Preparation method of low-thermal-shrinkage polyester polyester reflective film

A technology of reflective film and shrinkage rate, applied in the field of optical reflective film, can solve the problems affecting the taste of backlight modules, heat shrinkage of reflective film, etc., and achieve the effect of excellent reflectivity, low heat shrinkage rate, and reduction of heat shrinkage phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

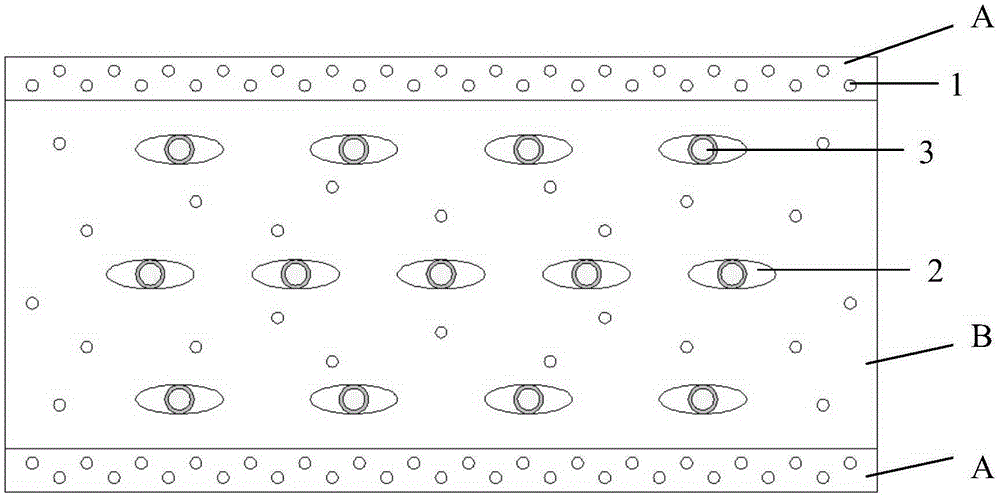

[0053] The preparation method of the polyester reflective film with low heat shrinkage provided by the present invention, wherein the polyester reflective film with low heat shrinkage is an ABA three-layer co-extruded structure, and the ratio of the A layer is 95% PET chips and 5% silicon dioxide particles. The proportion of layer B is 76% PET chips, intrinsic viscosity 0.68dL / g, 10% rutile titanium dioxide (inorganic particles), 10% polymethylpentene (incompatible resin), 2% MAH grafted HDPE (grafted branch rate ≥ 0.5%) (toughening resin), 2% acrylic resin (tackifying resin), and the percentages are percentages by weight. The thickness of layer A accounts for 5% of the total thickness, and the thickness of layer B accounts for 90% of the total thickness. The resulting reflective film had a thickness of 188 μm.

[0054] In the method, in the stretching process: the longitudinal stretching ratio is 3.5, and the longitudinal stretching temperature is 80-95°C; the transverse str...

Embodiment 2

[0057] The preparation method of the polyester reflective film with low heat shrinkage provided by the present invention, wherein the polyester reflective film with low heat shrinkage is an ABA three-layer co-extrusion structure, and the proportion of A layer is 95% PET chips and 5% calcium carbonate. The proportion of layer B is 73% PET chips, intrinsic viscosity 0.68dL / g, 10% rutile titanium dioxide, 12% cycloolefin copolymer, 2% MAH grafted SEBS (grafting rate ≥ 0.5%), 3% unsaturated Resin, said percentage is weight percentage. The thickness of layer A accounts for 5% of the total thickness, and the thickness of layer B accounts for 90% of the total thickness. The resulting reflective film had a thickness of 188 μm.

[0058] In the method, in the stretching process: the longitudinal stretching ratio is 4.2, and the longitudinal stretching temperature is 80-95°C; the transverse stretching ratio is 4.2, and the transverse stretching temperature is 100-125°C. In the process ...

Embodiment 3

[0061] The preparation method of the polyester reflective film with low heat shrinkage provided by the present invention, wherein the polyester reflective film with low heat shrinkage is an ABA three-layer co-extruded structure, and the ratio of the A layer is 90% of PET chips and 10% of silicon dioxide particles. The proportion of layer B is 60% PET chips, intrinsic viscosity 0.68dL / g, 15% anatase titanium dioxide, 15% polypropylene, 5% MAH grafted SEBS (grafting rate ≥ 0.5%), 5% acrylic resin , said percentage is a percentage by weight. The thickness of layer A accounts for 5% of the total thickness, and the thickness of layer B accounts for 90% of the total thickness. The resulting reflective film had a thickness of 188 μm.

[0062] In the method, in the stretching process: the longitudinal stretching ratio is 3.8, and the longitudinal stretching temperature is 80-95°C; the transverse stretching ratio is 3.8, and the transverse stretching temperature is 100-125°C. In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com