Process for preparing transparent ceramic through 3D printing

A transparent ceramic and 3D printing technology, applied in the field of 3D printing, can solve the problems of poor product quality stability, high elongation at break, and fragility, and achieve the goals of improving quality stability, moderate elongation at break, and good antibacterial function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

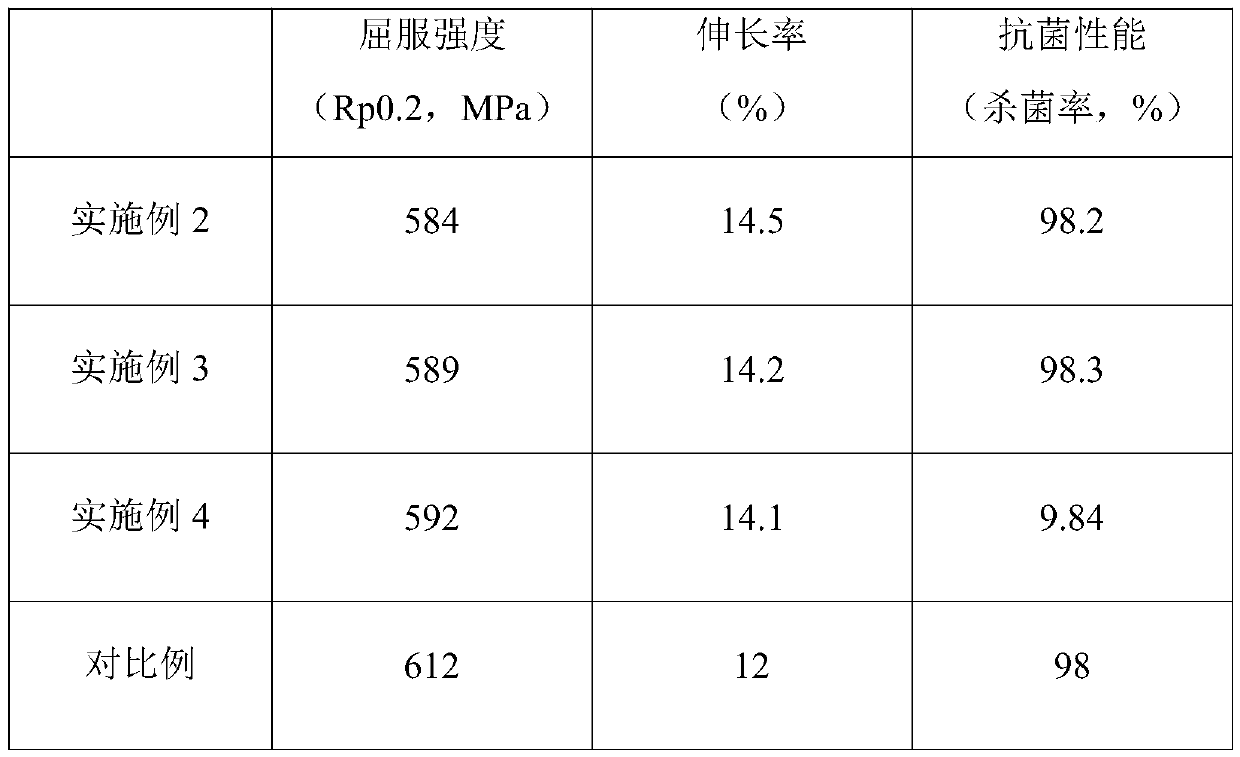

Examples

Embodiment 1

[0067] A process for preparing transparent ceramics by 3D printing, comprising the following steps:

[0068] A. After mixing zirconia, ethylene-vinyl acetate copolymer, hexanediol diacrylate, carboxyl silica microspheres, nano-titanium dioxide, alumina fibers and edge graphene oxide, in ethanol solution dissolved with dispersant Perform ball milling for 1 to 2 hours to obtain ball milled slurry;

[0069] B. Add a photoinitiator to the ball mill slurry and mix evenly; then adjust the solid content to 80-85% by adding ethanol or ethanol volatilization to obtain a 3D printing ceramic slurry;

[0070] C. Using a DLP printer with a wavelength of 390-420nm to print the 3D printing ceramic slurry and dry it to obtain transparent ceramics.

[0071] Preferably, in step B, the solid content is adjusted to 82.5% by adding ethanol or volatilizing the ethanol to obtain a 3D printing ceramic slurry.

[0072] Preferably, in step C, a DLP printer with a wavelength of 405 nm is used to print...

Embodiment 2

[0104] A process for preparing transparent ceramics by 3D printing, comprising the following steps:

[0105] A. After mixing zirconia, ethylene-vinyl acetate copolymer, hexanediol diacrylate, carboxyl silica microspheres, nano-titanium dioxide, alumina fibers and edge graphene oxide, in ethanol solution dissolved with dispersant Carry out ball milling 1h, obtain ball milling slurry;

[0106] B. Add a photoinitiator to the ball mill slurry and mix evenly; then adjust the solid content to 80% by adding ethanol or ethanol volatilization to obtain a 3D printing ceramic slurry;

[0107] C. Use a DLP printer with a wavelength of 390nm to print the 3D printing ceramic slurry and dry it to obtain transparent ceramics.

[0108] In this embodiment, in step C, a DLP printer with a wavelength of 390nm is used to print the 3D printing ceramic slurry to obtain a transparent ceramic semi-finished product; then immerse the transparent ceramic semi-finished product in absolute ethanol for 3 m...

Embodiment 3

[0127] A process for preparing transparent ceramics by 3D printing, comprising the following steps:

[0128] A. After mixing zirconia, ethylene-vinyl acetate copolymer, hexanediol diacrylate, carboxyl silica microspheres, nano-titanium dioxide, alumina fibers and edge graphene oxide, in ethanol solution dissolved with dispersant Carry out ball milling 2h, obtain ball milling slurry;

[0129] B. Add the photoinitiator to the ball mill slurry and mix evenly; then adjust the solid content to 85% by adding ethanol or ethanol volatilization to obtain 3D printing ceramic slurry;

[0130] C. Using a DLP printer with a wavelength of 420nm, the 3D printing ceramic slurry is printed and dried to obtain transparent ceramics.

[0131] In this embodiment, in step C, a DLP printer with a wavelength of 420nm is used to print the 3D printing ceramic slurry to obtain a transparent ceramic semi-finished product; then immerse the transparent ceramic semi-finished product in absolute ethanol for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com