Preparation method of ZIF-67 nondestructive modified carbon fiber reinforced composite material

A technology of ZIF-67, 1. ZIF-67 is applied in the fields of carbon fiber, fiber treatment, textile and paper making, and can solve problems such as poor wettability, poor bonding performance, and damage to the inherent strength of carbon fiber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The preparation method of the ZIF-67 non-destructively modified carbon fiber reinforced composite material of the present invention is specifically implemented according to the following steps:

[0051] Step 1, using acetone to remove pollutants on the carbon fiber surface;

[0052] Specifically: under oil bath conditions, acetone and a mixture of acetone and water are used in a Soxhlet extractor to treat carbon fibers in a supercritical state;

[0053] When using acetone for treatment, the treatment temperature is 80°C and the treatment time is 2h;

[0054] When using a mixture of acetone and water for treatment, the treatment temperature is 110°C and the treatment time is 30 minutes; the volume ratio of acetone and water in the mixture of acetone and water is 5:1;

[0055] The diameter of carbon fiber is 7-10μm;

[0056] Step 2, immersing the carbon fibers obtained in step 1 in nitric acid for treatment to obtain functionalized carbon fibers;

[0057] The treatment...

Embodiment 2

[0063] The preparation method of the ZIF-67 non-destructively modified carbon fiber reinforced composite material of the present invention is specifically implemented according to the following steps:

[0064] Step 1, using acetone to remove pollutants on the carbon fiber surface;

[0065] Specifically: under oil bath conditions, acetone and a mixture of acetone and water are used in a Soxhlet extractor to treat carbon fibers in a supercritical state;

[0066] When using acetone for treatment, the treatment temperature is 80°C and the treatment time is 2h;

[0067] When using a mixture of acetone and water for treatment, the treatment temperature is 110°C and the treatment time is 30 minutes; the volume ratio of acetone and water in the mixture of acetone and water is 5:1;

[0068] The diameter of carbon fiber is 7-10μm;

[0069] Step 2, immersing the carbon fibers obtained in step 1 in nitric acid for treatment to obtain functionalized carbon fibers;

[0070] The treatment...

Embodiment 3

[0075] The preparation method of the ZIF-67 non-destructively modified carbon fiber reinforced composite material of the present invention is specifically implemented according to the following steps:

[0076] Step 1, using acetone to remove pollutants on the carbon fiber surface;

[0077] Specifically: under oil bath conditions, acetone and a mixture of acetone and water are used in a Soxhlet extractor to treat carbon fibers in a supercritical state;

[0078] When using acetone for treatment, the treatment temperature is 80°C and the treatment time is 2h;

[0079] When using a mixture of acetone and water for treatment, the treatment temperature is 110°C and the treatment time is 30 minutes; the volume ratio of acetone and water in the mixture of acetone and water is 5:1;

[0080] The diameter of carbon fiber is 7-10μm;

[0081] Step 2, immersing the carbon fibers obtained in step 1 in nitric acid for treatment to obtain functionalized carbon fibers;

[0082] Step 3, disso...

PUM

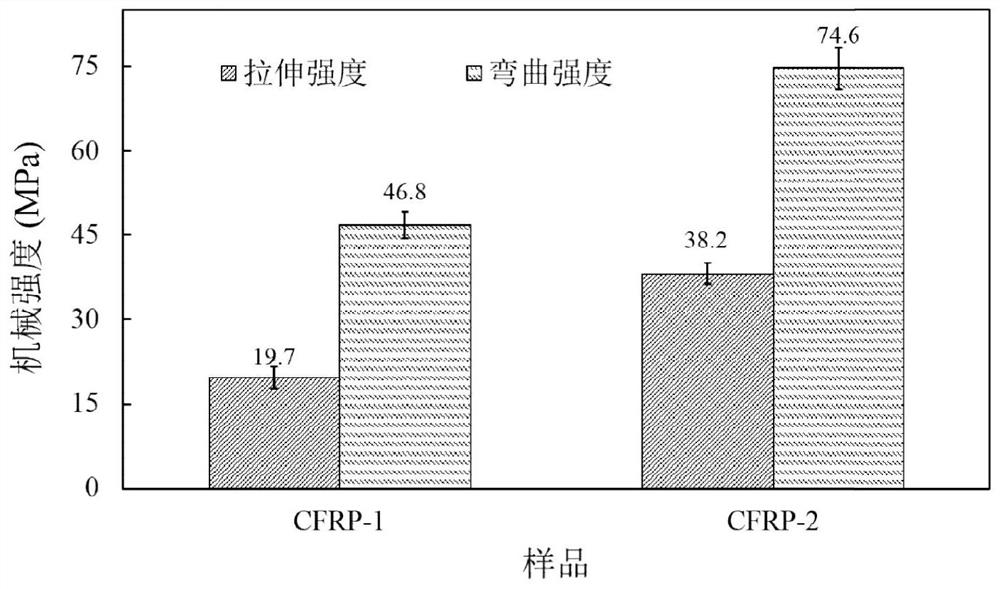

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com