Modified polyimide nanofiber membrane as well as preparation and application thereof

A nanofiber membrane, polyimide technology, applied in fiber processing, textiles and papermaking, non-woven fabrics, etc., can solve the problems of difficult to control porosity uniformity, direct contact between positive and negative electrodes, insufficient heat resistance, etc. Achieve the effect of reducing performance defects, low interface contact resistance, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] 1. Preparation of modified polyimide.

[0040] S01, preparation of dinitro compounds: 6.606g hydroquinone, 19.349g anhydrous potassium carbonate, 27.517g 2-chloro-5 nitrobenzotrifluoride were dissolved in 200mL N, N-dimethylformamide, in After stirring and mixing in an oil bath at 130°C for 20 h, the mixed solution was transferred to 300 mL of deionized water, and 10 mL of hydrogen chloride solution with a mass fraction of 37% was added dropwise, then filtered, washed with deionized water, and dried to obtain a white dinitro compound.

[0041] S02, amination of dinitro compounds: add 7.325g of dinitro compounds to 150mL of ethanol and hydrazine hydrate mixed solution (hydrazine hydrate in the mixed solution is 15mL), then add 0.201g of Raney nickel catalyst, condense and reflux at 105°C React for 5h, then filter and recrystallize to obtain a light yellow modified polyimide intermediate.

[0042] S03, preparation of modified polyimide: Dissolve 4.283g of modified polyim...

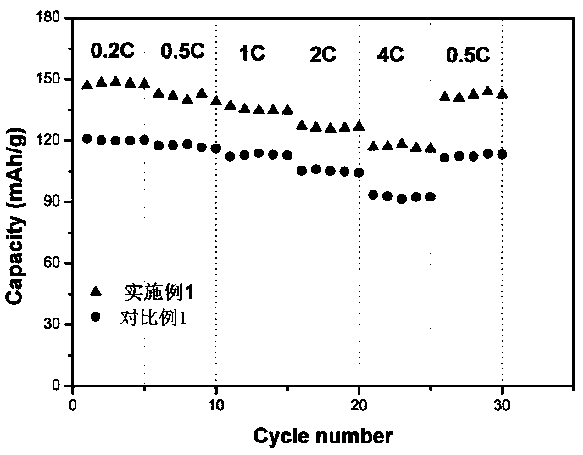

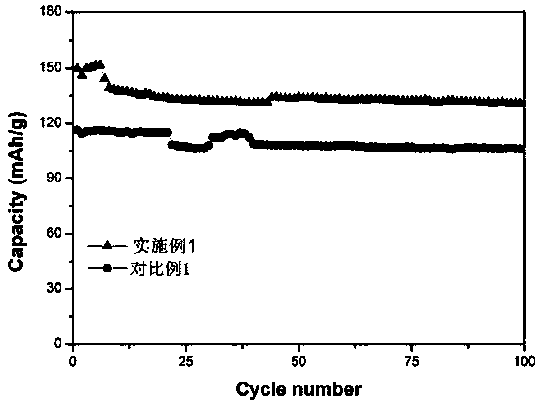

Embodiment 1

[0045] Step 1: Preparation of spinning solution: disperse 0.025g of sulfonated graphene oxide in 15mL of N,N-dimethylacetamide by ultrasonic dispersion to obtain dispersion A, and the ultrasonic conditions are ultrasonic power 200W, ultrasonic 12min; Dissolve 4.211g of modified polyimide in 35mL N,N-dimethylacetamide to obtain solution B, then mix dispersion A and solution B uniformly to obtain the spinning solution;

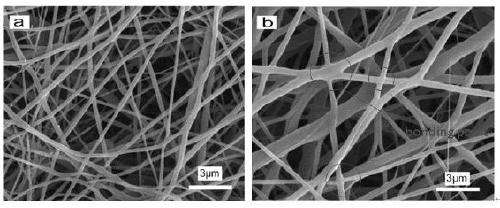

[0046] Step 2: Preparation of nanofiber membrane: Electrospinning the spinning solution to prepare a composite membrane, and drying at 150° C. for 2 hours. The electrospinning conditions were as follows: the diameter of the needle was 0.51 mm, the temperature was 10 °C, the humidity was 40% rh, the spinning voltage was 15 kV, and the flow rate of the spinning solution was 0.5 mL / h. Then the dried composite membrane was heat-treated at 300°C for 15s to obtain the nanofiber membrane.

[0047] In this embodiment, the average particle size of the sulfonated graphen...

Embodiment 2

[0050] Compared with Example 1, the difference of this example is that the addition amount of sulfonated graphene oxide is 0.042g, the addition amount of modified polyimide is 3.121g, and other parts are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com