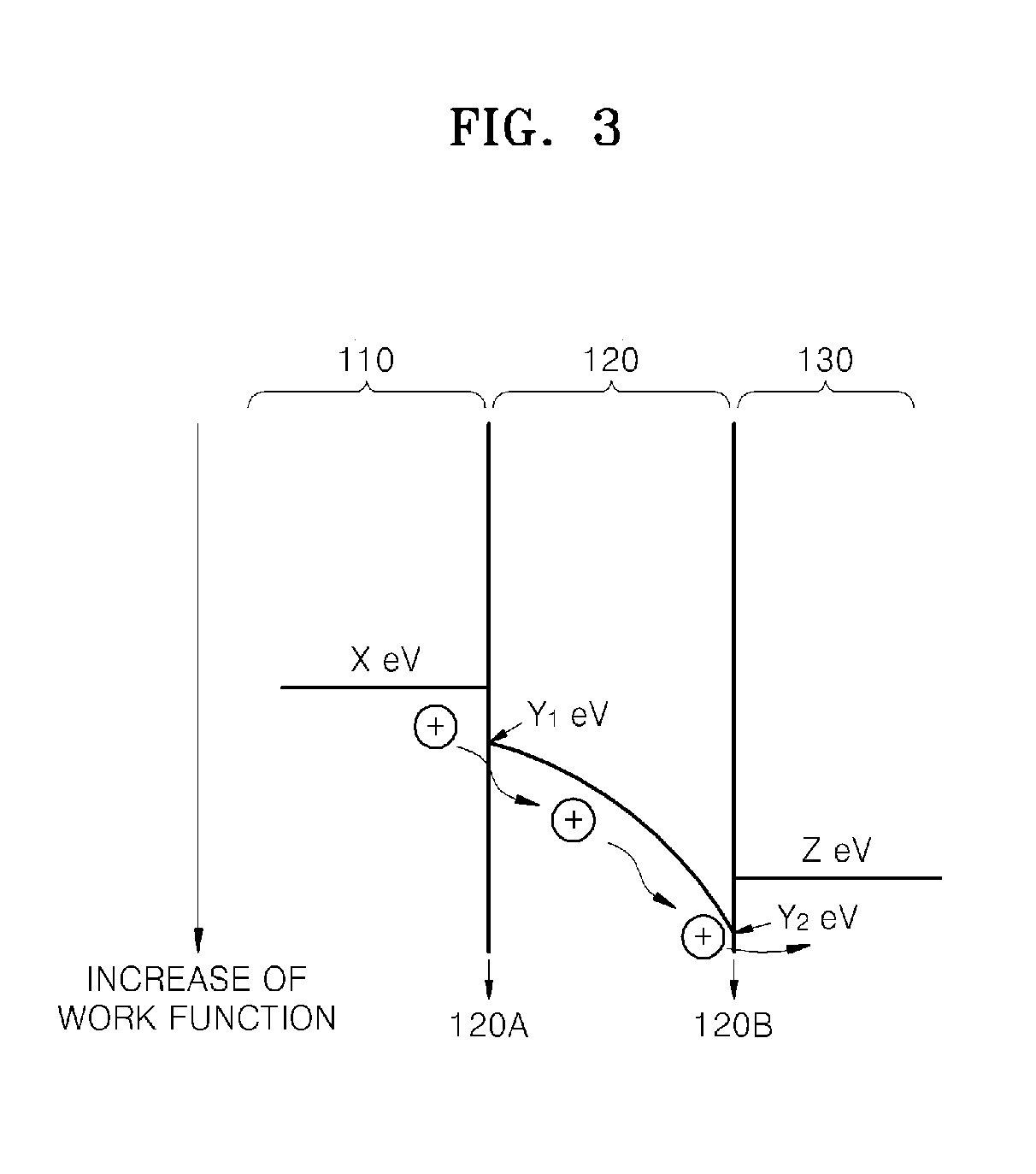

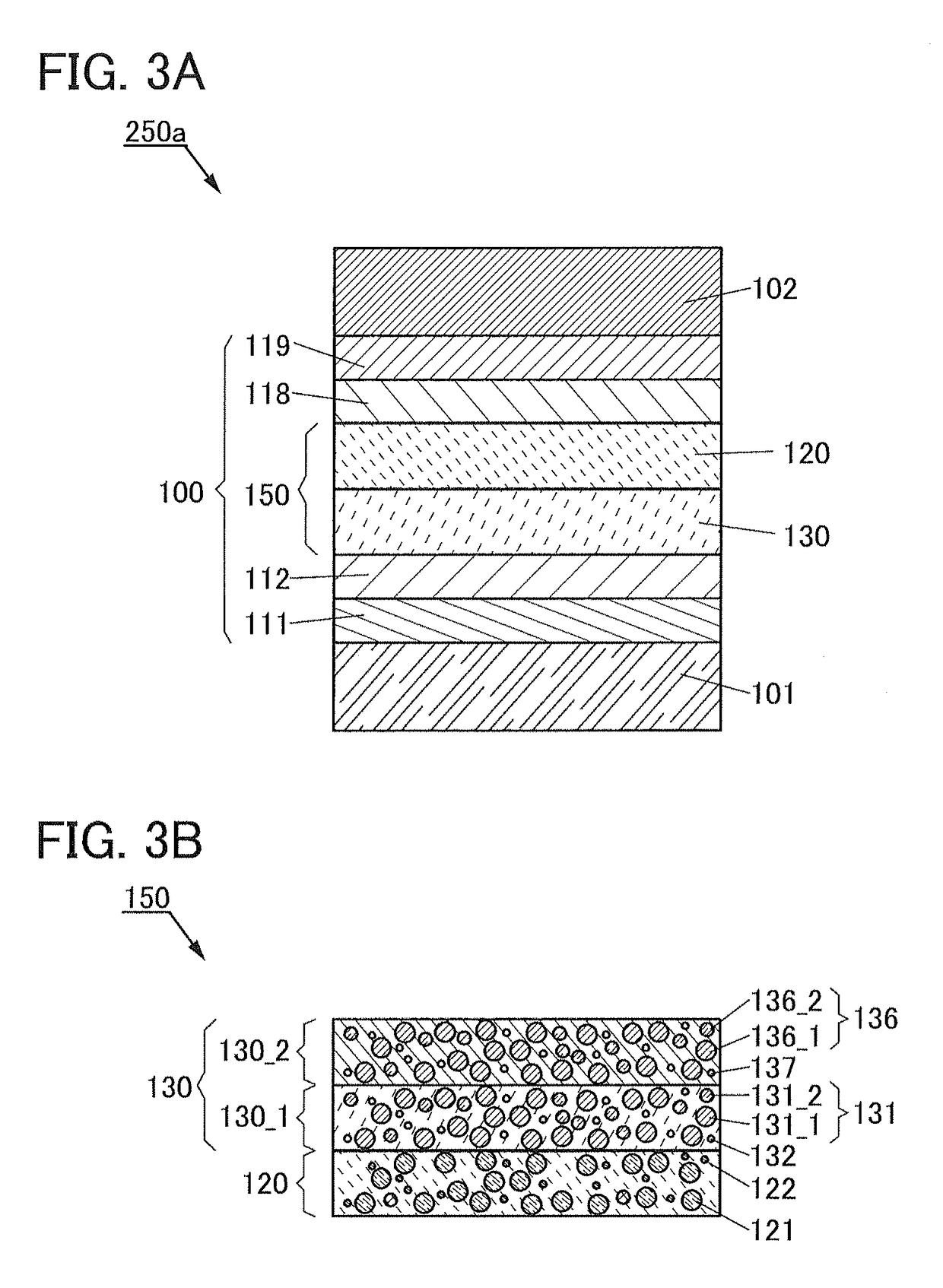

Disclosed white organic light emitting device includes an anode and a cathode opposing each other; a charge generation layer interposed between the anode and the cathode; a first stack interposed between the anode and the charge generation layer, the first stack including a first hole transport layer and a first light emitting layer emitting blue fluorescent light; and a second stack interposed between the charge generation layer and the cathode, the second stack including a second hole transport layer and a second light emitting layer formed by doping one host with at least one of phosphorescent dopant, wherein a triplet energy level of the first hole transport layer is higher than a triplet energy level of the first light emitting layer, and a hole mobility of the first hole transport layer is 5.0×10-4 cm2 / s·V to 9.9×10-3 cm2 / s·V.

Owner:LG DISPLAY CO LTD

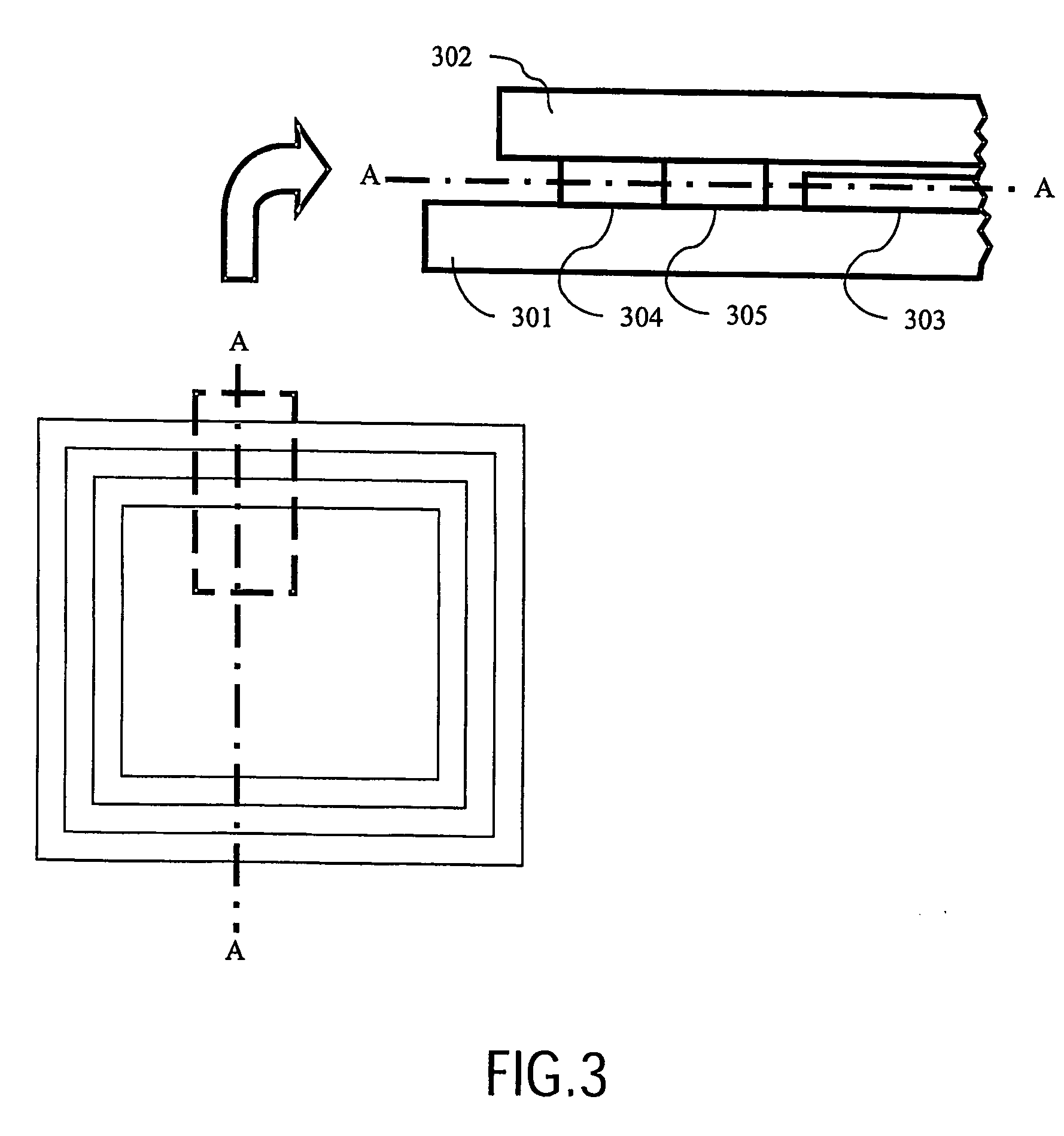

Organic light-emitting diode display and manufacturing method thereof

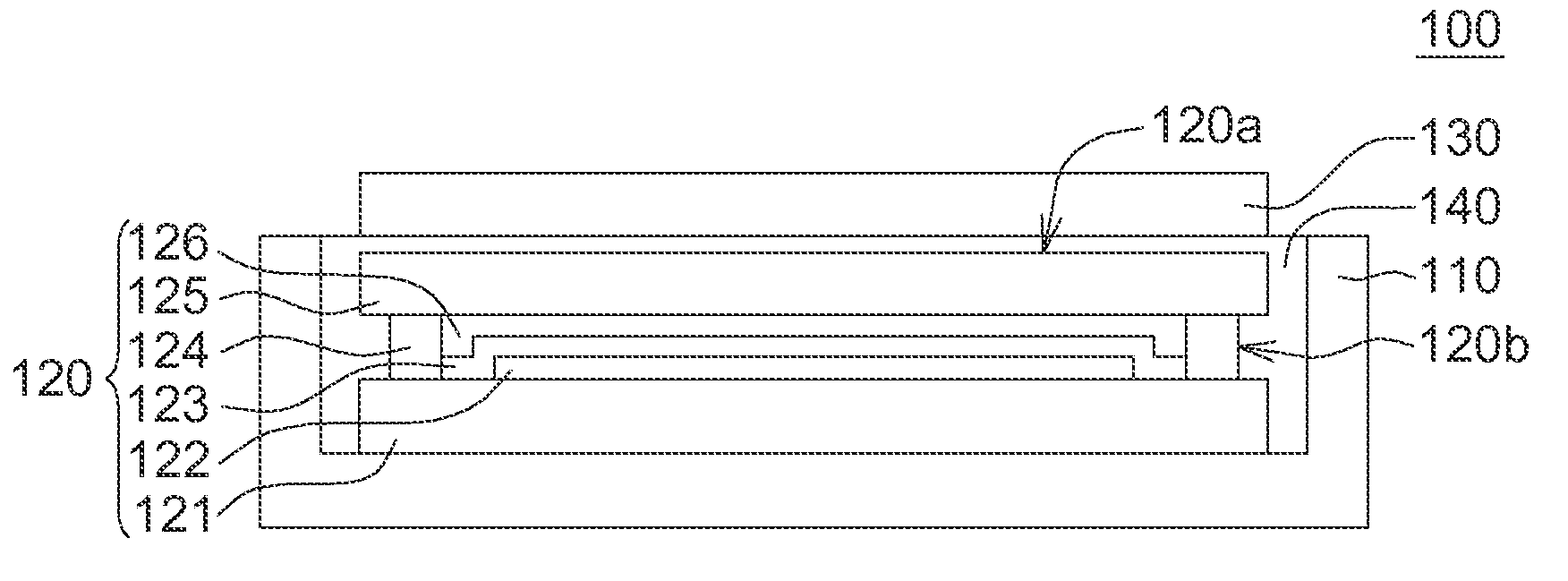

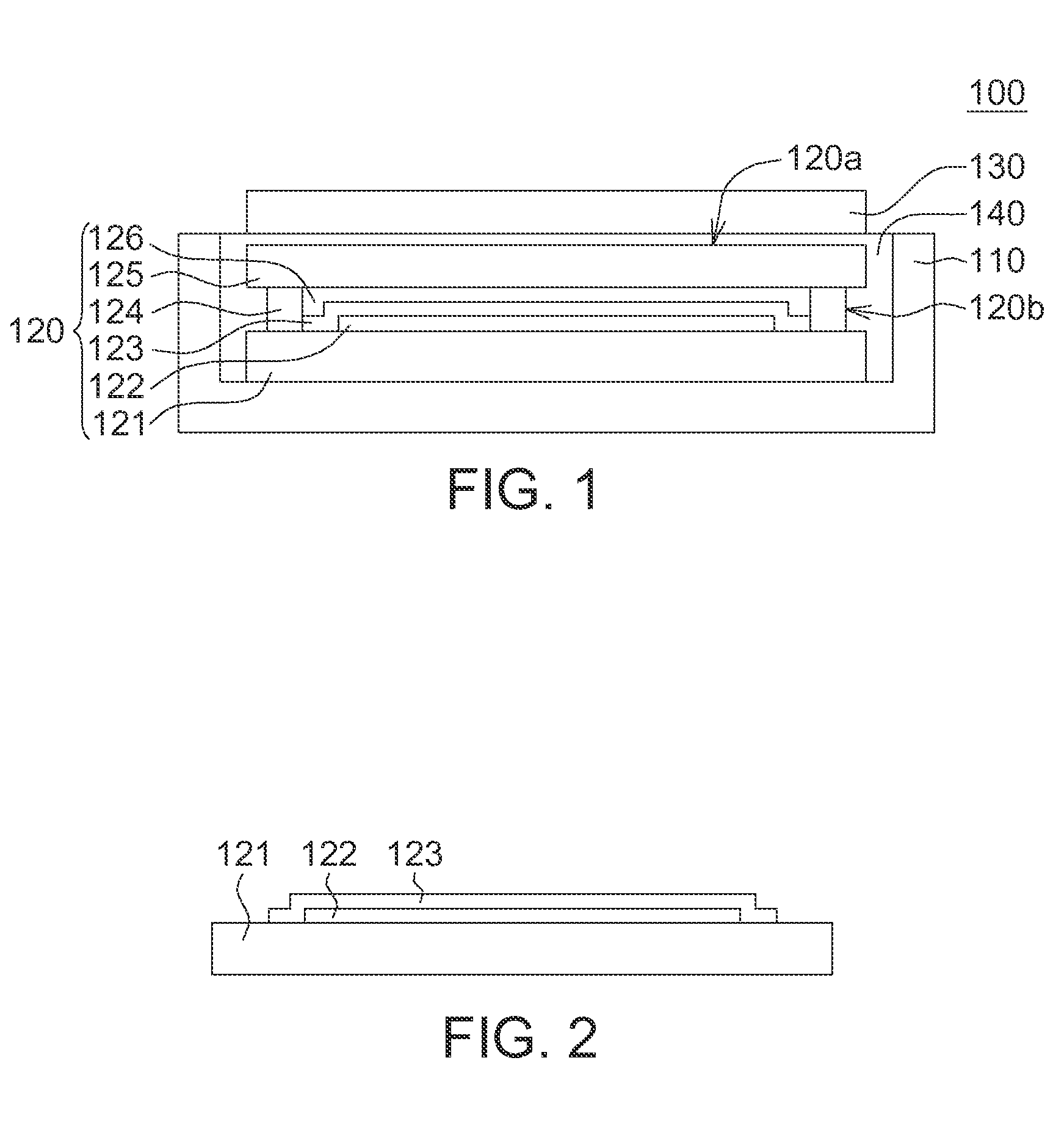

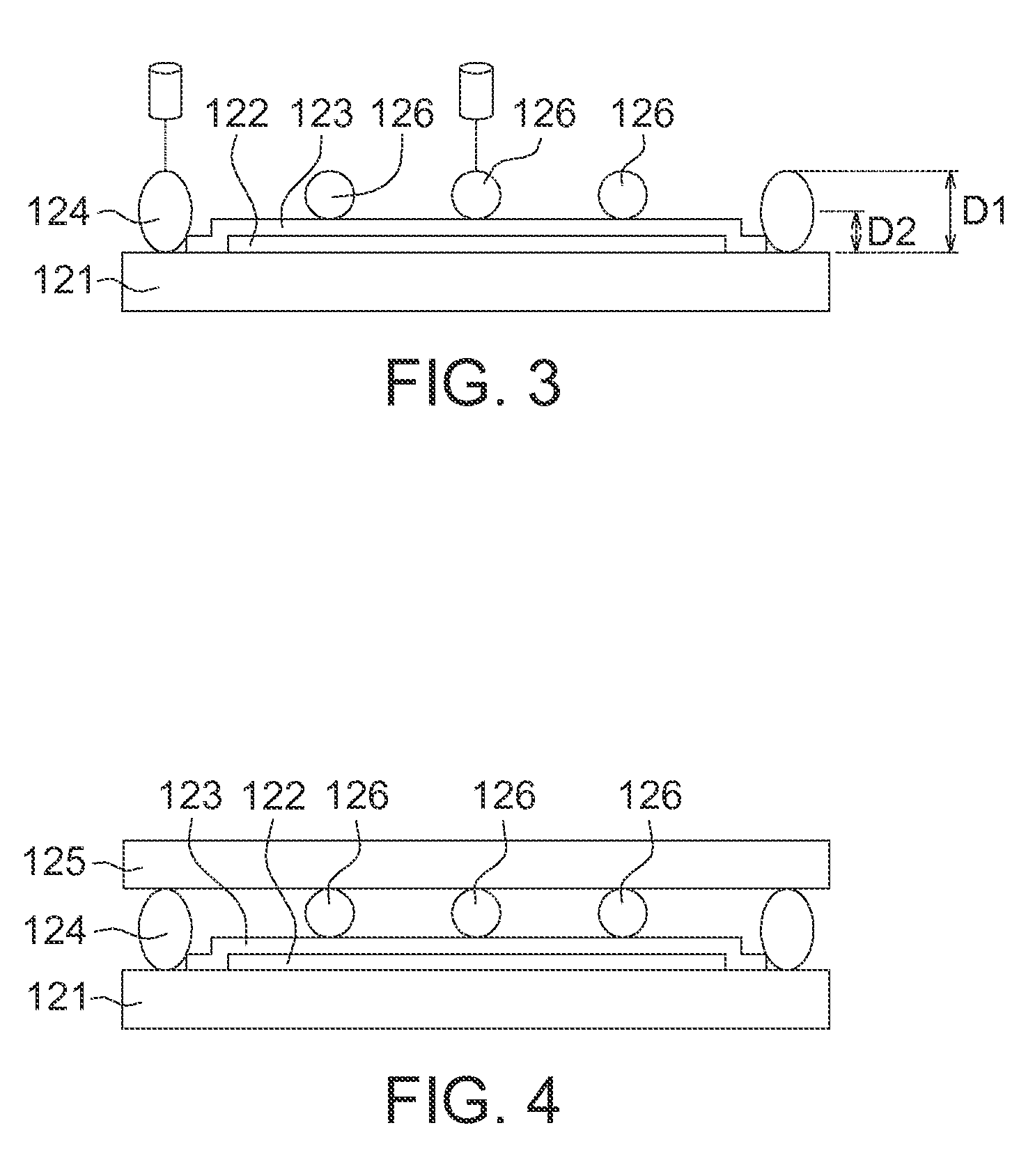

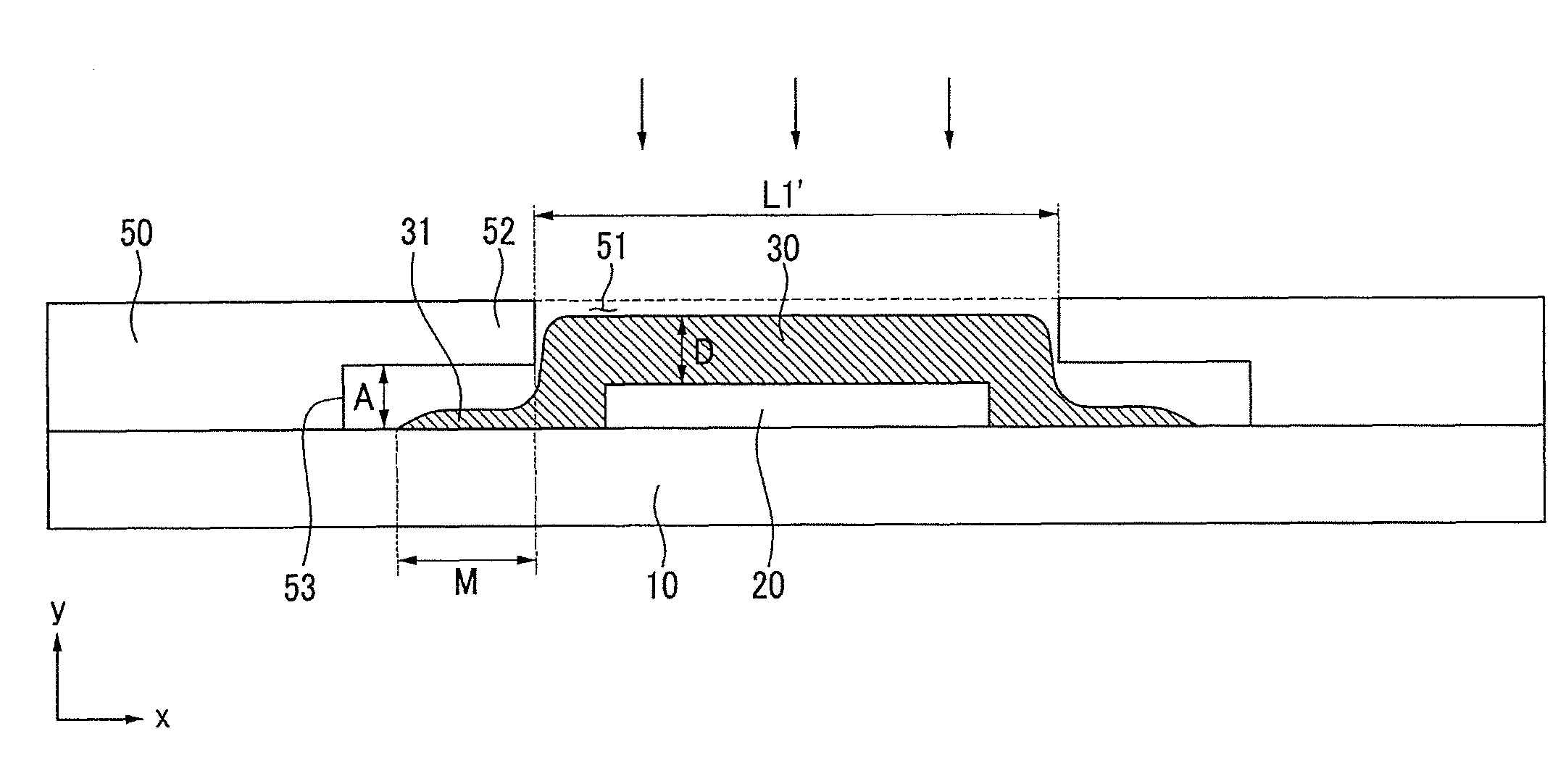

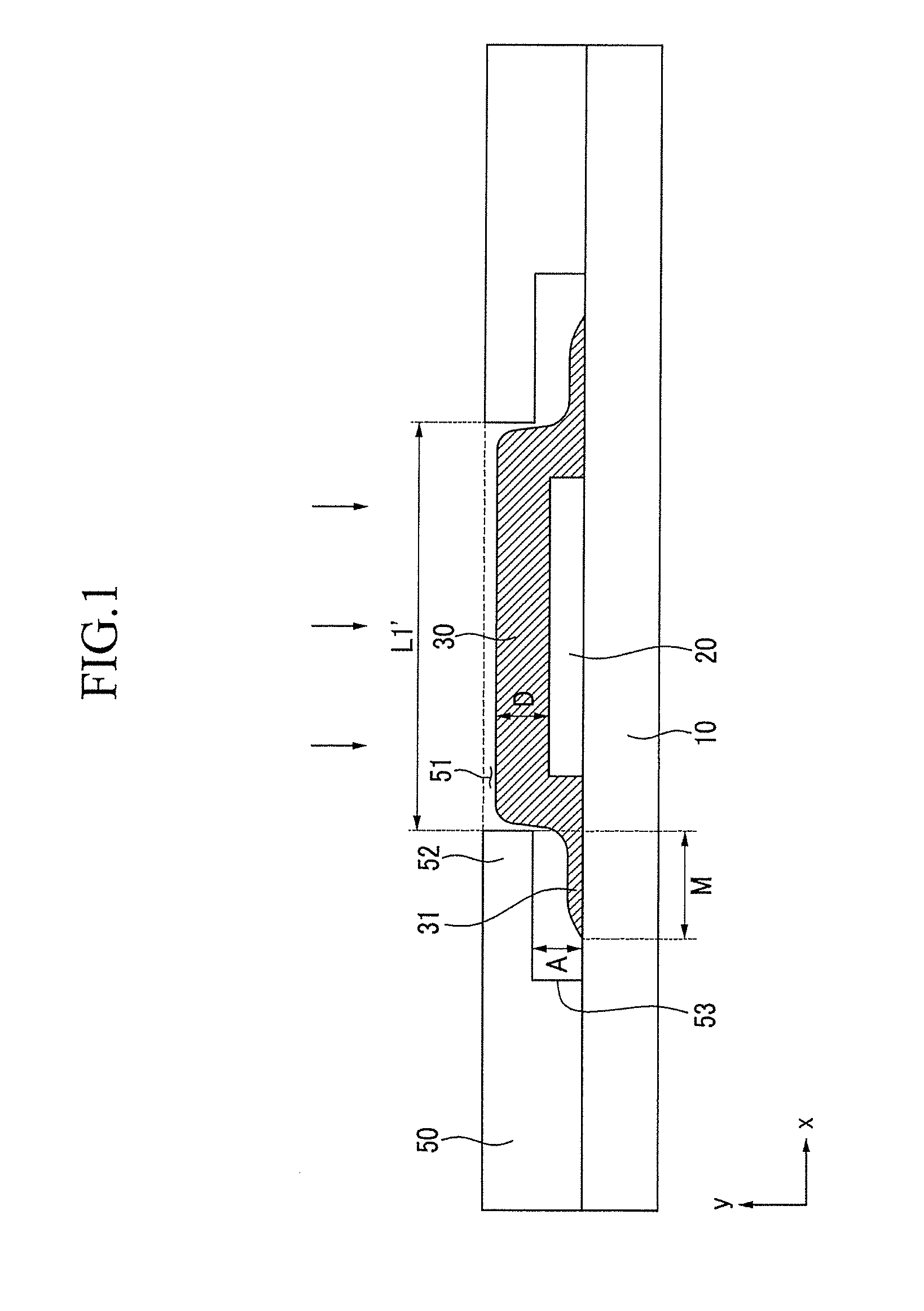

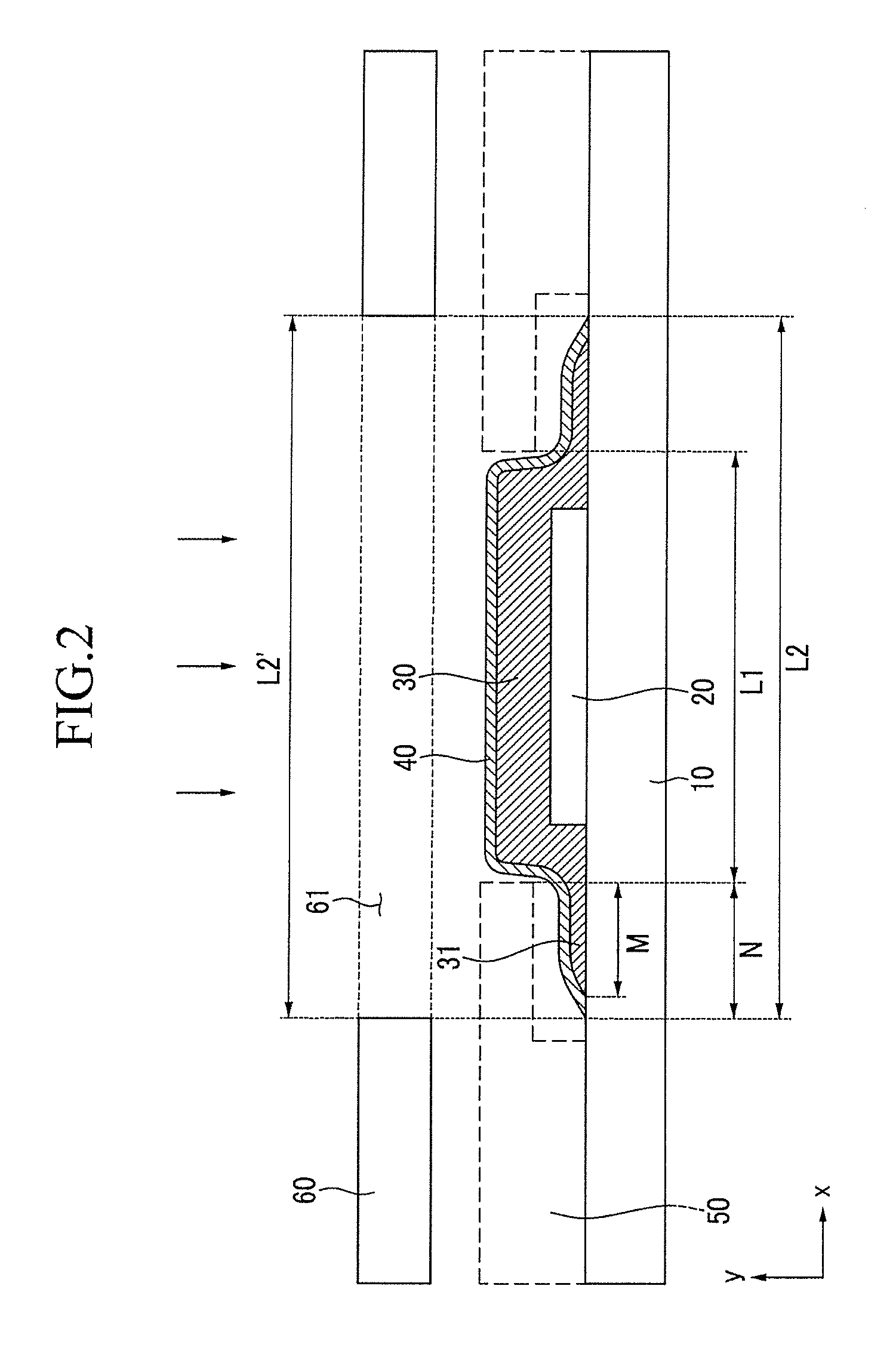

ActiveUS20130026533A1Effective controlReduce and prevent resultantOLED parametersElectroluminescent light sourcesOrganic filmDisplay device

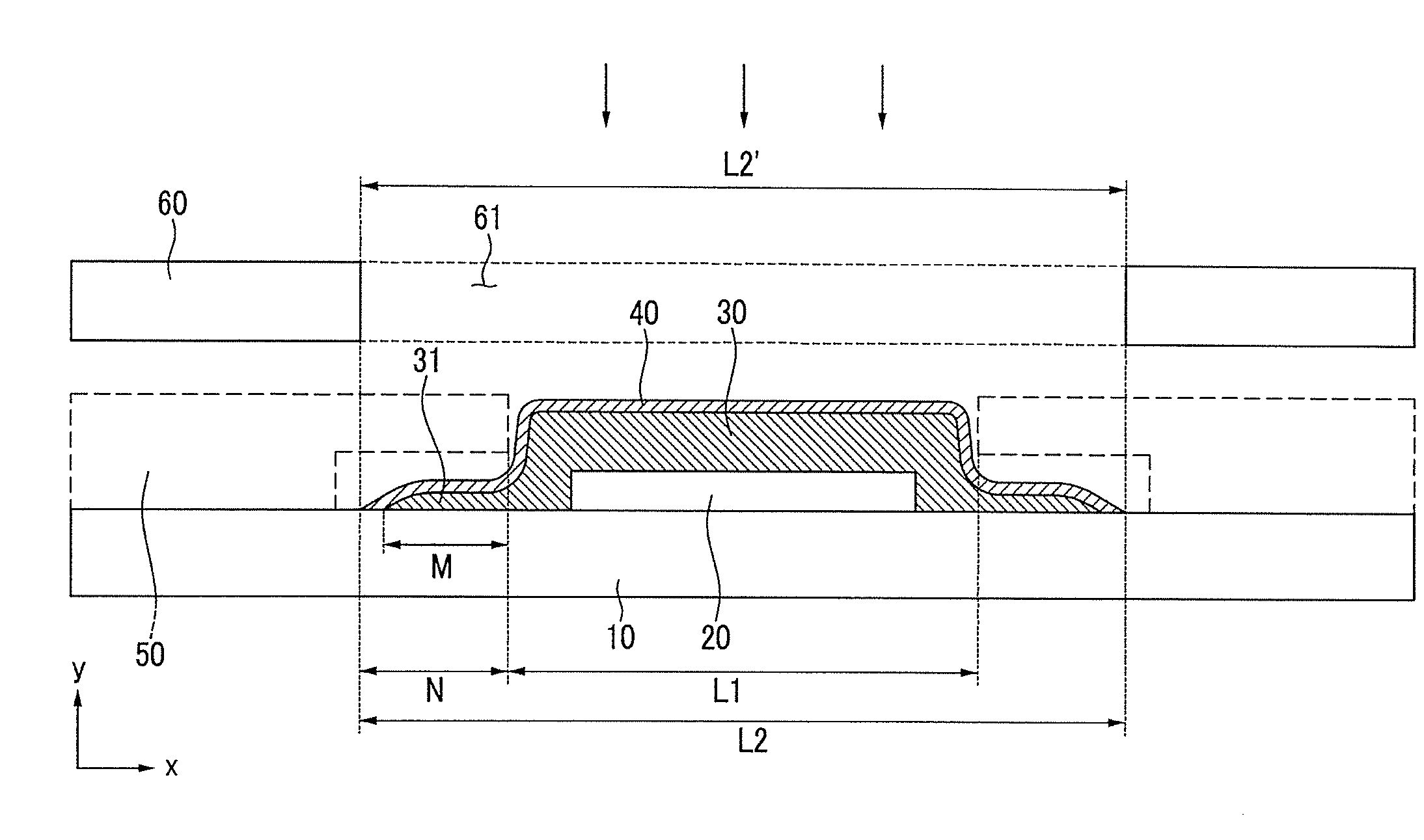

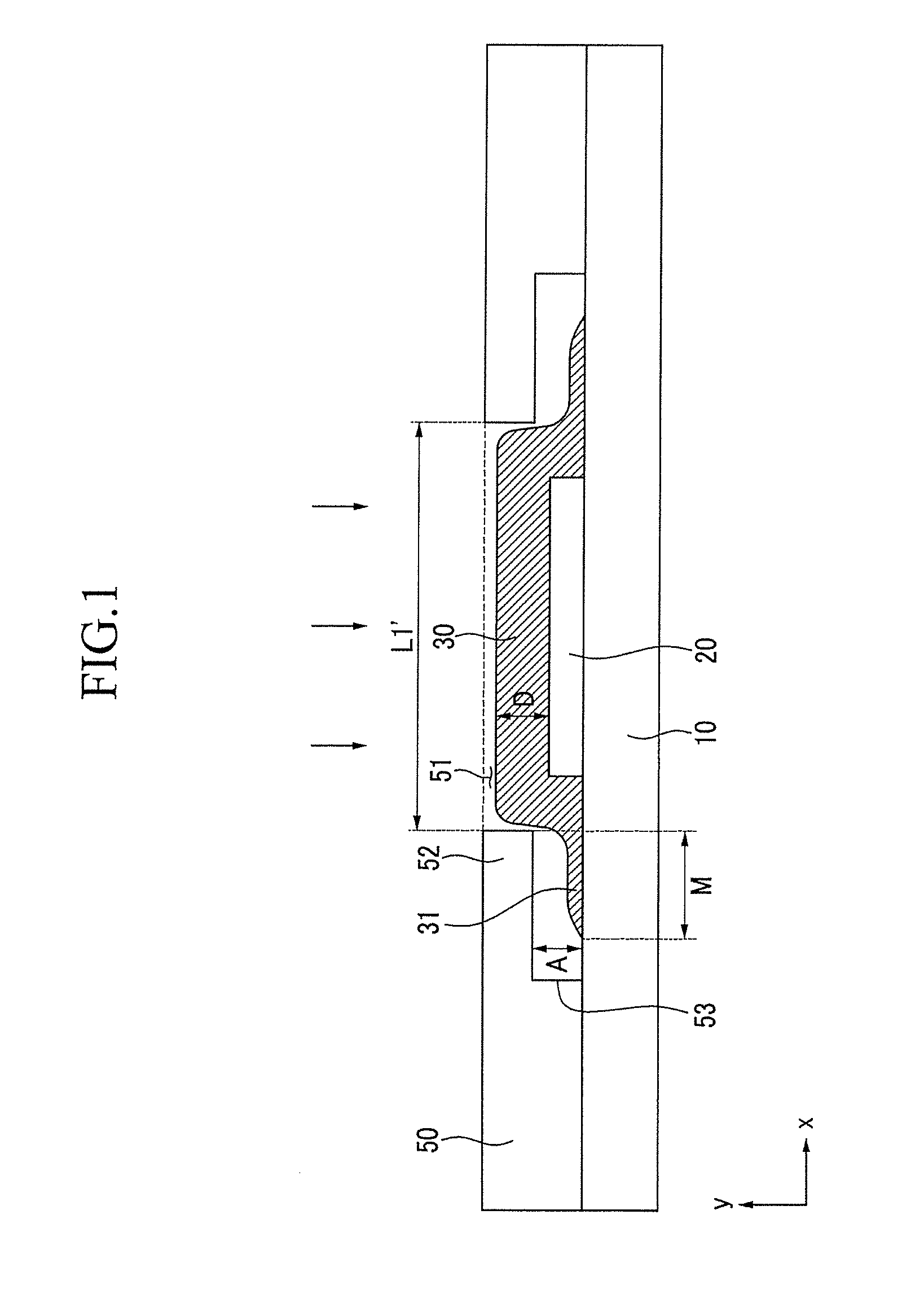

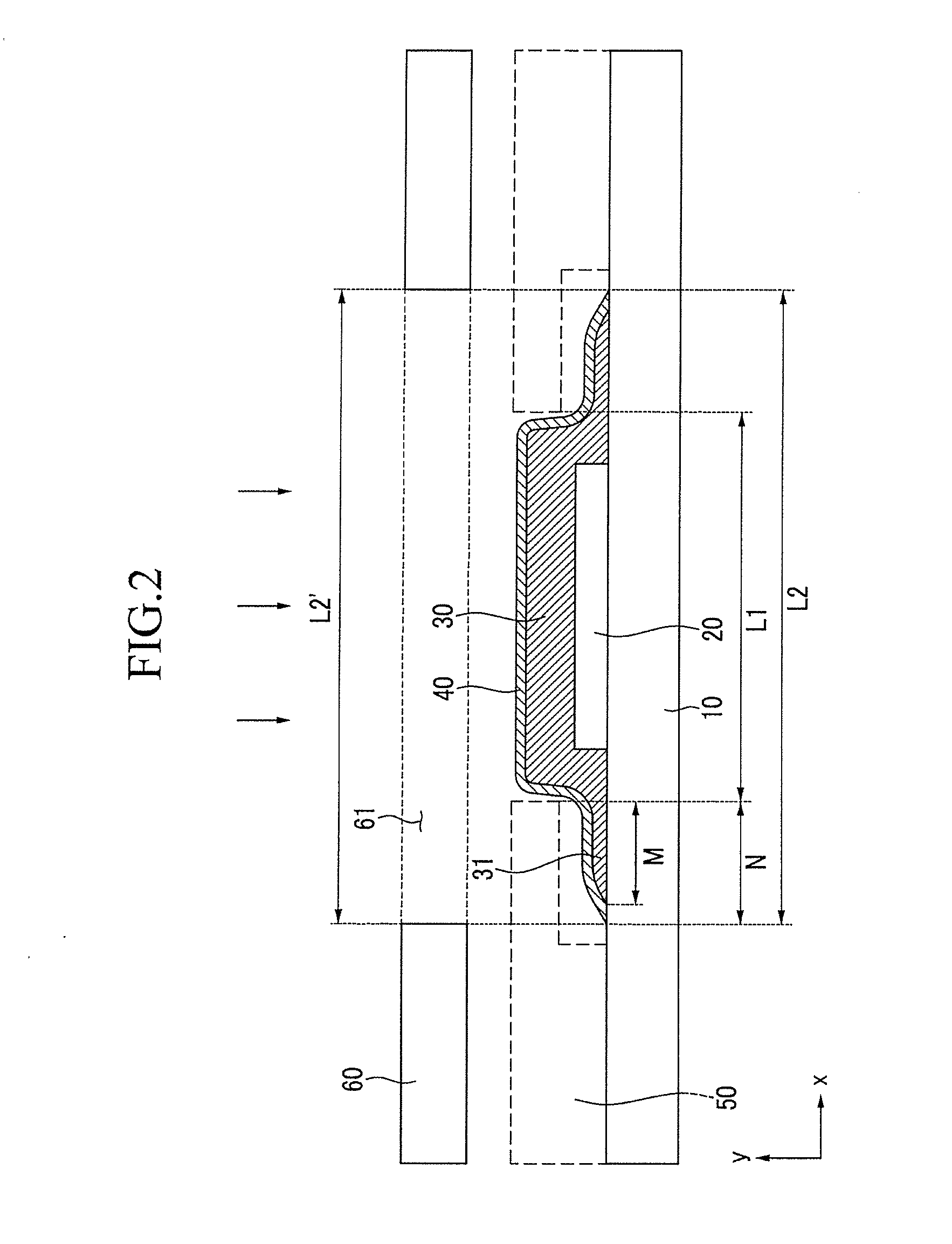

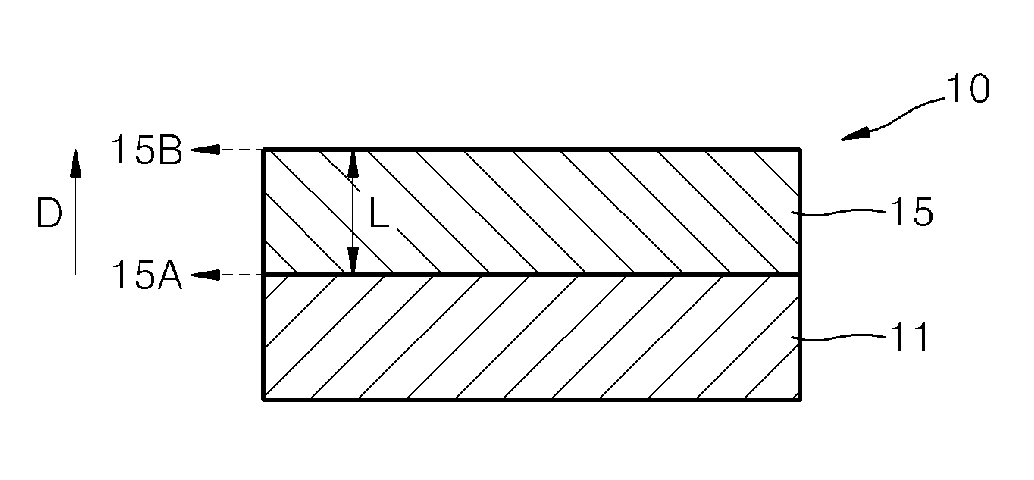

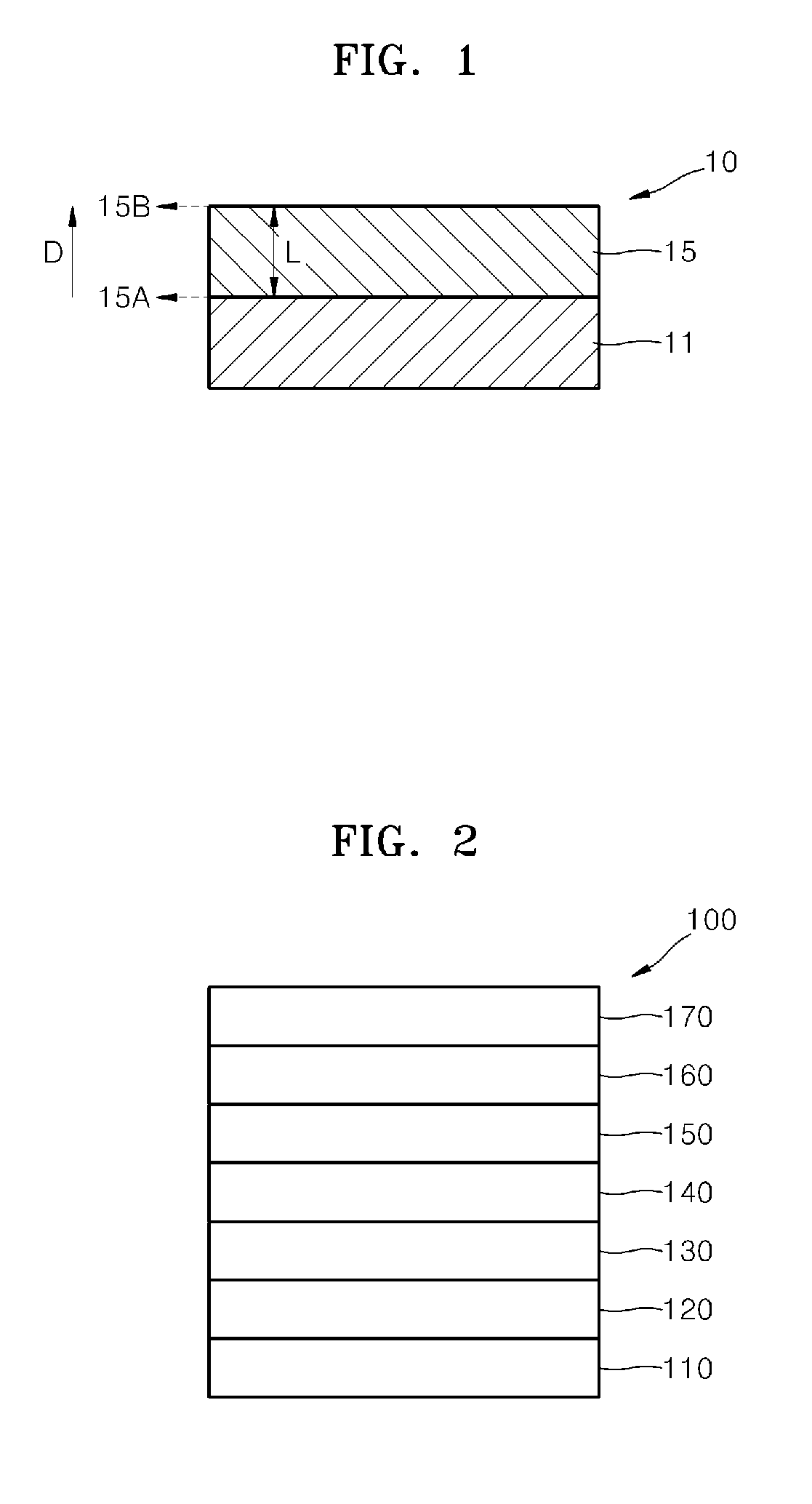

An organic light emitting diode display includes a substrate, an organic light emitting diode on the substrate, an organic film configured to cover the organic light emitting diode on the substrate in an organic film deposition area having a first diameter, and an inorganic film configured to cover the organic film on the substrate in an inorganic film deposition area having a second diameter, wherein L1 is the first diameter of the organic film deposition area in μm, wherein L2 is the second diameter of the inorganic film deposition area in μm, wherein D is a thickness of the organic film in μm, and wherein L2−L1≧2 (171D+150 μm).

Owner:SAMSUNG DISPLAY CO LTD

Simplified organic electronic device employing polymeric anode with high work function

InactiveUS20120298974A1Simple structureImprove conductivityOLED parametersSolid-state devicesPhysical chemistryMaterials science

Owner:POSTECH ACAD IND FOUND

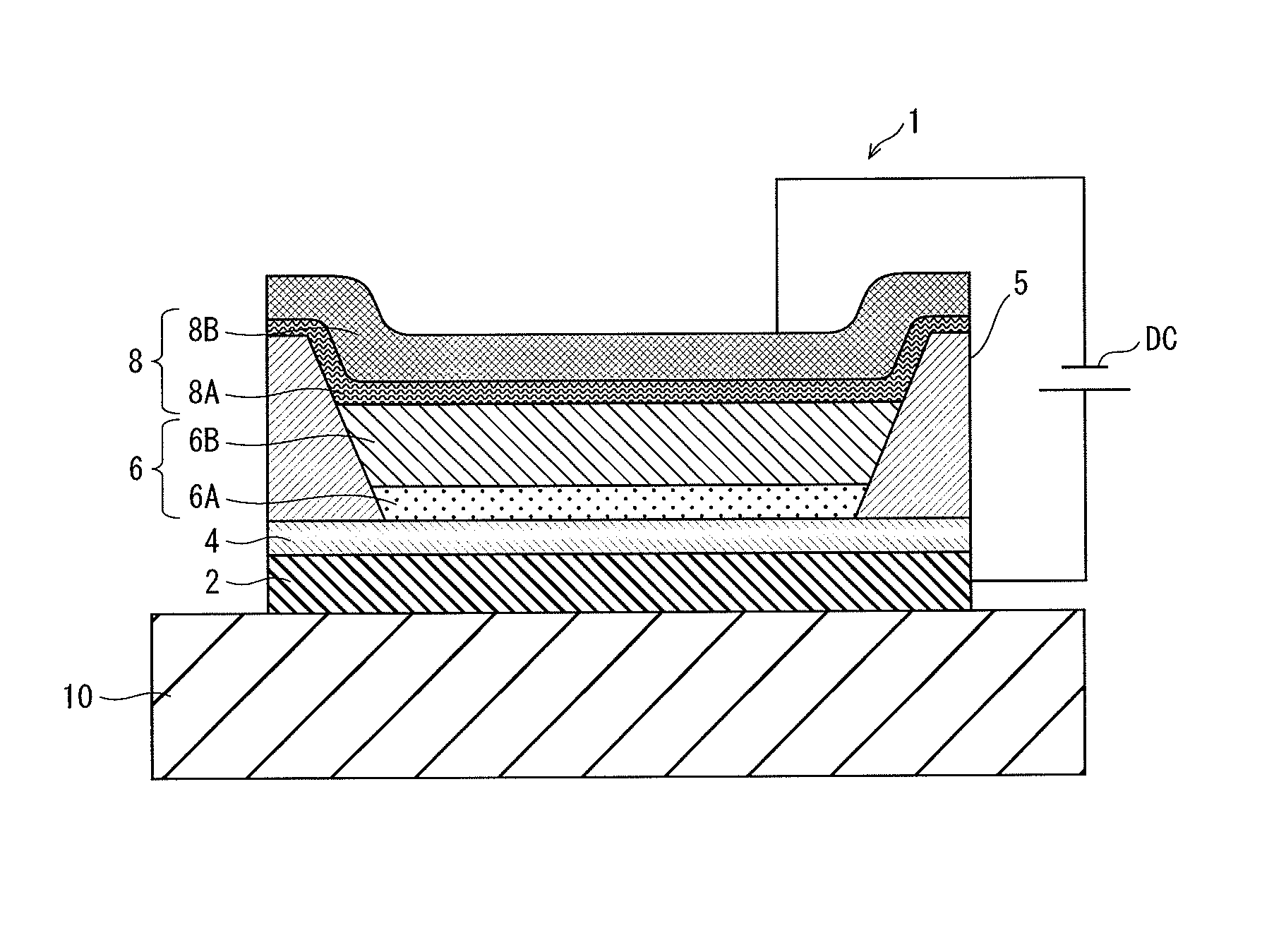

Display Device and Method of Manufacturing the Same

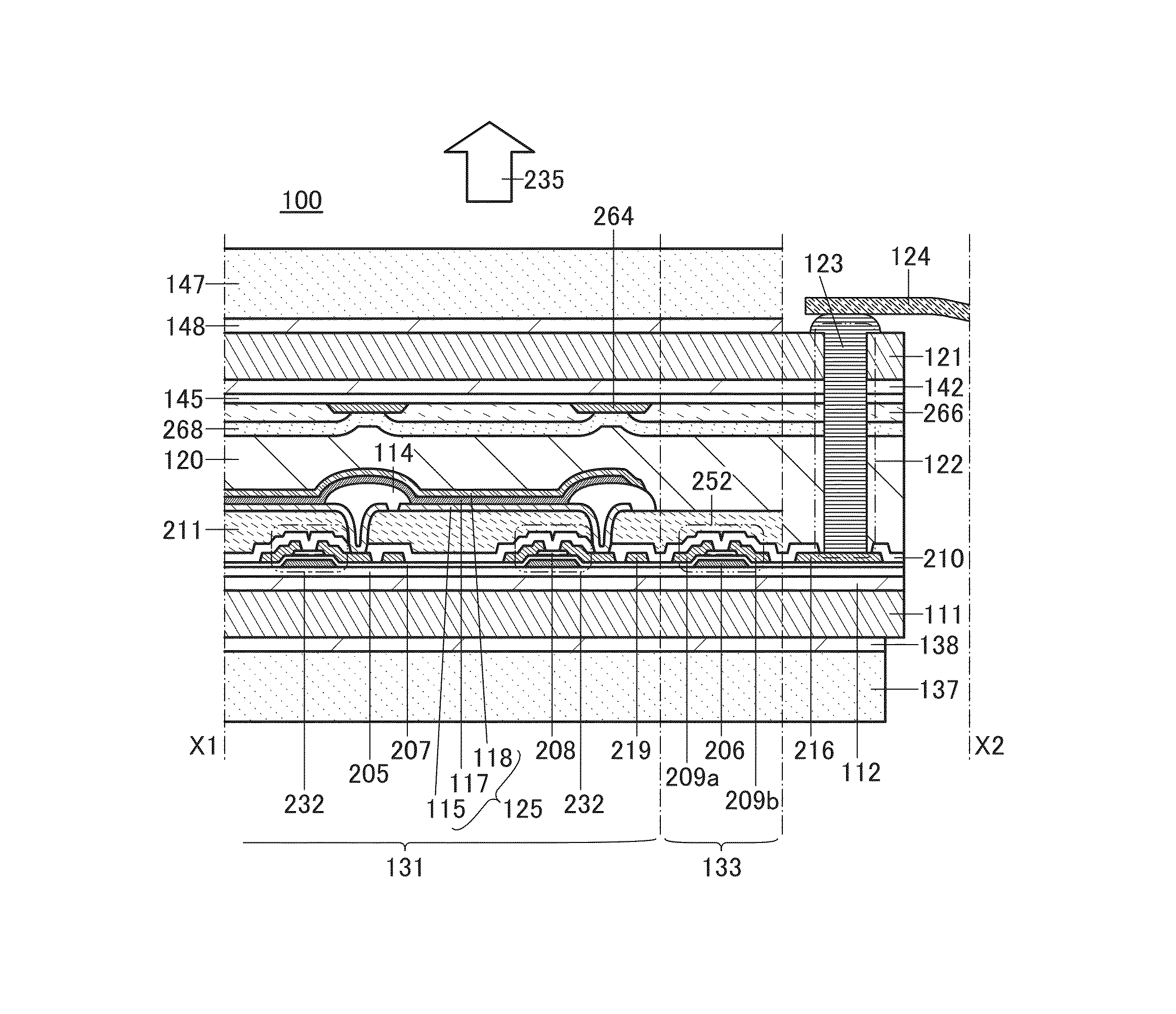

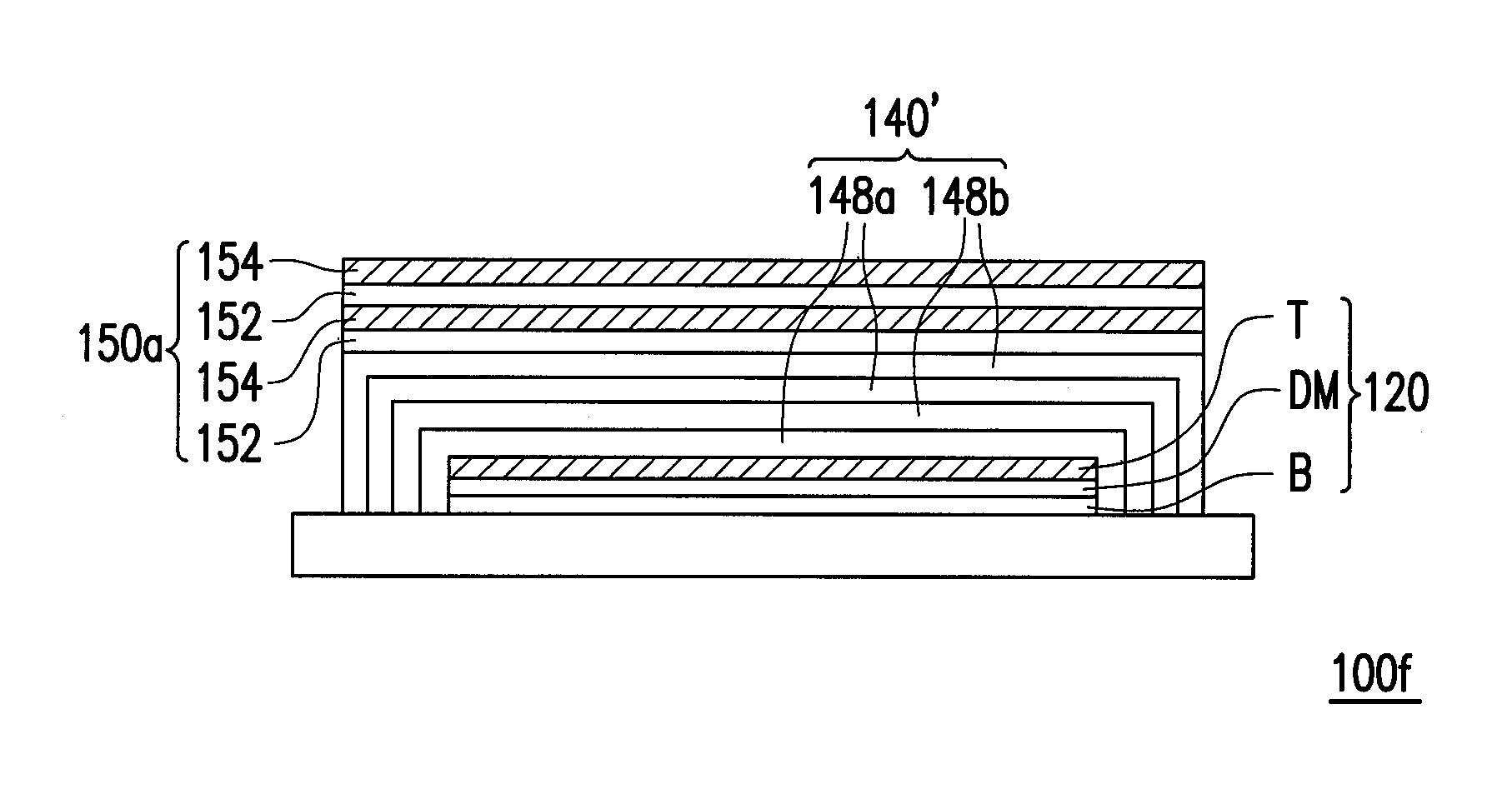

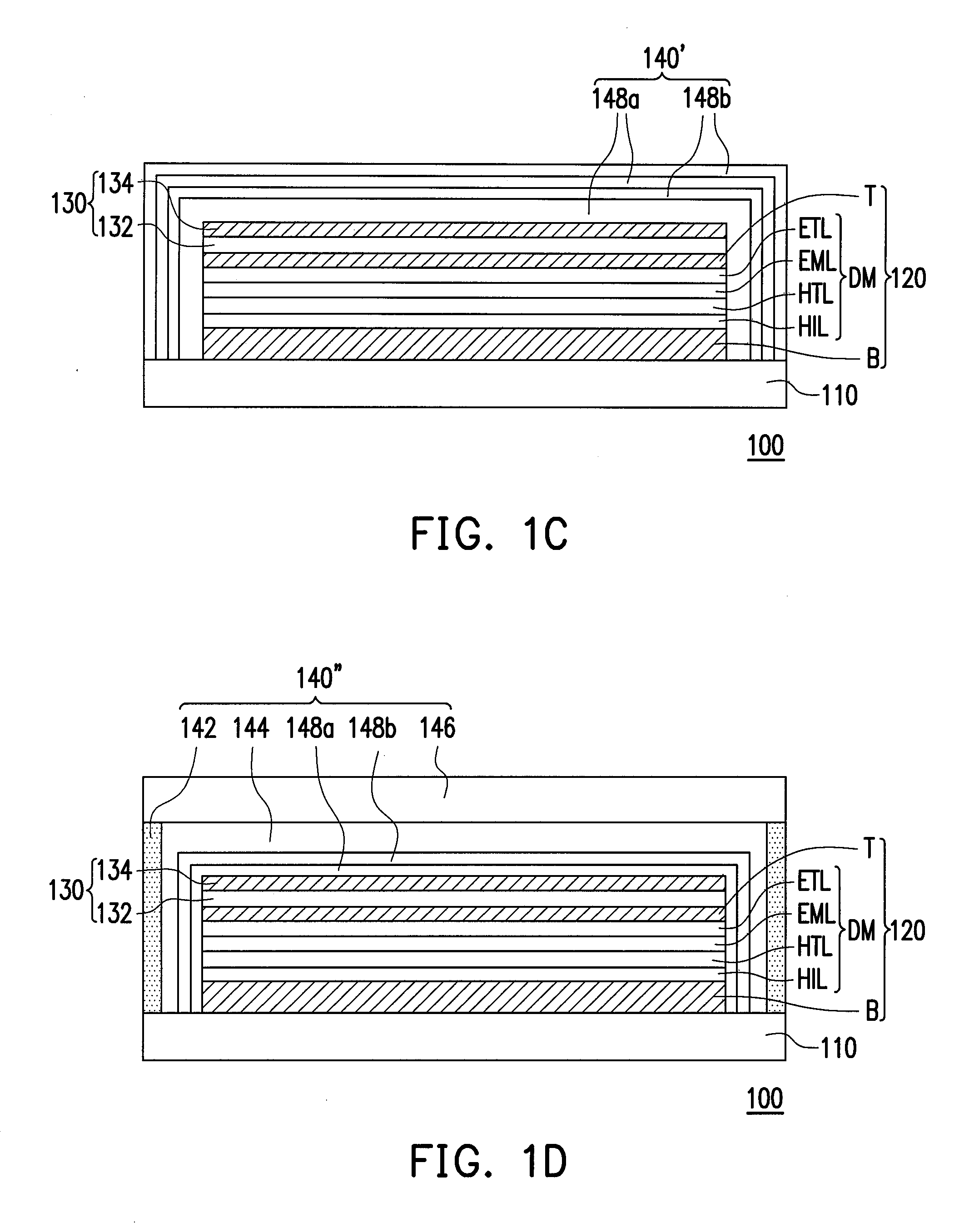

ActiveUS20170294493A1Reduce lossesExtended service lifeOLED parametersSolid-state devicesOrganic light emitting deviceDisplay device

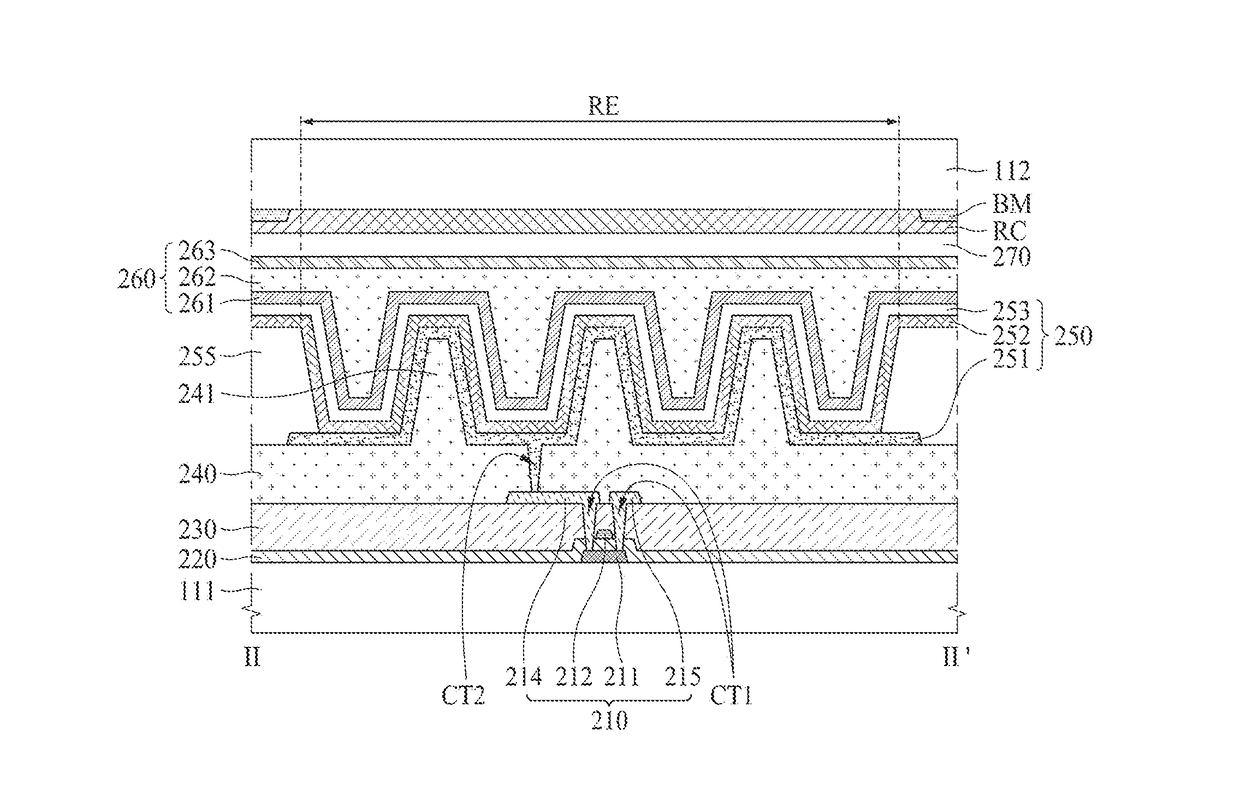

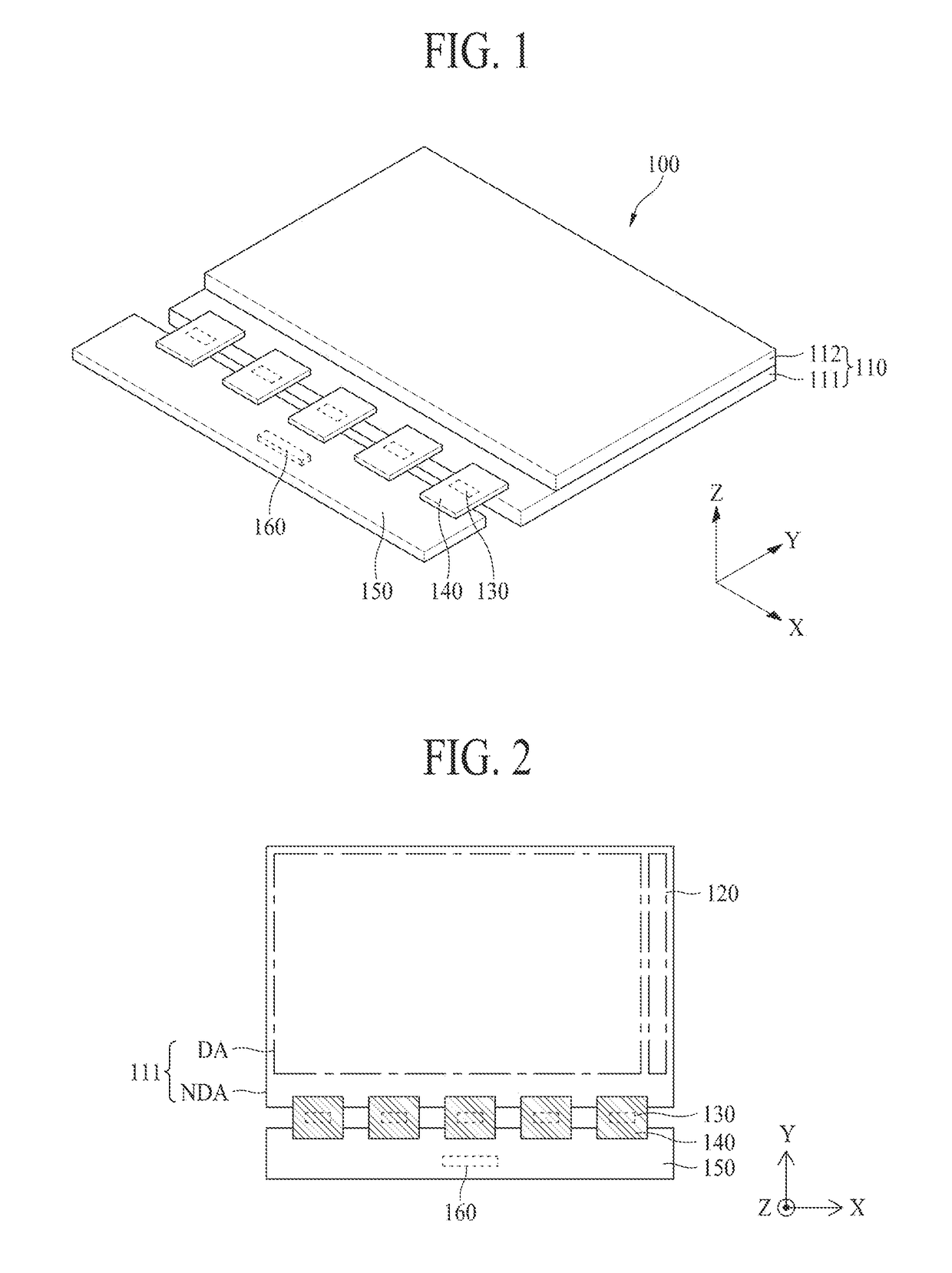

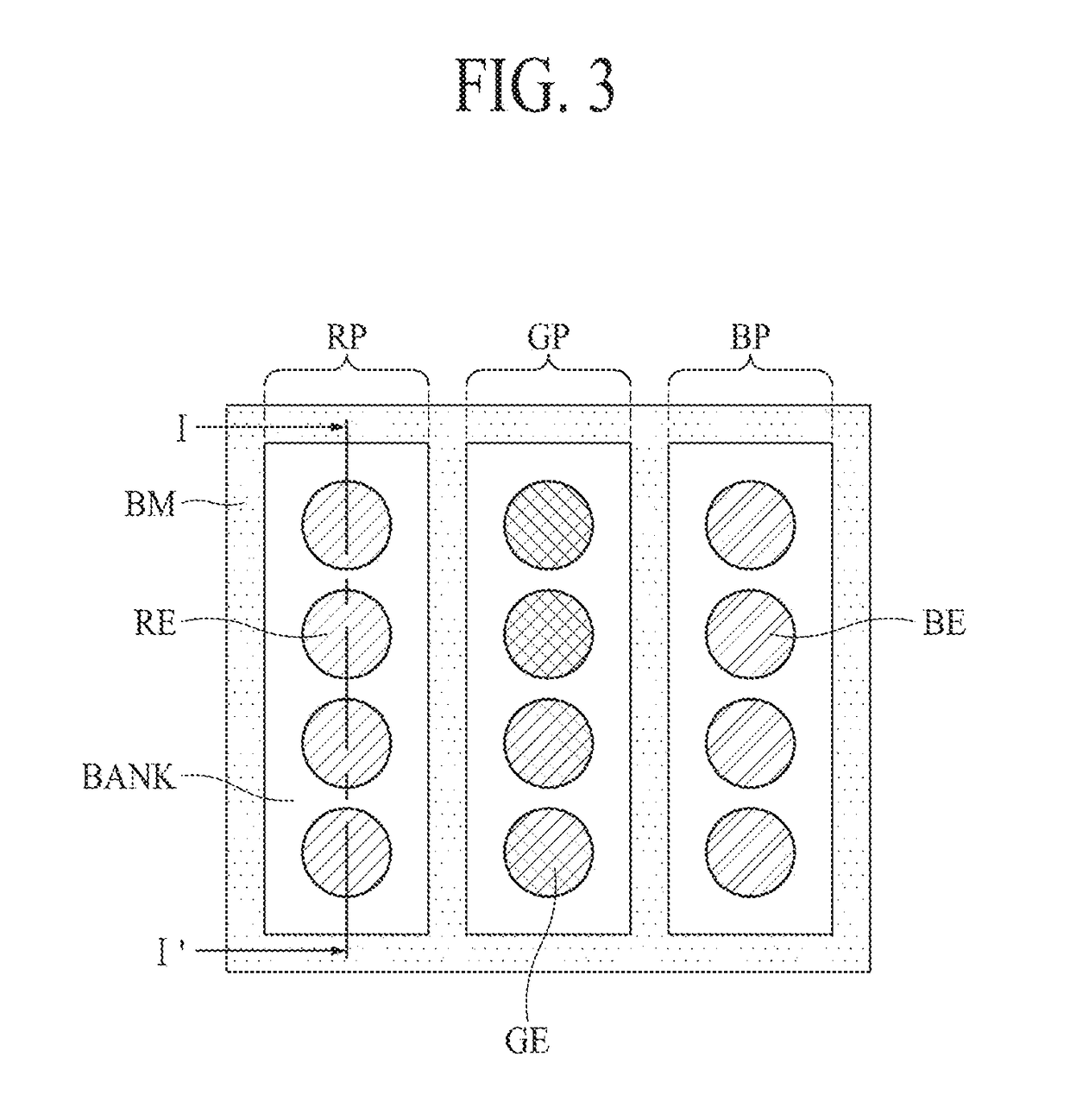

Disclosed are an organic light emitting display device and a method of manufacturing the same, which reduce a loss of light emitted from an organic light emitting device, increase a lifetime of the organic light emitting device, and decrease consumption power of the organic light emitting display device. The organic light emitting display device includes a first electrode disposed on a first substrate, a bank disposed on the first electrode for dividing a plurality of emission parts, an organic light emitting layer disposed on the first electrode and the bank, a second electrode disposed on the organic light emitting layer, and an encapsulation layer disposed on the second electrode. The encapsulation layer fills a space between adjacent banks, and a refractive index of the bank is lower than a refractive index of the organic light emitting layer and a refractive index of the encapsulation layer.

Owner:LG DISPLAY CO LTD

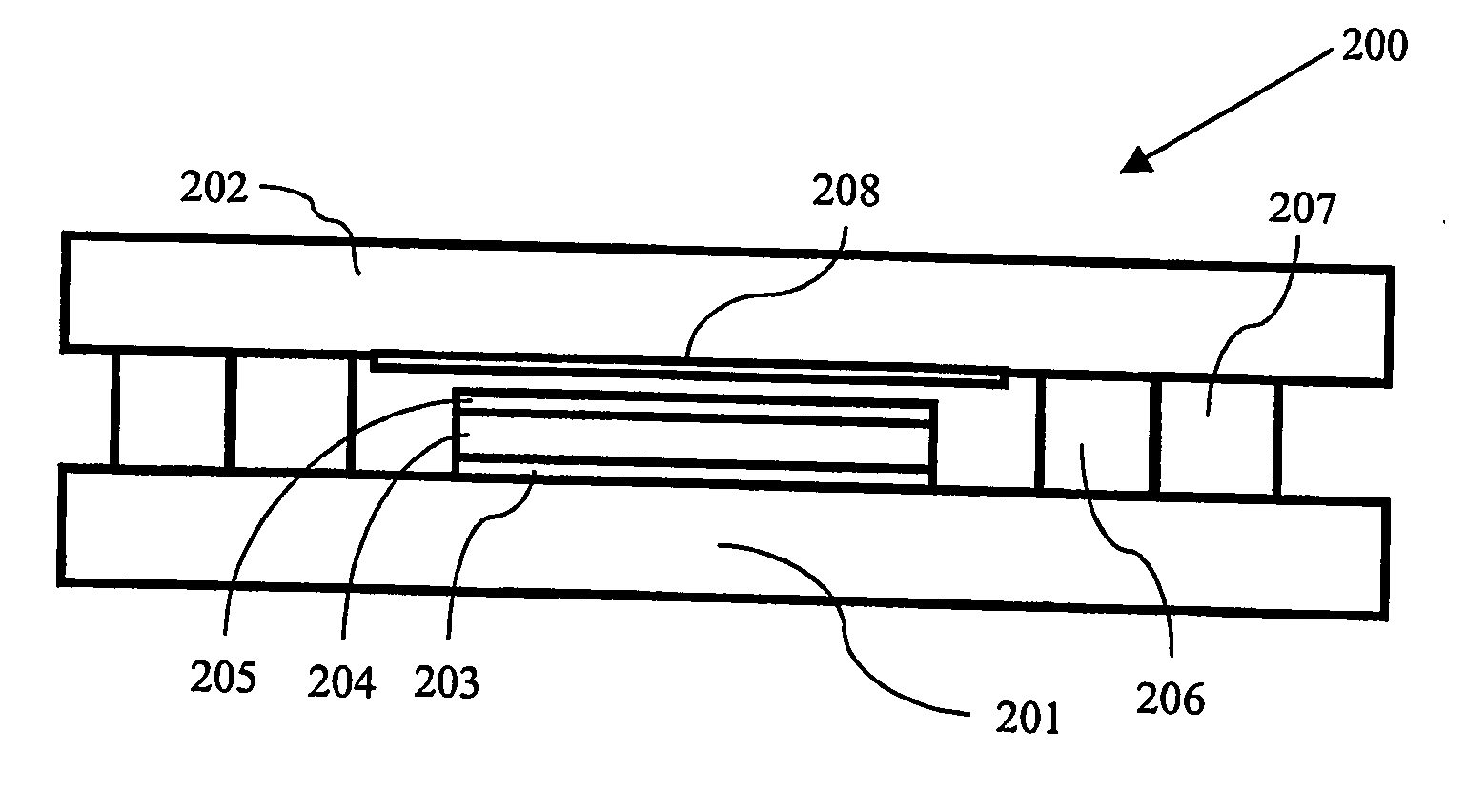

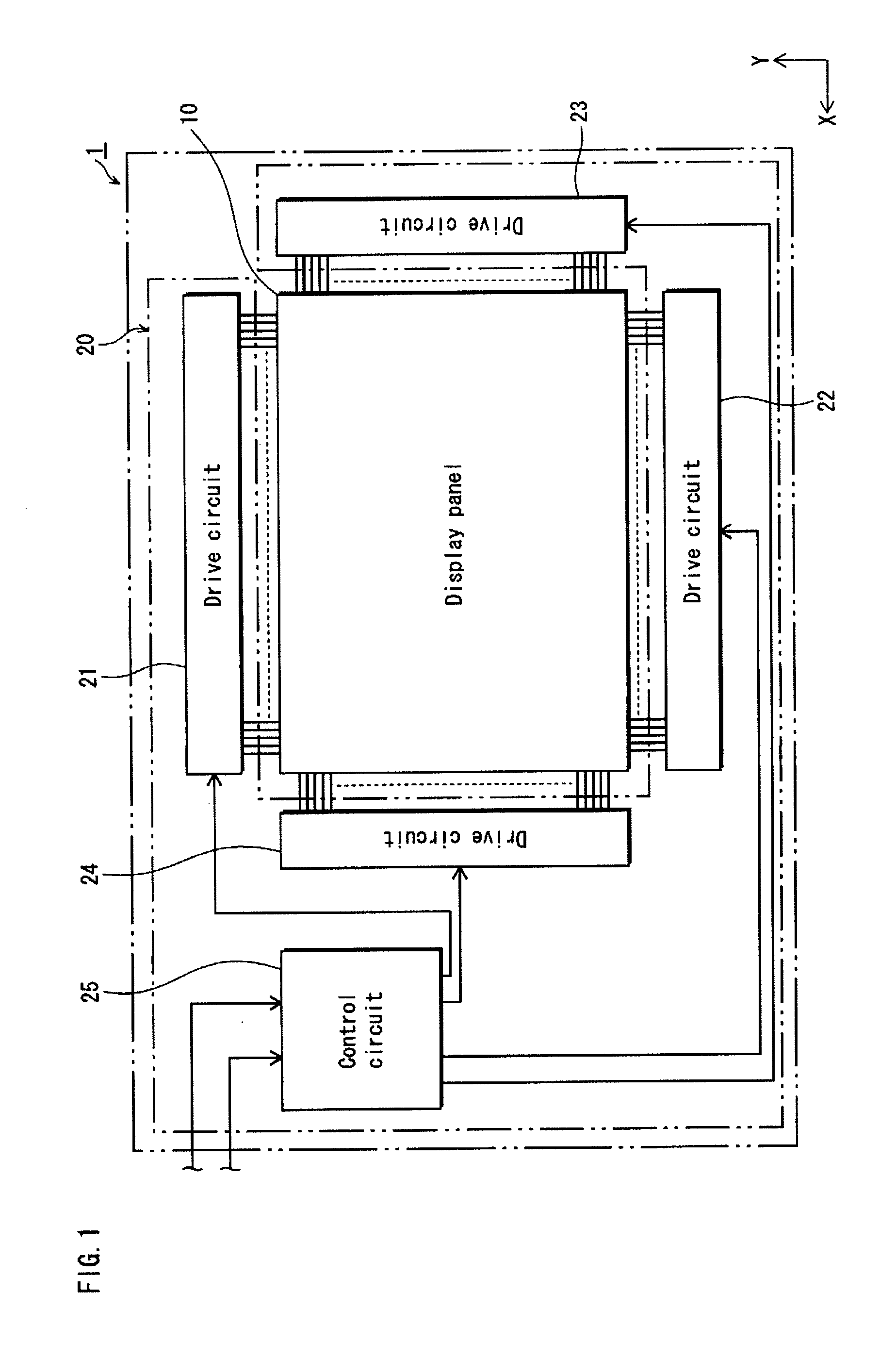

Display device

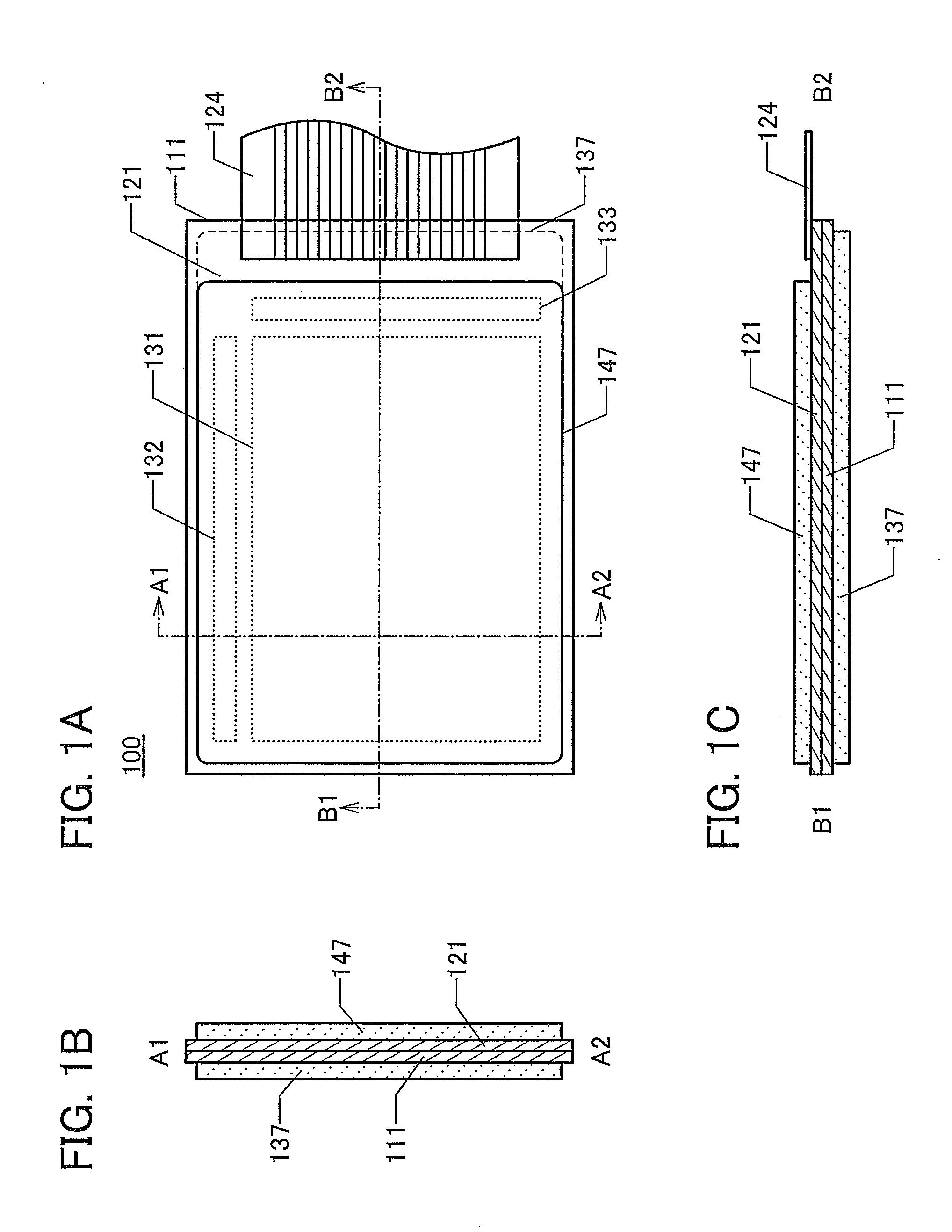

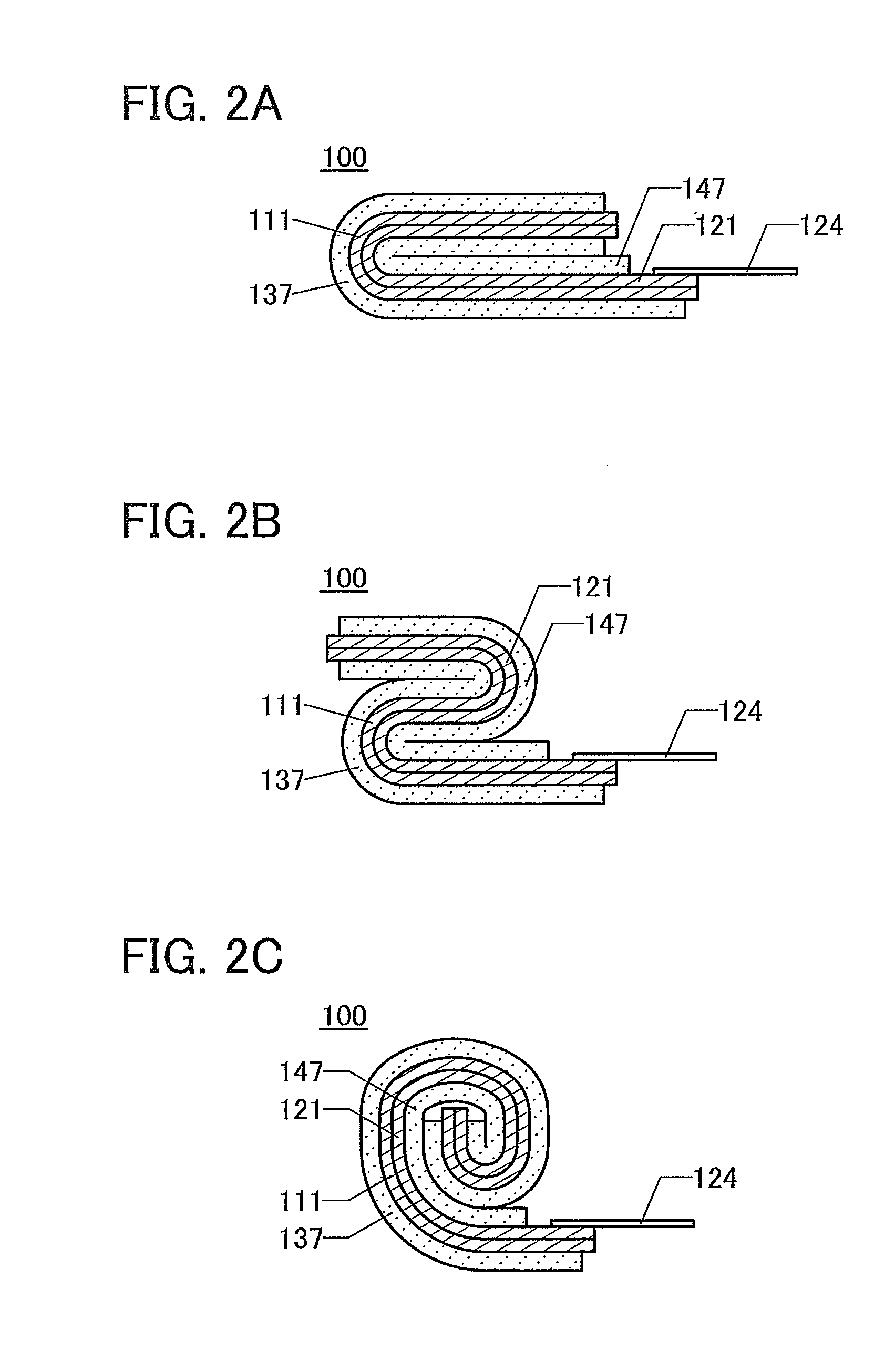

ActiveUS9431618B2Improve reliabilityReduce power consumptionLiquid crystal compositionsOLED parametersDisplay deviceEngineering

A display device, an electronic device, or a lighting device that is unlikely to be broken is provided. A flexible first substrate and a flexible second substrate overlap with each other with a display element provided therebetween. A flexible third substrate is bonded on the outer surface of the first substrate, and a flexible fourth substrate is bonded on the outer surface of the second substrate. The third substrate is formed using a material softer than the first substrate, and the fourth substrate is formed using a material softer than the second substrate.

Owner:SEMICON ENERGY LAB CO LTD

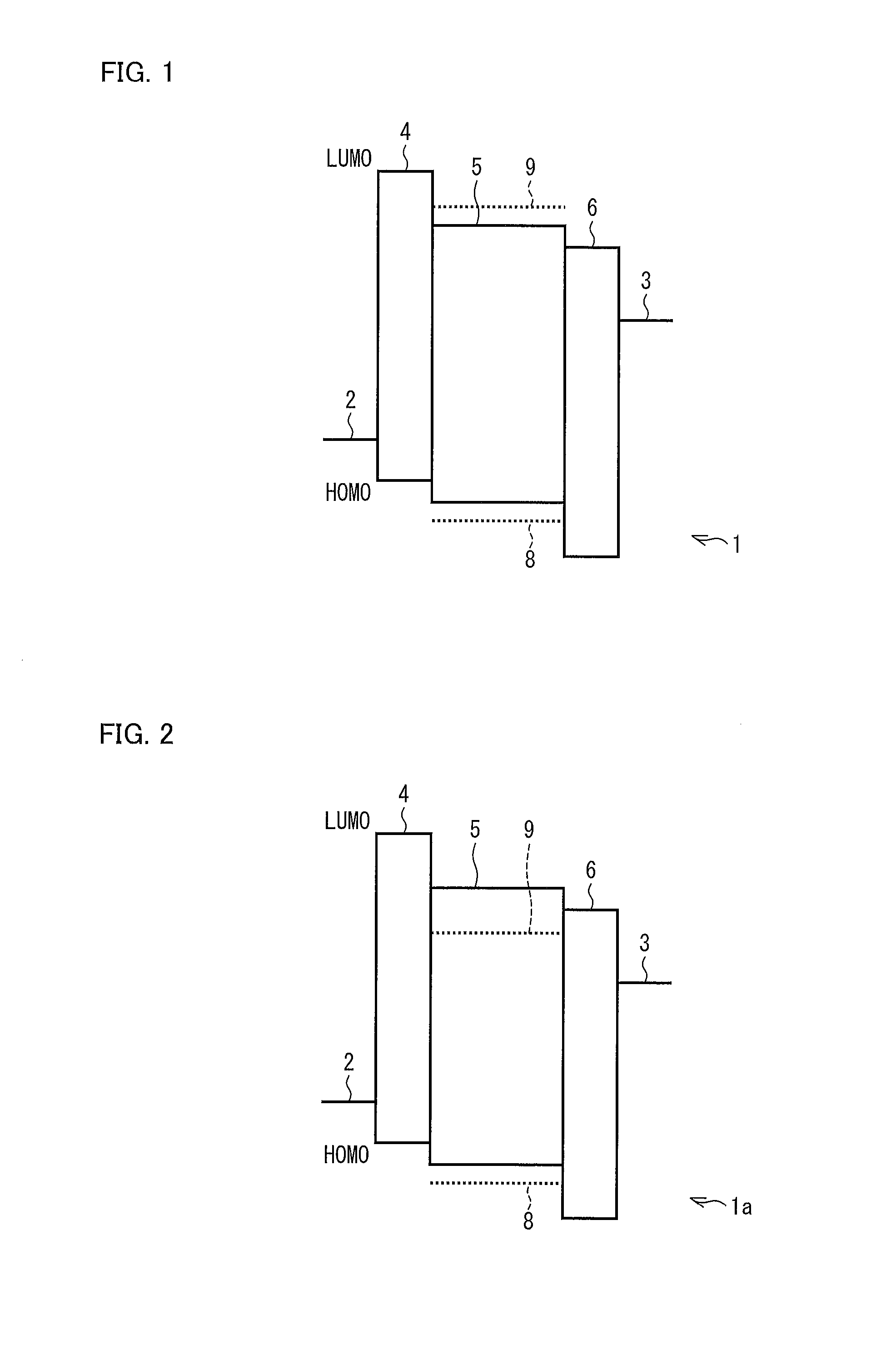

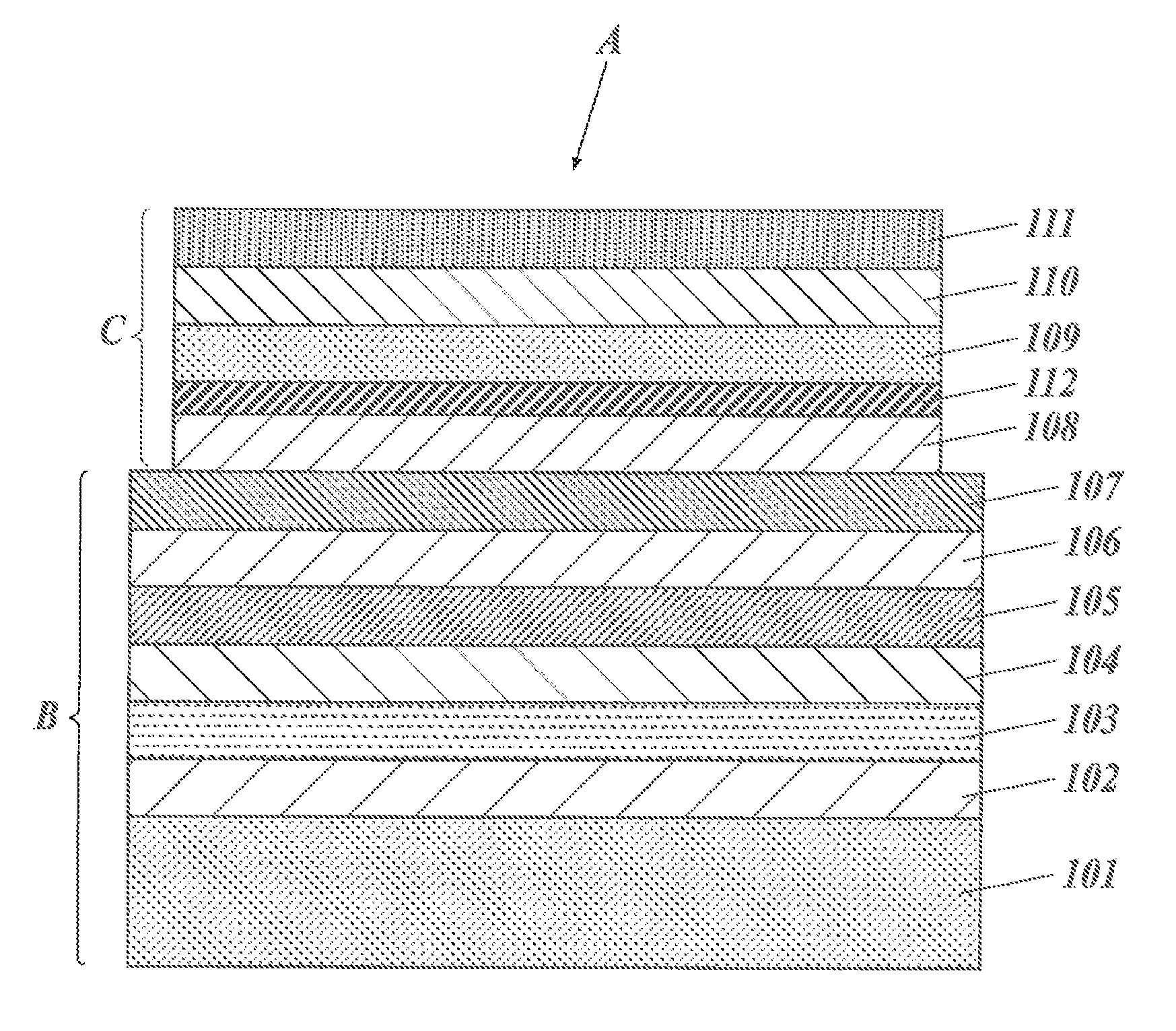

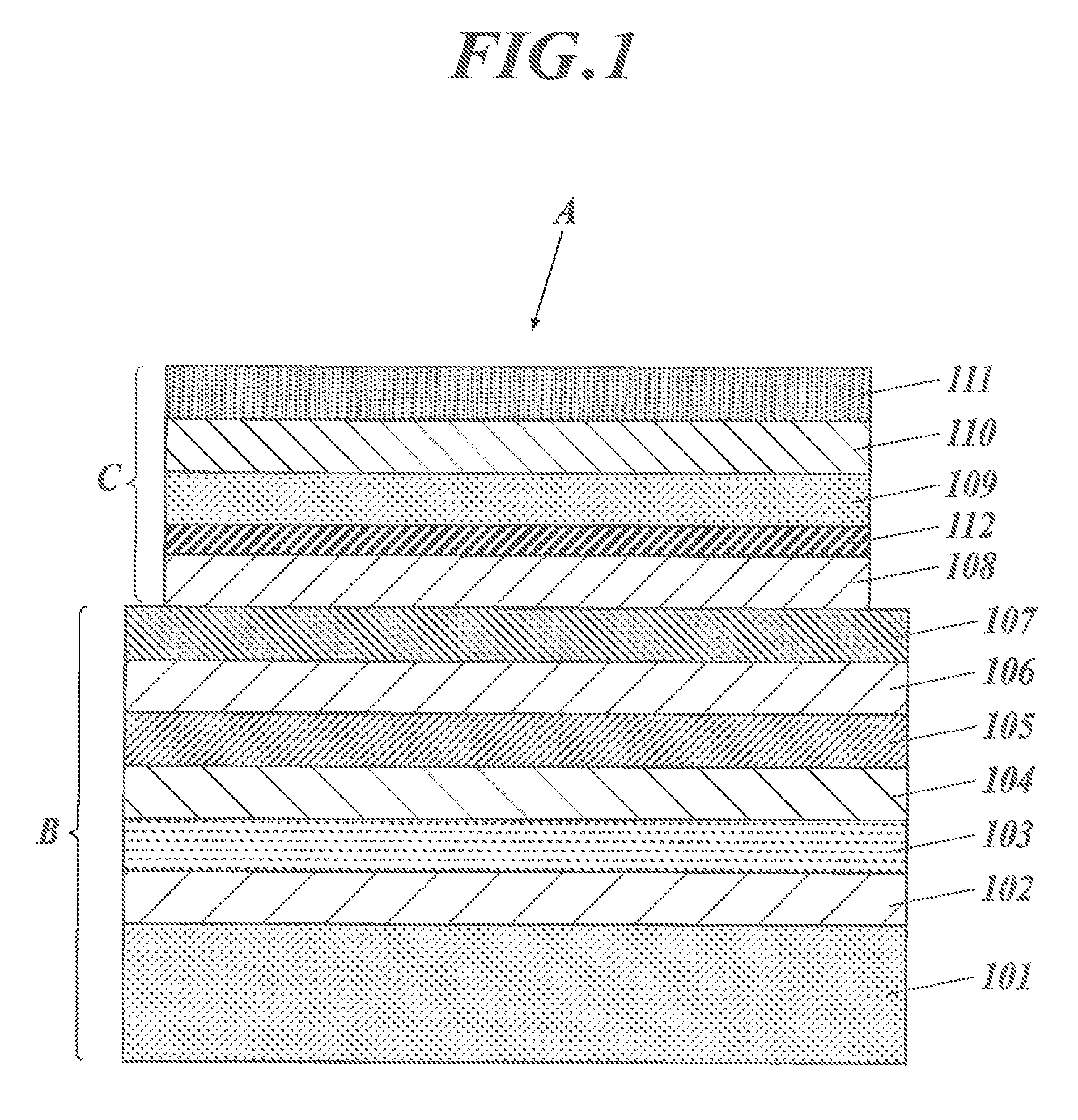

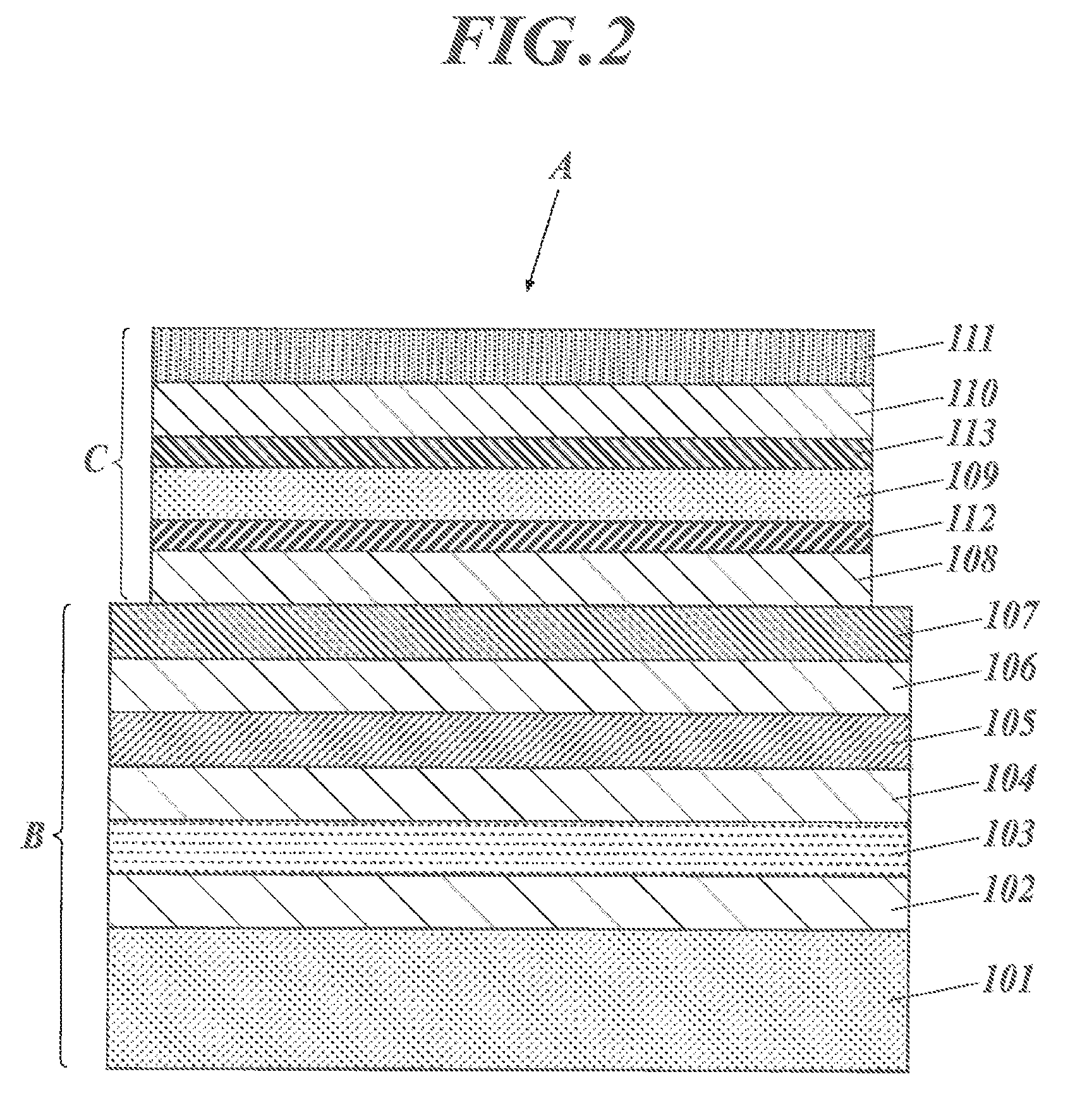

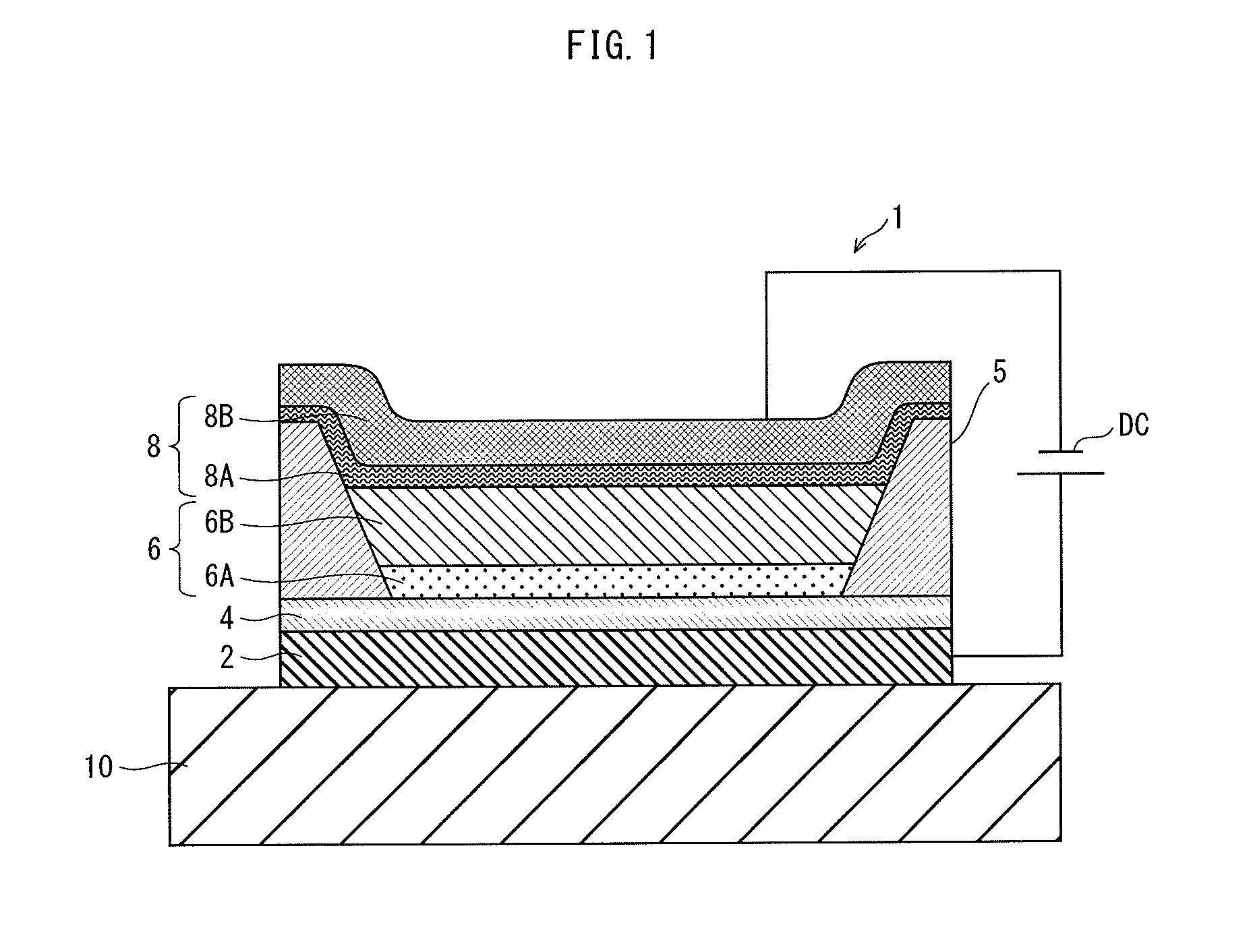

Organic electroluminescence element, manufacturing method thereof, and organic electroluminescence display device

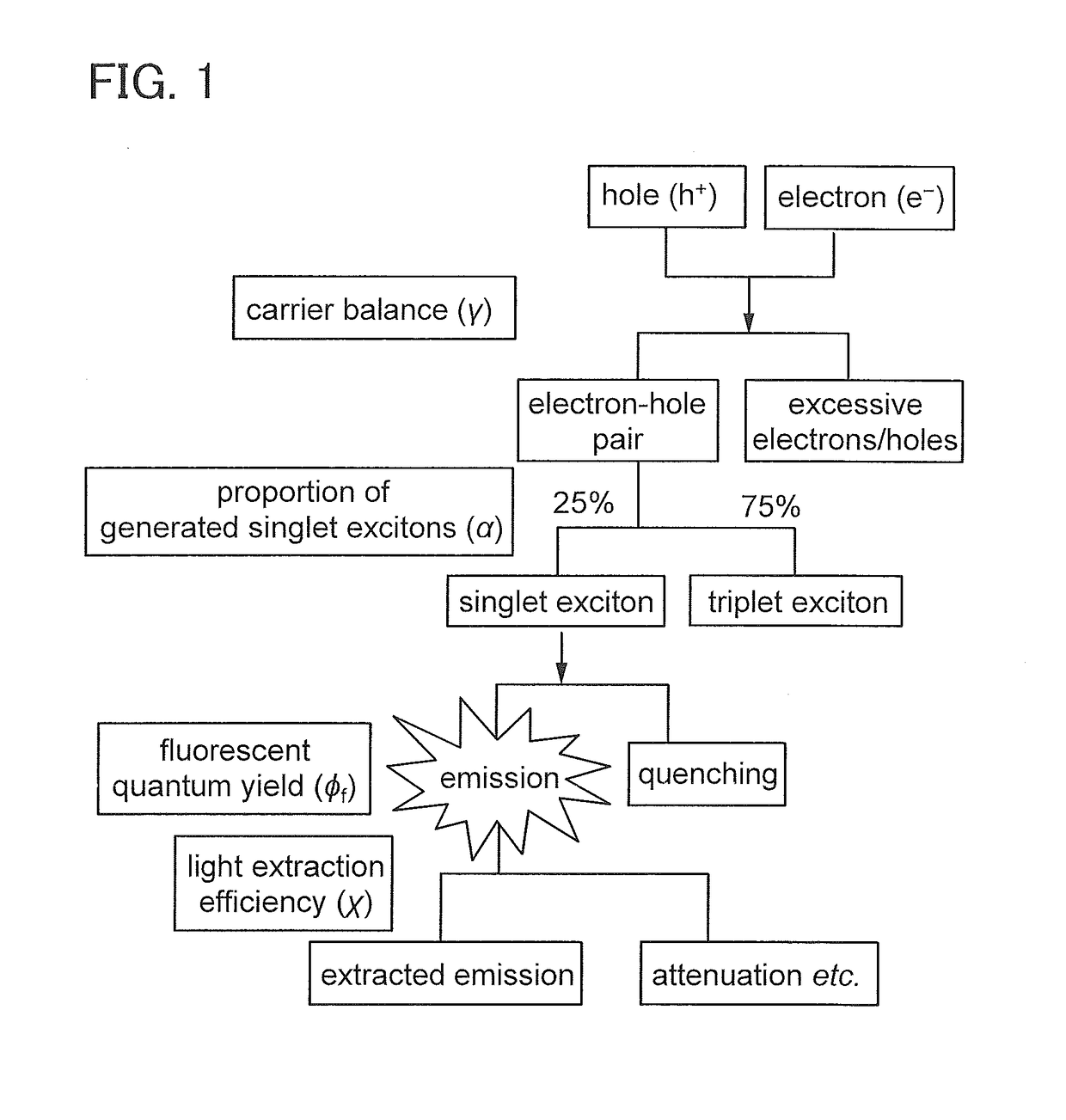

InactiveUS20120235131A1Improve yieldImprove luminous efficiencyOLED parametersElectroluminescent light sourcesQuantum yieldElectron hole

An organic EL element (1) of the present invention includes an emission layer (5) which is made of a host material having a highest occupied molecular orbital shallower than a highest occupied molecular orbital (8) of an organic light emitting material in the emission layer (5) (|HOMO of host material|<|HOMO of organic light emitting material|) or a host material having a lowest unoccupied molecular orbital deeper than a lowest unoccupied molecular orbital (9) of the organic light emitting material (|LUMO of host material|>|LUMO of organic light emitting material|). This makes it possible to keep the hole mobility and the electron mobility high in the host material of the emission layer (5), and therefore the hole and the electron can be efficiently transported to the emission layer (5). As a result, both the hole and the electron can be confined within the emission layer (5), and therefore the hole becomes more likely to recombine with the electron. On this account, the internal quantum yield rate can be improved, the luminous efficiency can be improved, and a driving voltage can be reduced.

Owner:SHARP KK

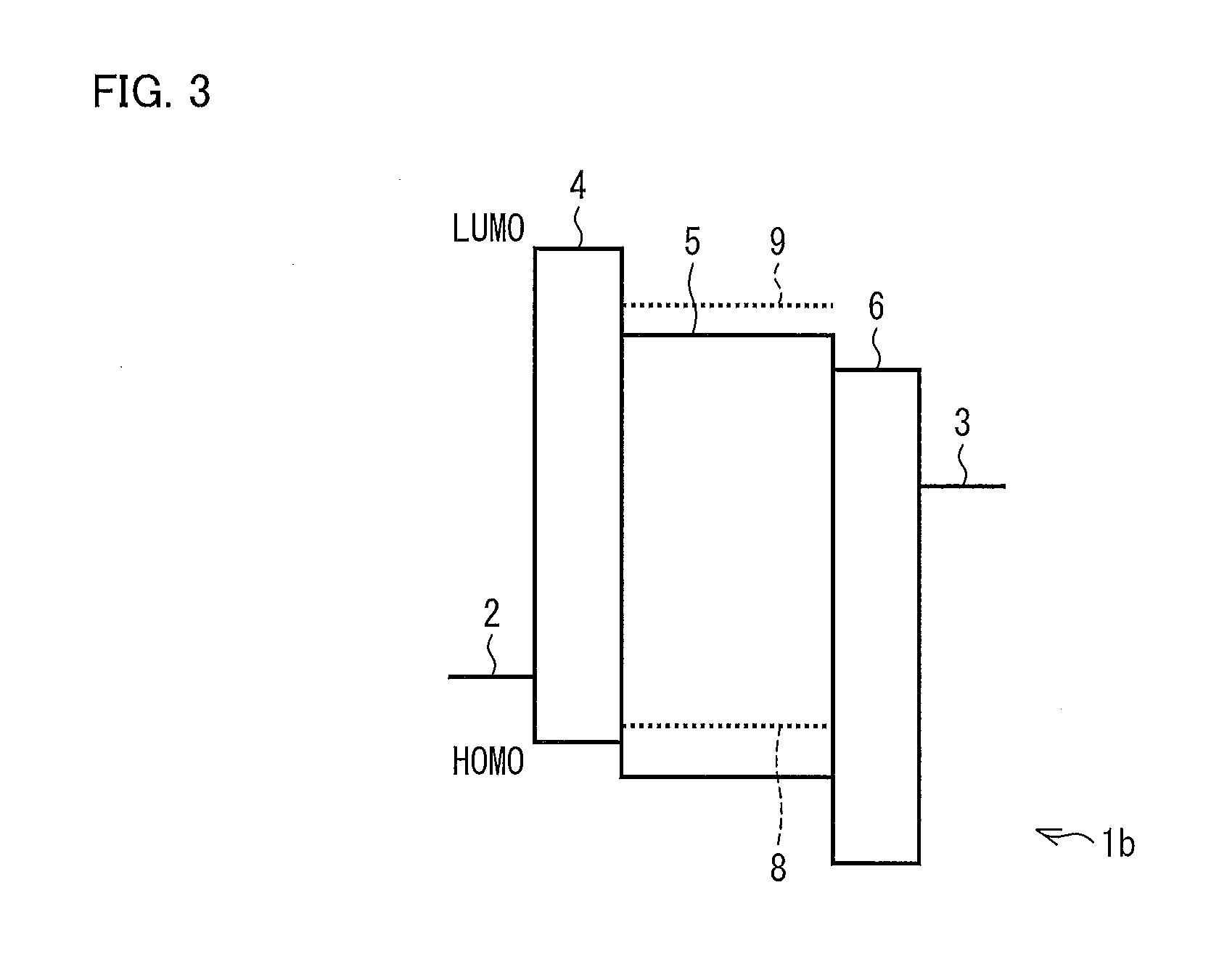

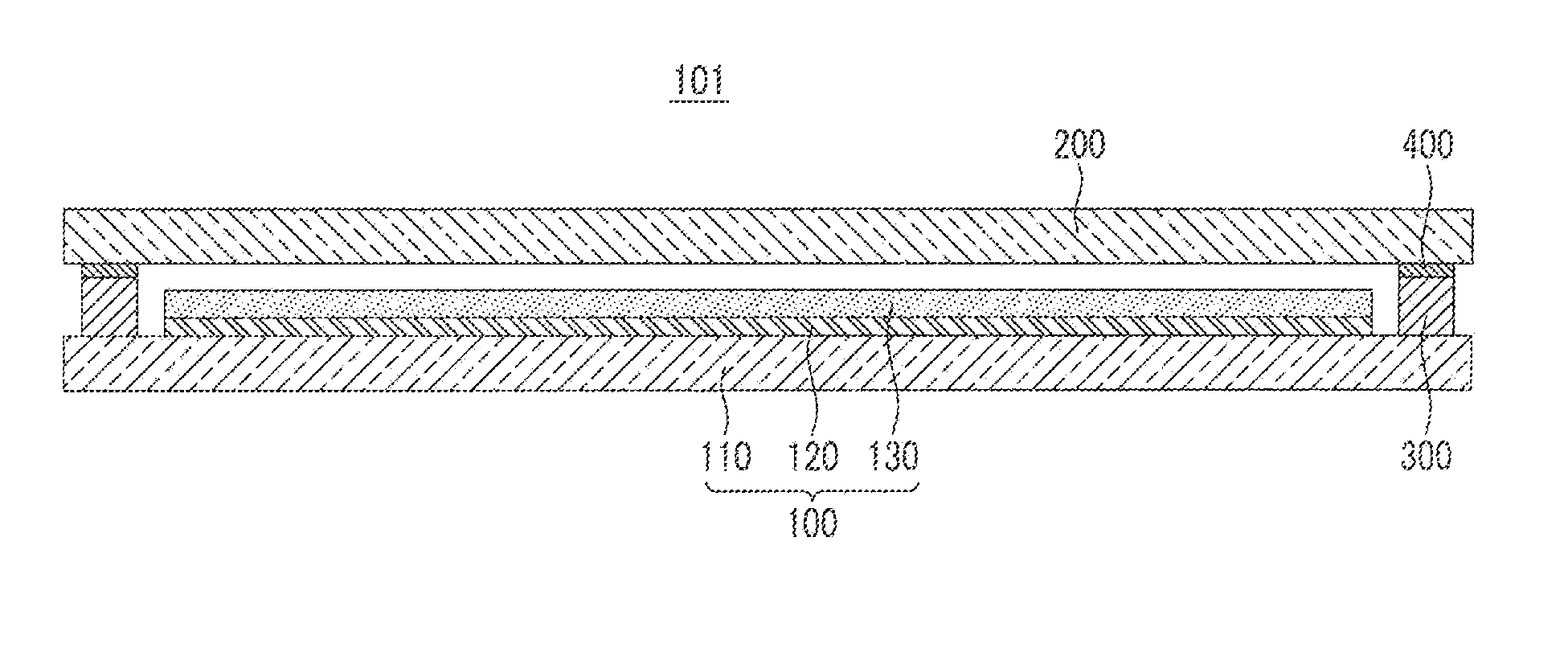

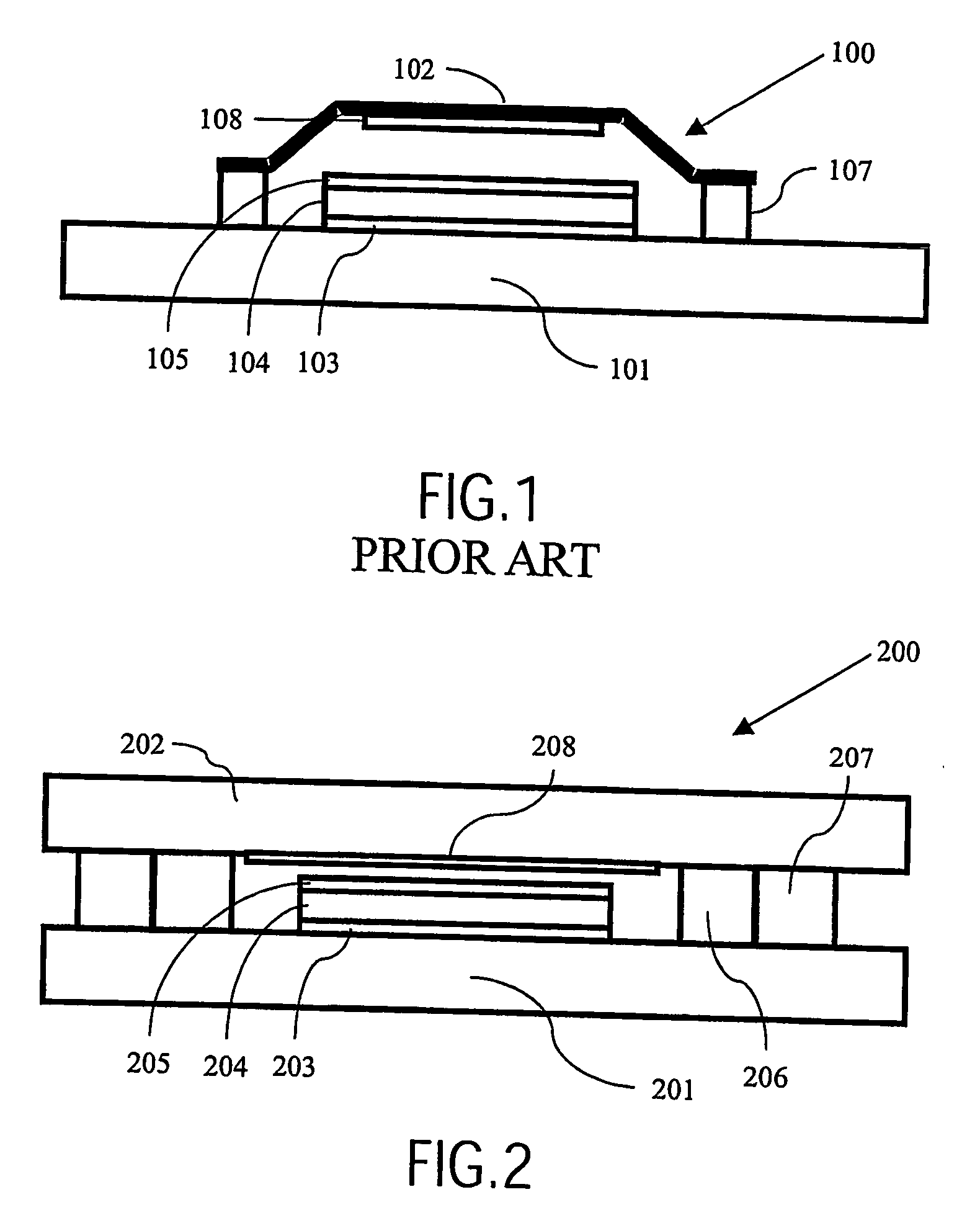

Organic light emitting diode display and method of manufacturing the same

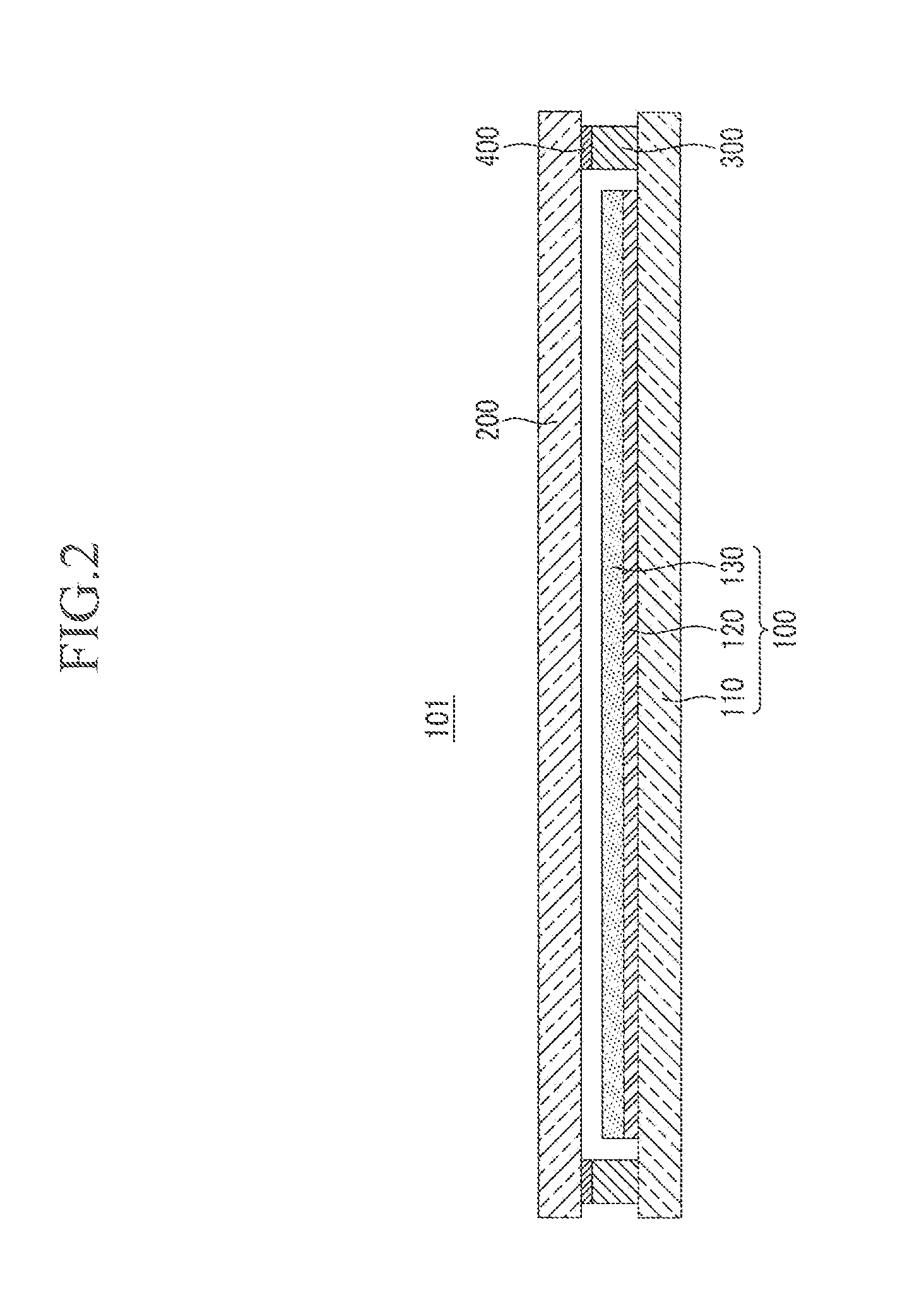

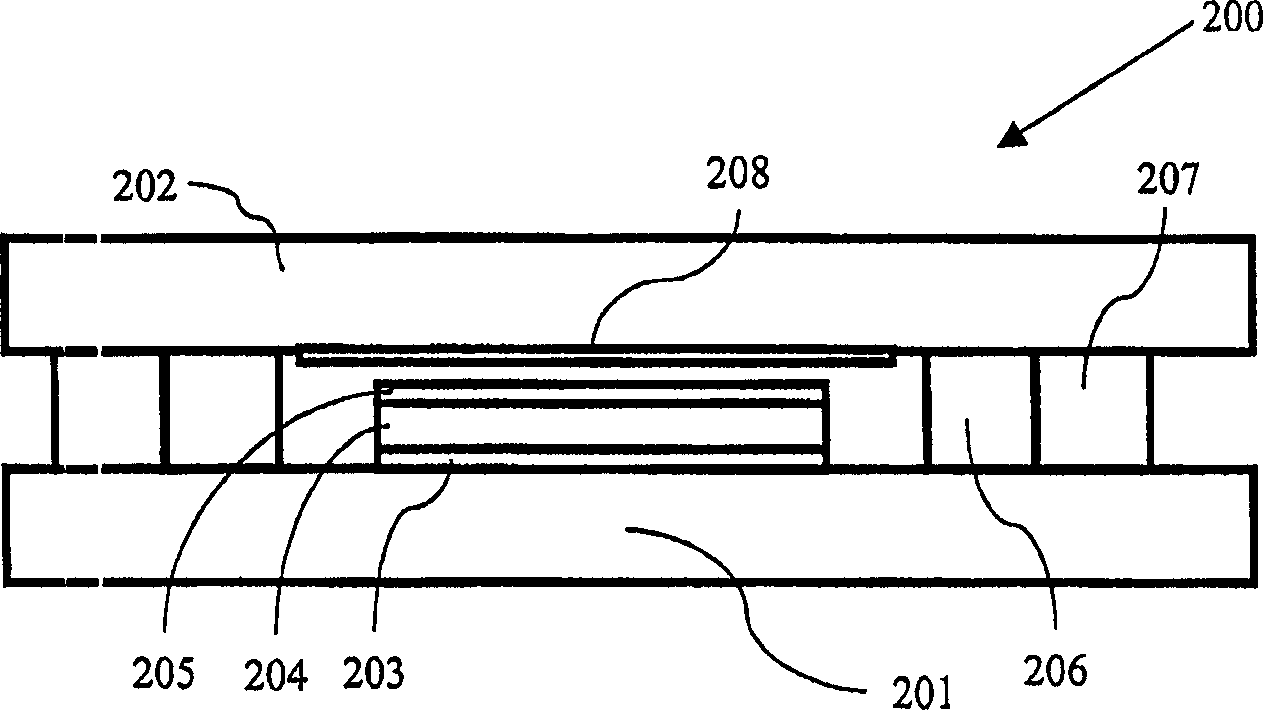

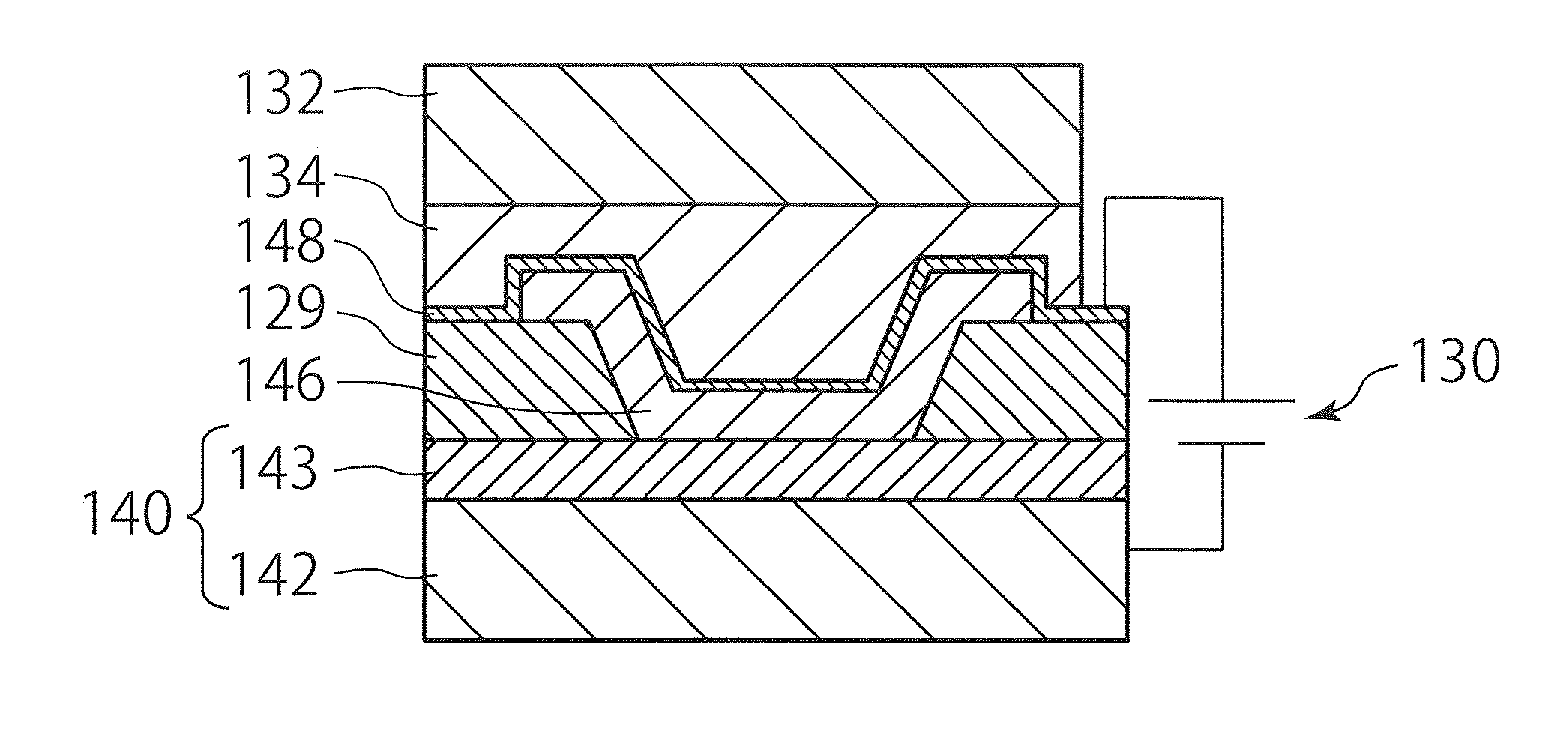

An organic light emitting diode (OLED) display includes: a first substrate including an OLED; a second substrate that is opposite to the first substrate; a sealant that is positioned between the first substrate and the second substrate and that couples the first substrate and the second substrate; and a sealant contraction reinforcement auxiliary structure that is positioned in at least one of a position between the first substrate and the sealant and a position between the second substrate and the sealant.

Owner:SAMSUNG DISPLAY CO LTD

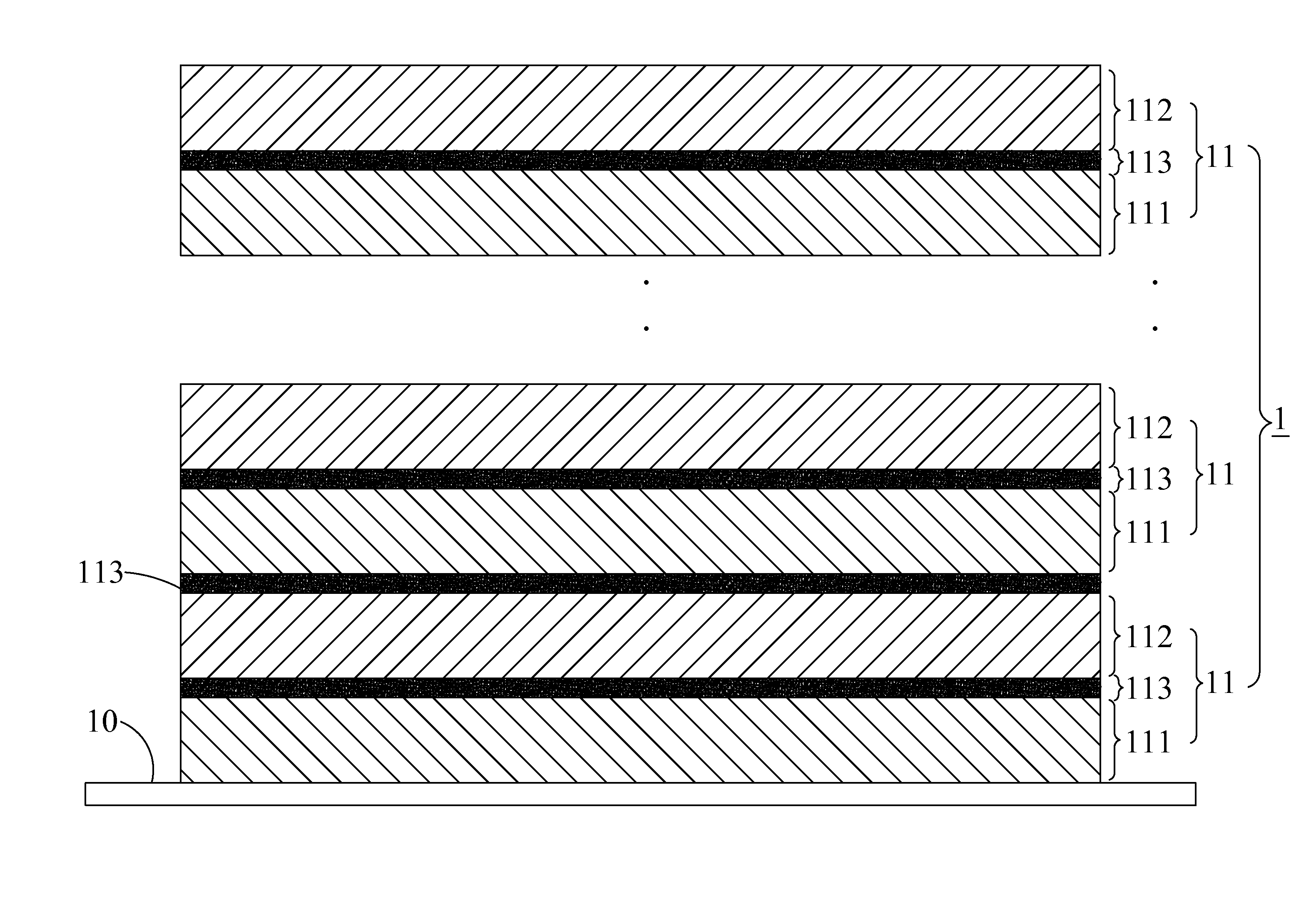

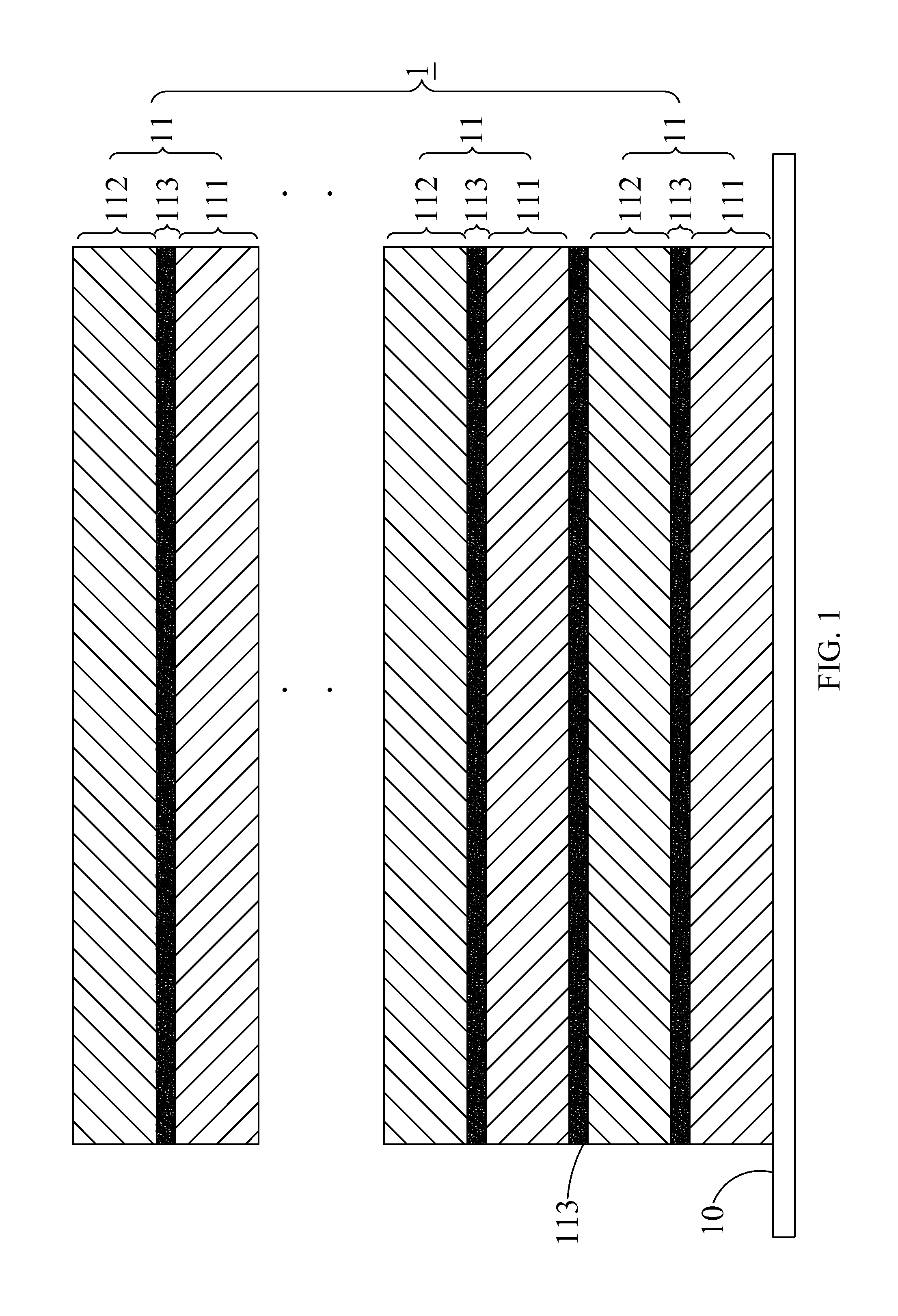

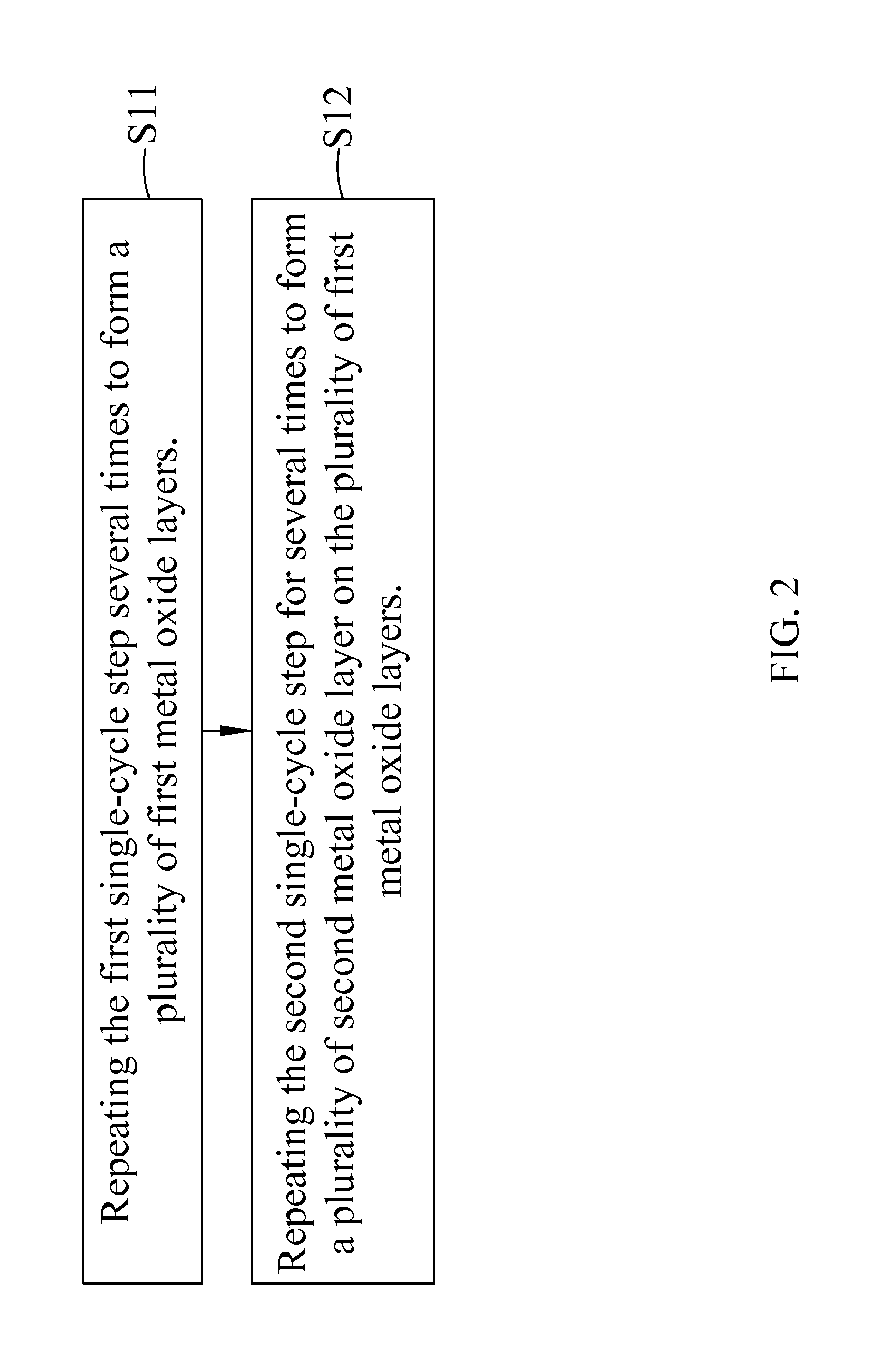

Nano-laminated film with transparent conductive property and water-vapor resistance function and method thereof

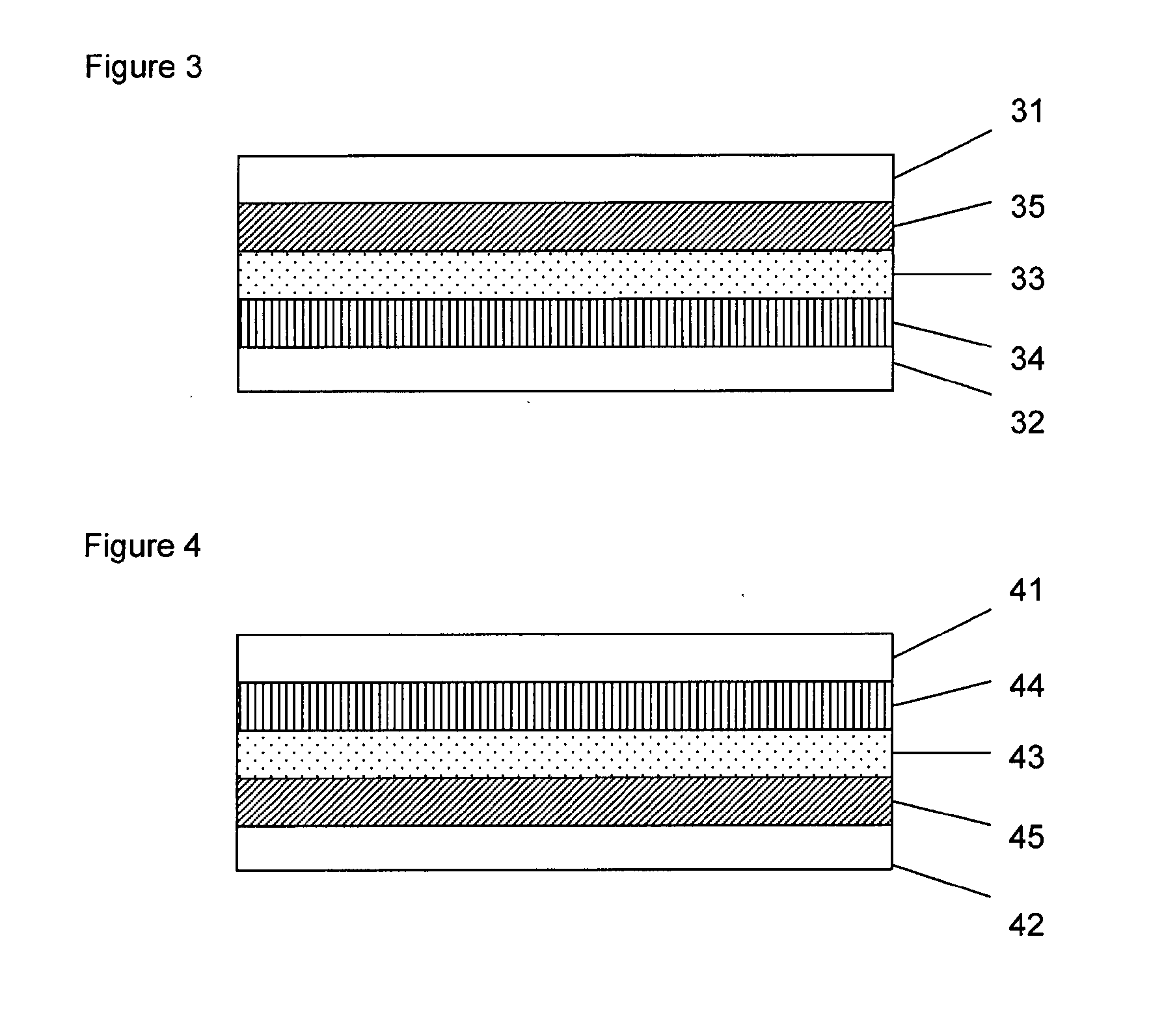

InactiveUS20130045374A1Few defectExcellent water vapor transmission rateOLED parametersSynthetic resin layered productsWater vaporMetal

The present invention discloses a nano-laminated film with transparent conductive property and water-vapor resistance function and method thereof. The nano-laminated film comprises a plurality of first metal oxide layers and a plurality of second metal oxide layers. Wherein, the first metal layers and the second metal layers are made of different materials, and there is a spinel phase formed between the first metal layers and the second metal layers.

Owner:NAT APPLIED RES LAB

Organic light emitting device and method for manufacturing the same

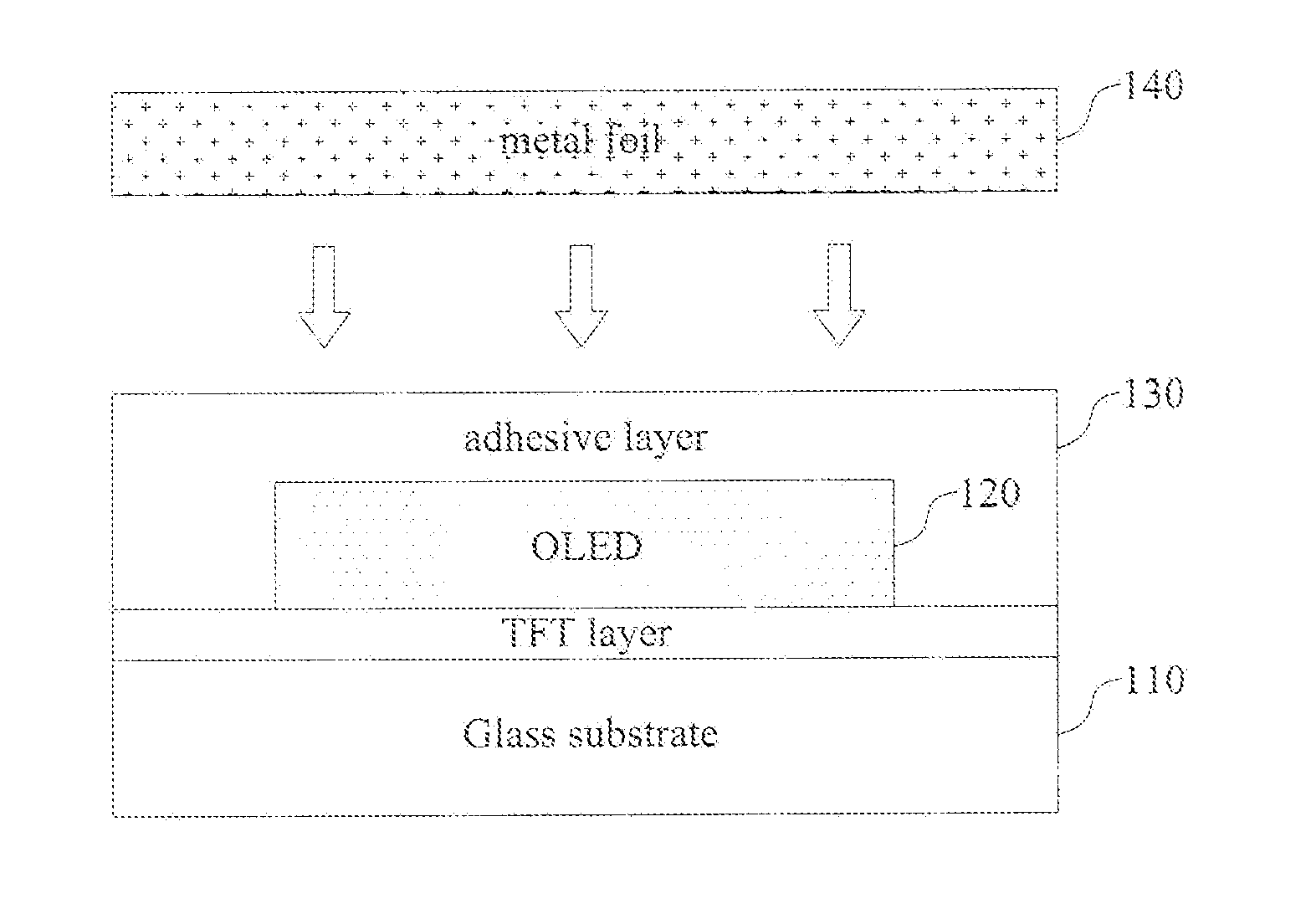

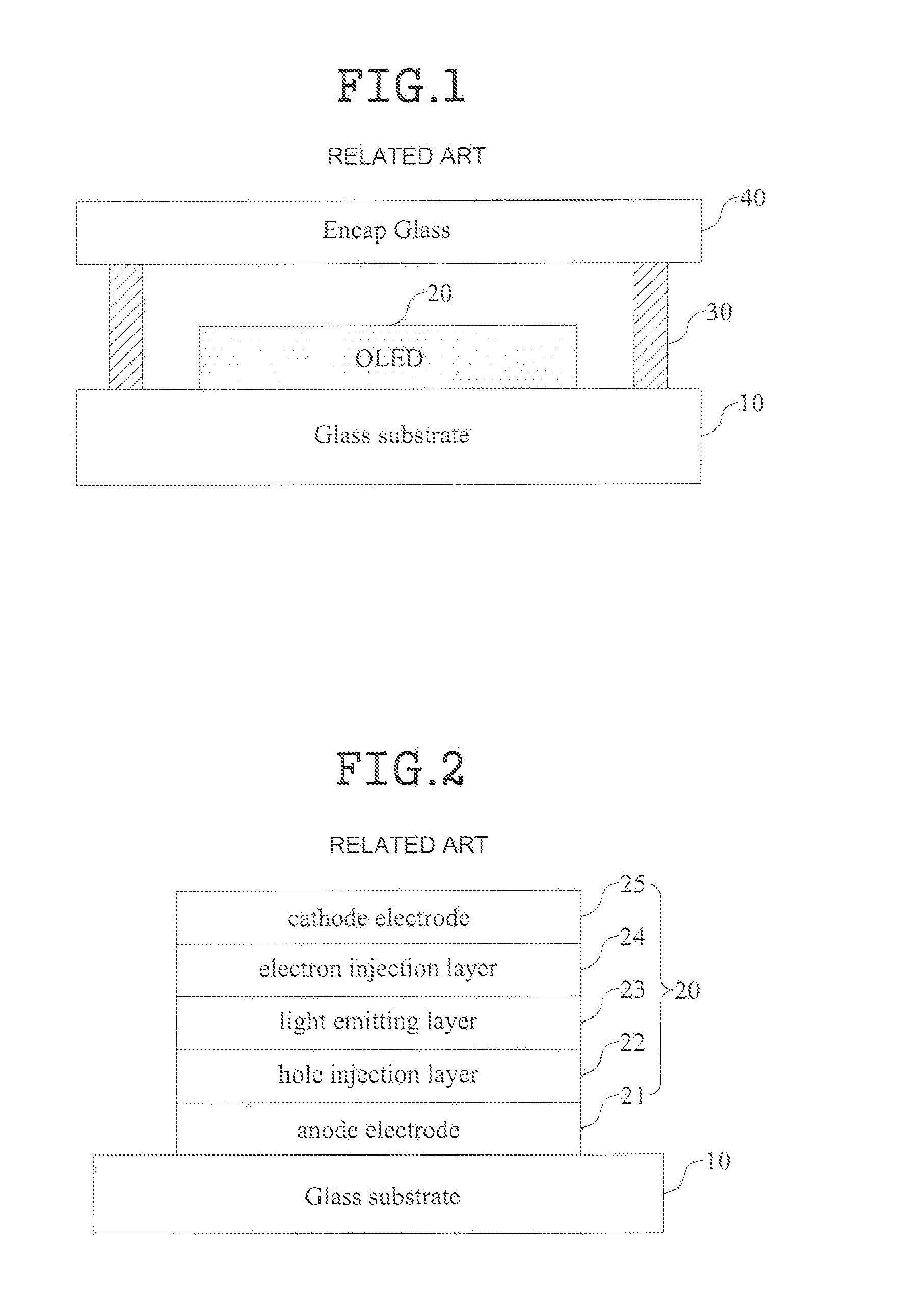

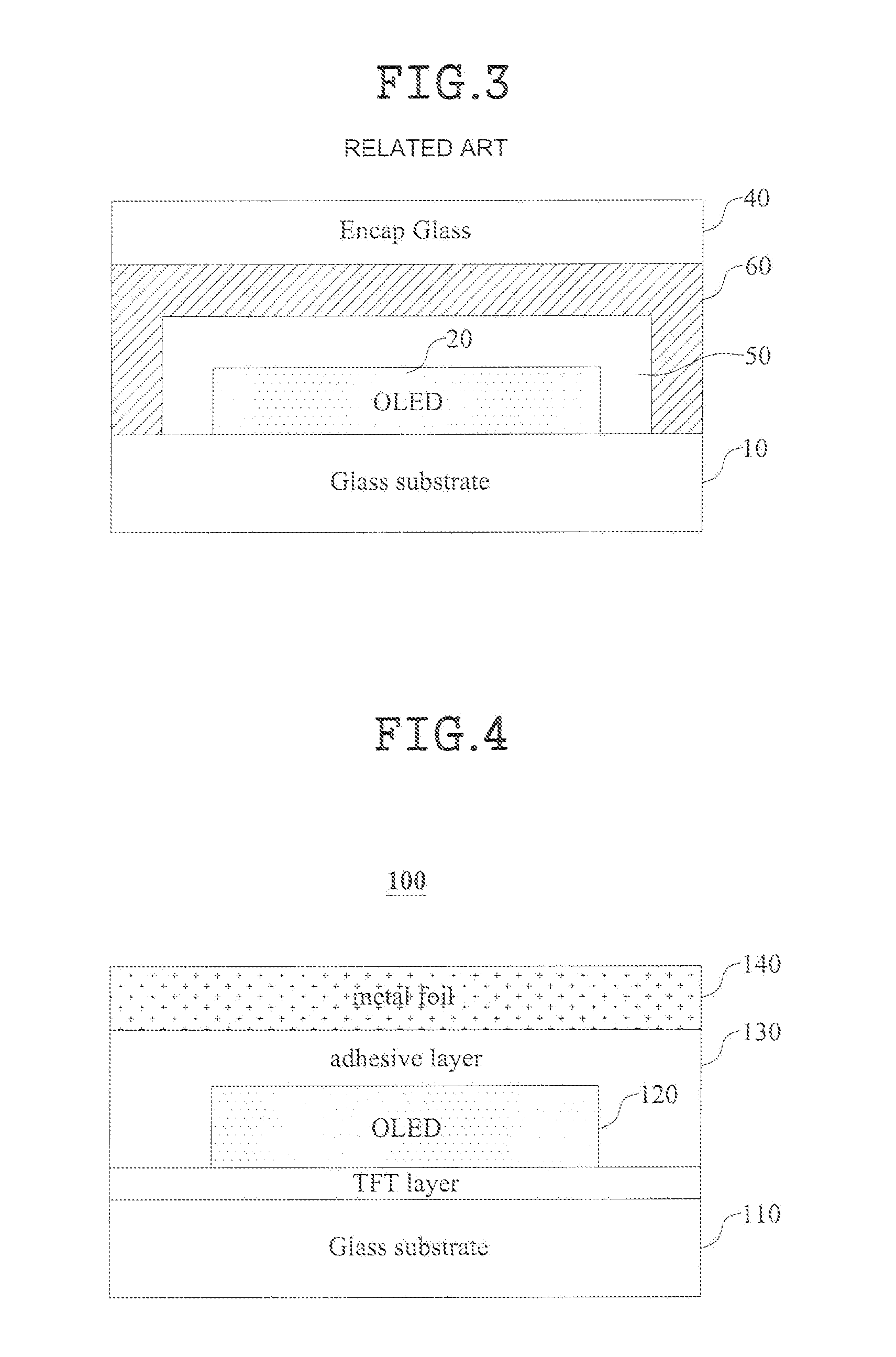

ActiveUS20120313137A1Reduce thicknessReduce weightOLED parametersElectroluminescent light sourcesMetal foilOrganic light emitting device

An organic light emitting device and a method for manufacturing that same are discussed, which can reduce thickness and weight of the device as well as the manufacturing cost. The organic light emitting device includes according to an embodiment an organic light emitting diode (OLED) formed on a glass substrate; an adhesive layer formed to cover the OLED; and a metal foil formed on the adhesive layer to seal the OLED and bonded to the glass substrate, wherein the metal foil is formed of an alloy having the same or substantially the same thermal expansion coefficient as that of the glass substrate.

Owner:LG DISPLAY CO LTD

Alkali-free glass

InactiveUS20130244859A1Increase production capacityHigh strain pointOLED parametersElectroluminescent light sourcesAlkali freeAlkali metal oxide

Provided is an alkali-free glass, which is substantially free of alkali metal oxides, and has a strain point of more than 680° C., an average coefficient of thermal expansion in the temperature range of 30 to 380° C. of 40 to 55×10−7 / ° C., and a liquidus temperature of less than 1,200° C. Further, the alkali-free glass comprises, as a glass composition in terms of mass %, 55 to 70% of SiO2, 10 to 20% of Al2O3, 0.1 to 4.5% of B2O3, 0 to 1% of MgO, 5 to 15% of CaO, 0.5 to 5% of SrO, and 5 to 15% of BaO.

Owner:NIPPON ELECTRIC GLASS CO LTD

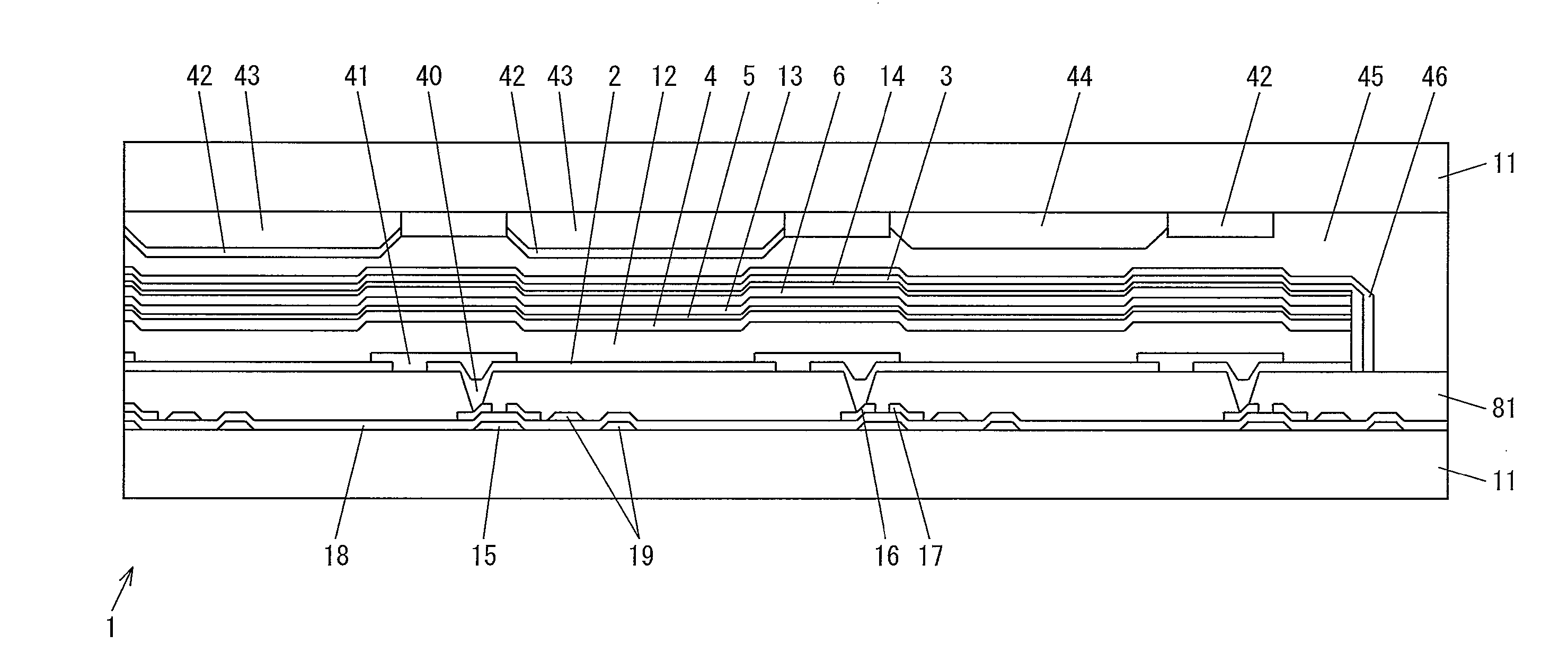

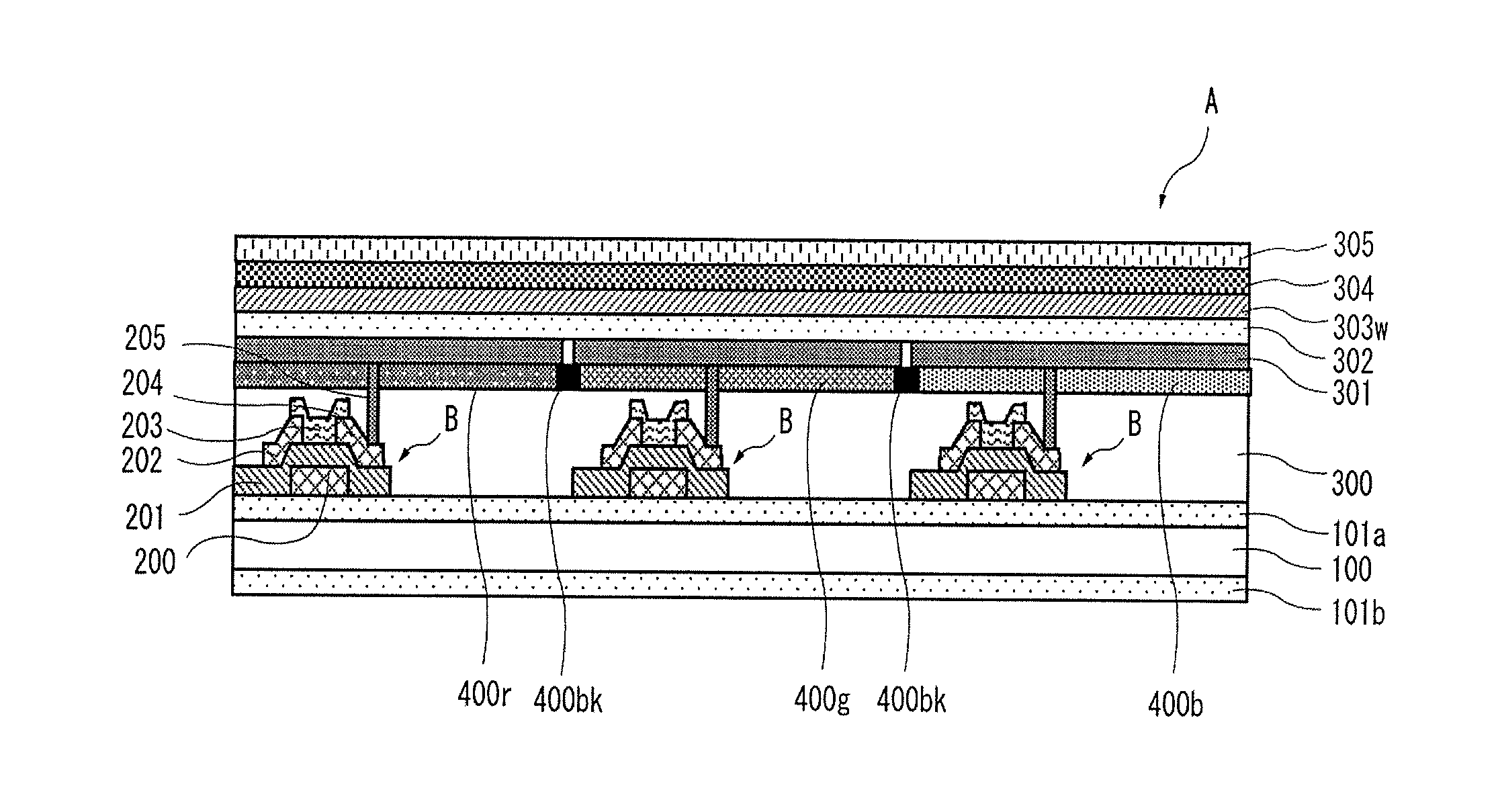

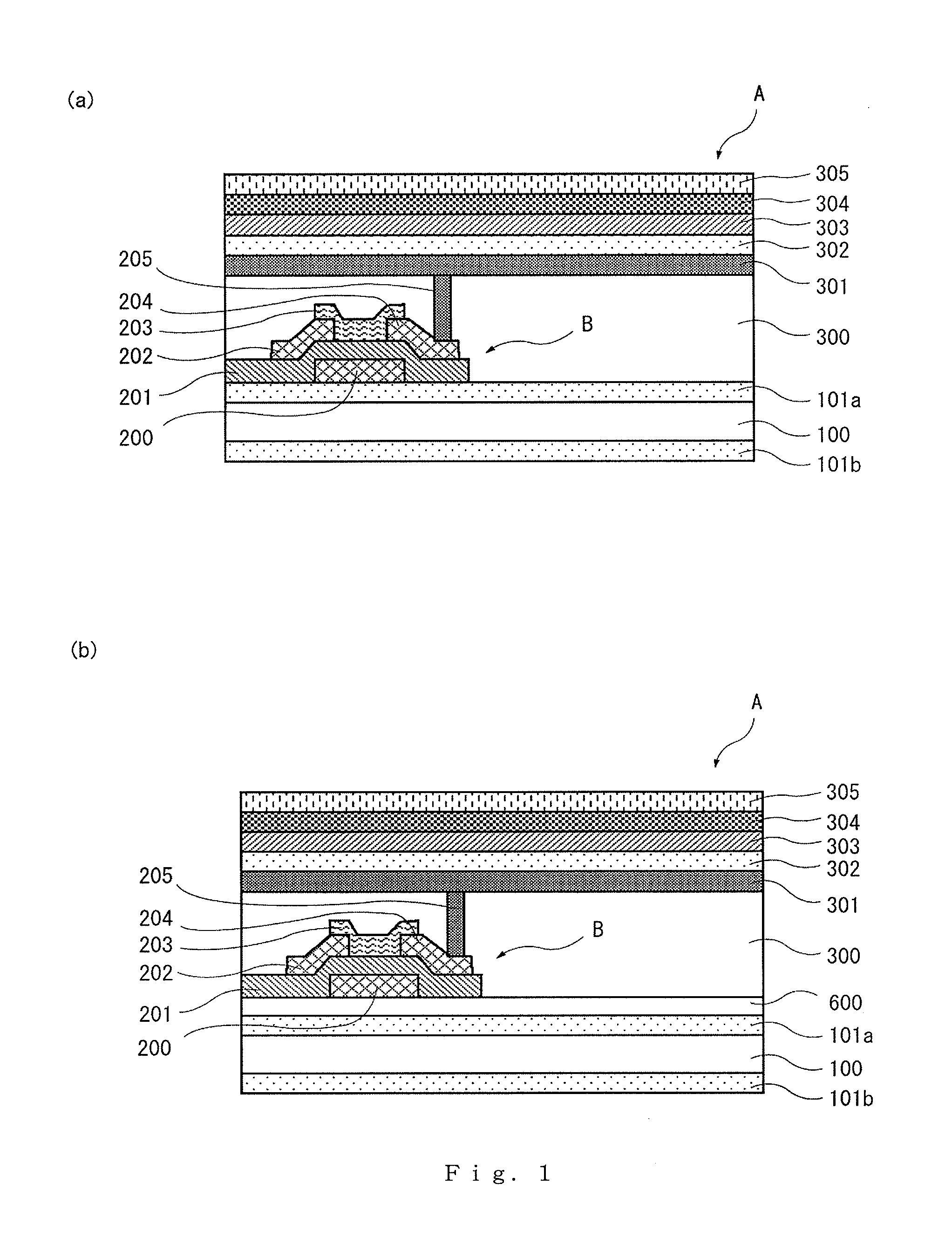

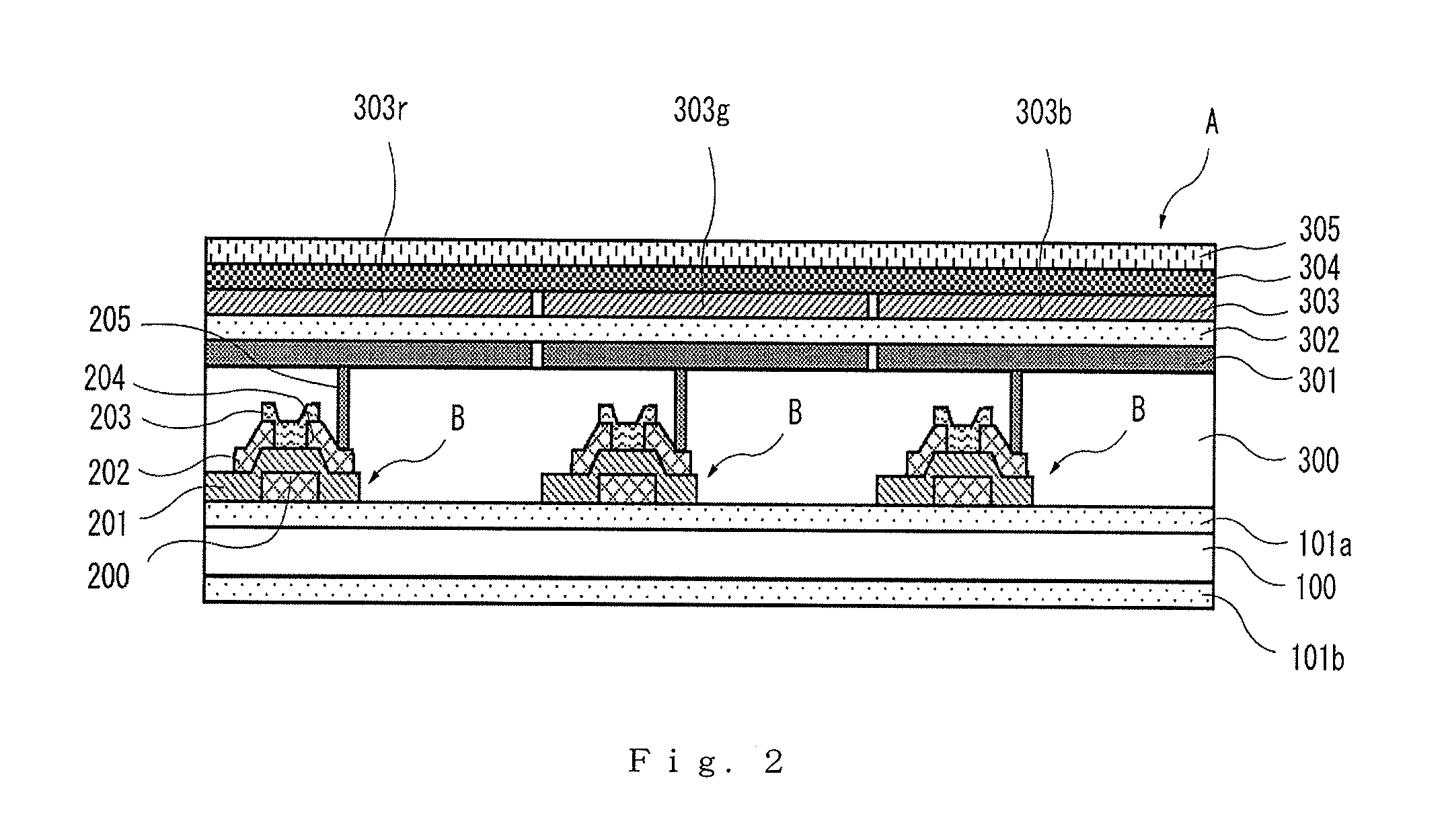

Organic el display and method of manufacturing organic el display

It is possible to manufacture a large-size, high-accuracy organic EL display using a plastic substrate and an organic EL display using a roll-shaped long plastic substrate.The organic EL display includes an organic EL device A having at least a lower electrode 300, an organic layer including at least a light emitting layer, and an upper electrode 305 and a thin film transistor B on a transparent plastic substrate 100, a source electrode or drain electrode of the thin film transistor B is connected to the lower electrode 300, the plastic substrate 100 has a gas barrier layer 101a, the thin film transistor B is formed on the gas barrier layer 101a, the thin film transistor B includes an active layer 203 containing a non-metallic element which a mixture of oxygen (O) and nitrogen (N) and has a ratio of N to O (N number density / O number density) from 0 to 2, and the organic EL device A is formed at least on the gas barrier layer 101a or one the thin film transistor B.

Owner:SUMITOMO BAKELITE CO LTD

Formulation for the preparation of organic electronic (OE) devices comprising a polymeric binder

InactiveUS20160181552A1Improve device efficiencyImprove production efficiencyOLED parametersSolid-state devicesOrganic solventOrganic semiconductor

The present invention relates to a formulation comprising at least one organic semiconducting compound (OSC) having a molecular weight of at most 5000 g / mol, at least one organic solvent, and at least one polymeric binder having a weight average molecular weight of at least 5.000.000 g / mol, wherein the formulation comprises a viscosity at 25° C. of at least 15 mPas. Furthermore, the present invention relates to the use of these formulations as inks for the preparation of organic electronic (OE) devices, preferably organic photovoltaic (OPV) cells and organic light emitting diodes (OLED) devices, to methods for preparing OE devices using these formulations, and to OE devices, OLED devices and OPV cells prepared from such methods and formulations.

Owner:MERCK PATENT GMBH

Display and manufacturing method thereof

ActiveUS20130241402A1Improve oxygen barrier performanceImprove processing speedOLED parametersDischarge tube luminescnet screensDisplay deviceAdhesive glue

A display and a manufacturing method thereof are provided. The display includes a frame, an organic light-emitting diode (OLED) panel, a transparent element and a glue. The OLED panel is disposed in the frame. The transparent element is disposed on the OLED panel. The glue is filled between the OLED panel and the transparent element and between the OLED panel and the frame.

Owner:INNOLUX CORP

Light-emitting device comprising an organic compound

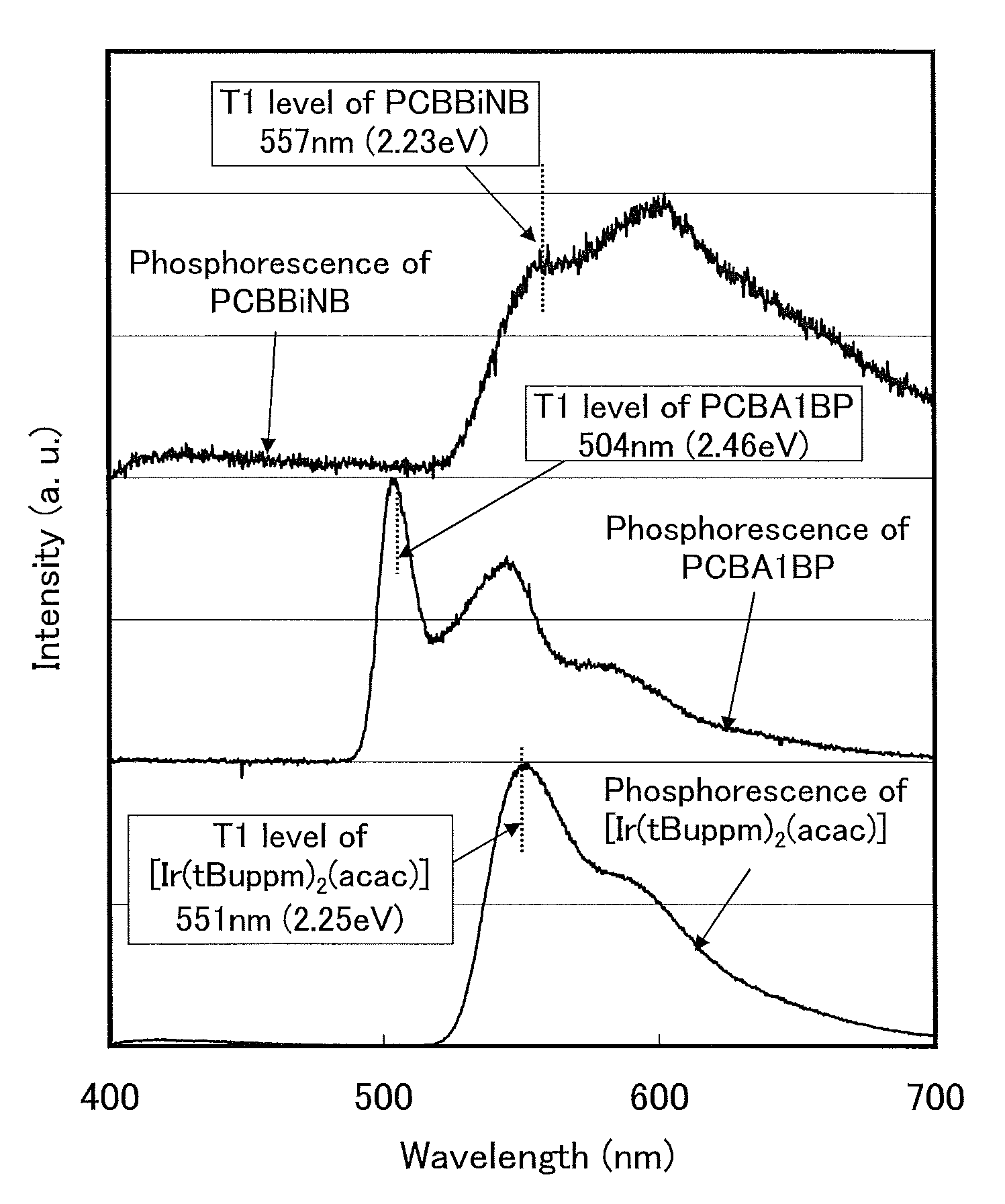

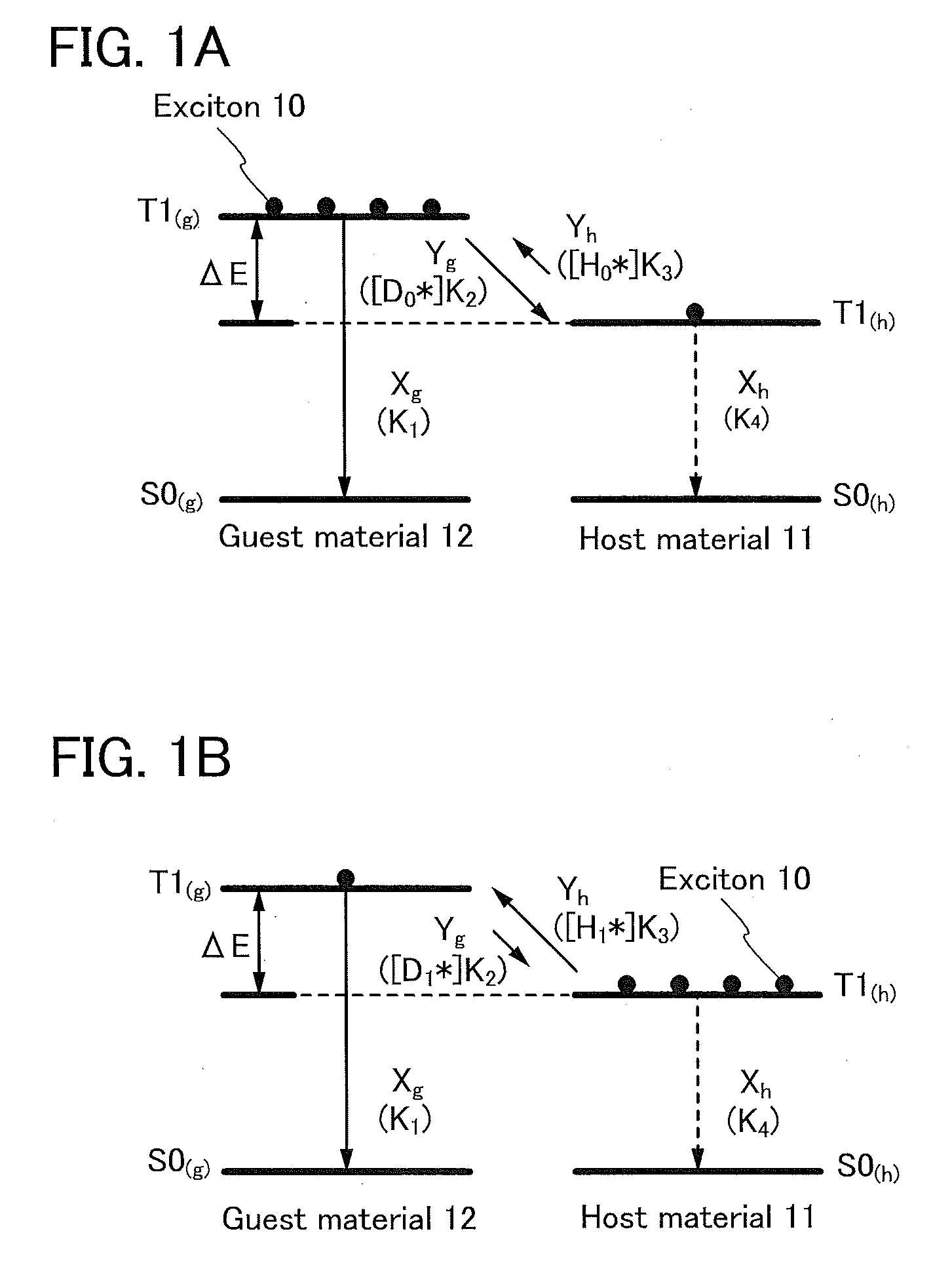

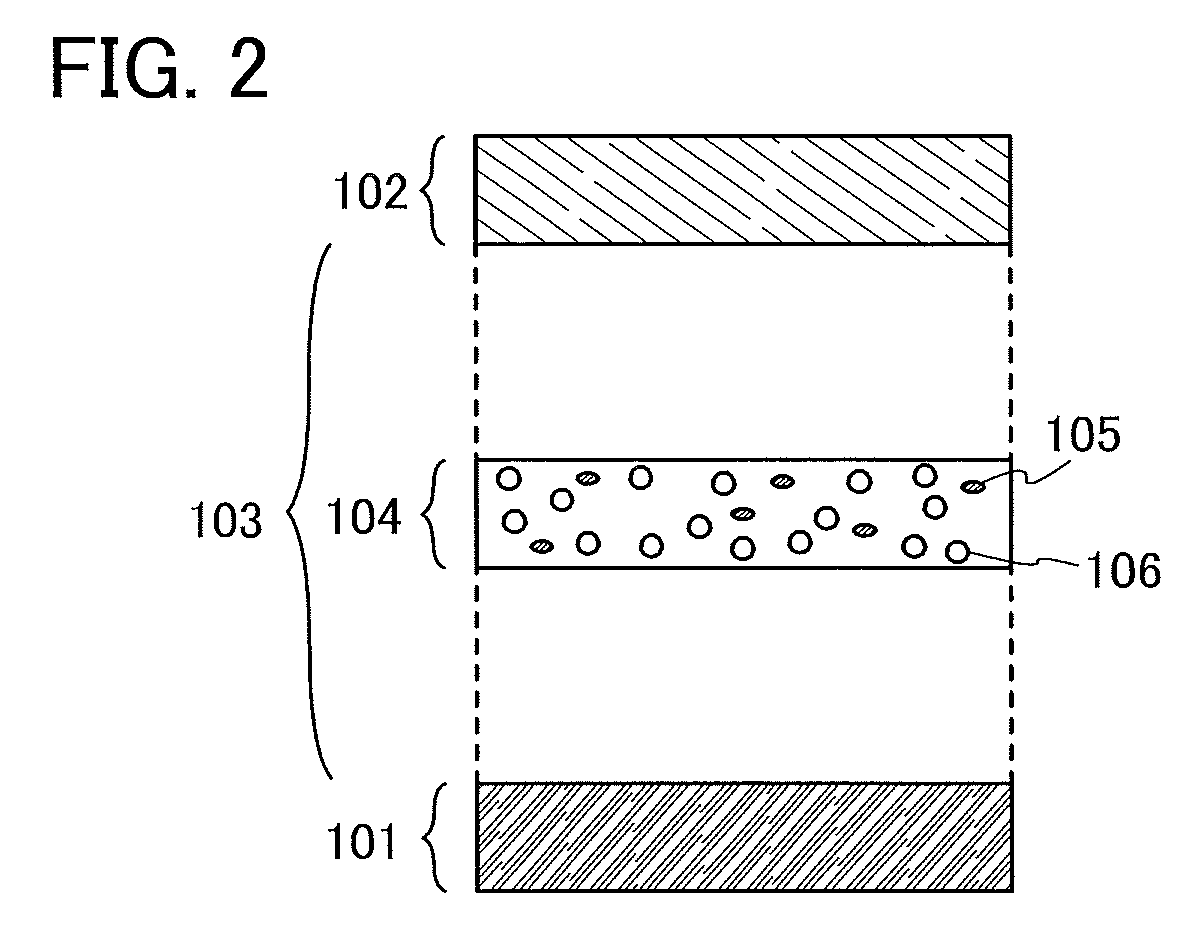

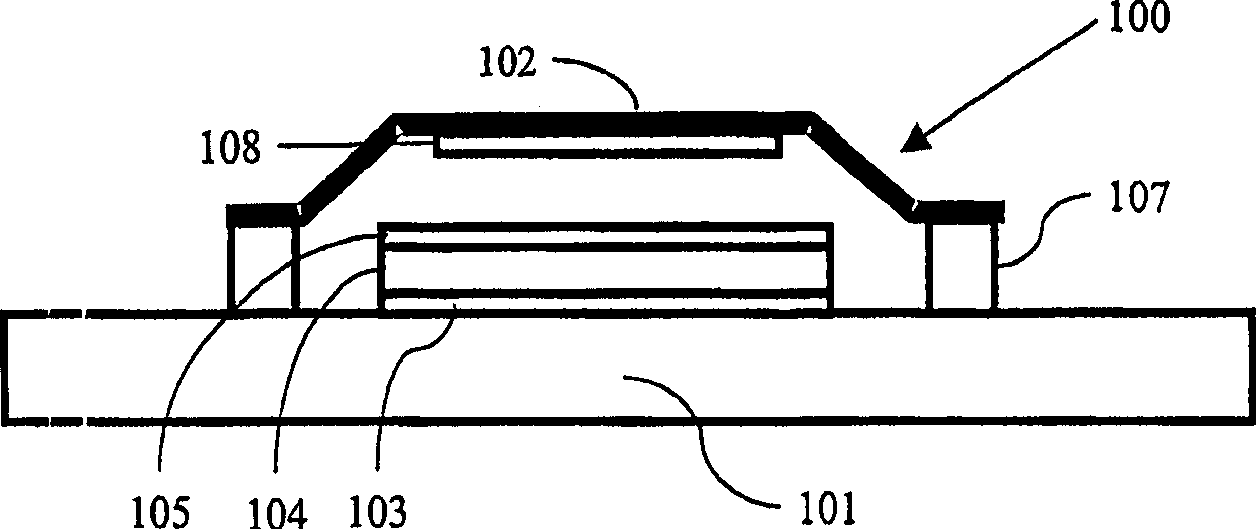

ActiveUS9391290B2Improve efficiencyDelayed EmissionOLED parametersSolid-state devicesLuminous intensityHost material

A light-emitting element of the present invention can have sufficiently high emission efficiency with a structure including a host material being able to remain chemically stable even if a phosphorescent compound having higher emission energy is used as a guest material. The relation between the relative emission intensity and the emission time of light emission obtained from the host material and the guest material contained in a light-emitting layer is represented by a multicomponent decay curve. The relative emission intensity of the slowest component of the multicomponent decay curve becomes 1 / 100 for a short time within a range where the slowest component is not interfered with by quenching of the host material (the emission time of the slowest component is preferably less than or equal to 15 μsec); thus, sufficiently high emission efficiency can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

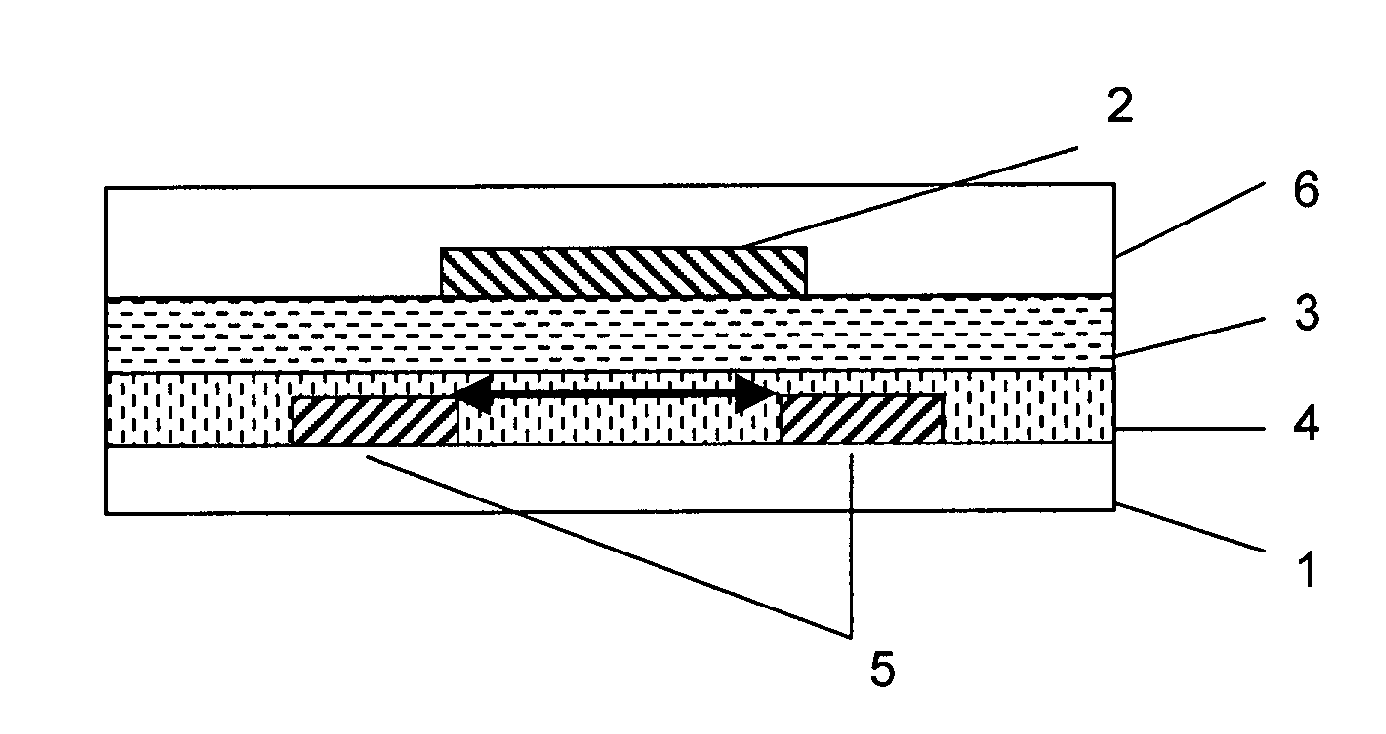

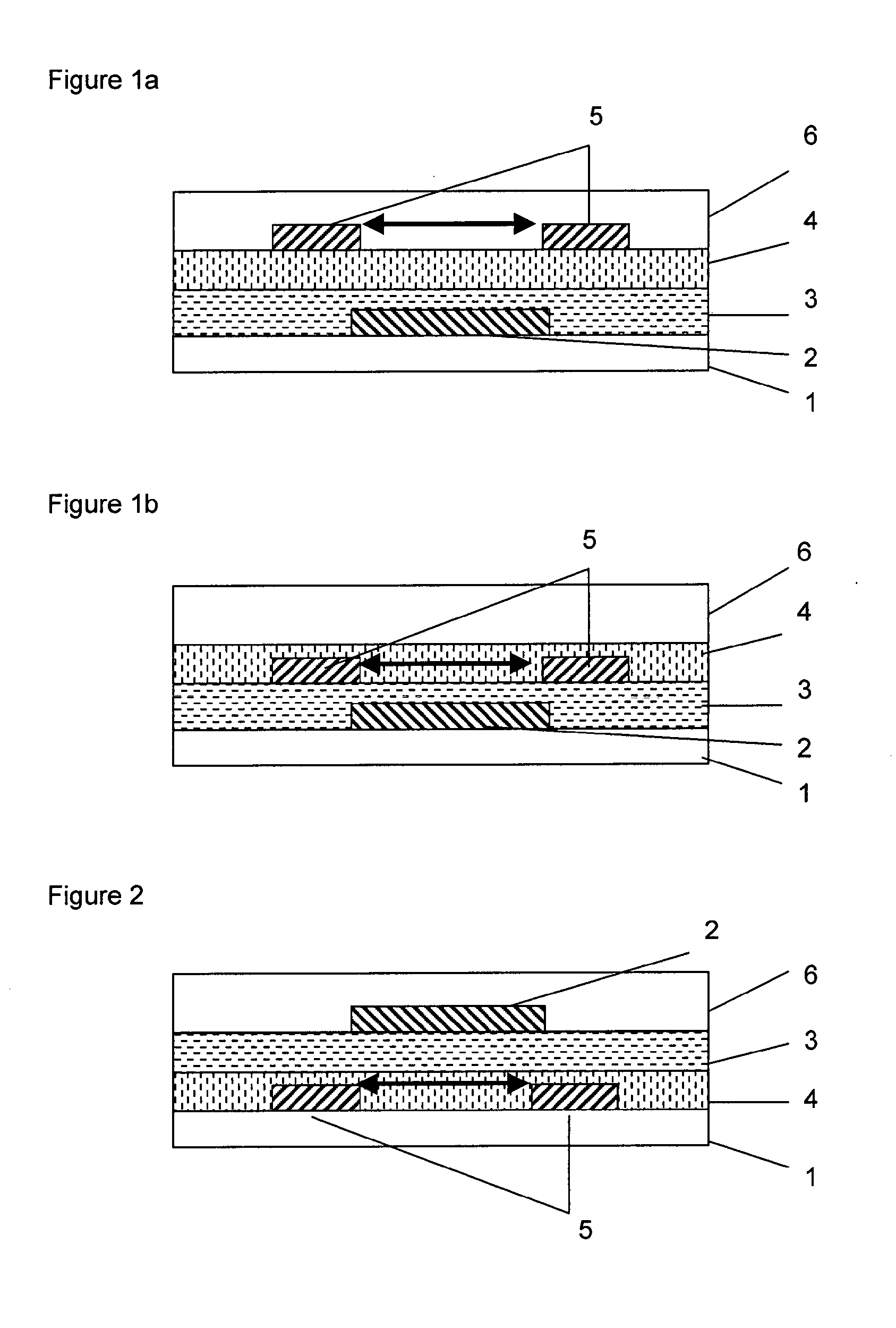

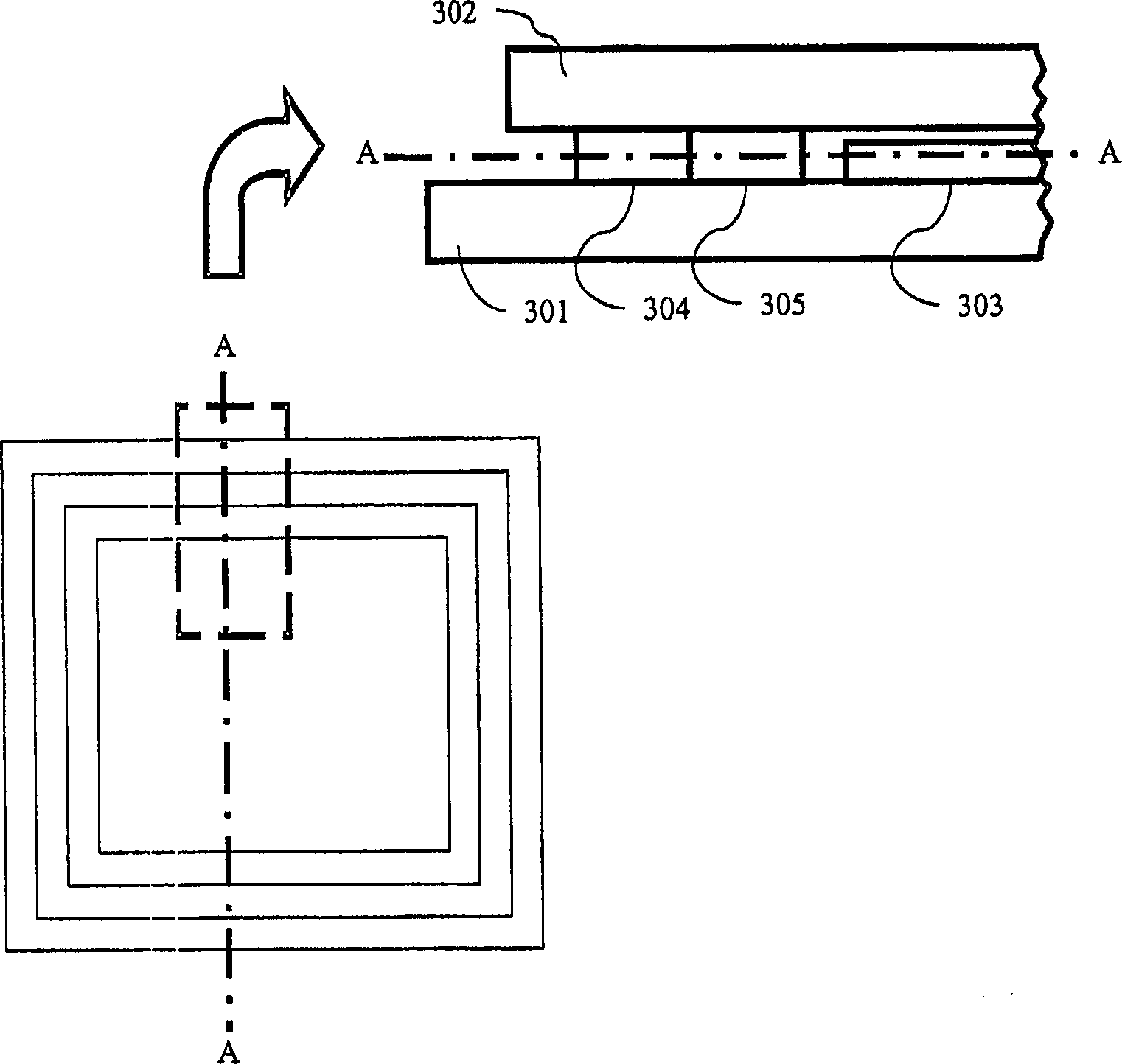

Double seal with getter in flexible organic displays

Improved seal for flexible organic light emitting displays are provided. For the purpose of the present invention it is realisd that a homogenous seal cannot provide for the combination of resuired robusness and required impermeability, which are essential for the life time of the display. Therefore, a seal comprising an inner seal portion and an outer seal portion is proposed. The outer seal portion is flexible as compared to the inner seal portion and the inner seal portion is impermeable as compared to the outer seal portion and being deposited between the outer seal portion and the display element.

Owner:KONINK PHILIPS ELECTRONICS NV

Package of environmental sensitive element

ActiveUS20130229108A1OLED parametersDischarge tube luminescnet screensEngineeringUltimate tensile strength

A package of an environmental sensitive element including a flexible substrate, an environmental sensitive element, a flexible sacrificial layer and a packaging structure is provided. The environmental sensitive element is disposed on the flexible substrate. The flexible sacrificial layer is disposed on the environmental sensitive element, wherein the environmental sensitive element includes a plurality of first thin films and the flexible sacrificial layer includes a plurality of second thin films. The bonding strength between two adjacent second thin films is substantially equal to or lower than the bonding strength between two adjacent first thin films. Further, the packaging structure covers the environmental sensitive element and the flexible sacrificial layer.

Owner:HANNSTAR DISPLAY CORPORATION

Organic electroluminescent display device and circularly polarizing plate

InactiveUS9064826B2Increased durabilityImprove visibilityOLED parametersSolid-state devicesVisibilityHigh humidity

The objective of the present invention is to provide: a circularly polarizing plate which comprises a λ / 4 retardation film and has excellent visibility, excellent durability (resistance to image unevenness) and excellent resistance to panel deterioration (flatness) after storage in a high-temperature high-humidity environment for a long period of time; and an organic electroluminescent display device which uses the circularly polarizing plate. This organic electroluminescent display device comprises, from the viewing side, a protective film, a polarizer, a λ / 4 retardation film and an organic electroluminescent element in this order, and is characterized in that at least one surface of the λ / 4 retardation film has a layer A which has a storage modulus of from 100 MPa to 500 MPa (inclusive).

Owner:KONICA MINOLTA INC

Alkali-free glass

InactiveUS9023744B2Increase production capacityHigh strain pointOLED parametersElectroluminescent light sourcesAlkali freeAlkali metal oxide

Owner:NIPPON ELECTRIC GLASS CO LTD

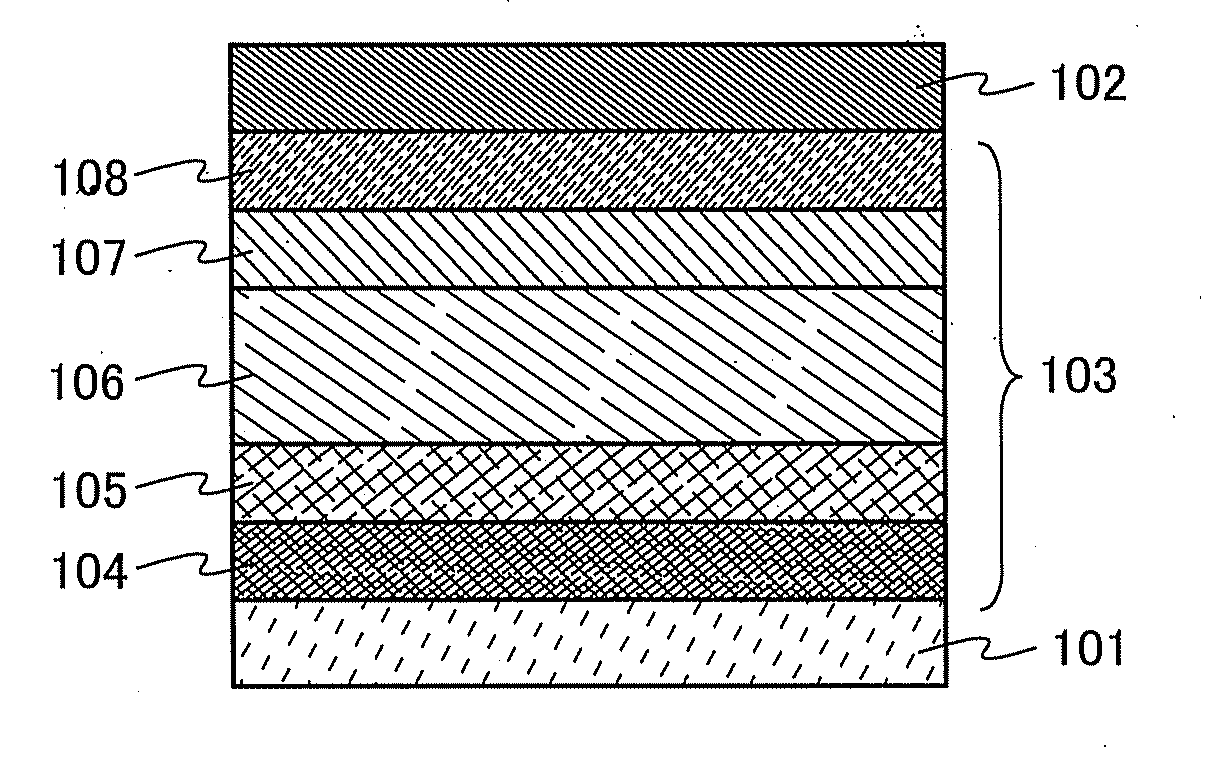

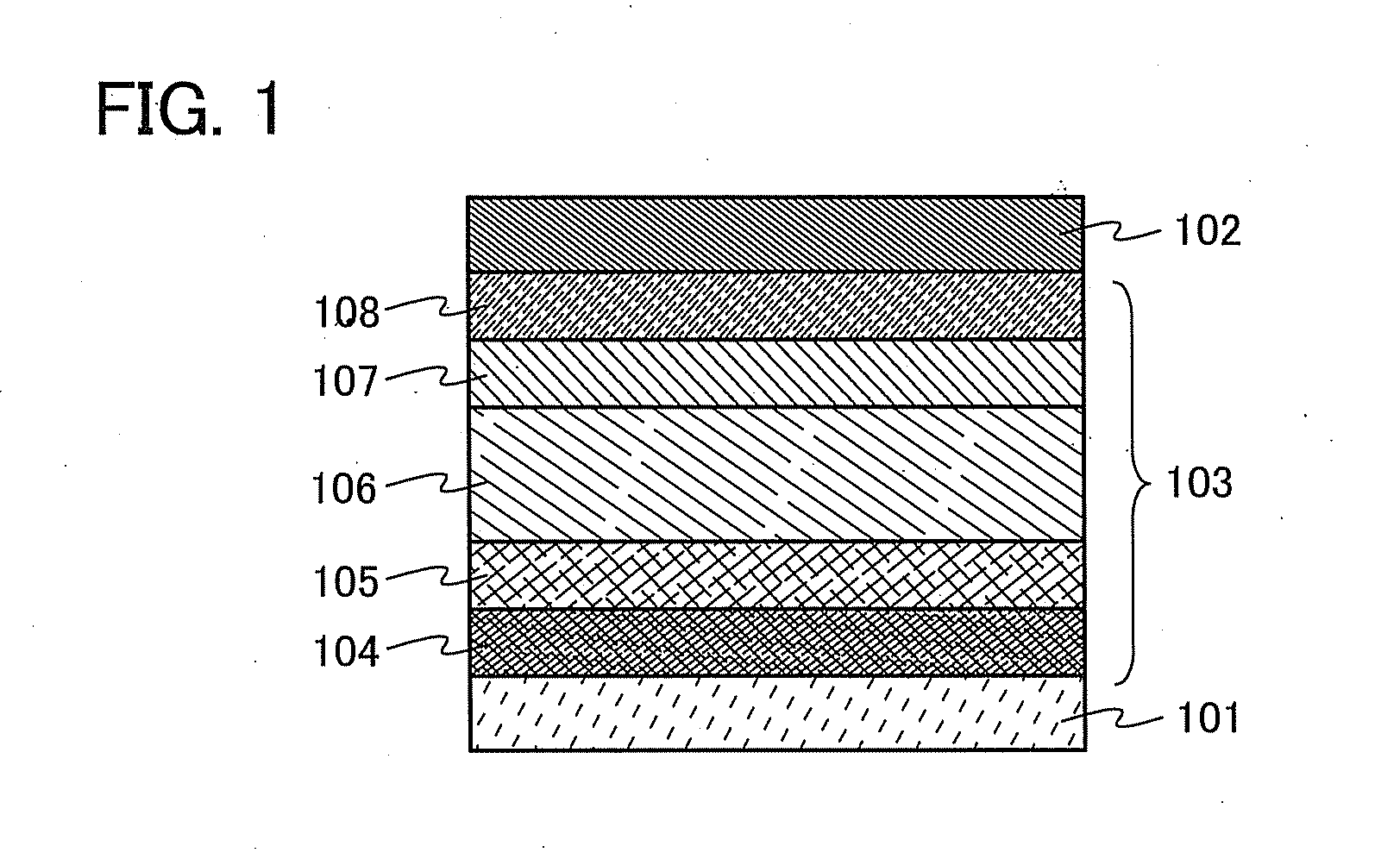

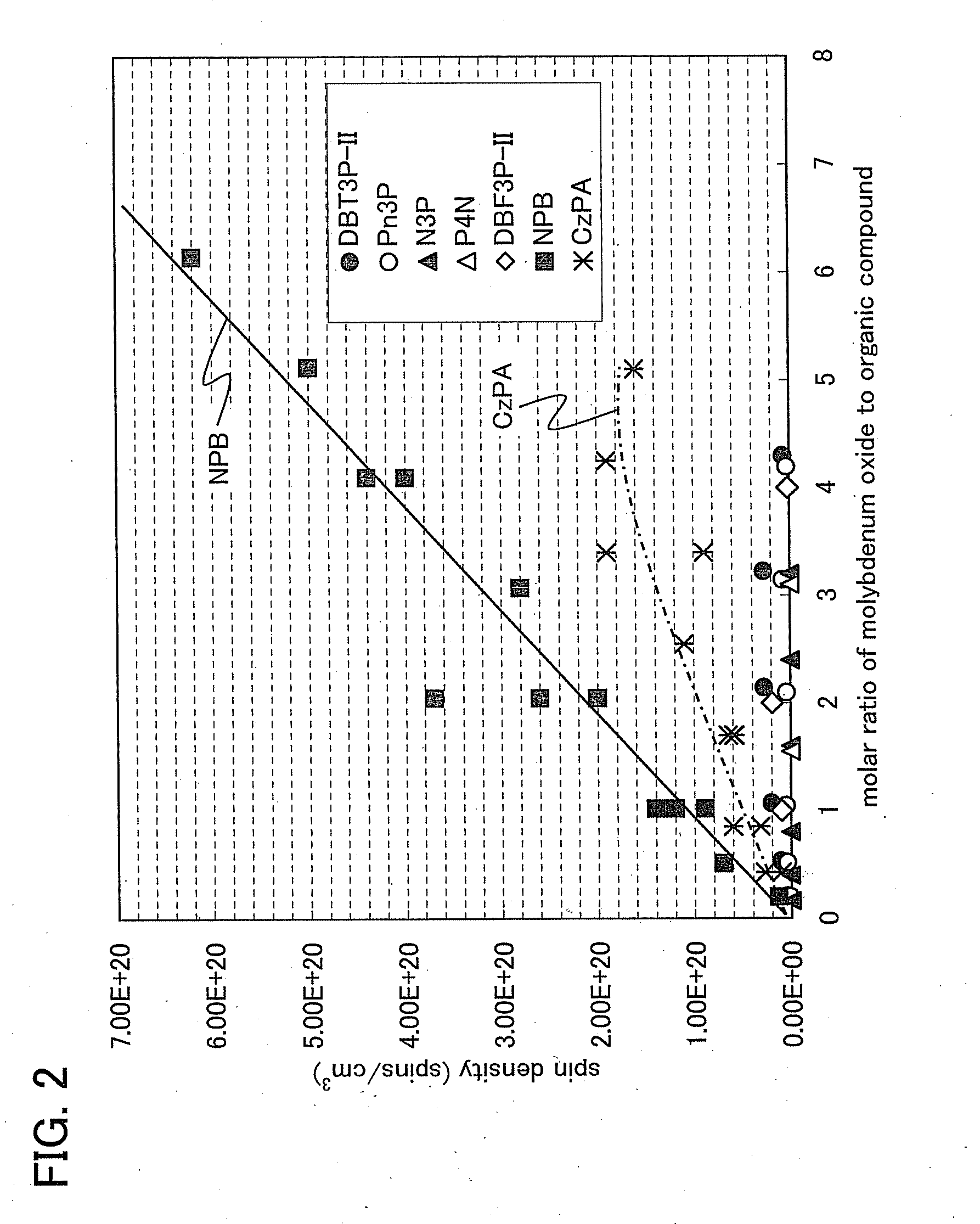

Light-Emitting Element and Light-Emitting Device

ActiveUS20120286252A1Reduce power consumptionHigh visible light transmittanceOLED parametersSolid-state devicesResonanceSpins

Provided are a light-emitting element capable of reducing power consumption by increasing its light extraction efficiency and a light-emitting device using the light-emitting element. A light-emitting element includes a composite material, which contains an organic compound having a high hole-transport property and an electron acceptor and in which the spin density measured by an electron spin resonance (ESR) method is less than or equal to 1×1019 spins / cm3, the spin density is less than or equal to 3×1019 spins / cm3 when the molar ratio of the electron acceptor to the organic compound is greater than or equal to 1, or the spin density is less than or equal to 5×1019 spins / cm3 when the molar ratio is greater than or equal to 2.

Owner:SEMICON ENERGY LAB CO LTD

Double seal with getter in flexible organic displays

InactiveUS20060139555A1Improve sealingReadily delaminateOLED parametersElectroluminescent light sourcesDisplay deviceEngineering

Improved seal for flexible organic light emitting displays are provided. For the purpose of the present invention it is realisd that a homogenous seal cannot provide for the combination of resuired robusness and required impermeability, which are essential for the life time of the display. Therefore, a seal comprising an inner seal portion and an outer seal portion is proposed. The outer seal portion is flexible as compared to the inner seal portion and the inner seal portion is impermeable as compared to the outer seal portion and being deposited between the outer seal portion and the display element.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

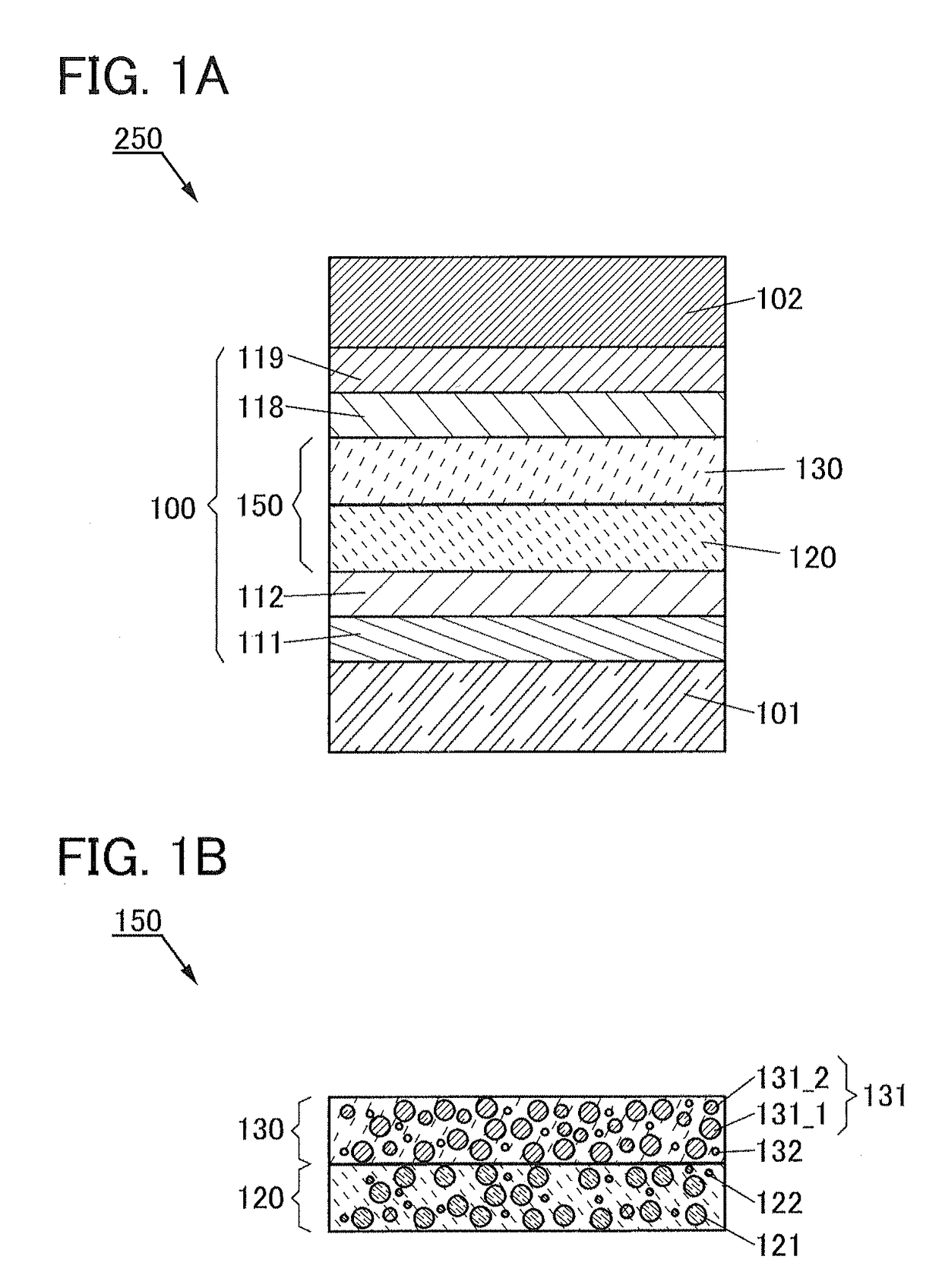

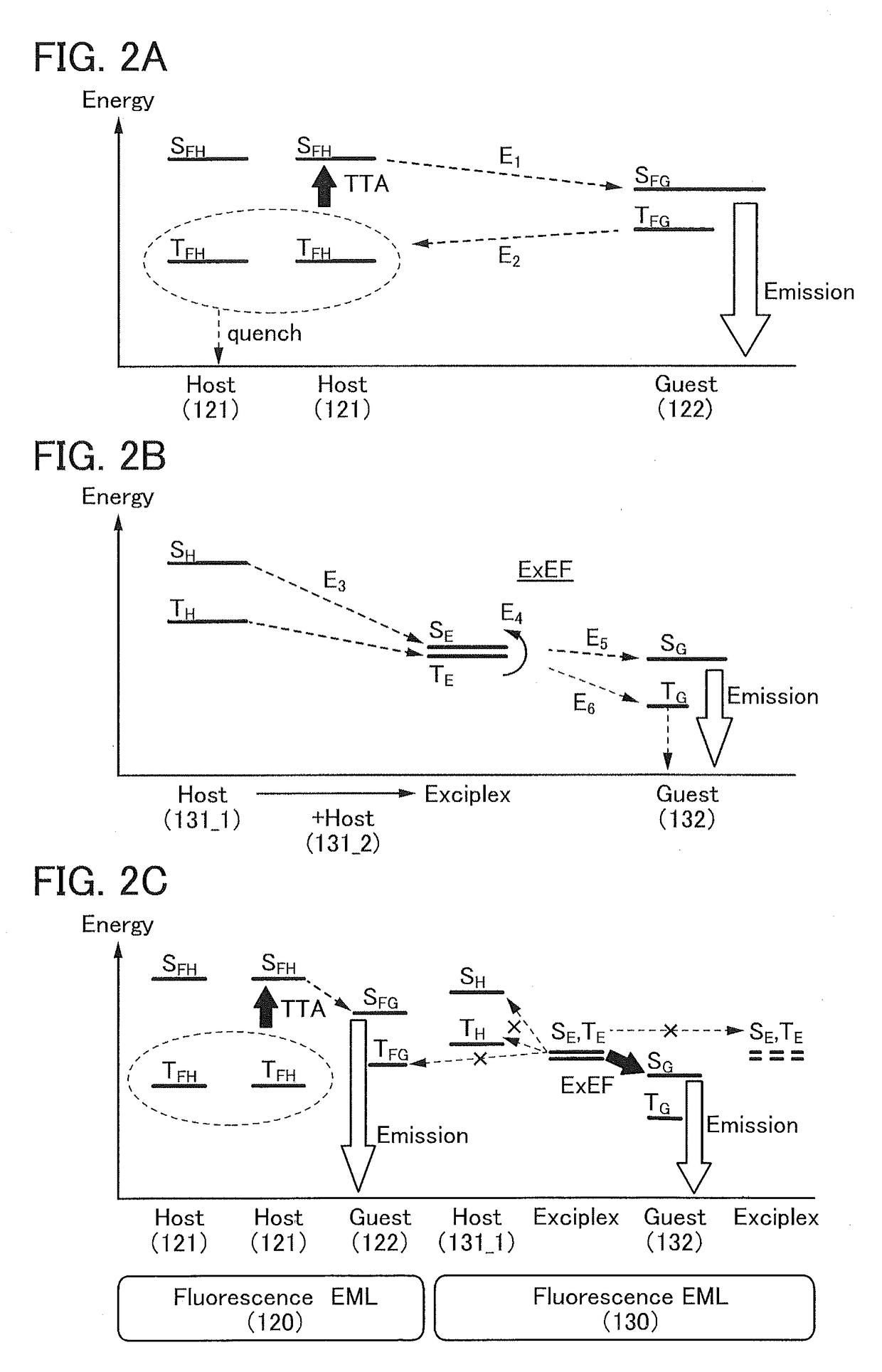

Light-emitting element, display device, electronic device, and lighting device

ActiveUS10062861B2Improve efficiencyPoor sublimation propertyOLED parametersSolid-state devicesLight equipmentDisplay device

A light-emitting element with high emission efficiency which includes fluorescent materials is provided. The light-emitting element includes a first light-emitting layer and a second light-emitting layer. The first light-emitting layer includes a first fluorescent material and a first host material, and the second light-emitting layer includes a second fluorescent material and a second host material. The second host material includes a first organic compound and a second organic compound. The first organic compound and the second organic compound form an exciplex. A singlet excited energy level of the first host material is higher than a singlet excited energy level of the first fluorescent material, and a triplet excited energy level of the first host material is lower than a triplet excited energy level of the first fluorescent material.

Owner:SEMICON ENERGY LAB CO LTD

Electrode foil and organic device

InactiveUS20130048976A1Improve thermal conductivityOLED parametersFinal product manufactureMetal foilReflective layer

There are provided an electrode foil which has all the functions of a supporting base material, an electrode and a reflective layer and also has a superior thermal conductivity; and an organic device using the same. The electrode foil comprises a metal foil, wherein the electrode foil has at least one outermost surface which is an ultra-smooth surface having an arithmetic average roughness Ra of 10.0 nm or less as measured in accordance with JIS B 0601-2001.

Owner:MITSUI MINING & SMELTING CO LTD

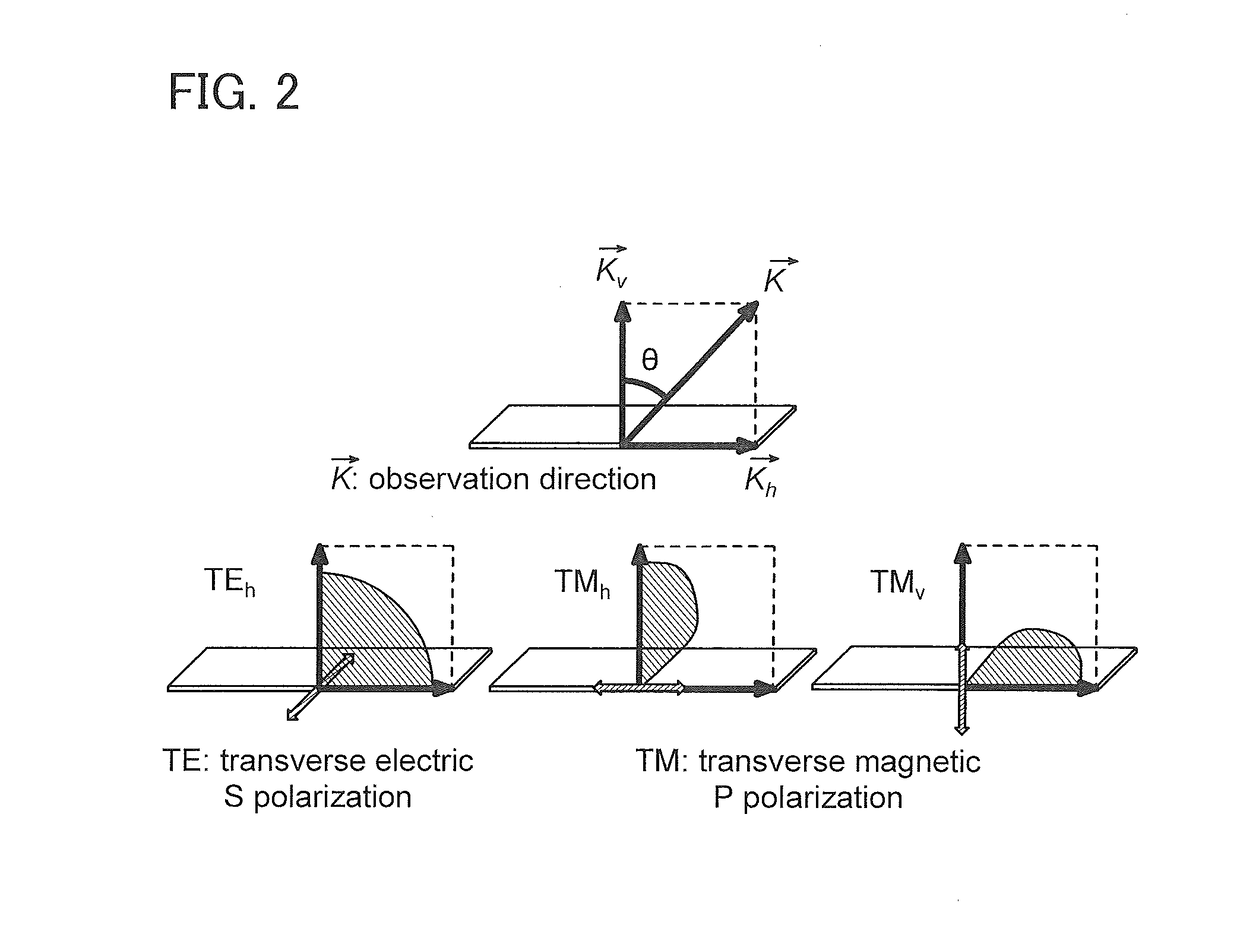

Light-Emitting Element, Light-Emitting Device, Electronic Device, and Lighting Device

ActiveUS20170338435A1Improve emission efficiencyImprove efficiencyOLED parametersOrganic chemistryEngineeringLight emitting device

A light-emitting element is provided. The light-emitting element includes first and second electrodes and an EL layer therebetween. The EL layer includes a light-emitting layer containing first and second substances. The amount of the first substance is larger than that of the second substance. The second substance emits light. Average transition dipole moments of the second substance are divided into three components in x-, y-, and z-directions which are orthogonal to each other. Components parallel to the first or second electrode are assumed to be the components in the x- and y-directions, and a component perpendicular to the first or second electrode is assumed to be the component in the z-direction. The proportion of the component in the z-direction is represented by a, which is less than or equal to 0.2.

Owner:SEMICON ENERGY LAB CO LTD

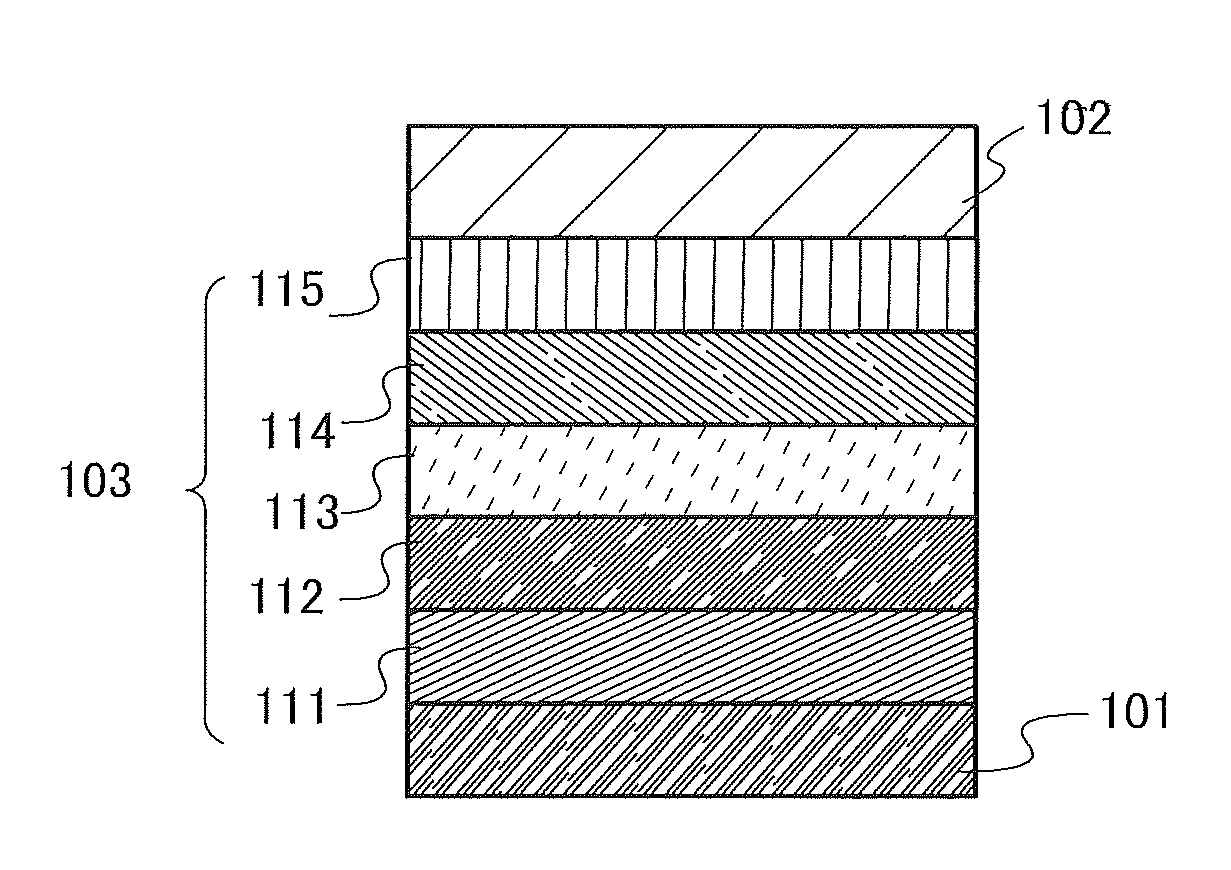

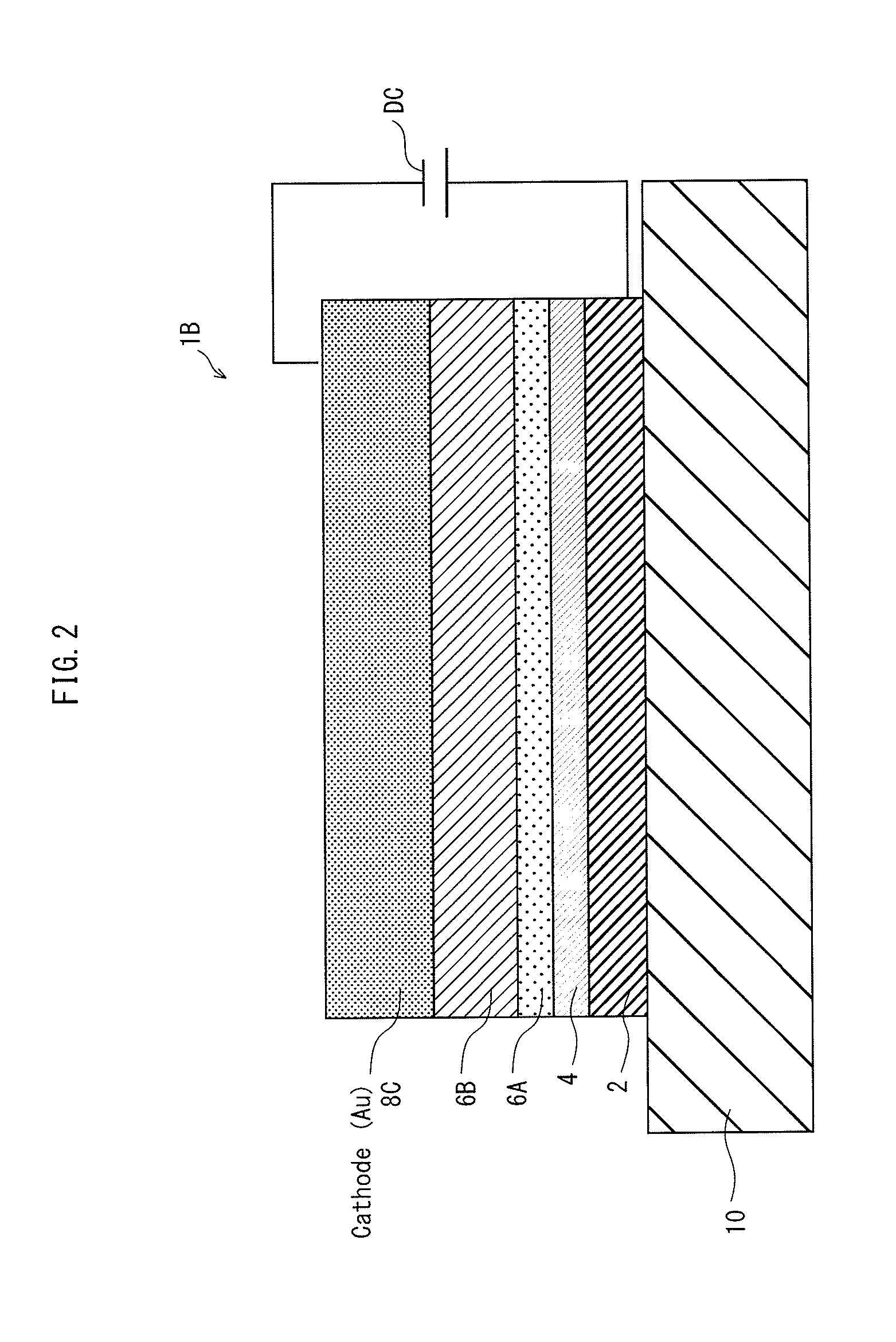

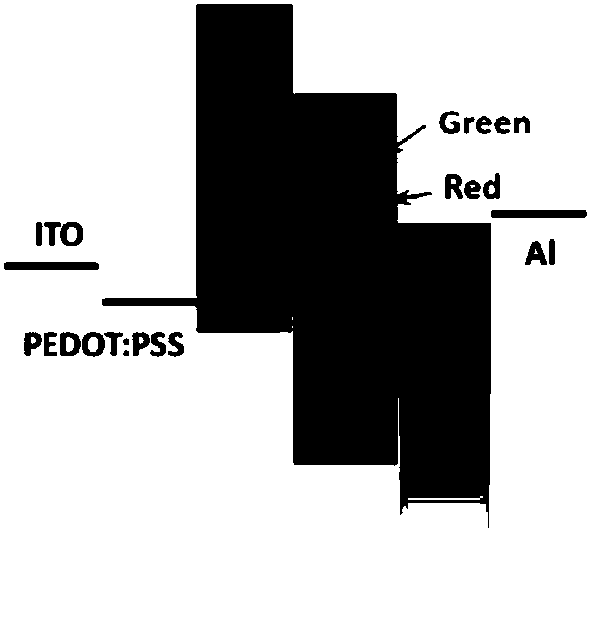

Organic EL element

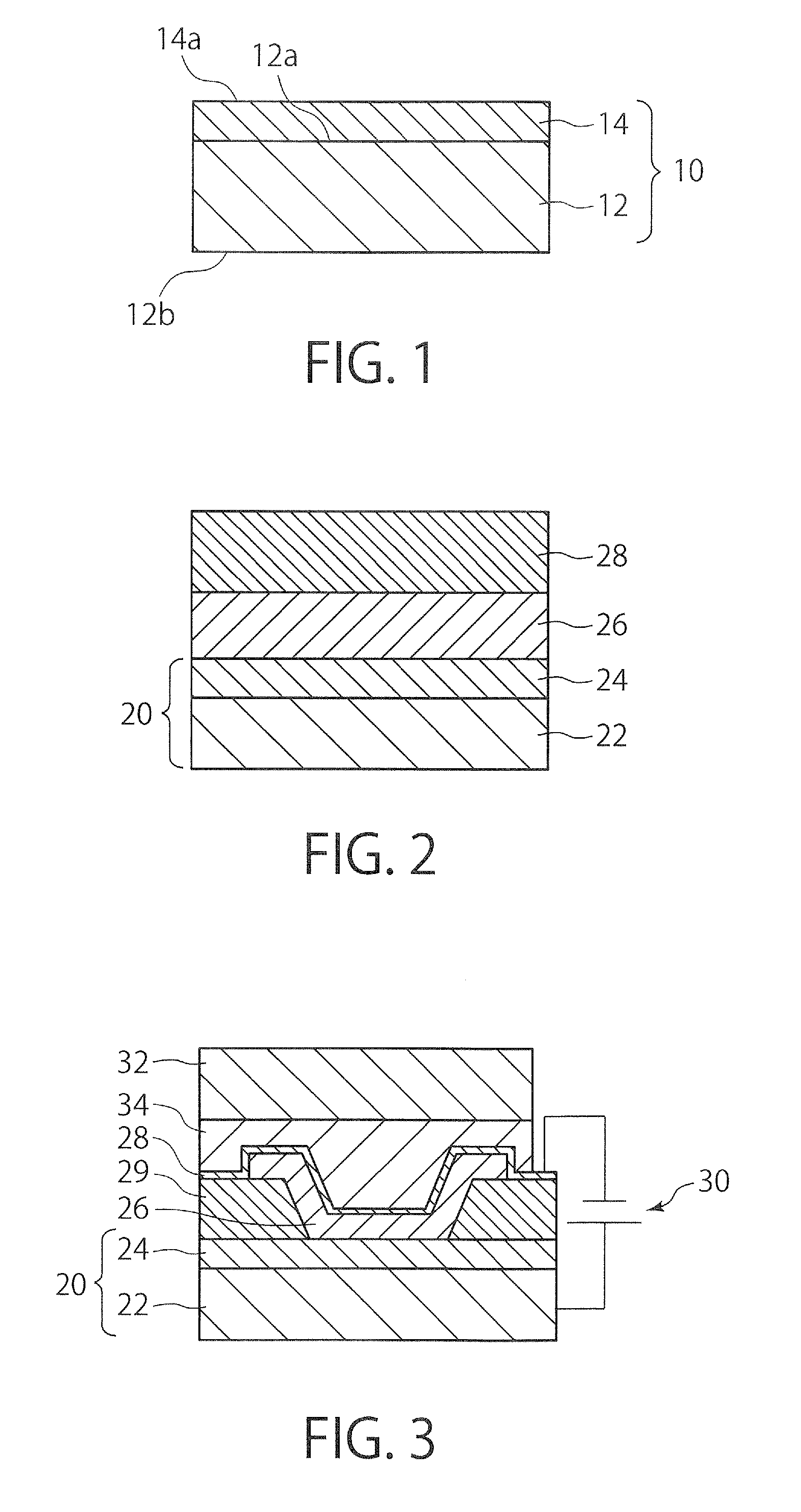

ActiveUS8884281B2Reduce voltageReduce hole injectionOLED parametersSolid-state devicesBinding energyValence band

Provided is an organic EL element which withstands mass production of organic EL display panels, and promises driving at a low voltage and high luminous efficiency due to excellent hole-injection efficiency. Specifically, an organic EL element is formed by sequentially laminating an anode, a hole injection layer, a buffer layer, a light-emitting layer, and a cathode on one surface of a substrate. The hole injection layer is a at least 2 nm thick tungsten oxide layer formed under predetermined film forming conditions, and includes an occupied energy level that is 1.8 eV to 3.6 eV lower than a lowest energy level of a valence band of the hole injection layer in terms of a binding energy. This reduces the hole injection barrier between the anode and the hole injection layer and the hole injection barrier between the hole injection layer and the buffer layer.

Owner:JOLED INC

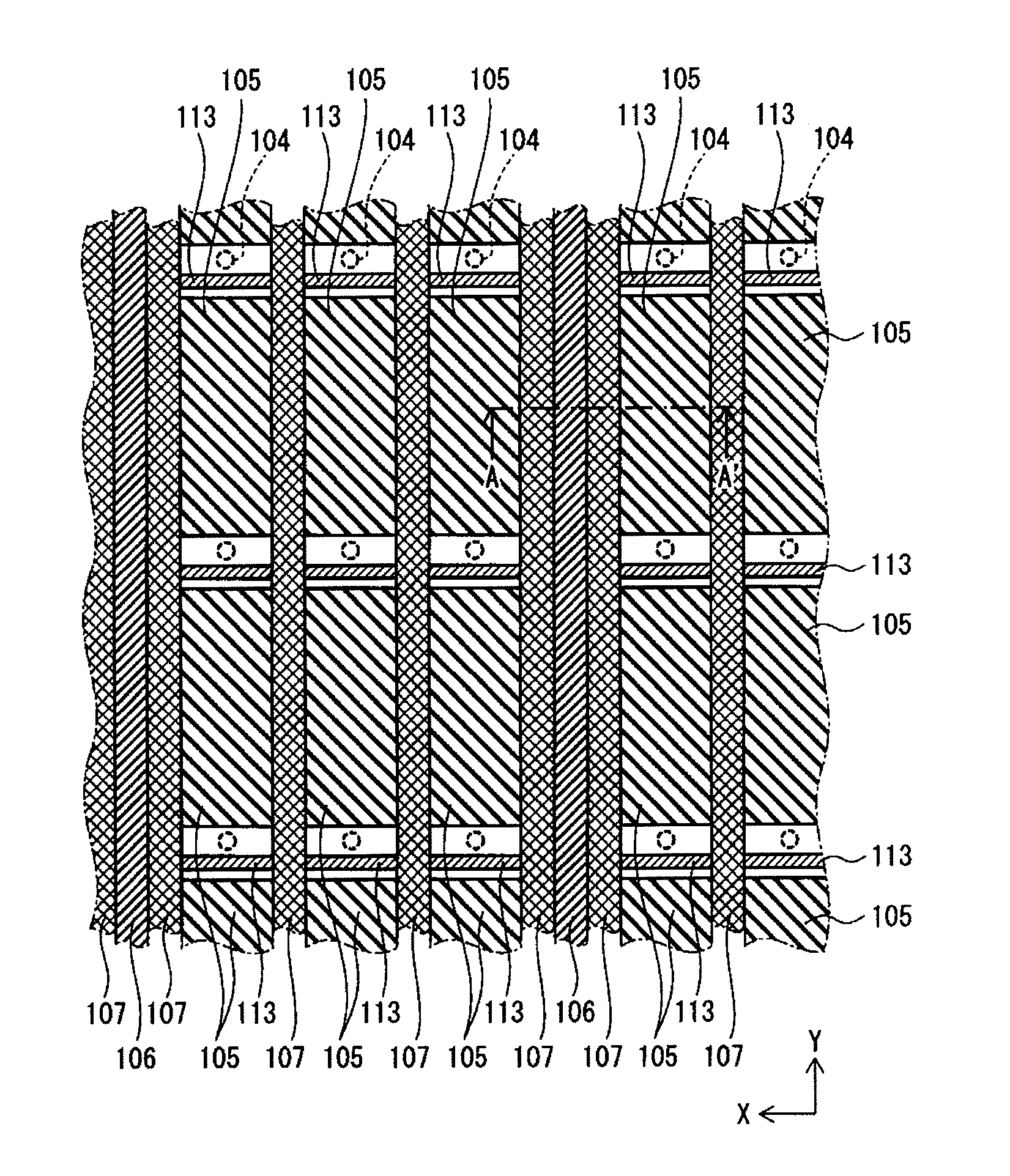

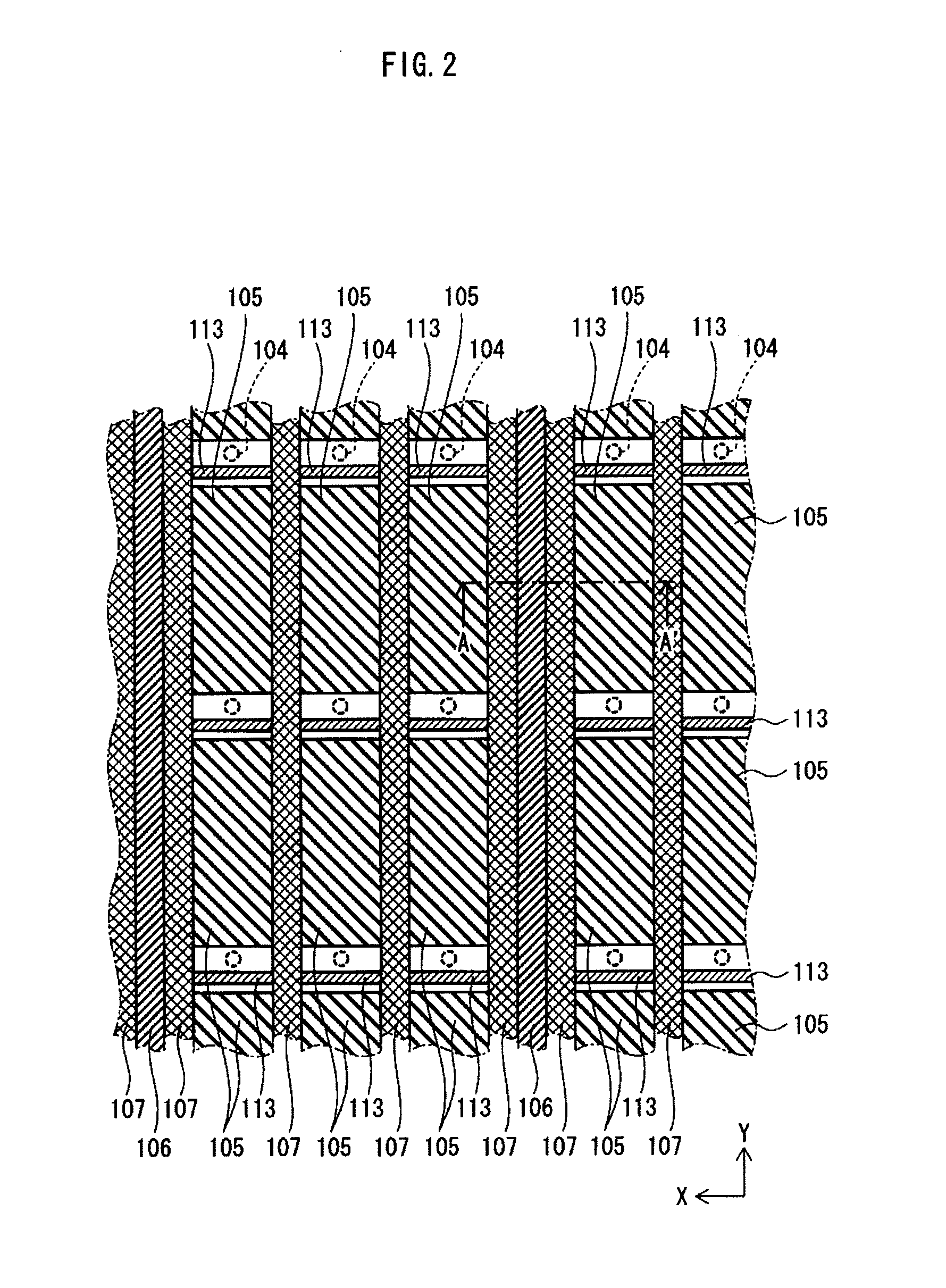

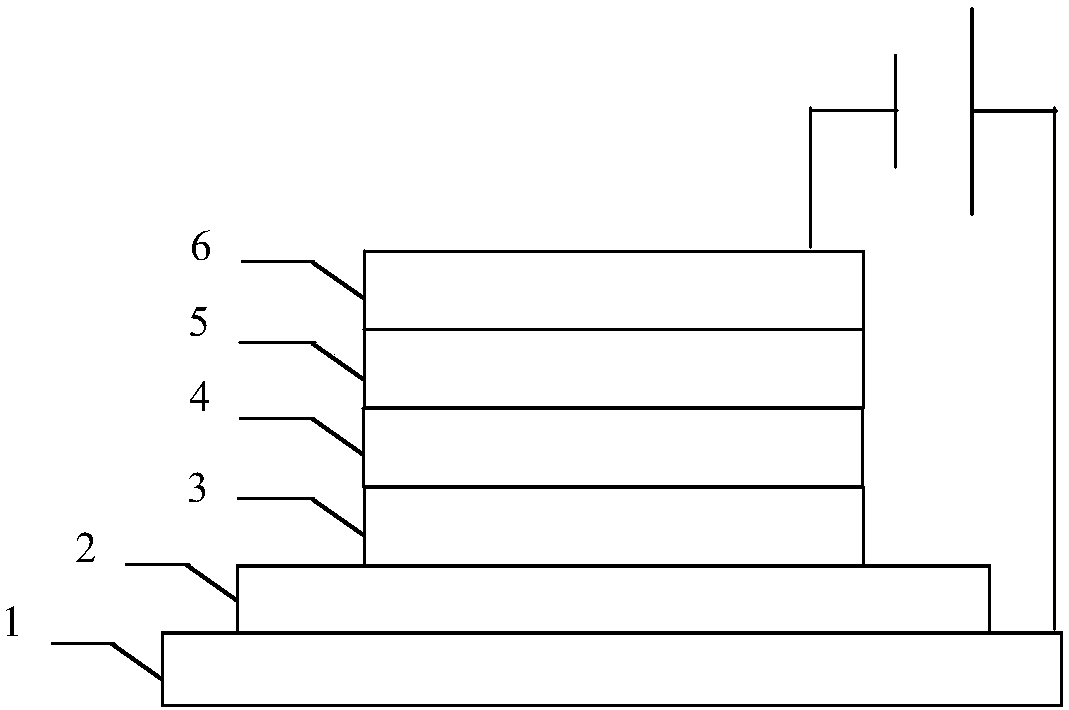

Organic light emitting element and manufacturing method of the same, organic display panel, and organic display device

ActiveUS20110316414A1Reduce in quantityReduced light-emitting characteristicOLED parametersDischarge tube luminescnet screensMetal alloyDisplay device

An organic light emitting element and method for manufacturing an organic light emitting element. A first electrode is formed from a metal alloy that includes a first metal material that exhibits a carrier-injection property upon oxidation, and a second metal material that is light-reflective and electrically conductive, a precipitate of the first metal material forming on at least part of a surface of the first electrode, and a metal oxide layer being formed in the precipitate. A functional layer contacts the surface of the first electrode and includes at least a light-emitting layer configured to accept a carrier injected by the first electrode. A second electrode is disposed opposite the first electrode with the functional layer therebetween and has a polarity different from a polarity of the first electrode.

Owner:JOLED INC

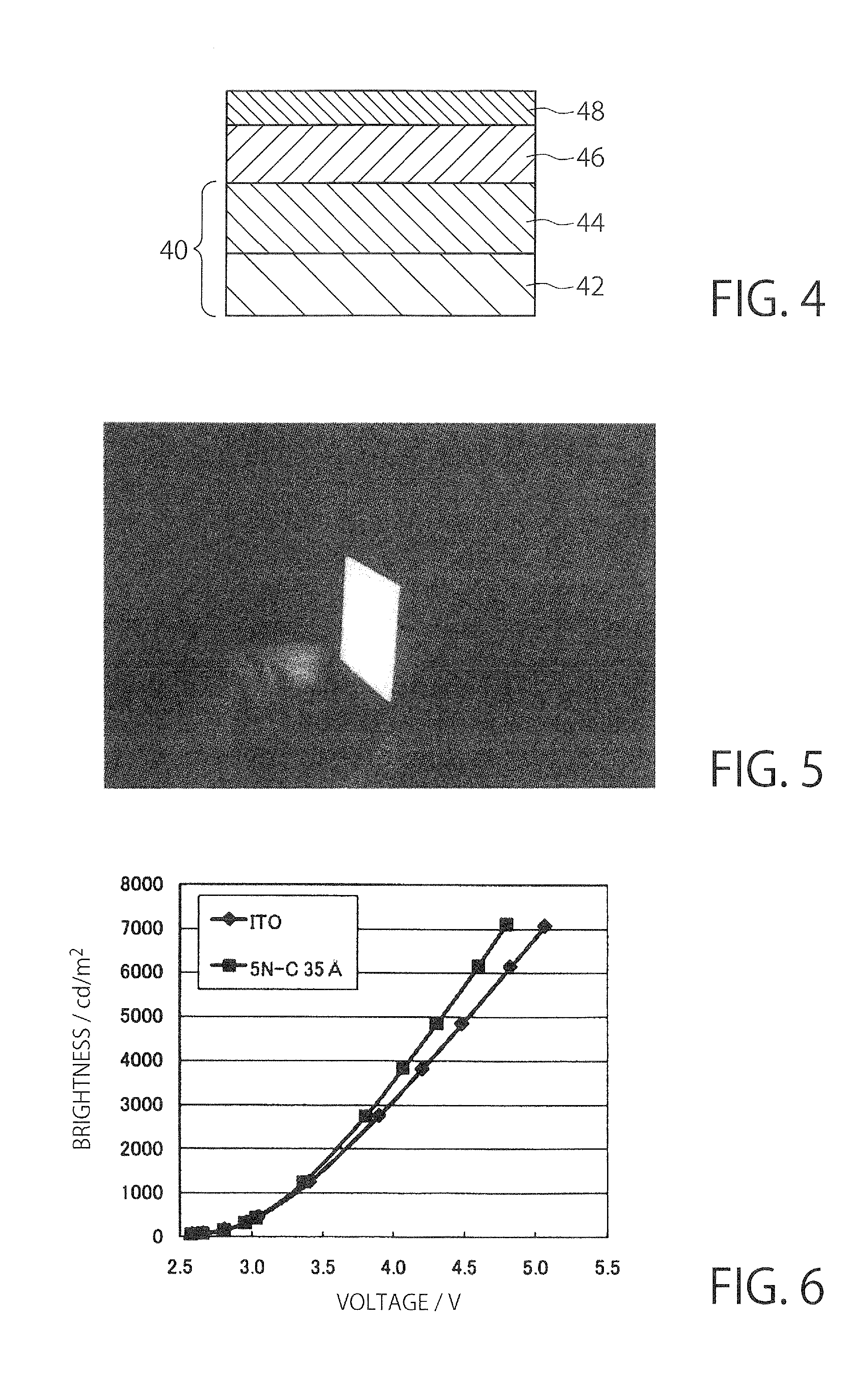

Scattering film for organic el, and organic el light-emitting device equipped with same

ActiveUS20130069524A1Lowered field-of-view dependenceLight utilization efficiency can be improvedOLED parametersDischarge tube luminescnet screensRefractive indexMicroparticle

Disclosed is a scattering film which can be used in an organic EL light-emitting device, in which the light utilization efficiency and field-of-view dependence, which have been problems so far in organic EL light-emitting devices, can be improved without interfering the two properties with each other. Specifically disclosed is a scattering film for an organic EL, which can be placed on the light emission surface side of an organic EL light-emitting device for use, and involves a scattering layer, wherein the scattering layer comprises a binder resin, microparticles having a different refractive index from that of the binder resin, and resin particles having a larger average particle diameter than that of the microparticles. The content of the microparticles is preferably 5 to 90 parts by weight relative to 100 parts by weight of the binder resin, and the content of the resin particles is preferably 100 to 300 parts by weight relative to 100 parts by weight of the binder resin.

Owner:KIMOTO CO LTD

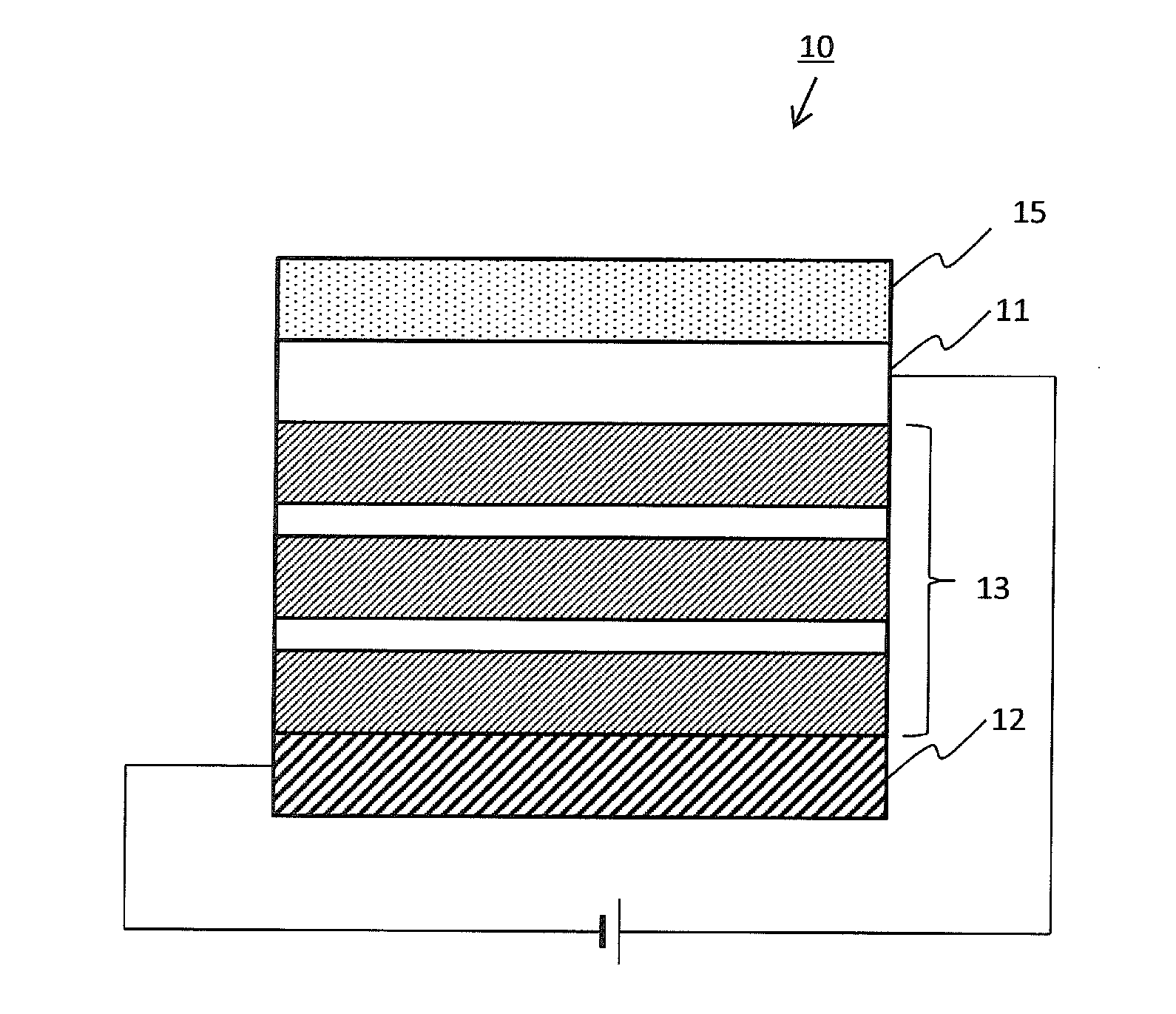

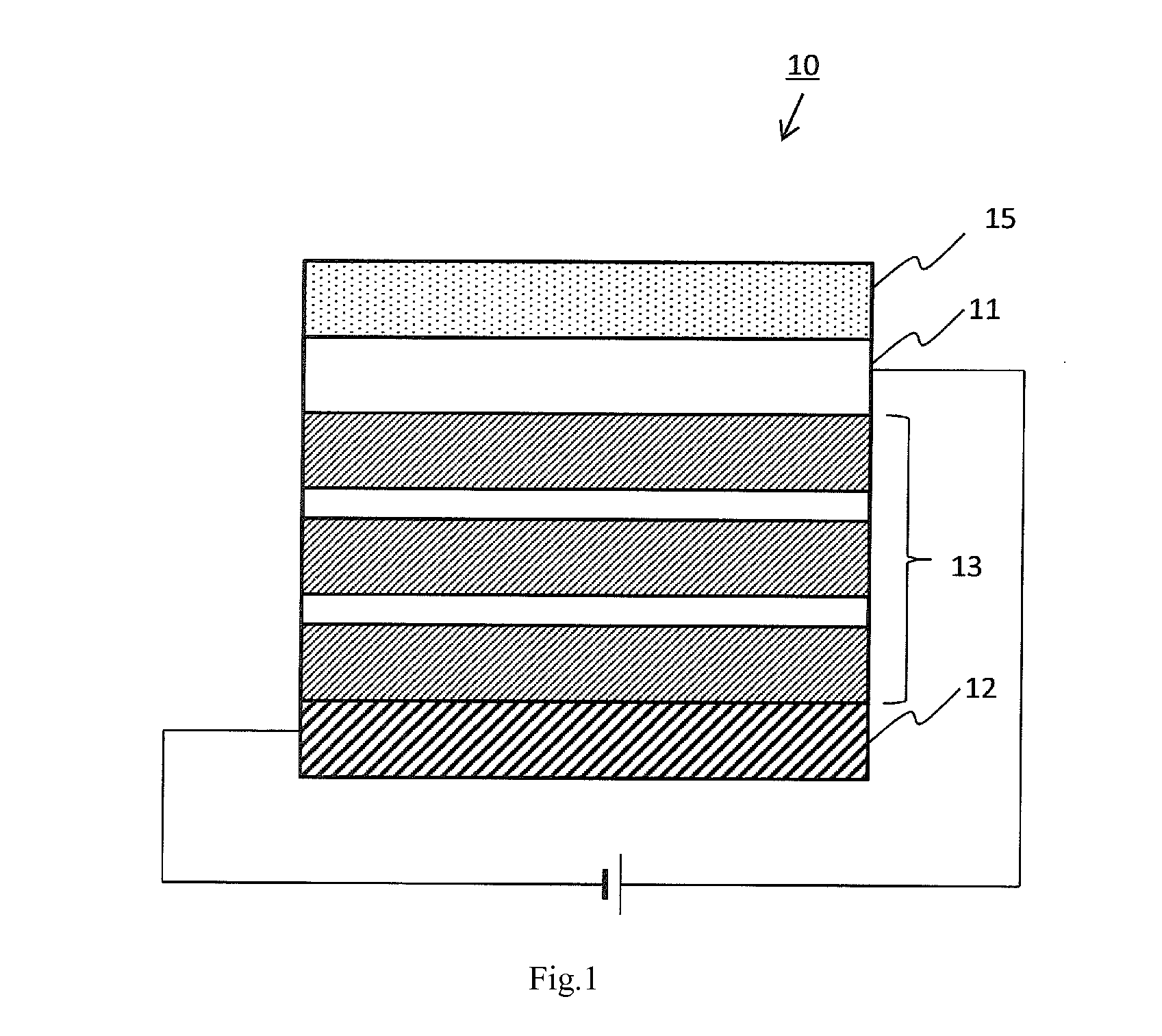

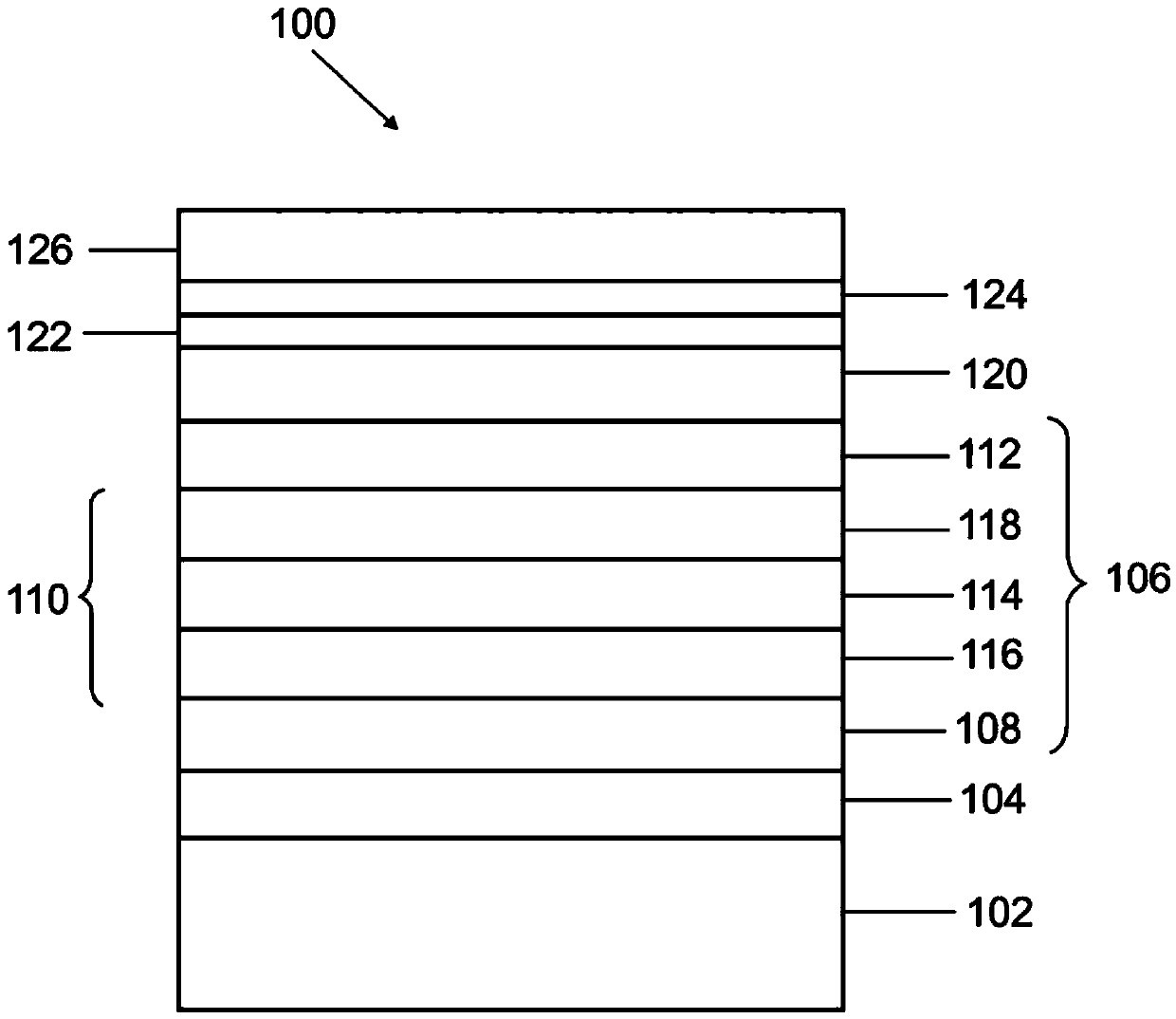

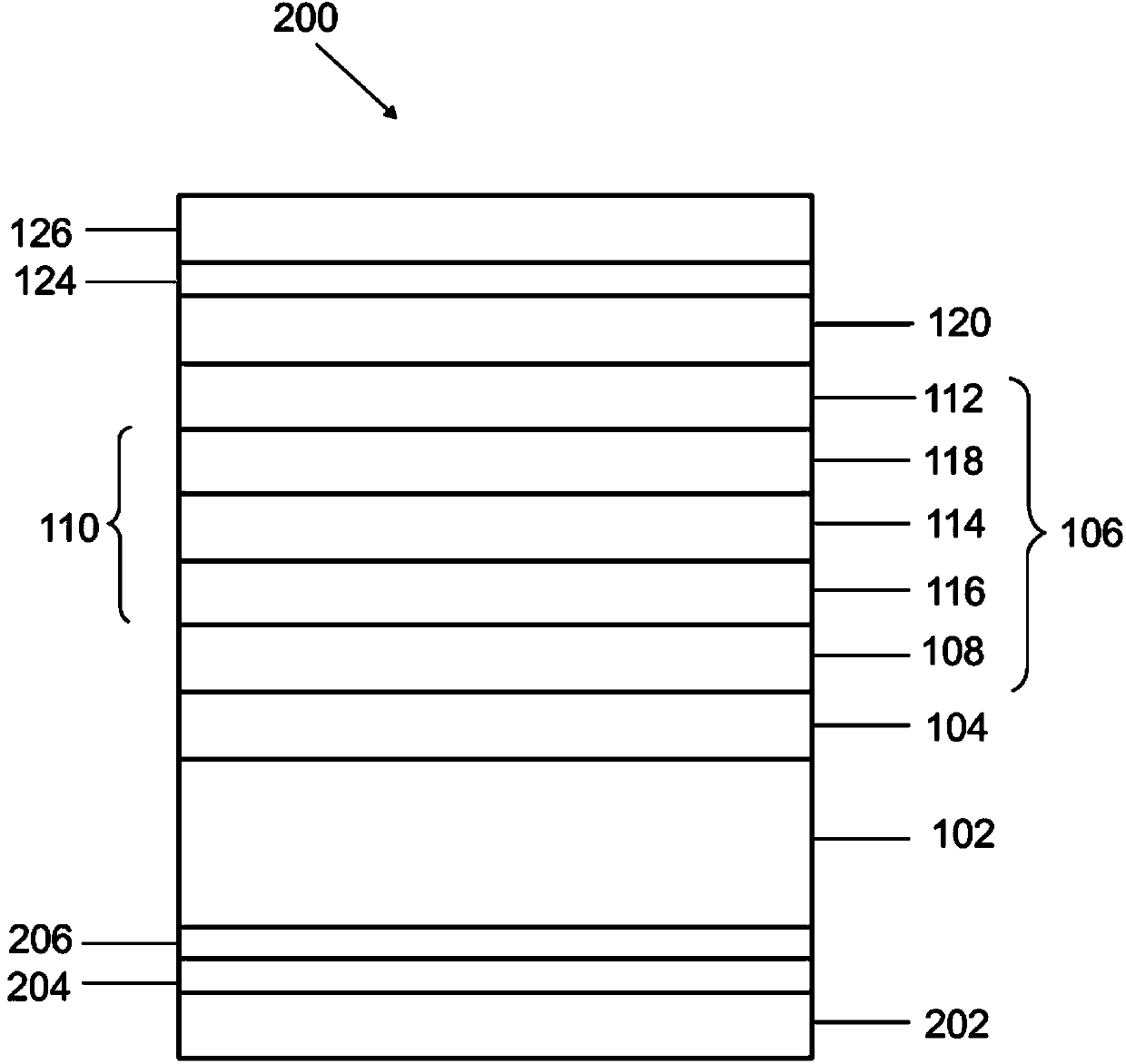

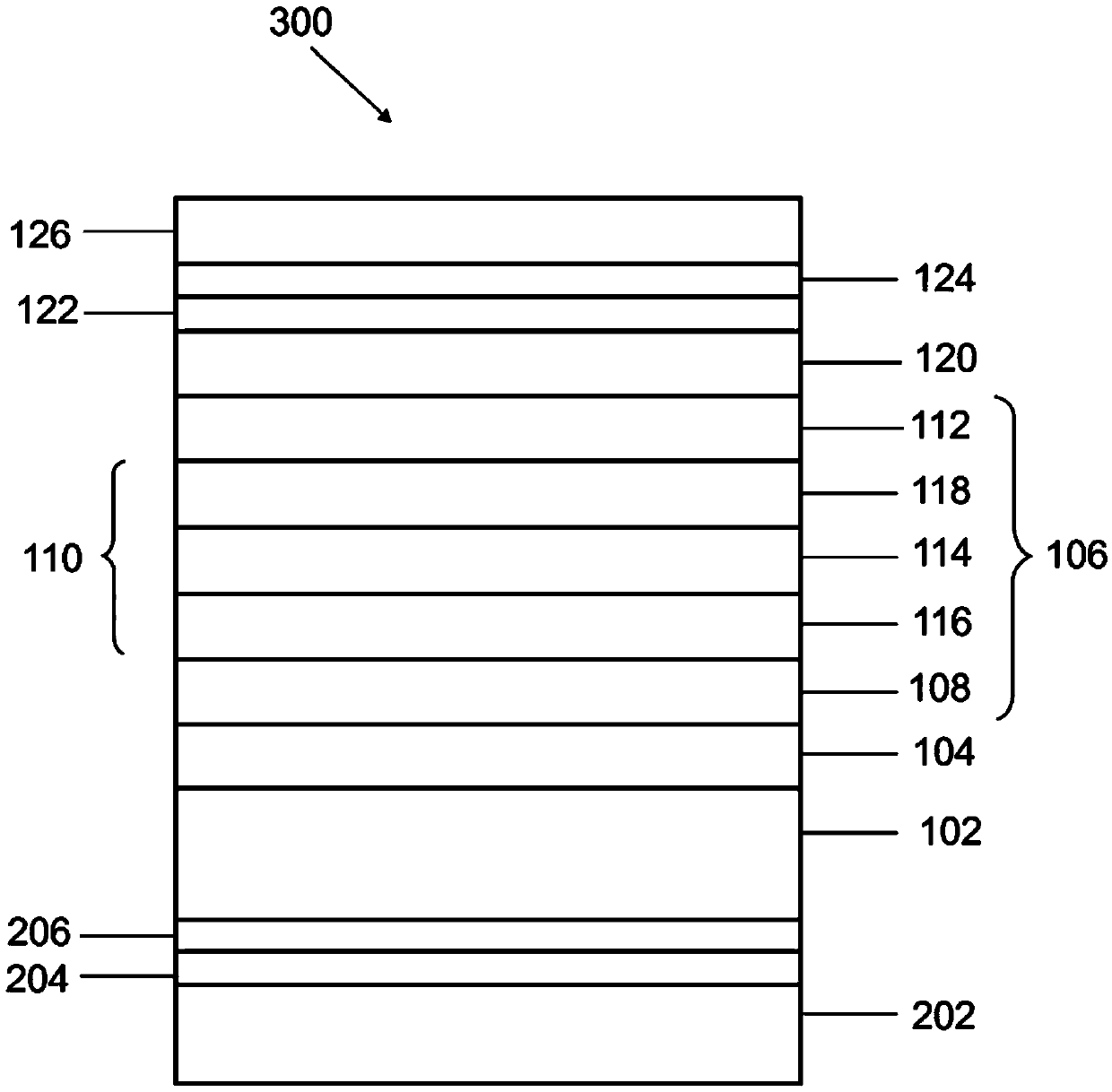

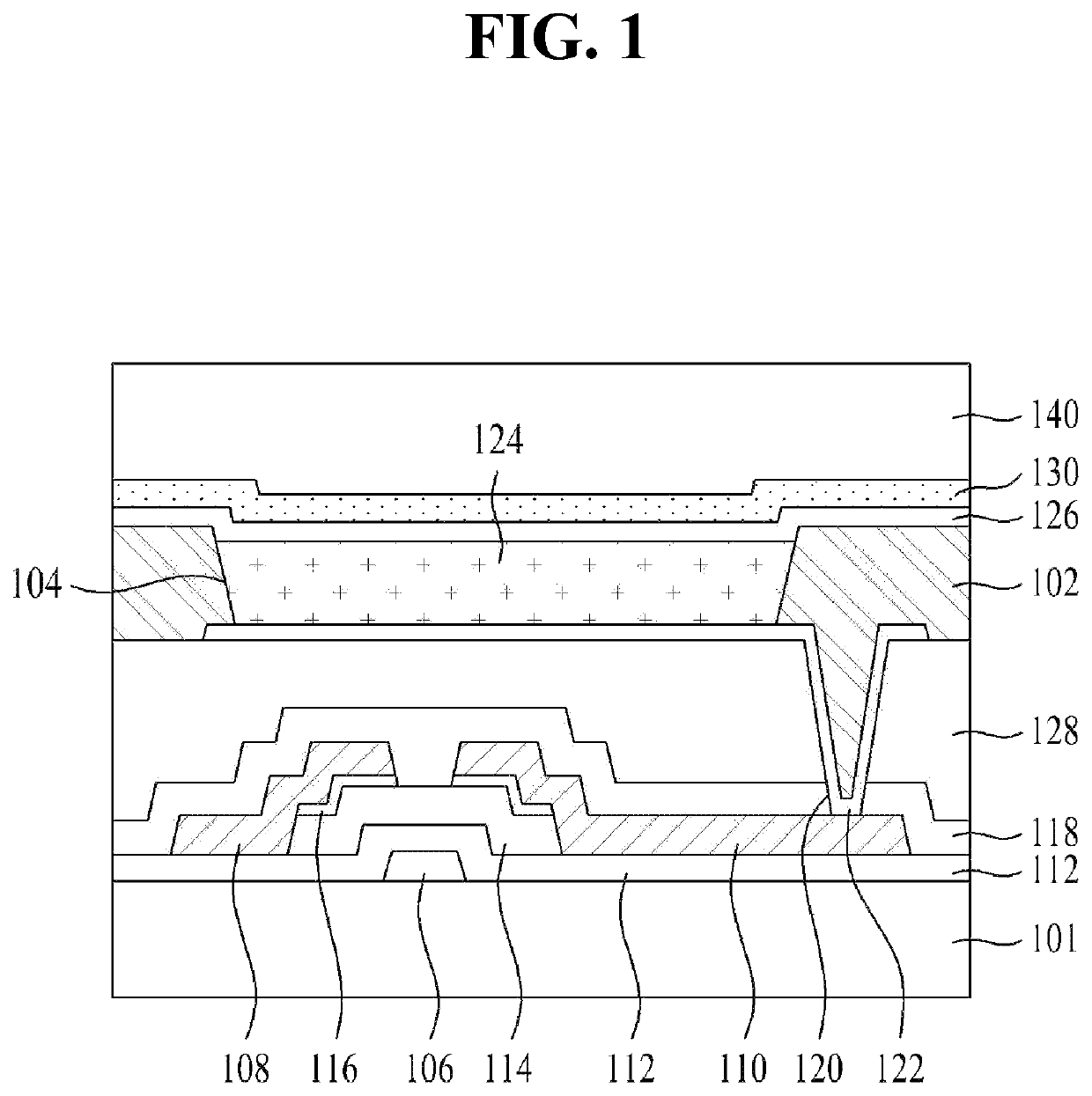

Light-emitting component and method for producing a light-emitting component

The invention relates to a light-emitting component and to a method for producing a light-emitting component. In various embodiments a light-emitting component (100) is provided, having: an electrically active region (106), having: a first electrode (108), a second electrode (112), and an organic functional layer structure (110) between the first electrode (108) and the second electrode (112); a cover (126) which is disposed above the electrically active region (106); and an intermediate layer structure (122) disposed between the cover (126) and the electrically active region (106) and having at least one layer, wherein the at least one layer has an index of refraction which is less than the index of refraction of the cover (126).

Owner:OSRAM OLED

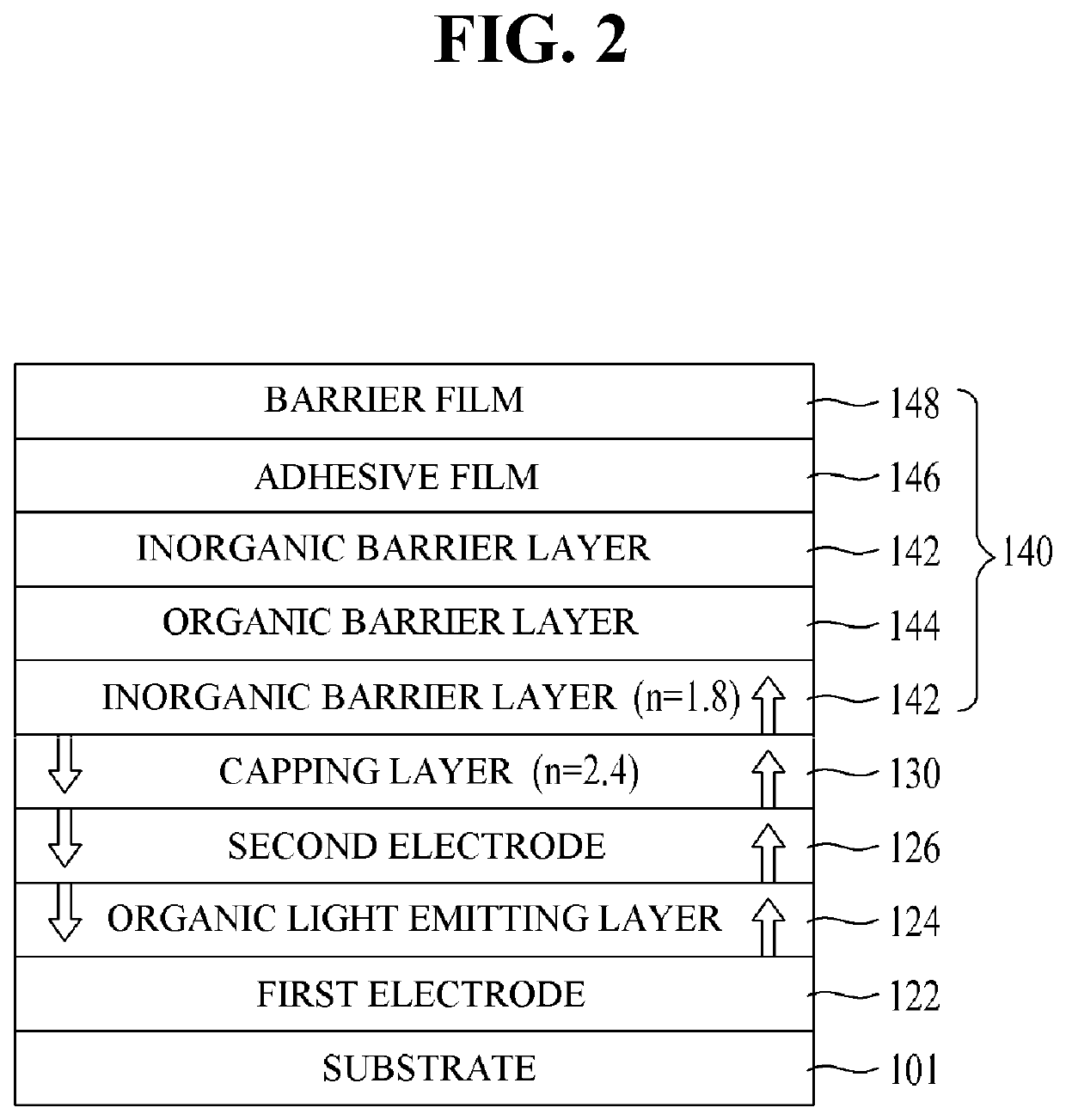

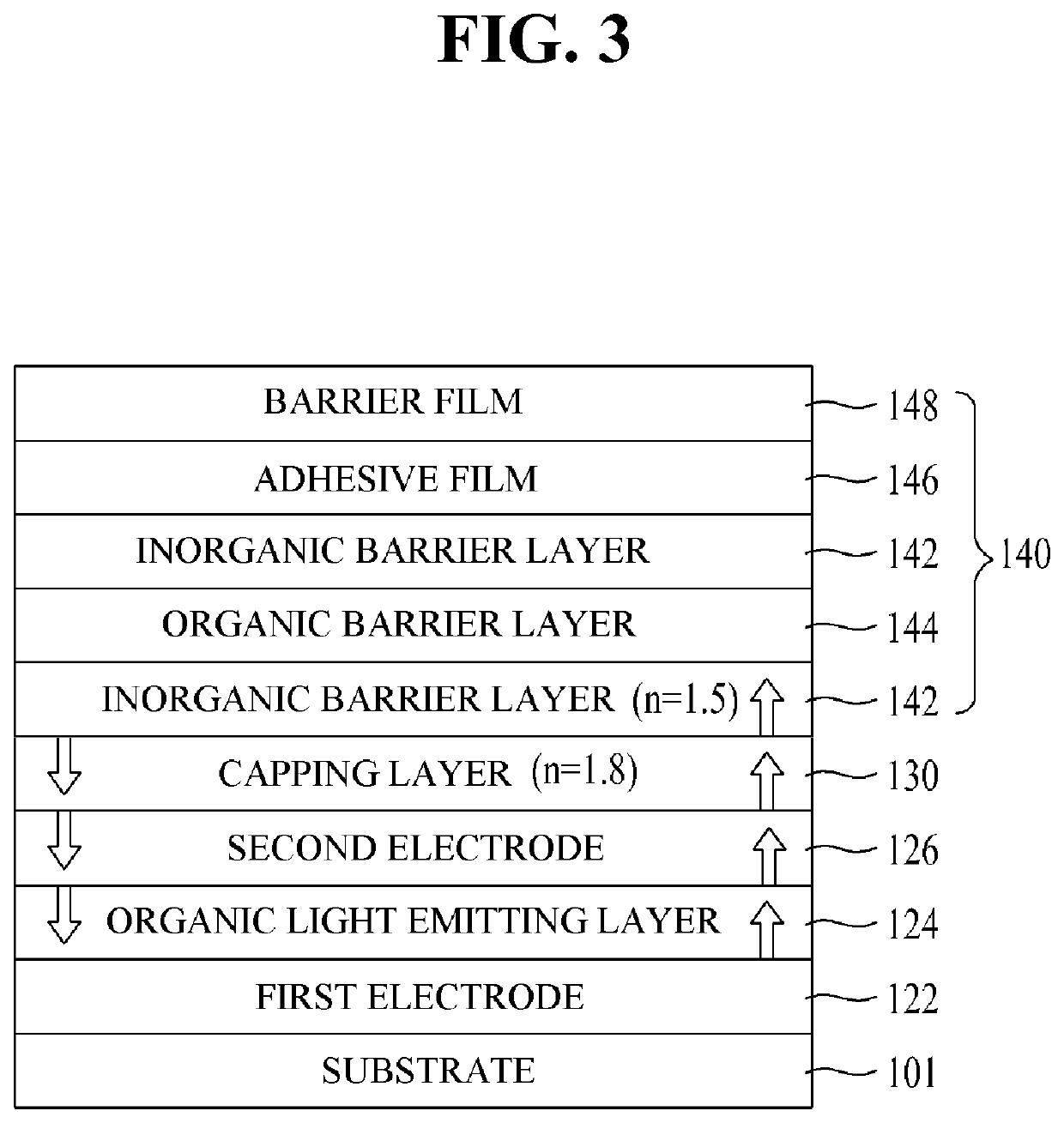

Organic light emitting display panel

ActiveUS10720596B2Improve luminous efficiencyEffective lightingOLED parametersSolid-state devicesRefractive indexThin membrane

The organic light emitting display panel includes a first electrode formed on a substrate, an organic light emitting layer formed on the first electrode, a second electrode formed on the organic light emitting layer, a front sealing layer formed on the second electrode, wherein the front sealing layer is formed by alternately laminating an inorganic barrier layer and an organic barrier layer at least once, and at least one capping layer formed between the lowest layer closest to the second electrode among a plurality of thin films of the front sealing layer and the second electrode and having a higher index of refraction than an index of refraction of the lowest layer.

Owner:LG DISPLAY CO LTD

Composite thin film, and preparation method and application thereof

ActiveCN109994629AImprove the blocking effectImprove luminous efficiencyOLED parametersMaterial nanotechnologyComposite filmZno nanoparticles

The invention provides a composite thin film. The composite thin film comprises N layers of thin films sequentially stacked and combined; the N layers of the thin films are all nano-zinc oxide thin films; and from the first layer of the thin film to the Nth layer of the thin film, the particle sizes of nano-zinc oxide in the nano-zinc oxide thin films are increased layer by layer, wherein N is greater than or equal to 3 and less than or equal to 9.

Owner:TCL CORPORATION

Organic light-emitting diode display and manufacturing method thereof

ActiveUS8664649B2Prevent penetrationReducing and minimizing space of displayOLED parametersDischarge tube luminescnet screensOrganic filmDisplay device

An organic light emitting diode display includes a substrate, an organic light emitting diode on the substrate, an organic film configured to cover the organic light emitting diode on the substrate in an organic film deposition area having a first diameter, and an inorganic film configured to cover the organic film on the substrate in an inorganic film deposition area having a second diameter, wherein L1 is the first diameter of the organic film deposition area in μm, wherein L2 is the second diameter of the inorganic film deposition area in μm, wherein D is a thickness of the organic film in μm, and wherein L2−L1≧2 (171D+150 μm).

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com