Hot melt adhesive for packaging

A technology for hot melt adhesives and packaging, applied in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of high cost of hot melt adhesives, no right to speak in material selection, and thin processing profits, etc., to achieve Improve the wetting effect, wide temperature range, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

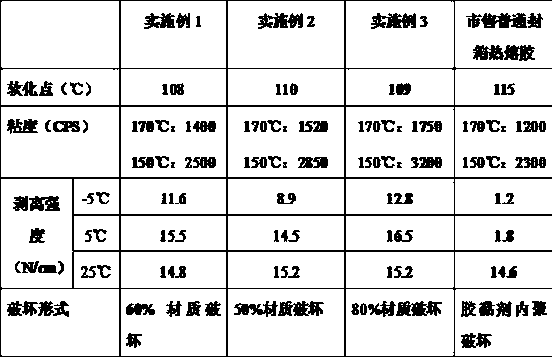

Examples

Embodiment 1

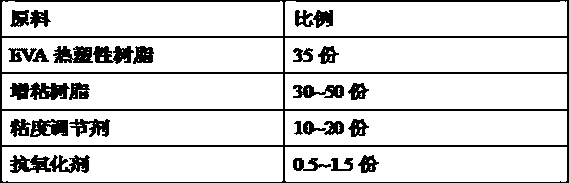

[0022] A hot-melt adhesive for packaging, in parts by mass, its preparation raw materials at least include:

[0023] raw material

Proportion

EVA thermoplastic resin 1 (VA40%, MI 65)

10 copies

EVA thermoplastic resin 2 (VA 28%, MI 800)

25 copies

C9 petroleum resin

15 copies

Rosin pentaerythritol ester

15 copies

Rosin Glycerides

20 copies

Fischer-Tropsch wax

15 copies

Antioxidants

0.5 parts

[0024] The preferred EVA thermoplastic resin 1 is DuPont 40W, and the EVA thermoplastic resin 2 is Taiju UE 647;

[0025] The preferred C9 petroleum resin is Taiwan Yuanliang YL120H;

[0026] Preferred rosin pentaerythritol fat is Guangxi Wuzhou Richeng PER100F;

[0027] Preferred rosin glyceride is Guangxi Wuzhou Richeng GER85;

[0028] The preferred Feituo wax is Shell SX80;

[0029] A preferred antioxidant is BASF 1010.

[0030] The preparation process of above-mentioned hot melt adhesive c...

Embodiment 2

[0035] A hot-melt adhesive for packaging, in parts by mass, its preparation raw materials at least include:

[0036] raw material

Proportion

EVA thermoplastic resin 1 (VA40%, MI 65)

10 copies

EVA thermoplastic resin 2 (VA 28%, MI 800)

25 copies

C9 petroleum resin

20 copies

Rosin pentaerythritol ester

15 copies

Rosin Glycerides

15 copies

Fischer-Tropsch wax

15 copies

Antioxidants

0.5 parts

[0037] The preferred C9 petroleum resin is Taiwan Yuanliang YL120H;

[0038] Preferred rosin pentaerythritol fat is Guangxi Wuzhou Richeng PER100F;

[0039] Preferred rosin glyceride is Guangxi Wuzhou Richeng GER85;

[0040] The preferred Feituo wax is Shell SX80;

[0041] A preferred antioxidant is BASF 1010.

[0042] The preparation process of above-mentioned hot melt adhesive comprises the following processes:

[0043] (1) Add EVA thermoplastic resin 1, EVA thermoplastic resin 2, and Fische...

Embodiment 3

[0047] A hot-melt adhesive for packaging, in parts by mass, its preparation raw materials at least include:

[0048] raw material

Proportion

EVA thermoplastic resin 1 (VA40%, MI 65)

12 copies

EVA thermoplastic resin 2 (VA 28%, MI 800)

23 copies

15 copies

Rosin pentaerythritol ester

15 copies

Rosin Glycerides

20 copies

Fischer-Tropsch wax

15 copies

Antioxidants

0.5 parts

[0049] The preferred C9 petroleum resin is Taiwan Yuanliang YL120H;

[0050] Preferred rosin pentaerythritol fat is Guangxi Wuzhou Richeng PER100F;

[0051] Preferred rosin glyceride is Guangxi Wuzhou Richeng GER85;

[0052] The preferred Feituo wax is Shell SX80;

[0053] A preferred antioxidant is BASF 1010.

[0054] The preparation process of above-mentioned hot melt adhesive comprises the following processes:

[0055] (1) Add EVA thermoplastic resin 1, EVA thermoplastic resin 2, and Fische...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com