Patents

Literature

73results about How to "Excellent devitrification resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tempered glass substrate and method of producing the same

ActiveUS20090197088A1High ion exchange capacityExcellent devitrification resistanceGlass/slag layered productsThin material handlingToughened glassMaterials science

A tempered glass substrate of the present invention is a tempered glass substrate, which has a compression stress layer on a surface thereof, and has a glass composition comprising, in terms of mass %, 40 to 71% of SiO2, 3 to 21% of Al2O3, 0 to 3.5% of Li2O, to 20% of Na2O, and 0 to 15% of K2O.

Owner:NIPPON ELECTRIC GLASS CO LTD

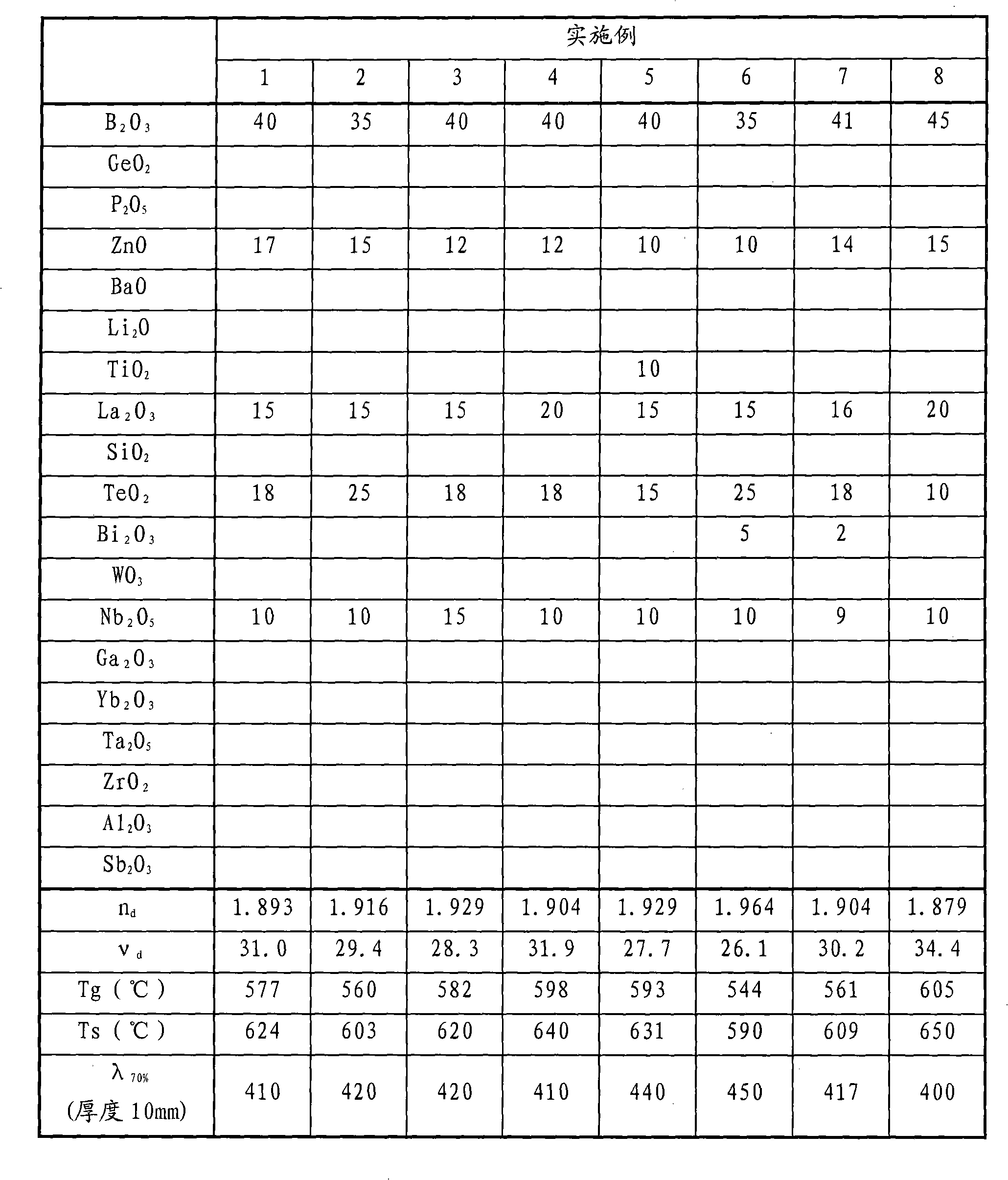

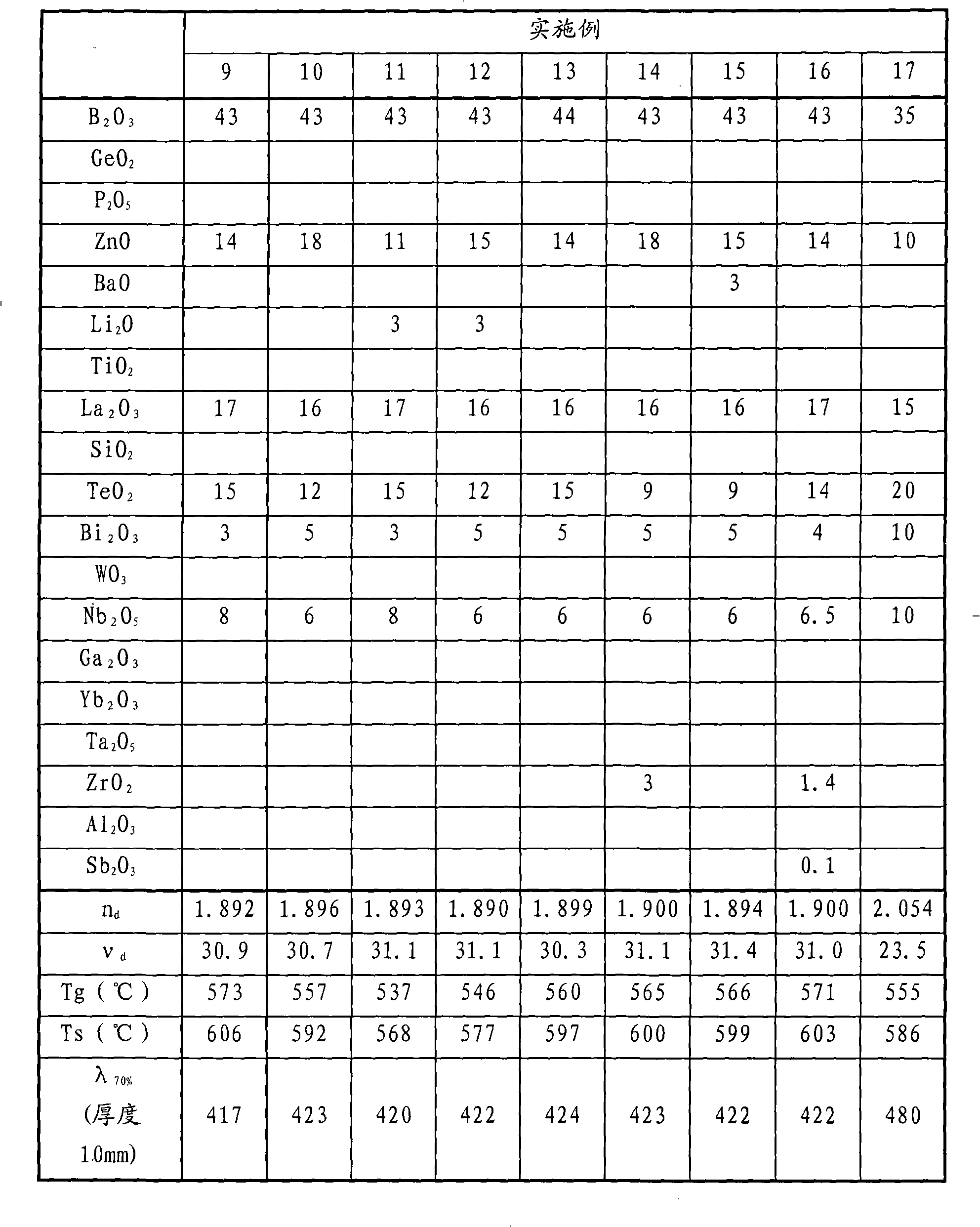

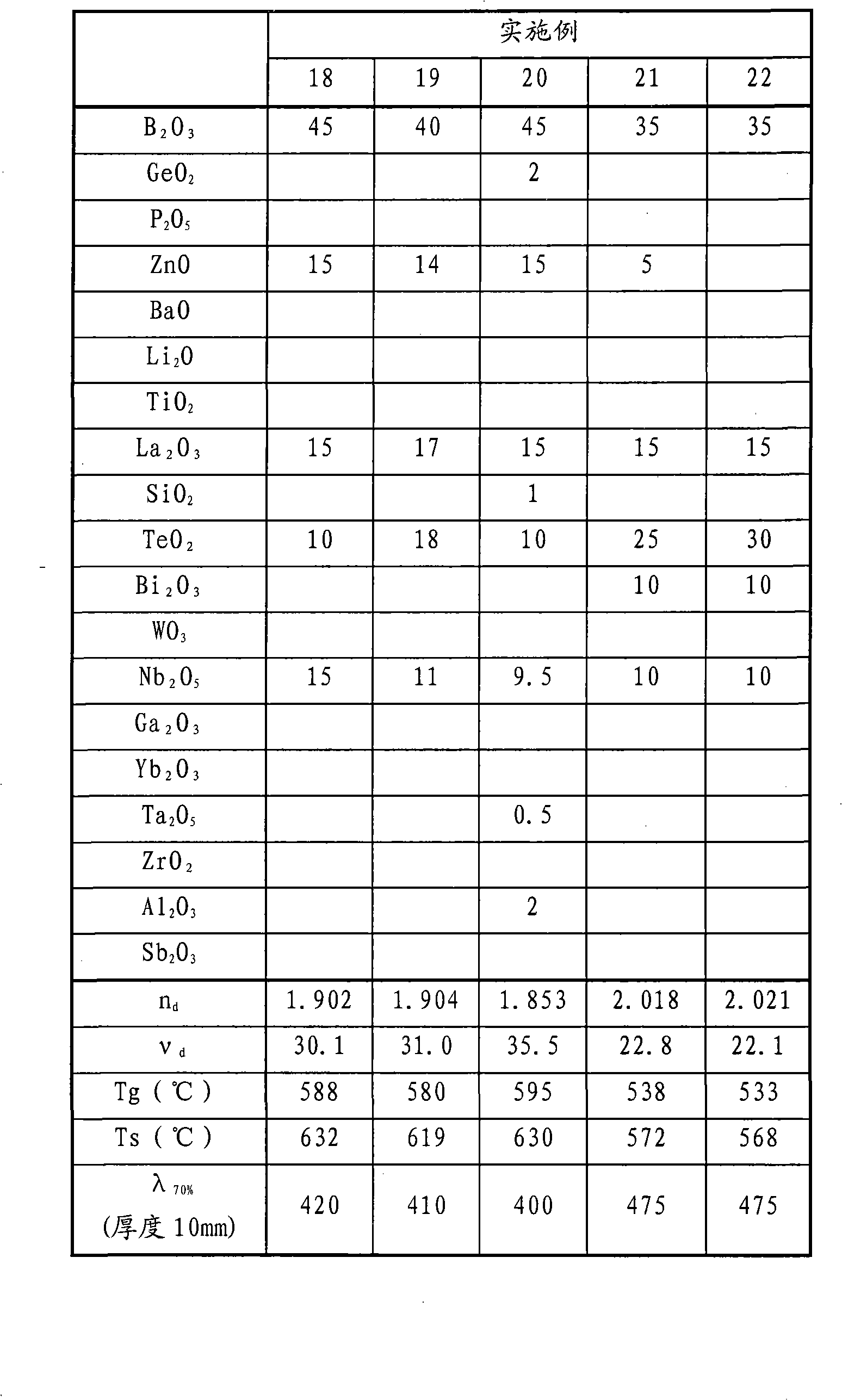

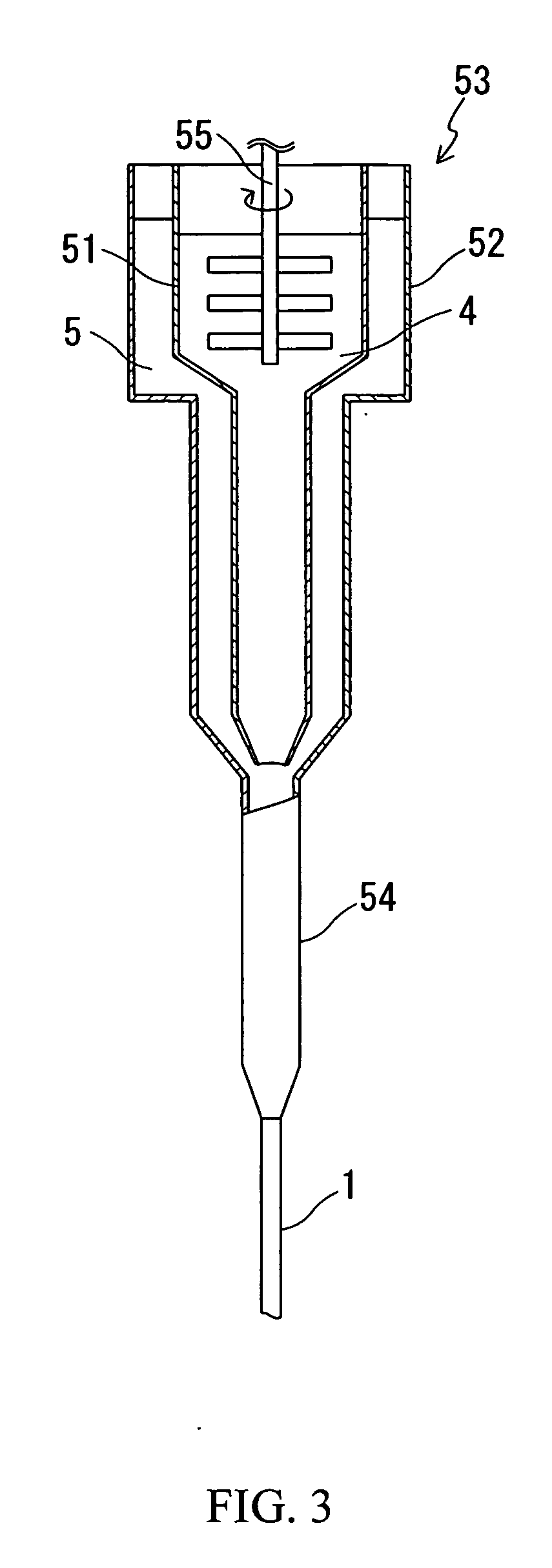

Optical glass

InactiveCN101279816ALower glass transition temperatureExcellent devitrification resistanceGlass pressing apparatusOptical elementsCompression moldingResist

The present invention provides a novel optical glass, which is B2O3-TeO2-La2O3 composed of glass with good resist-losing of transparency at the same time, having optical constant (refractive index, abbe number and so on) required by aspheric lens and so on, having low glass transition temperature, and being suitable for accurate compression molding.The optical glass is characterized in that: mole percentage (Mol%) based on oxide, having 5-60% B2O3, and having 0.2-60% TeO2.In addition, refractive index (nd) being 1.80-2.20, abbe number (Gammad) being 16-40 optical constant, and glass transition temperature (Tg) below 680 EDG C.

Owner:OHARA

Flame-retardant polyester-based fiber for artificial hair

InactiveCN1846019AUsually heat resistanceUsual strengthFlame-proof filament manufactureWigsPolyesterFiber

The present invention provides a common polyester fiber which maintains fiber physical properties such as heat resistance and elongation, and is excellent in flame retardancy, fixation, drip resistance, transparency, and devitrification resistance, and the fiber beauty is controlled Polyester fiber and its artificial hair. It consists of 100 parts by weight of polyester (A) composed of one or more of polyalkylene terephthalate polyesters and copolyesters mainly composed of polyalkylene terephthalate polyesters, and organic cyclic phosphorus compounds and / or a composition obtained by melt-kneading 2 to 20 parts by weight of a phosphate ester amide compound (B), and a composition in which organic microparticles (C) and / or inorganic microparticles (D) are mixed in the composition, by By melt spinning, a flame-retardant polyester-based artificial hair fiber having solved the above-mentioned problems was obtained.

Owner:KANEKA CORP

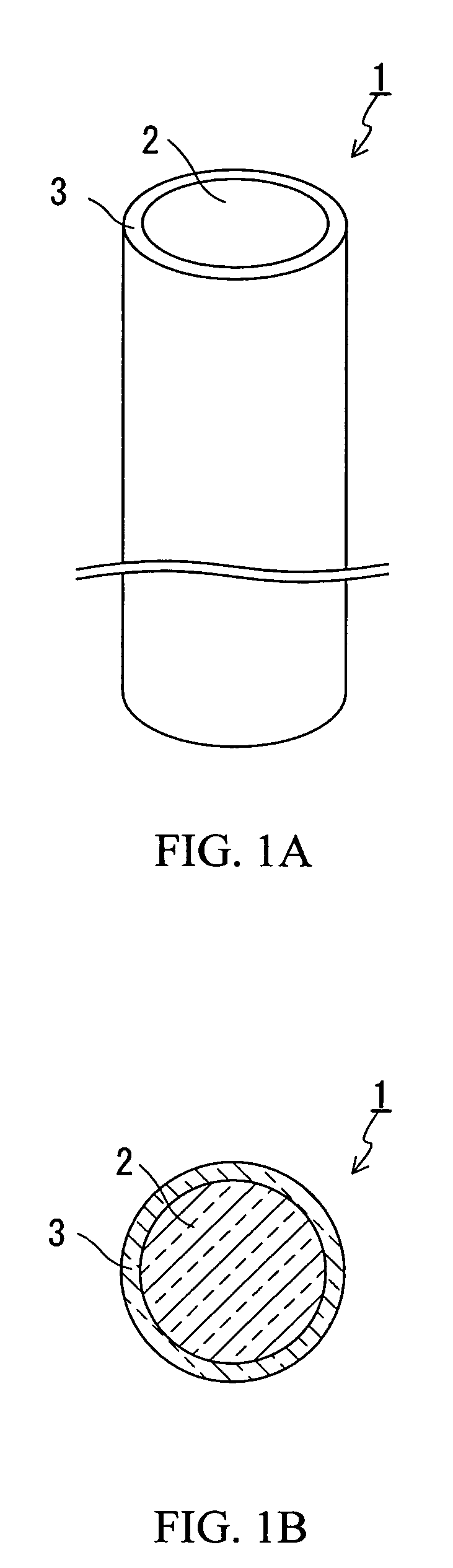

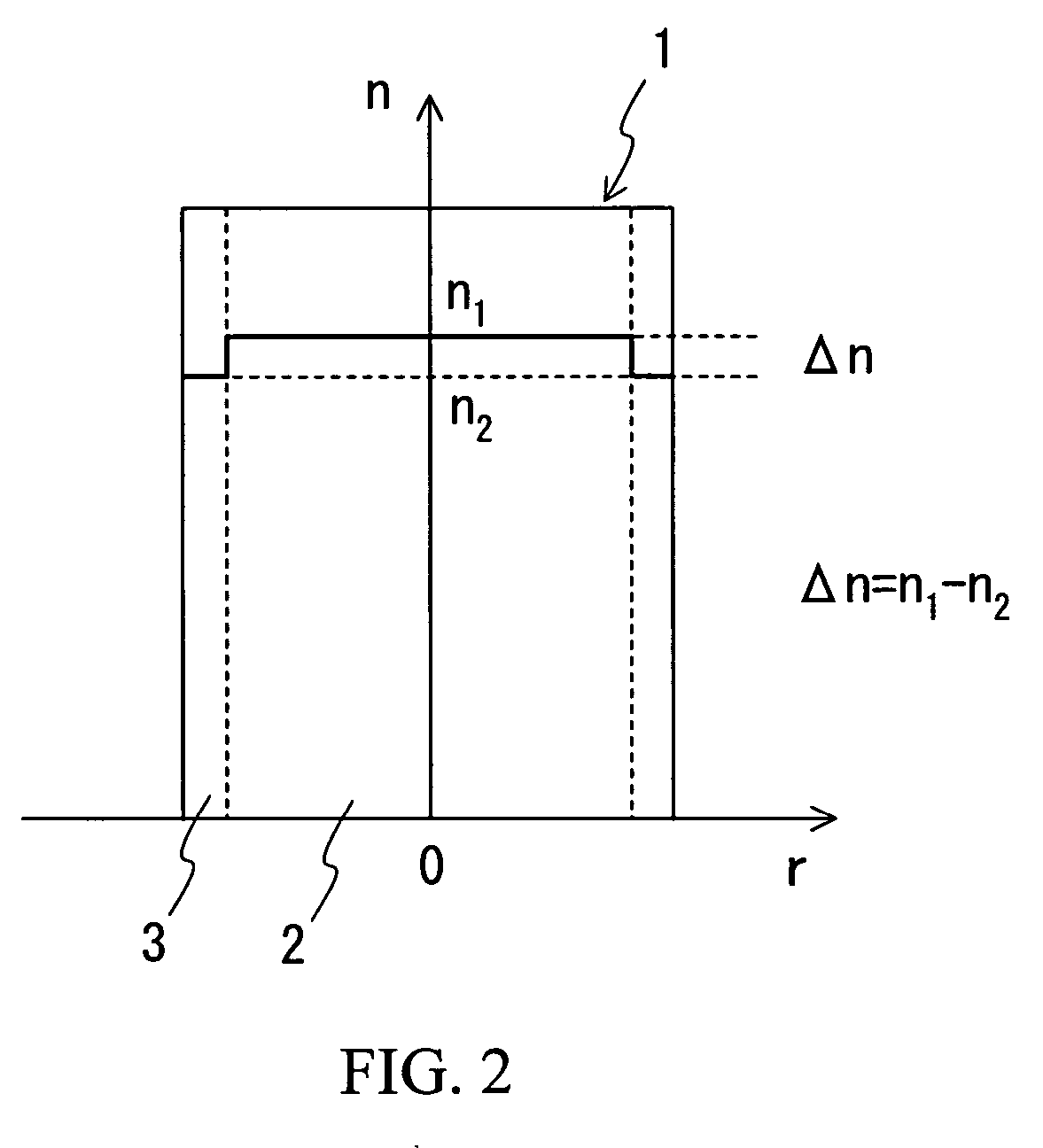

Clad glass composition and mother glass rod for gradient-index rod lens formed using the same, gradient-index rod lens and method of manufacturing the same, rod lens array, and image processor

InactiveUS20060019815A1Excellent devitrification resistanceThin material handlingDevitrificationRefractive index

The present invention provides a clad glass composition that is excellent in devitrification resistance and that prevents the whole mother glass rod from devitrifying by preventing a core glass composition from devitrifying in forming a mother glass rod using a concentric crucible drawing method. The clad glass composition forms a clad of a mother glass rod for a gradient-index rod lens having a core / clad structure. The clad glass composition includes the following components, indicated by mol %: 45 to 65% SiO2; 0.5 to 10% TiO2; 0 to 15% B2O3; 0 to 7% Al2O3; 0.1 to 10% Bi2O3; 0 to 5% Li2O; 5 to 30% Na2O; 0 to 10% K2O; 0 to 15% MgO; 0 to 10% CaO; 0 to 10% SrO; 0.5 to 10% BaO; 0 to 10% Cs2O; 0 to 10% ZnO; 0 to 7% Y2O3; 0 to 7% Nb2O5; 0 to 7% In2O3; 0 to 7% La2O3; 0 to 10% Ta2O5; 0 to 7% ZrO2; and 0 to 1% Sb2O3, where the total of Li2O+Na2O+K2O is in the range of 5 to 35 mol %, the total of MgO+CaO+SrO+BaO is in the range of 2 to 20 mol %, the total of Li2O+Na2O+K2O+MgO+CaO+SrO+BaO is in the range of 7 to 50 mol %, and the total of Cs2O+ZnO+Y2O3+Nb2O5+In2O3+La2O3+ZrO2+Ta2O5 is in the range of 0 to 15 mol %. In the clad glass composition, at least two molar ratios selected from the group consisting of MgO / (MgO+CaO+SrO+BaO); CaO / (MgO+CaO+SrO+BaO); SrO / (MgO+CaO+SrO+BaO); and BaO / (MgO+CaO+SrO+BaO) are at least 0.1. The clad glass composition is substantially free from lead and has a refractive index in the range of 1.56 to 1.68.

Owner:NIPPON SHEET GLASS CO LTD

Optical glass

InactiveCN1389414AExcellent devitrification resistanceLow costOptical elementsRefractive indexPhotochemistry

There is provided an optical glass suitable for precision mold pressing having optical constants of a refractive index (nd) within a range from 1.75 to 1.85 and an Abbe number ( nu d) within a range from 35 to 45, comprising in mass % on oxide basis: having a transition point (Tg) within a range from 500 DEG C to 590 DEG C and a yield point (At) within a range from 530 DEG C to 630 DEG C, and being free from devitrification in a devitrification test conducted under a condition of 950 DEG C / 2 hours.

Owner:OHARA

Optical glass

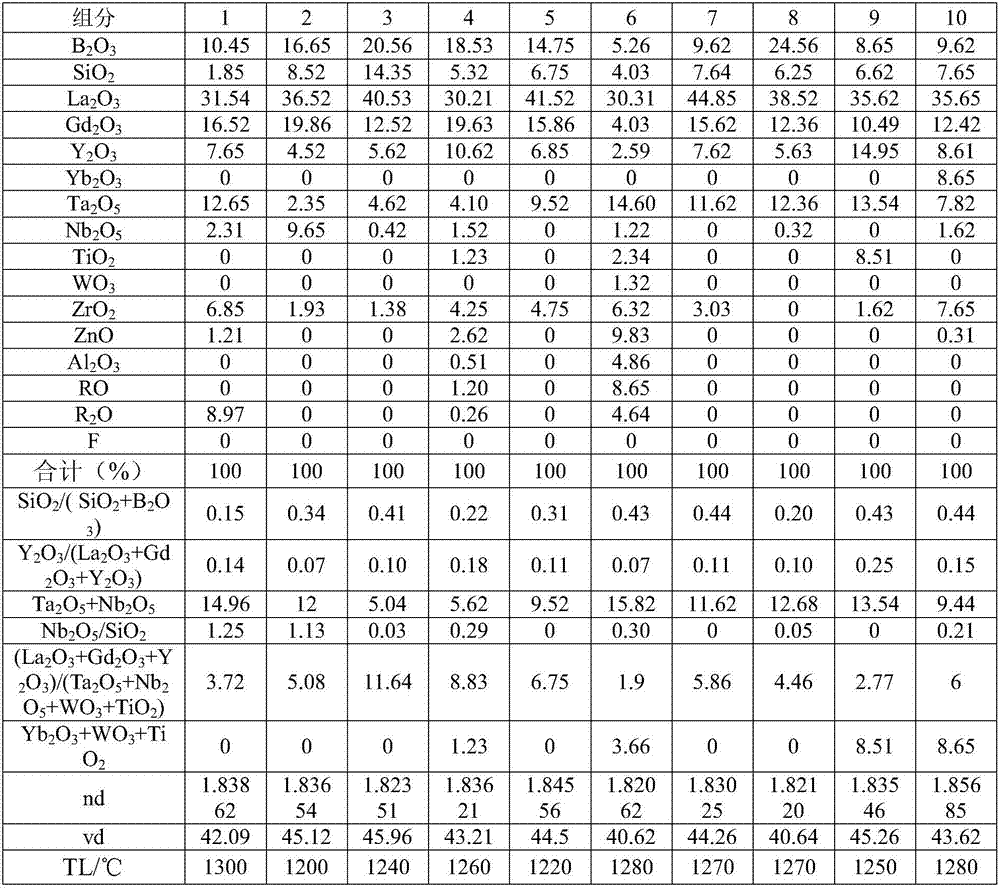

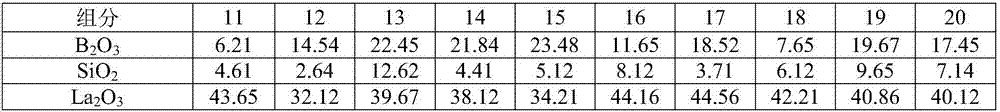

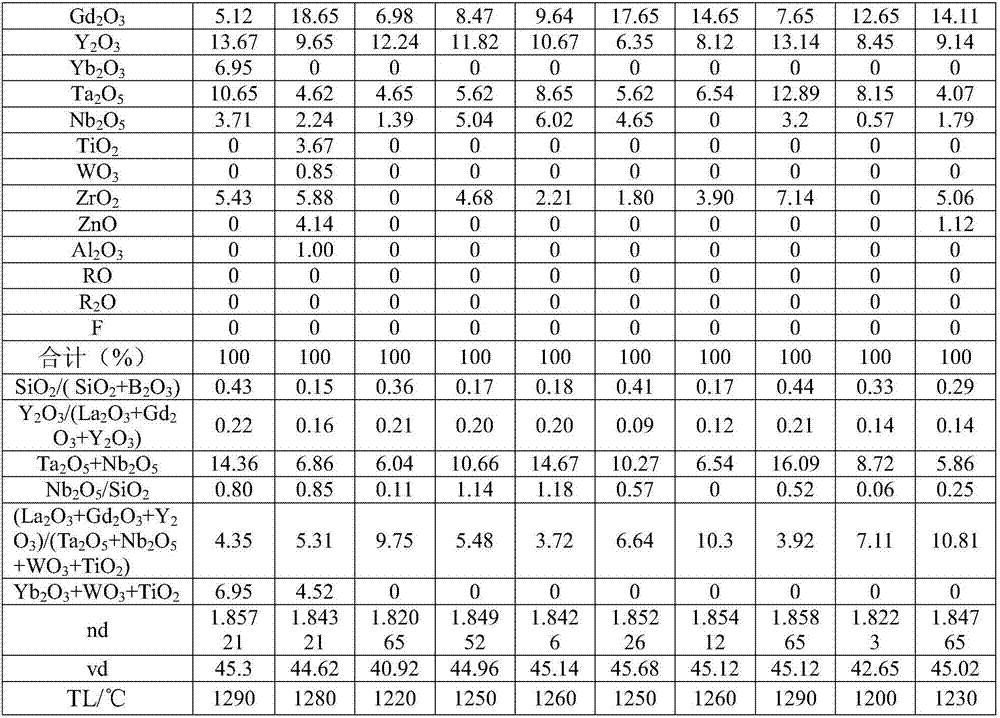

InactiveCN107572774AHigh refractive indexMeet actual needsOptical elementsRare earthRefractive index

The invention provides high-refraction low-dispersion optical glass with excellent impermeability. The optical glass comprises the following components in percentage by weight: 5-25% of B2O3, 1-15% ofSiO2, 30-50% of La2O3, 4-20% of Gd2O3, 2-15% of Y2O3, 0-15% of Ta2O5 and 0-8% of ZrO2, wherein the ratio of Y2O3 to (La2O3+Gd2O3+Y2O3) is 0.03-0.3. An appropriate amount of La2O3, Gd2O3, Y2O3 and other rare-earth oxide components with high-refraction low-dispersion effects is introduced, and the ratio of the various components is optimized, so that the high-refraction low-dispersion optical glasswith excellent impermeability as well as glass prefabricated parts and optical elements formed from the optical glass can be obtained. Moreover, the requirements on novel modern photoelectric products can be met.

Owner:CDGM OPTICAL GLASS

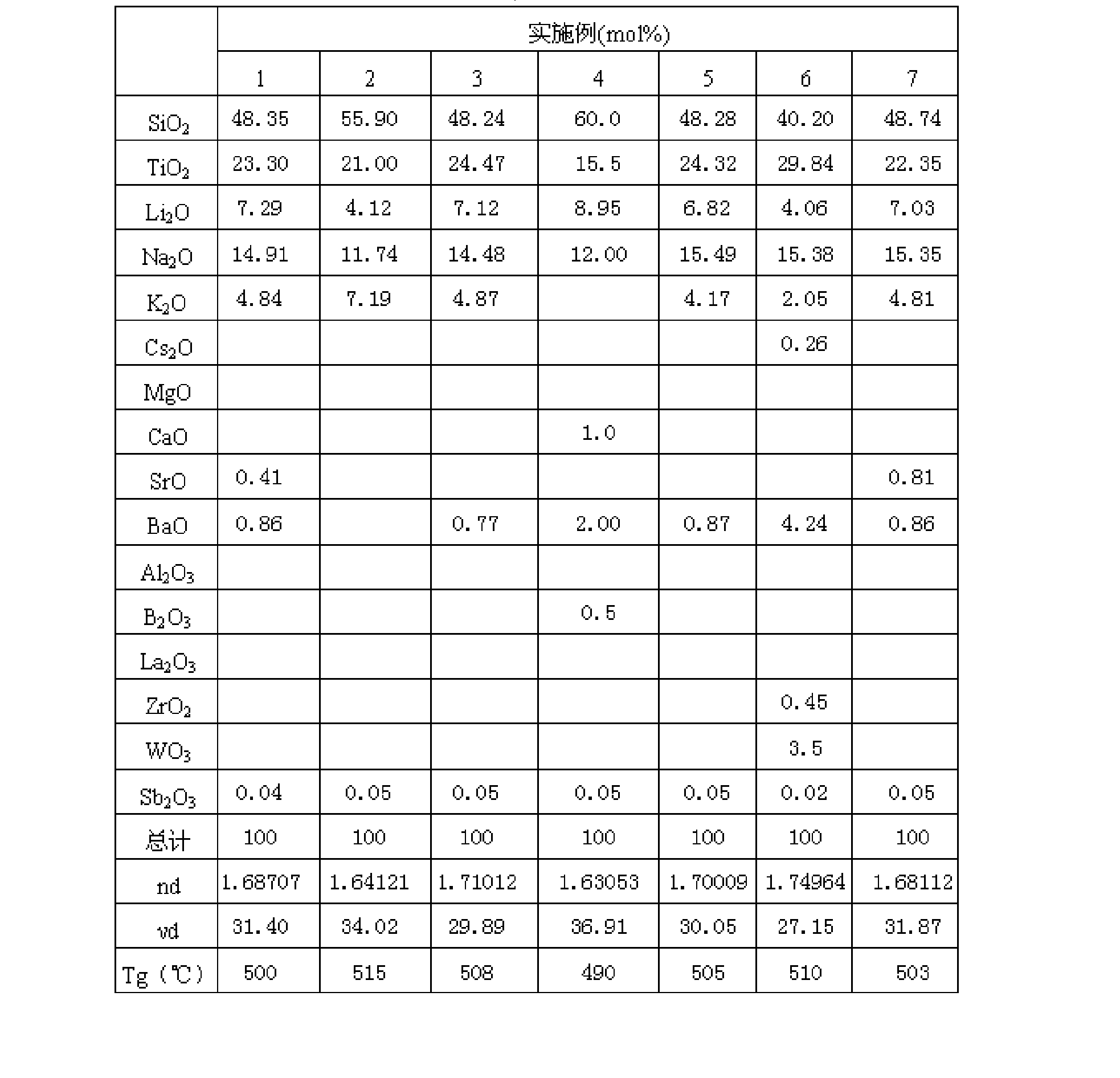

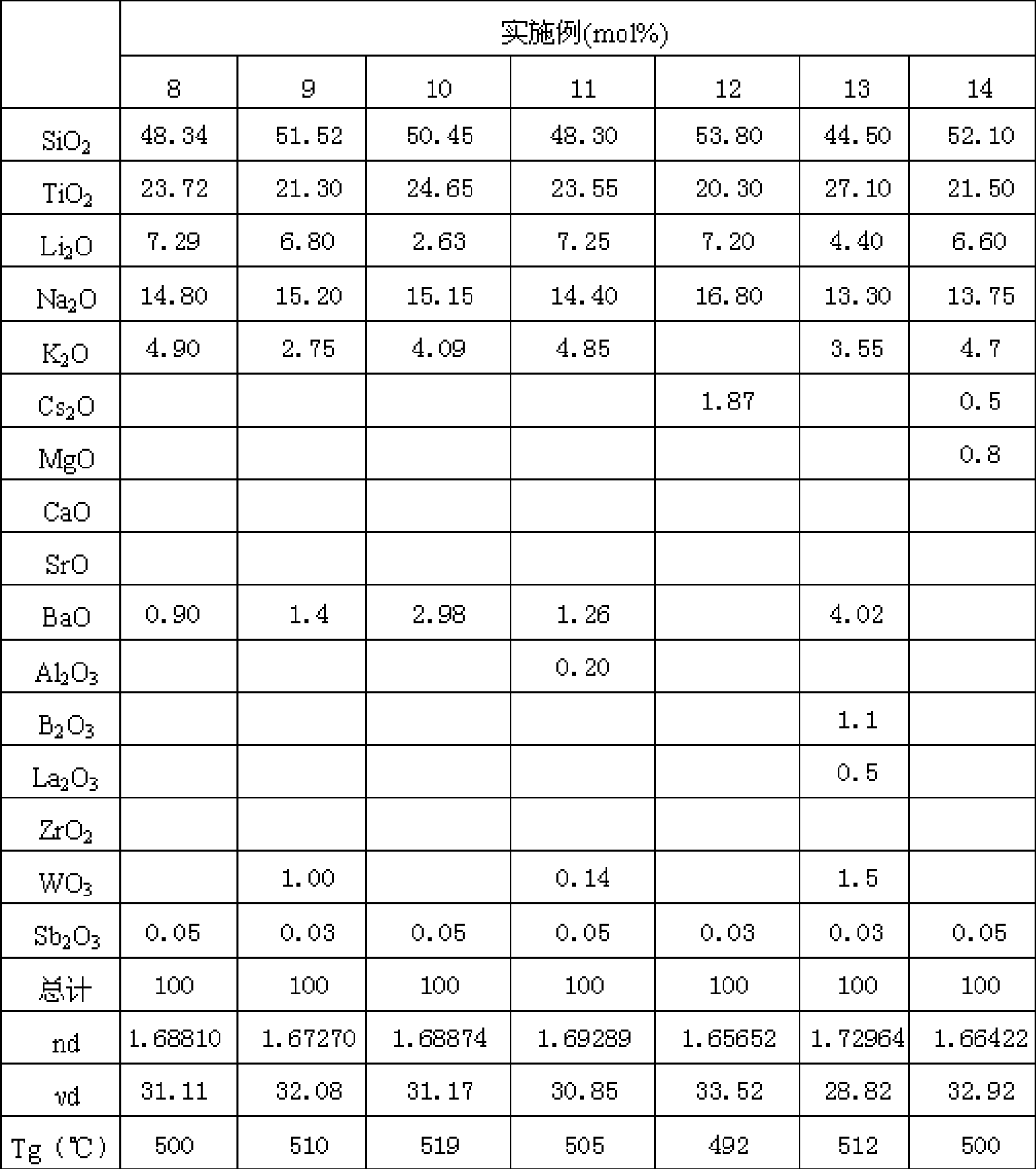

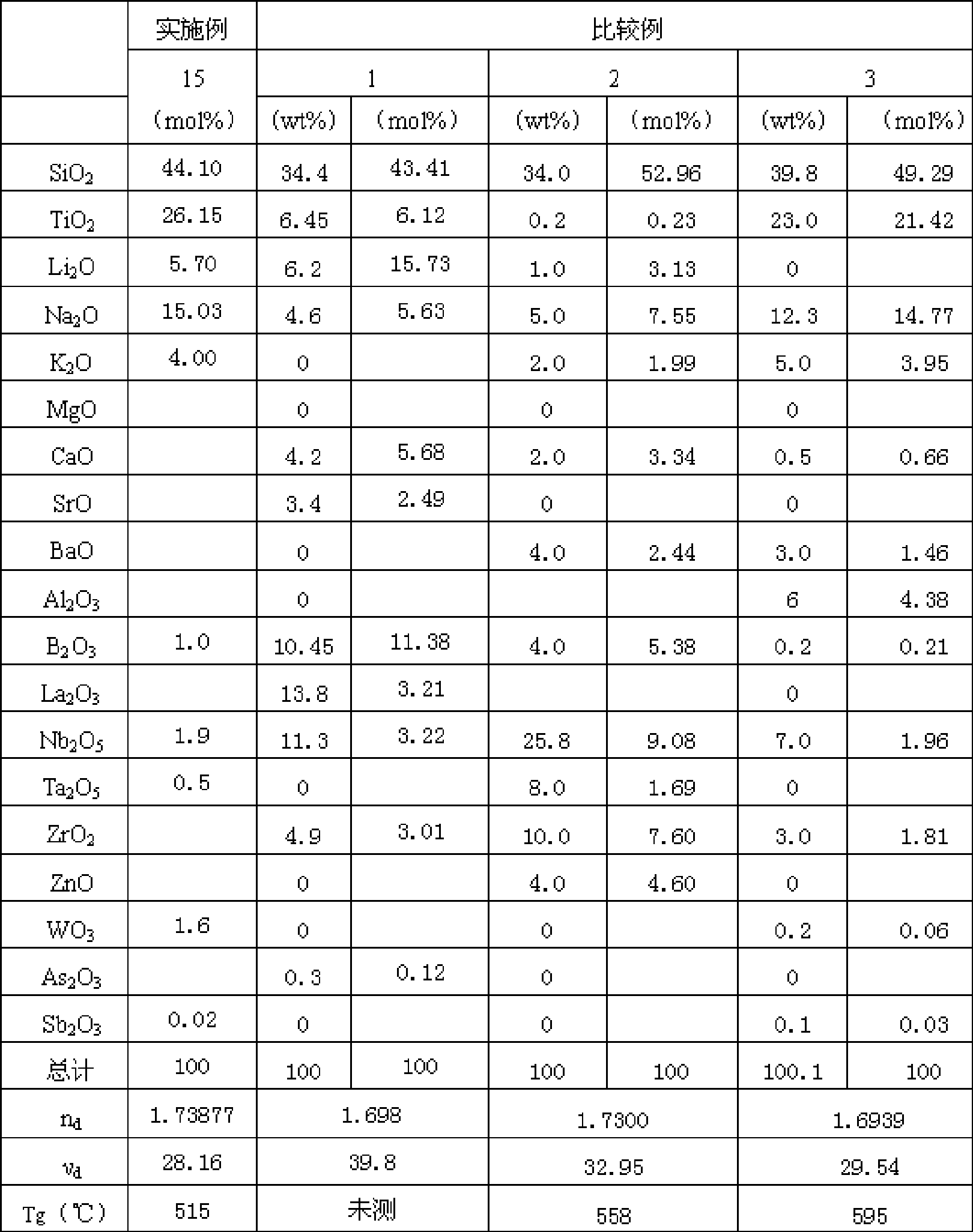

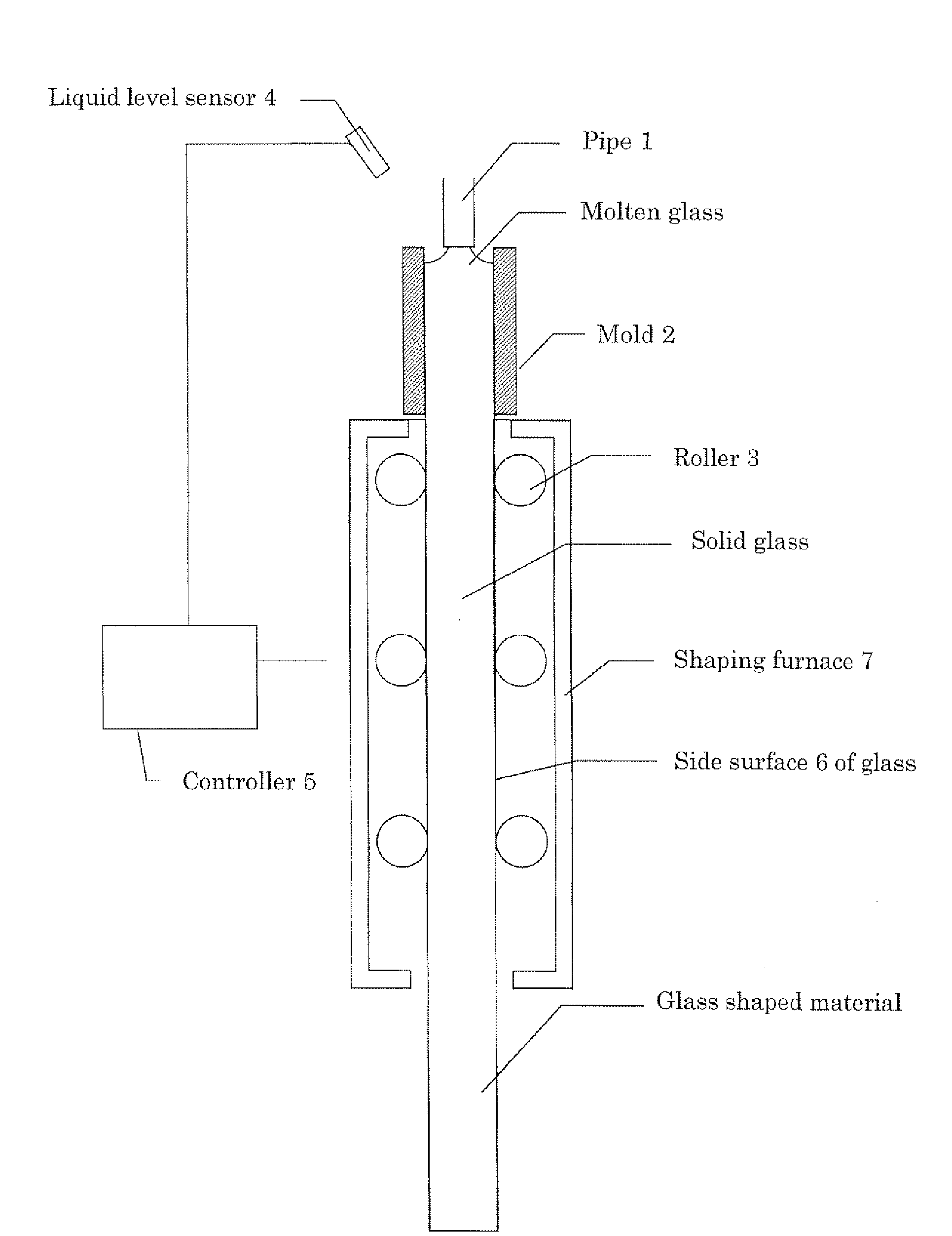

Optical glass for precise compression molding

The invention provides optical glass for precision compression moulding forming, wherein the nd is between 1.63 and 1.75, and the vd is between 27 and 37. The optical glass does not contain compositions with high price such as Nb2O5 and Ta2O5, and the Tg is less than 520 DEG C. The optical glass for precision compression moulding forming comprises the following compositions by molar percentage: 40 to 60 percent of SiO2, 15 to 30 percent of TiO2, 10.5 to 30 percent of Li2O+Na2O+K2O+Cs2O, 0 to 8 percent of MgO+CaO+SrO+BaO, 0 to 2 percent of Ta2O5+ WO3+Nb3O5, 0 to 1 percent of Al2O3, 0 to 1 percent of ZrO2, 0 to 5 percnet of B2O3, 0 to 2 percent of La2O3, and 0 to 0.1 percent of clarifying agent. The optical glass is suitable for precise compression molding forming, has superior devitrification resistance, good fusing performance, forming performance and processability, and crystallization stability for realizing continuous fusing. An optical element made of the optical glass is suitable for the technical fields such as imaging system, medical technology, digital projection, photoetching technique and wafer / chip.

Owner:CDGM OPTICAL GLASS

Optical glass, glass molded body, optical device and their production methods

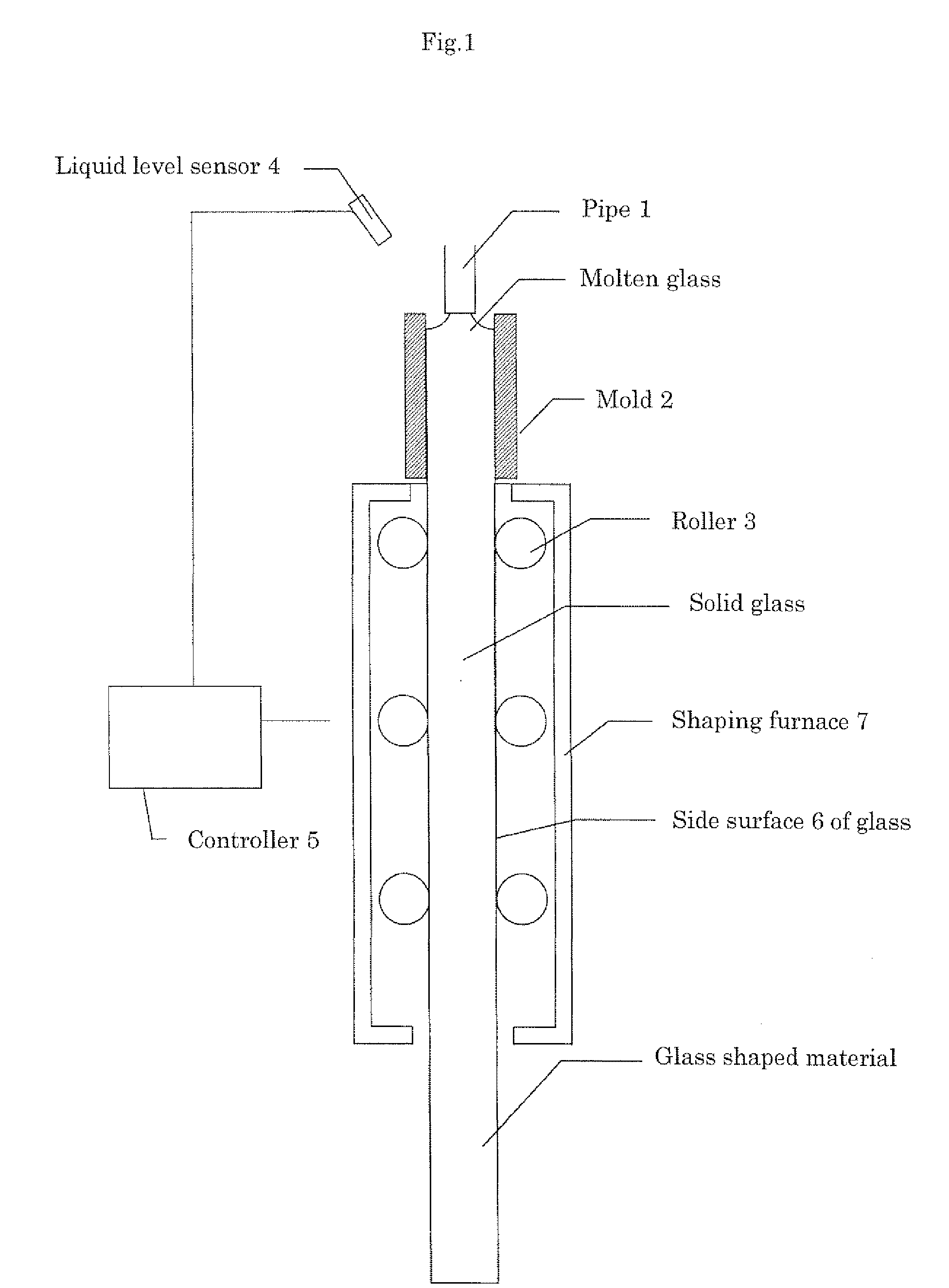

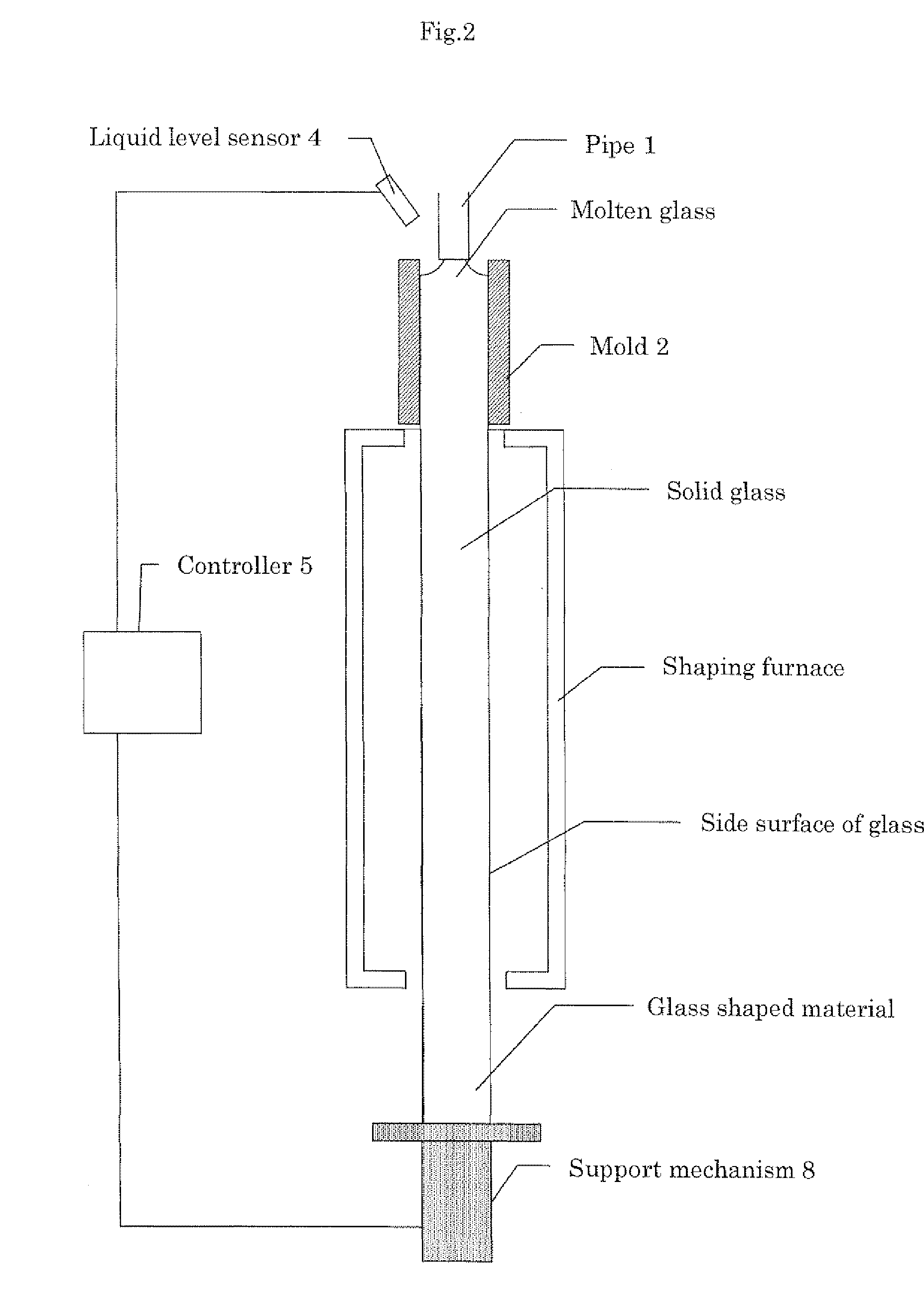

ActiveUS20090176641A1Excellent devitrification resistanceGlass drawing apparatusGlass forming apparatusGlass formingRefractive index

An optical class comprising, by mass %, 12 to 30% of total of B2O3 and SiO2, 55 to 80% of total of La2O3, Gd2O3, Y2O3, ZrO2, Nb2O5 and WO3, 2 to 10% of ZrO2, 0 to 15% of Nb2O5, 0 to 15% of ZnO and 0% or more but less than 13% of Ta2O5, wherein the ratio of the content of Ta2O5 to the total content of La2O3, Gd2O3, Y2O3, Yb2O3, ZrO2, Nb2O5 and WO3 is 0.23 or less, the ratio of the total content of La2O3, Gd2O3, Y2O3 and Yb2O3 to the total content of B2O3 and SiO2 is from 2 to 4, the optical glass having a refractive index nd of 1.86 or more and an Abbe's number νd of 38 or more, and a rod shaped glass shaped material and an optical element formed of the above optical glass each.

Owner:HOYA CORP

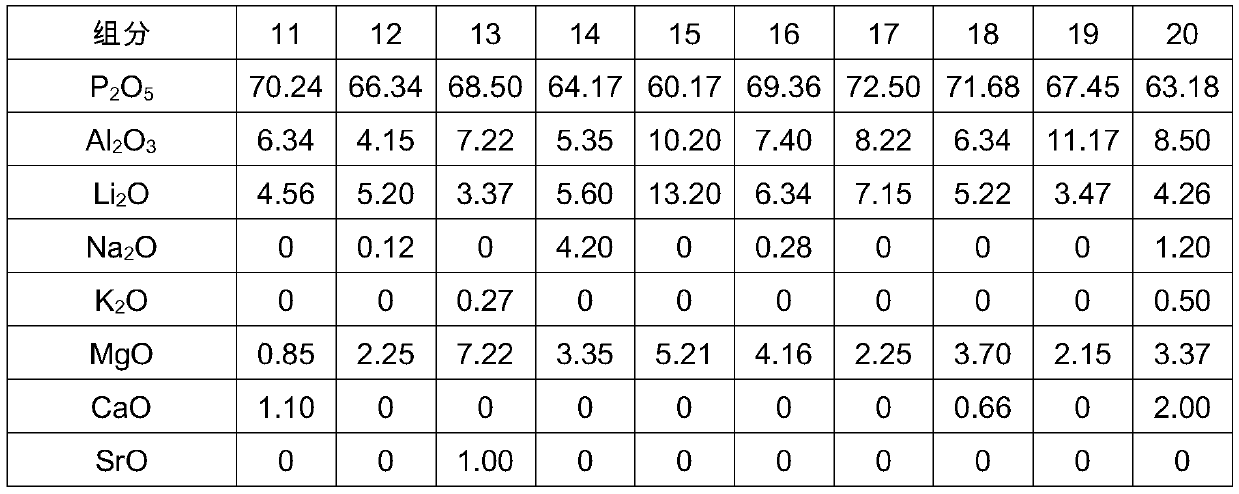

Glass, glass product and manufacturing method of glass product

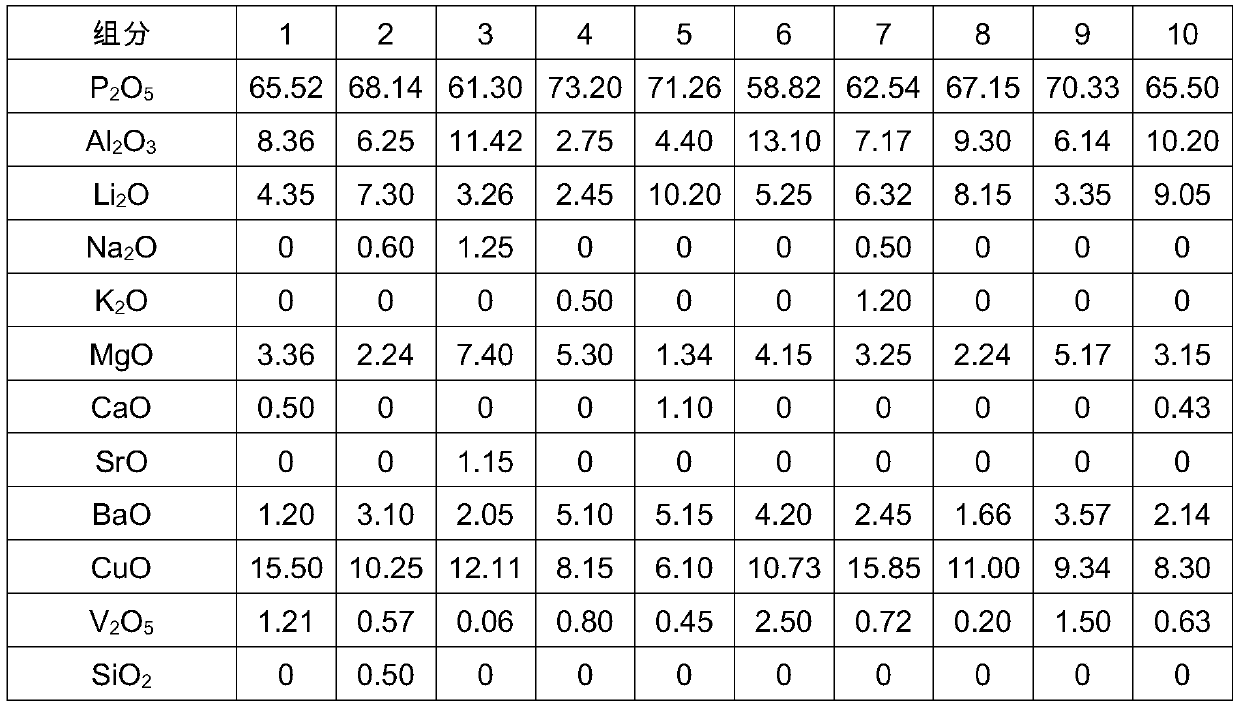

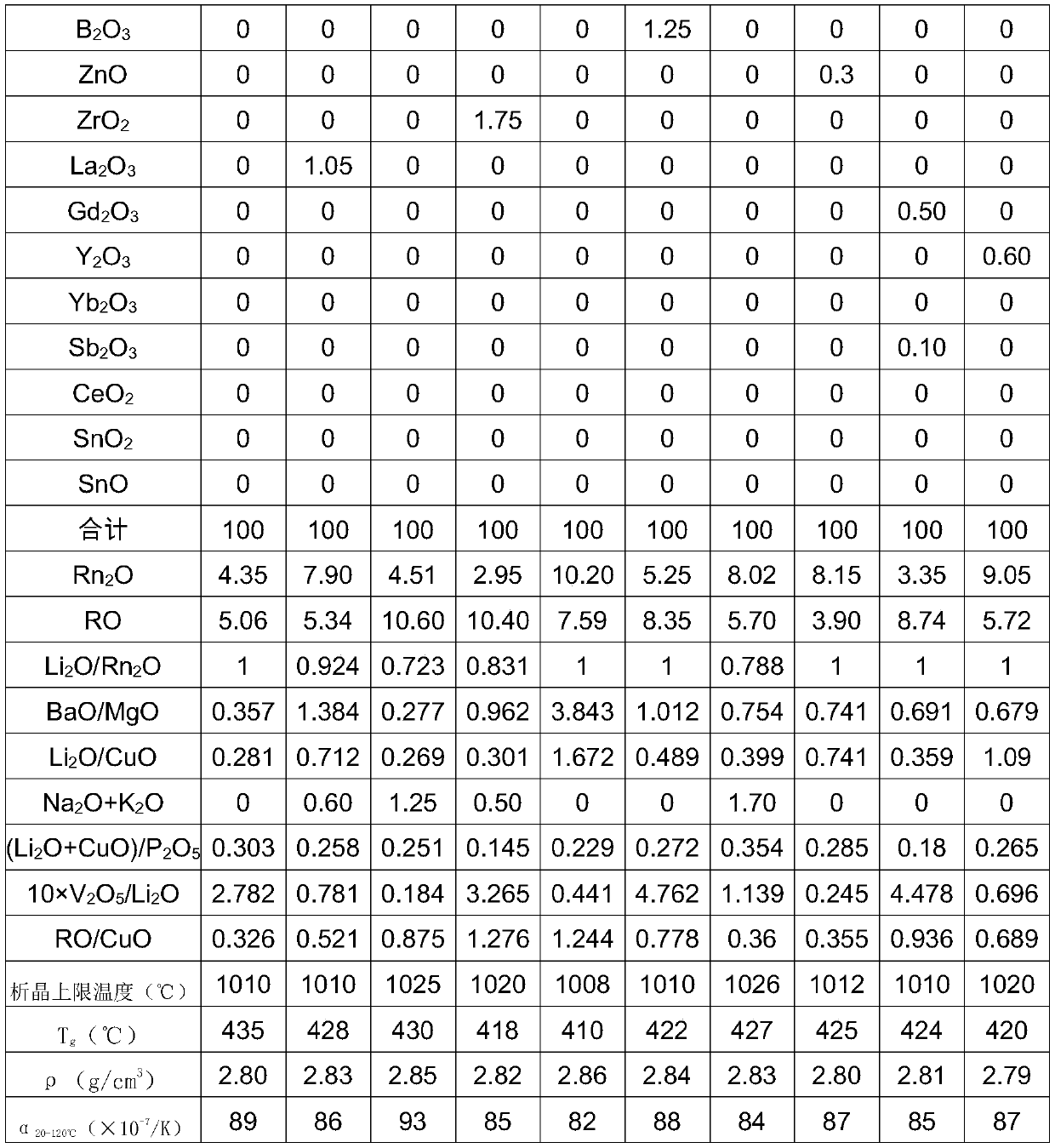

ActiveCN110255886AHigh Cu contentExcellent devitrification resistanceOptical elementsDevitrificationMetallurgy

The invention provides glass. The components of the glass comprise, in percent by weight: 55-75% of P2O5, 2-15% of Al2O3, 5-20% of CuO, 1-25% of Rn2O, 0-25% of RO, and 0.02-3% of V2O5, wherein Li2O / Rn2O is 0.3-1.0, the Rn2O is a total content of Li2O, Na2O and K2O, and the RO is a total content of MgO, CaO, SrO and BaO. By a reasonable component design, the obtained glass has excellent devitrification resistance in the case of having a high Cu content. At the same time, the glass is suitable for chemical strengthening, and a glass product obtained after chemical strengthening has excellent bending strength.

Owner:CDGM OPTICAL GLASS

Precisely pressed optical glass

ActiveCN1772671AExcellent devitrification resistanceImprove transmittanceDevitrificationRefractive index

The present invention provides one kind of precisely pressed optical glass. The optical glass consists of SiO2 8-30 wt%, B2O3 6-25 wt%, ZnO 8-30 wt%, Nb2O5 0.5-19 wt%, BaO 5-26 wt%, Li2O 0.5-7 wt% and ZrO2 1-6 wt% chemically. The optical glass of the present invention has refractivity of 1.65-1.74, Abbe number of 36-45, conversion temperature lower than 500 deg.c, high chemical stability, low liquid phase temperature, high devitrification resistance, high light permeability and low specific weight, and is especially suitable for precise mold pressing to form aspherical lens, spherical lens and other optical elements.

Owner:CDGM OPTICAL GLASS

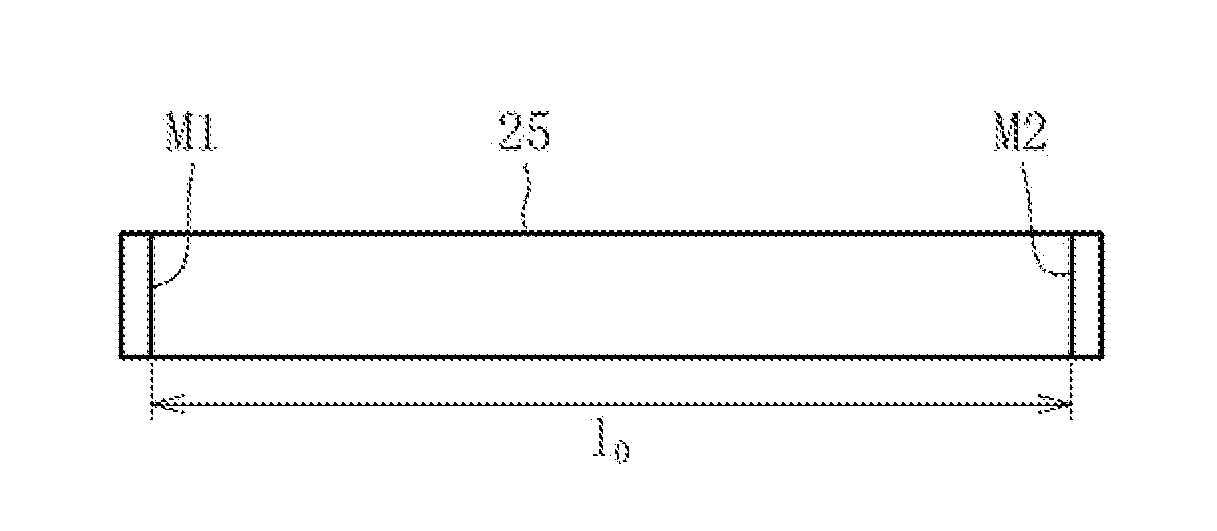

Glass substrate for flat panel display and manufacturing method thereof

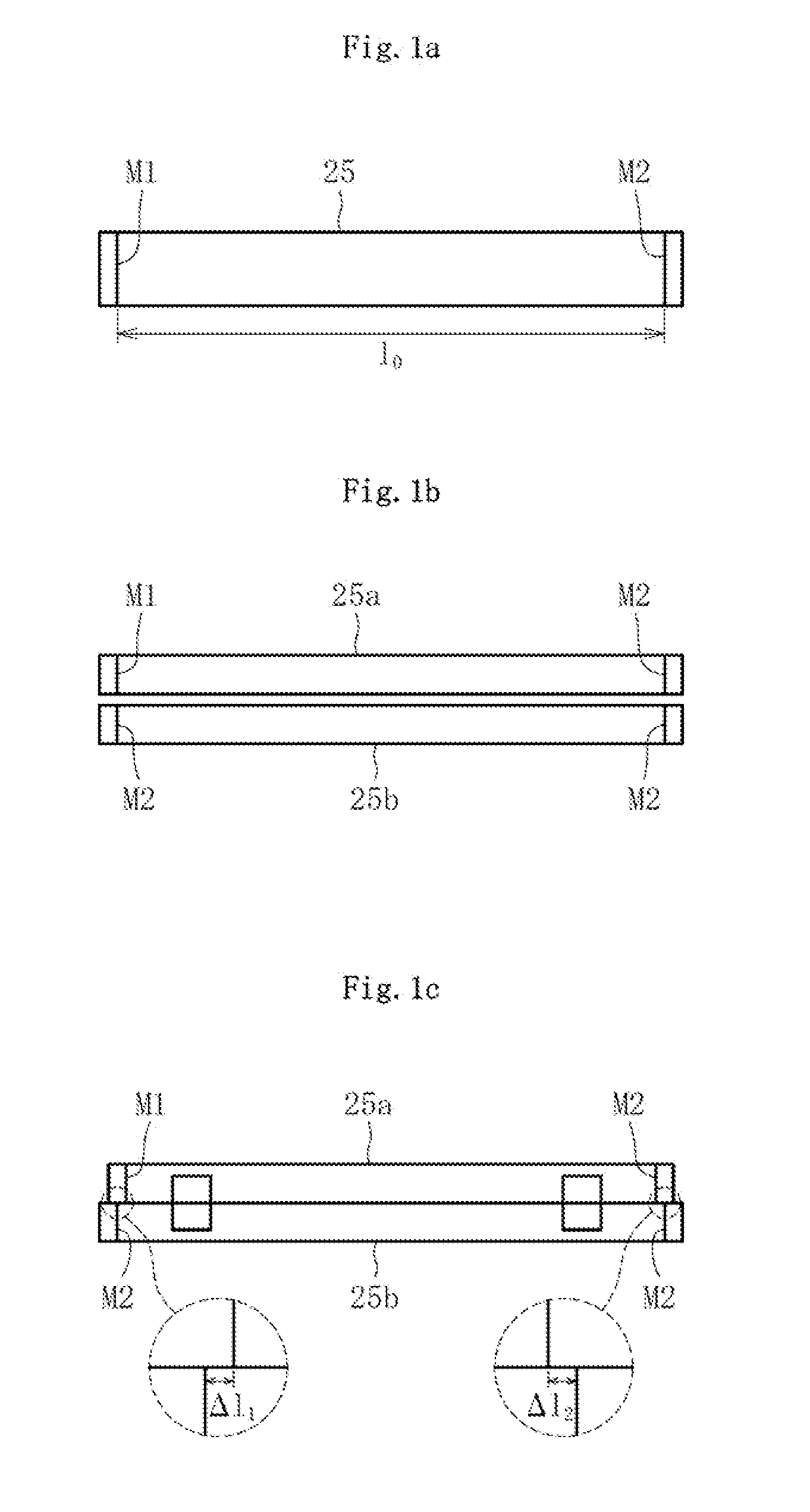

ActiveUS20130065748A1High Tg and strain pointExcellent devitrification resistanceGlass drawing apparatusGlass forming apparatusDevitrificationShrinkage rate

A flat panel display glass substrate includes a glass comprising, in mol %, 55-80% SiO2, 3-20% Al2O3, 3-15% B2O3, and 3-25% RO (the total amount of MgO, CaO, SrO, and BaO). The contents in mol % of SiO2, Al2O3, and B2O3 satisfy a relationship (SiO2+Al2O3) / (B2O3)=7.5-17. The strain point of the glass is 665° C. or more. The devitrification temperature of the glass is 1250° C. or less. The substrate has a heat shrinkage rate of 75 ppm or less. The rate of heat shrinkage is calculated from the amount of shrinkage of the substrate measured after a heat treatment which is performed at a rising and falling temperature rate of 10° C. / min and at 550° C. for 2 hours by the rate of heat shrinkage (ppm)={the amount of shrinkage of the substrate after the heat treatment / the length of the substrate before the heat treatment}×106.

Owner:AVANSTRATE INC

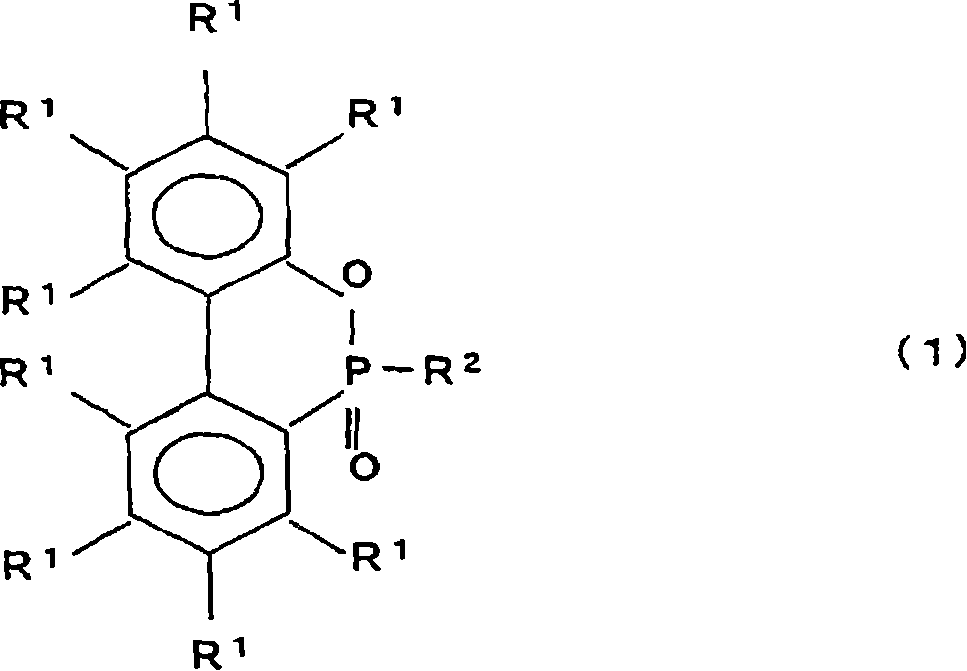

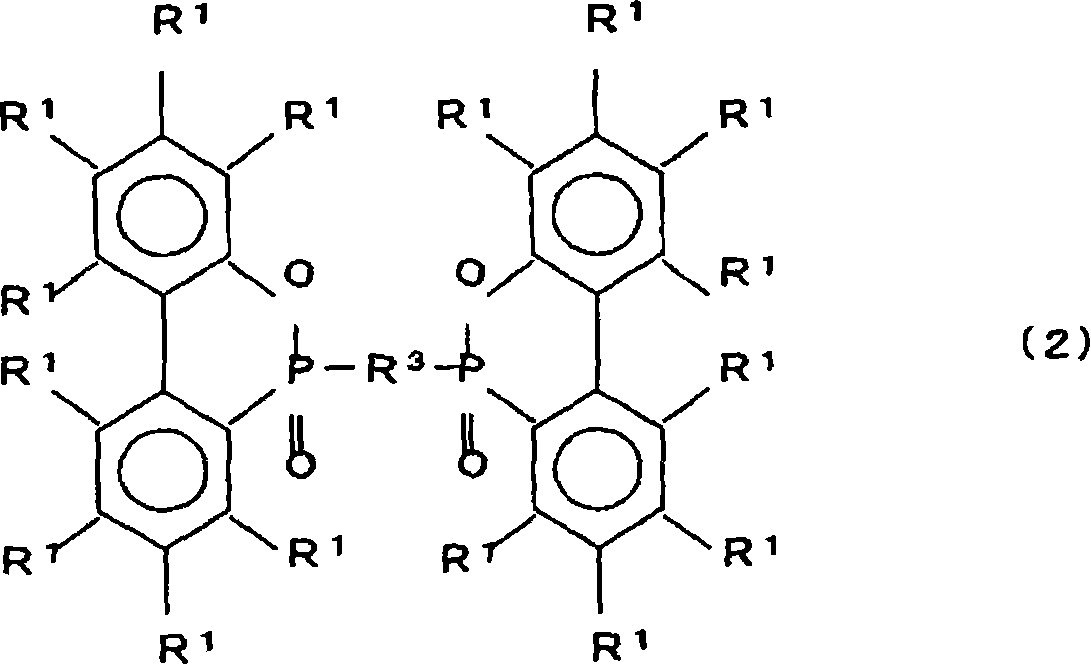

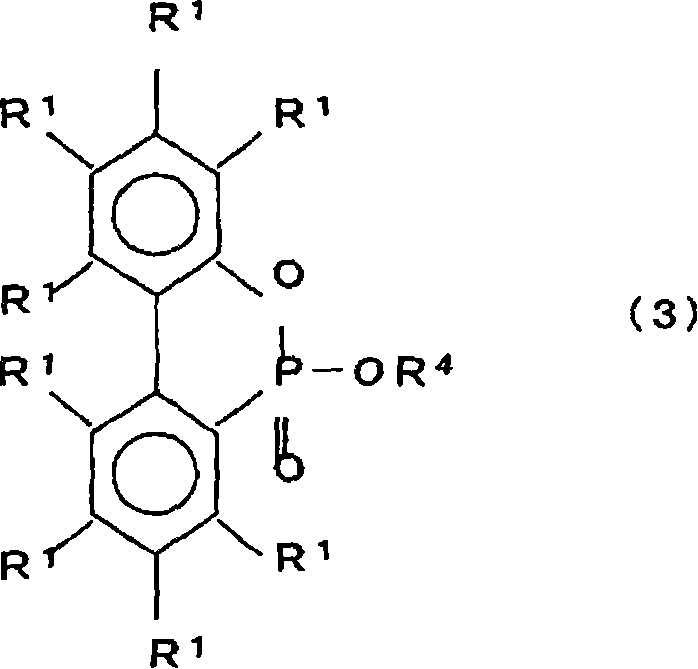

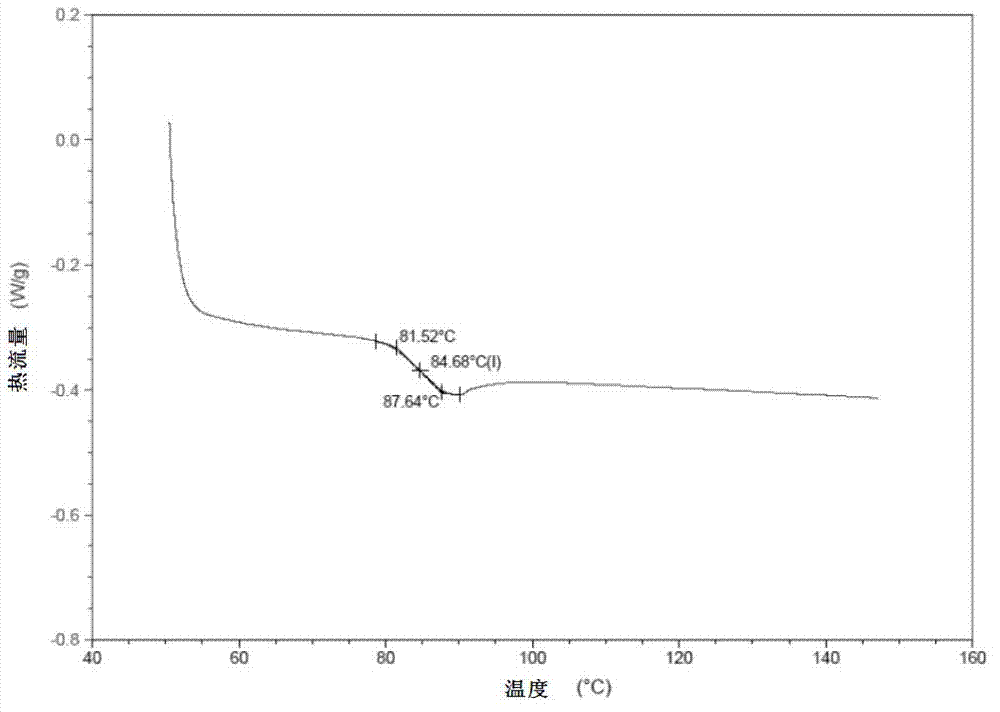

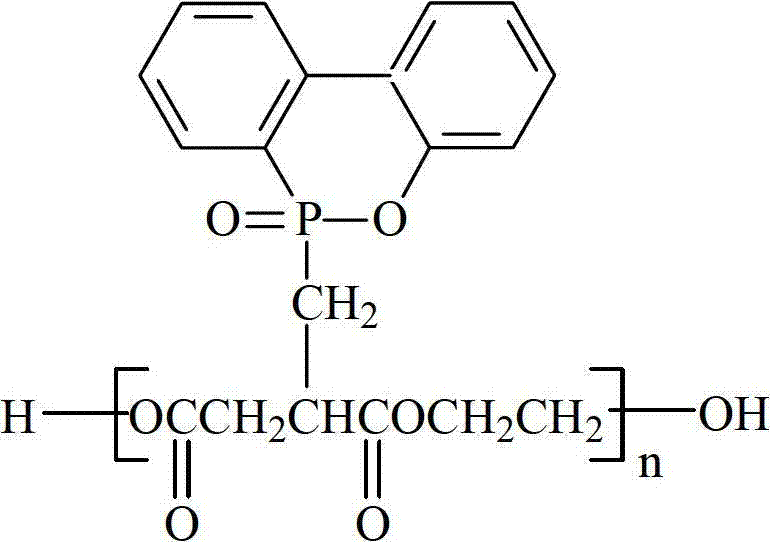

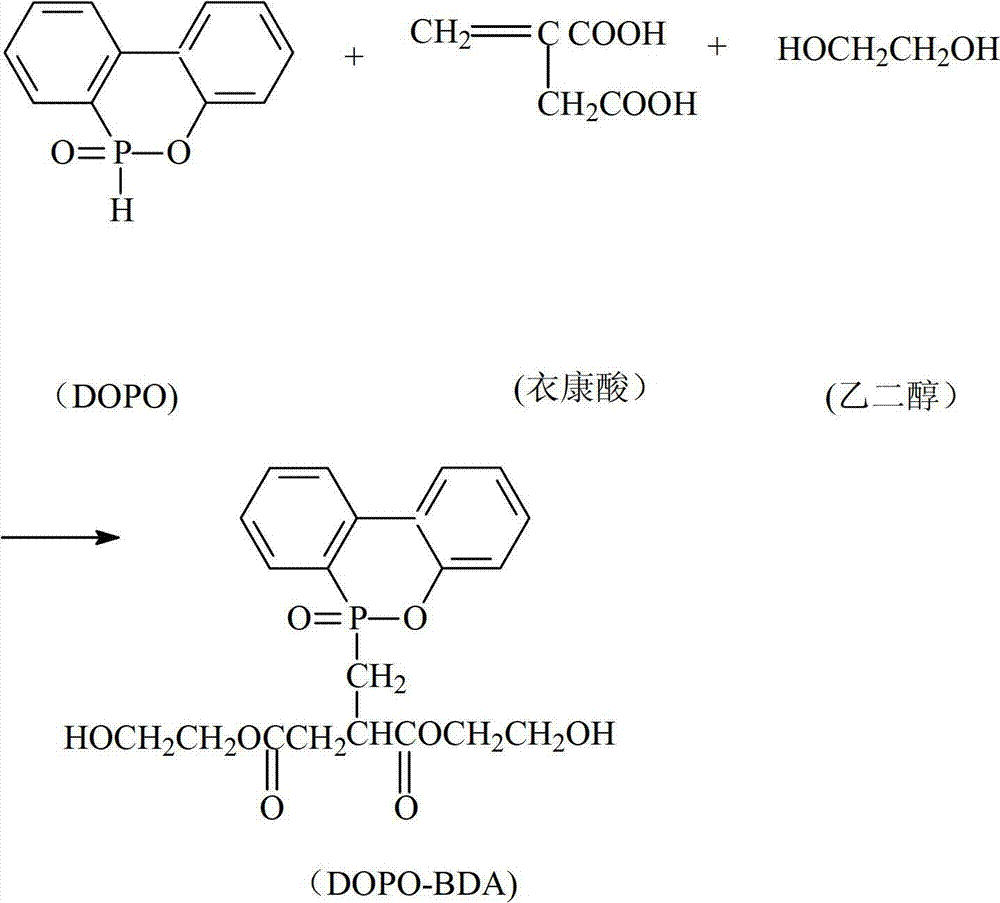

Additive type phosphorus phenanthrene oxa-flame retardant and preparation method thereof

InactiveCN102888085ARaise the processing temperatureImprove flame retardant performanceGroup 5/15 element organic compoundsFiberPolyester

The invention discloses an additive type phosphorus phenanthrene oxa-flame retardant and a preparation method thereof. The chemical name of the additive type phosphorus phenanthrene oxa-flame retardant is poly-(10-taconic acid gylcol ester-9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide). The preparation method comprises the following steps of: firstly carrying out a reaction on DOPO, itaconic acid and ethylene glycol to generate a monomer midbody 10-taconic acid gylcol ester-9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide; and polymerizing the reacting midbody at high temperature under the function of catalyst to obtain a target product. The additive type phosphorus phenanthrene oxa-flame retardant provided by the invention is applicable to various high molecular materials with higher processing temperature such as linear polyester, fiber, polyamide, polyurethane and the like; and the preparation method is free from halogen, environment-friendly, simple in operation process, easy to control, high in yield, good in product repeatability, and less in impurity, wherein the product yield can be 98.5%-99.9%, and the production cost can be reduced.

Owner:SHOUGUANG WEIDONG CHEM

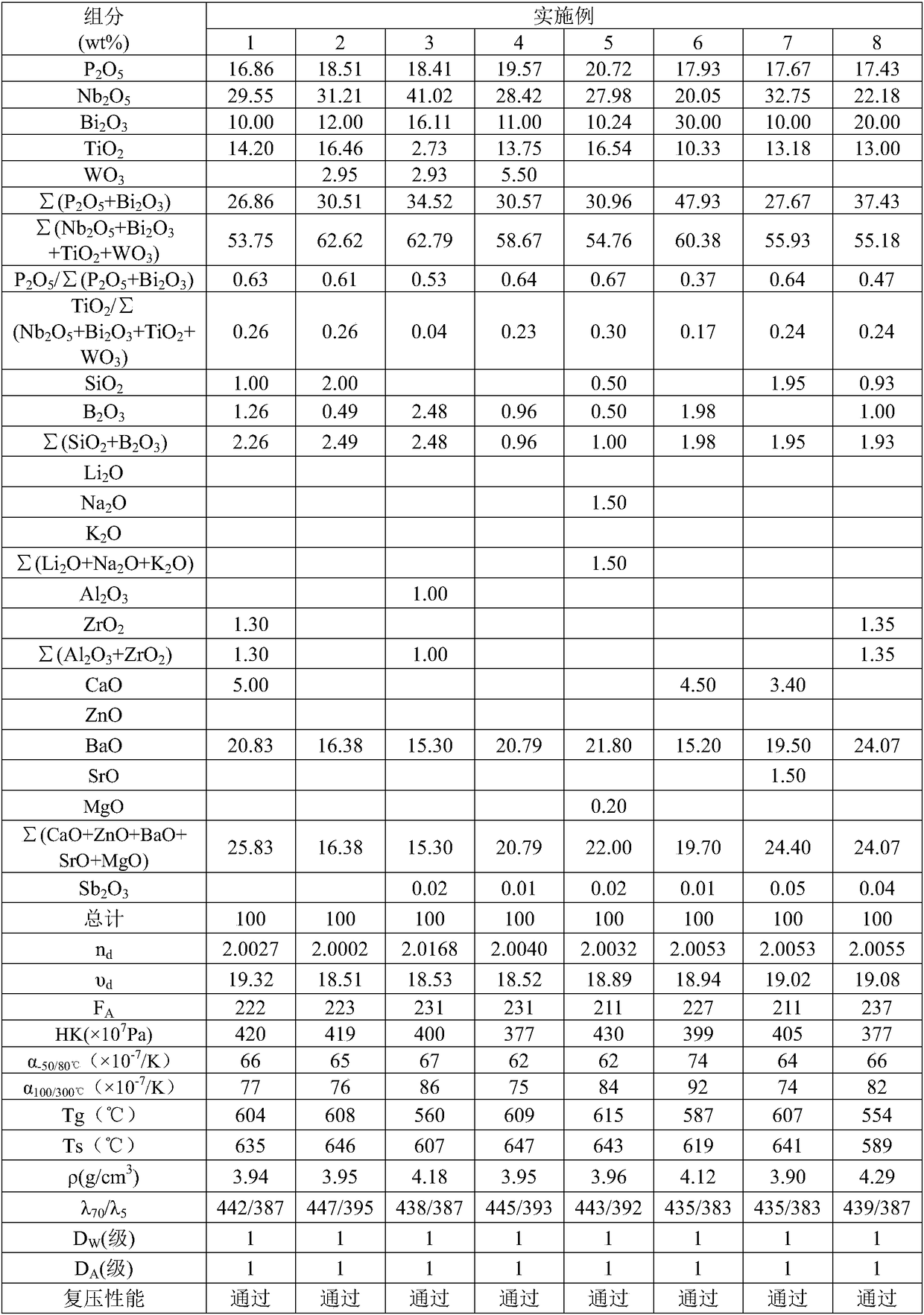

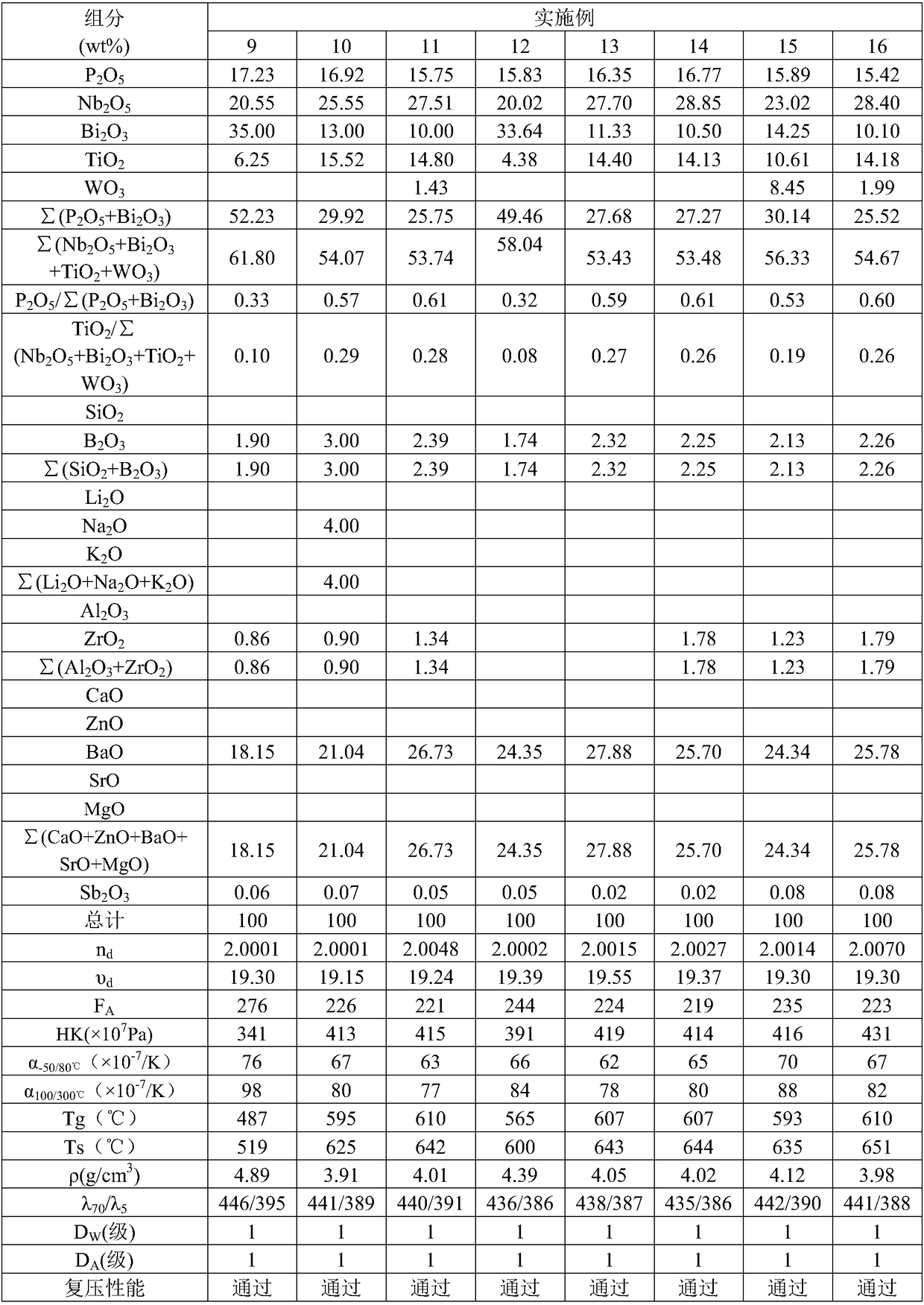

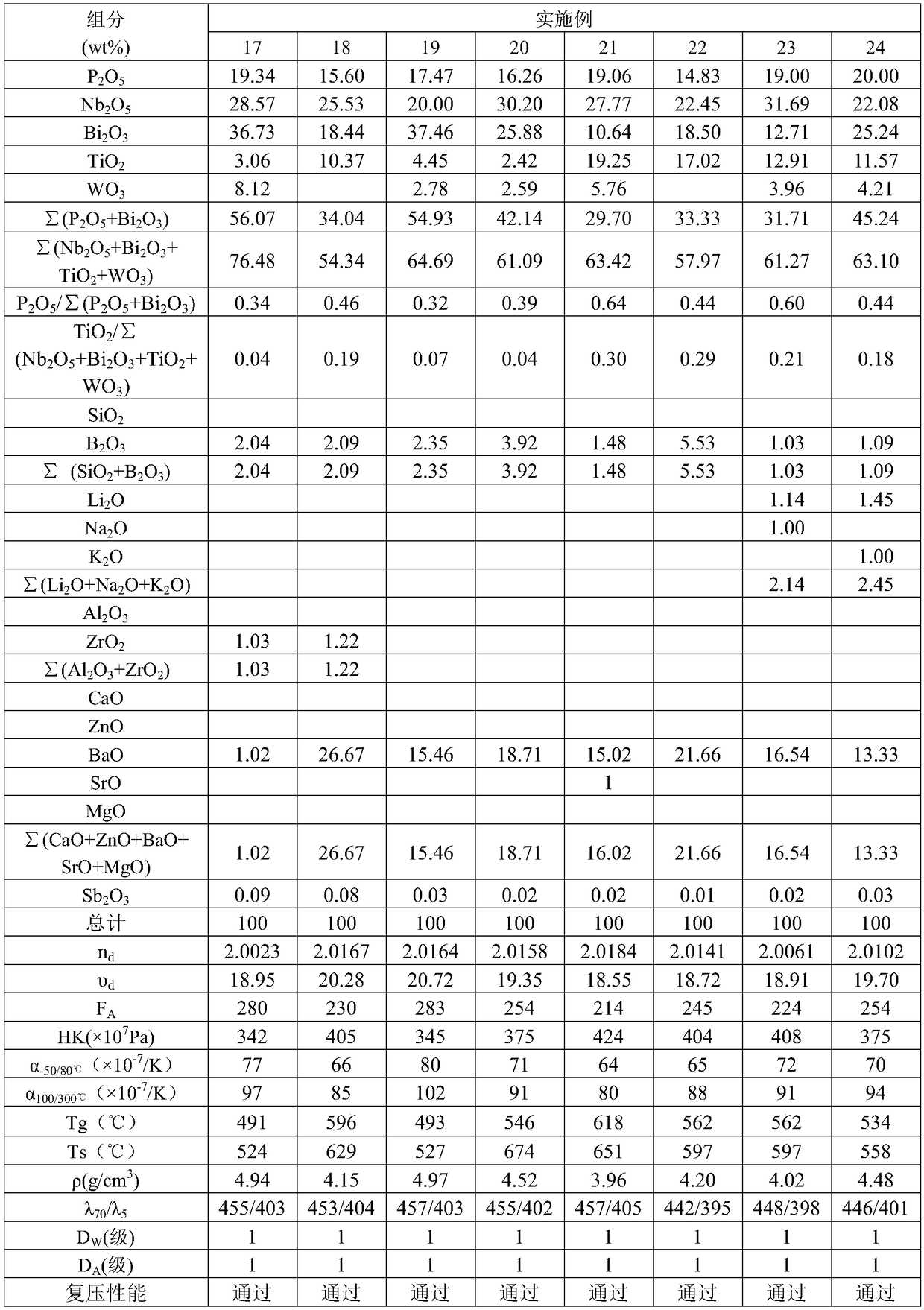

Optical glass and preparation method thereof

ActiveCN108975682AImprove performanceHigh refractive indexGlass pressing apparatusRefractive indexMiniaturization

The invention relates to optical glass and a preparation method thereof. The optical glass is prepared from the following components in percentage by weight: 10-21% of P2O5, 10-50% of Bi2O3, 0-50% ofNb2O5, 0-20% of TiO2, 0-12% of WO3, 0-6% of SiO2, 0-6% of B2O3, 0 -6% of Li2O, 0-4% of Na2O, 0-6% of K2O, 0-4% of Al2O3, 0-3% of ZrO2, 0-5% of CaO, 0-5% of ZnO, 0-30% of Ba0, 0-2% of MgO, 0-3% of SrOand 0-0.1% of Sb2O3. The optical glass has the advantages of being excellent in performance, high in refractive index, high in dispersion and capable of decreasing the number of lens, prisms and otheroptical elements used in an optical system, and therefore the requirements of light weight and miniaturization of the overall optical system are met.

Owner:HUBEI NEW HUAGUANG NEW INFORMATION MATERIALS CO LTD

Glass and glass substrate

ActiveUS20150315065A1High strain pointSatisfactory chemical resistanceDevitrificationYoung's modulus

Devised are a glass and glass substrate, which contain an alkaline component at a low content, are low in density and thermal expansion coefficient, are high in strain point and Young's modulus, and are excellent in devitrification resistance, meltability, formability, and the like. That is, the glass of the present invention includes as a glass composition, in terms of mass %, 58 to 70% of SiO2, 16 to 25% of Al2O3, 3 to 8% of B2O3, 0 to 5% of MgO, 3 to 13% of CaO, 0 to 6% of SrO, 0 to 6% of BaO, 0 to 5% of ZnO, 0 to 5% of ZrO2, 0 to 5% of TiO2, and 0 to 5% of P2O5.

Owner:NIPPON ELECTRIC GLASS CO LTD

Optical glass, glass preform, optical element and optical instrument

PendingCN110204196AWith negative anomalous dispersionExcellent devitrification resistanceOptical elementsDevitrificationOptical instrument

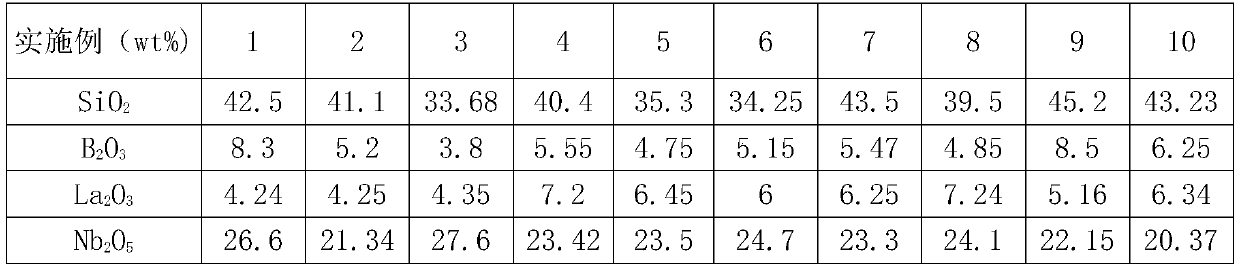

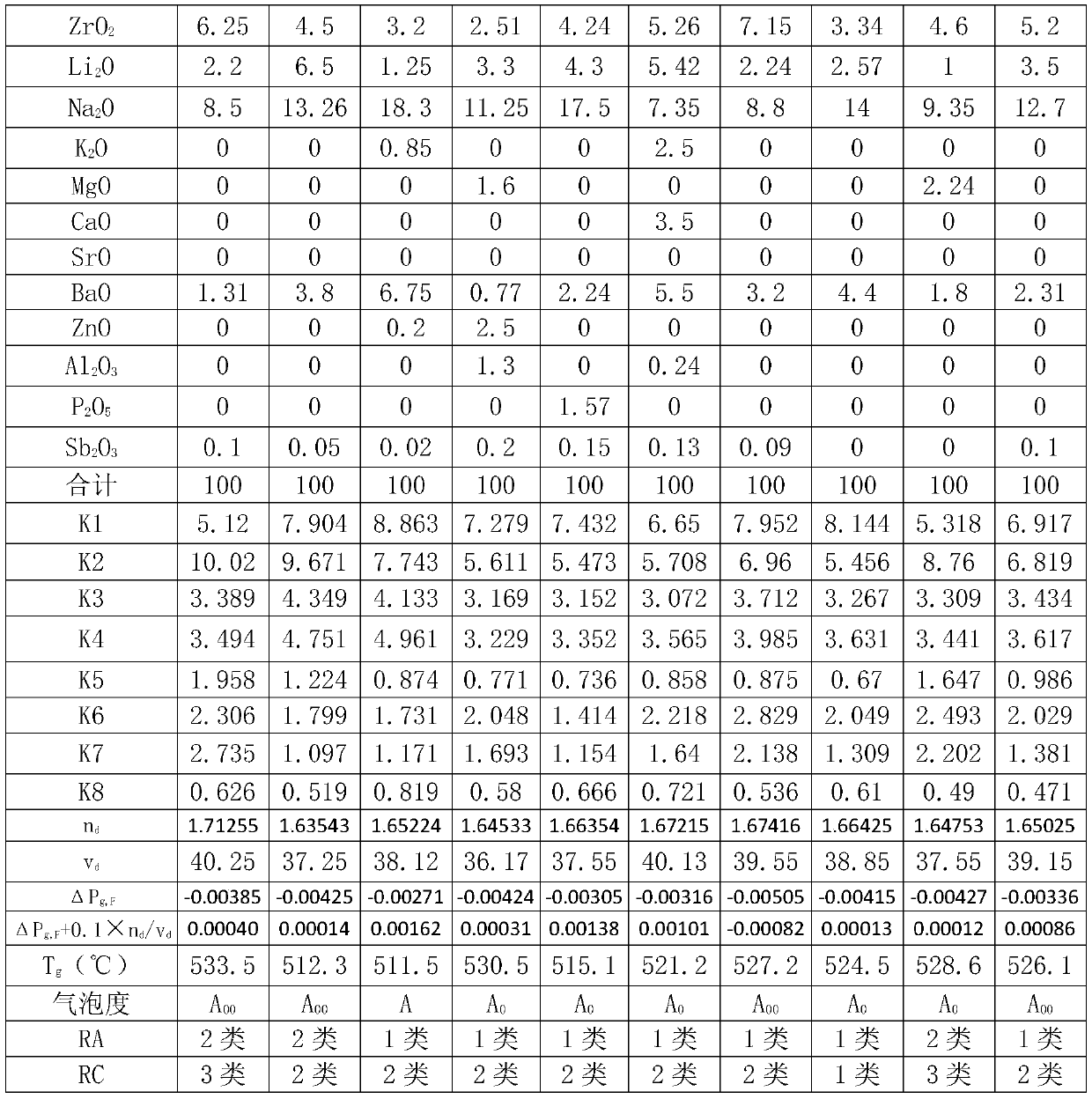

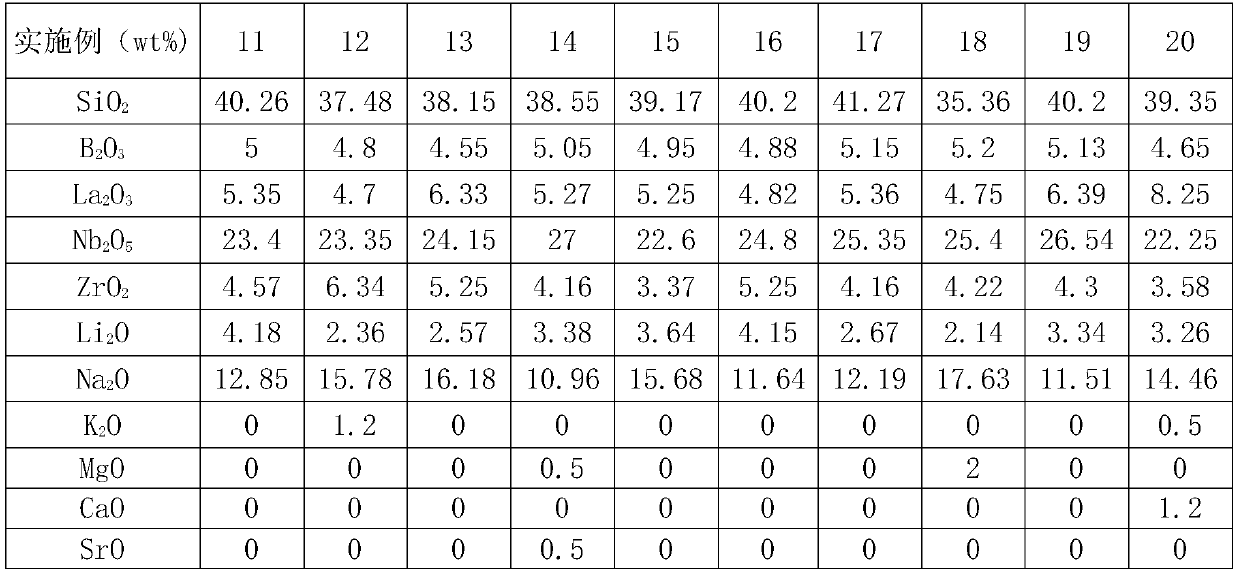

The invention provides an optical glass. The optical glass comprises 32-49 wt% of SiO2, 2-12 wt% of B2O3, 2-12 wt% of La2O3, 20-28 wt% of Nb2O5, 1-8 wt% of ZrO2, 0.5-7 wt% of BaO, 0.5-8 wt% of Li2O and 5-20 wt% of Na2O, wherein a ratio of SiO2 / B2O3 is 9.0 or less, a ratio of SiO2 / La2O3 is 4.0-12.0, a ratio of B2O3 / La2O3 is 0.5-2.0, a ratio of (BaO+SiO2) / (Li2O+Na2O+B2O3) is 1.0-3.0, and a ratio ofNb2O5 / SiO2 is 0.3-1.5. The optical glass obtained by the reasonable component proportioning has the advantages of negative anomalous dispersion and excellent devitrification resistance.

Owner:CDGM OPTICAL GLASS

Alkali-free glass and alkali-free glass substrate

ActiveUS8455378B2Excellent devitrification resistanceImprove meltabilityNon-linear opticsAlkali freeAlkali metal oxide

An alkali-free glass characterized by having a glass composition being substantially free of an alkali metal oxide, As2O3 and Sb2O3 and including, in terms of mol %, 55 to 75% of SiO2, 7 to 15% of Al2O3, 7 to 12% of B2O3, 0 to 3% of MgO, 7 to 12% of CaO, 0 to 5% of SrO, 0 to 2% of BaO, 0 to 5% of ZnO and 0.01 to 1% of SnO2 and has a liquidus viscosity of 105.2 dPa·s or higher and a temperature corresponding to a viscosity of 102.5 dPa·s of 1,550° C. or lower.

Owner:NIPPON ELECTRIC GLASS CO LTD

Optical glass

InactiveUS20100304950A1Not require time-consuming operationIncrease production capacityRefractive indexGlass transition point

The present invention relates to an optical glass containing, in terms of mass % on the basis of oxides, B2O3: 10 to 20%, SiO2: 0.5 to 12%, ZnO: 5 to 19%, Ta2O5: 2.5 to 17%, Li2O: 0.2 to 3%, ZrO2: 0.6 to 4.9%, WO3: 1 to 20%, La2O3: 25 to 50%, Gd2O3: 0 to 13%, and Y2O3: 0.2 to 20%, provided that La2O3+Gd2O3+Y2O3 is 35 to 60%, in which the optical glass does not substantially contain Nb2O5, and has a refractive index (nd) of 1.82 to 1.86, an Abbe's number (νd) of 37 to 44 and a glass transition point (Tg) of 630° C. or lower.

Owner:ASAHI GLASS CO LTD

Tempered glass substrate and method of producing the same

ActiveUS20110318572A1High ion exchange capacityExcellent devitrification resistanceRecord information storageLight beam reproducingMetallurgyCompression stress

A tempered glass substrate of the present invention is a tempered glass substrate, which has a compression stress layer on a surface thereof, and has a glass composition comprising, in terms of mass %, 40 to 71% of SiO2, 3 to 21% of Al2O3, 0 to 3.5% of Li2O, 7 to 20% of Na2O, and 0 to 15% of K2O.

Owner:NIPPON ELECTRIC GLASS CO LTD

Tempered glass substrate and method of producing the same

ActiveUS20110318571A1High ion exchange capacityExcellent devitrification resistanceRecord information storageLight beam reproducingMetallurgyCompression stress

A tempered glass substrate of the present invention is a tempered glass substrate, which has a compression stress layer on a surface thereof, and has a glass composition comprising, in terms of mass %, 40 to 71% of SiO2, 3 to 21% of Al2O3, 0 to 3.5% of Li2O, 7 to 20% of Na2O, and 0 to 15% of K2O.

Owner:NIPPON ELECTRIC GLASS CO LTD

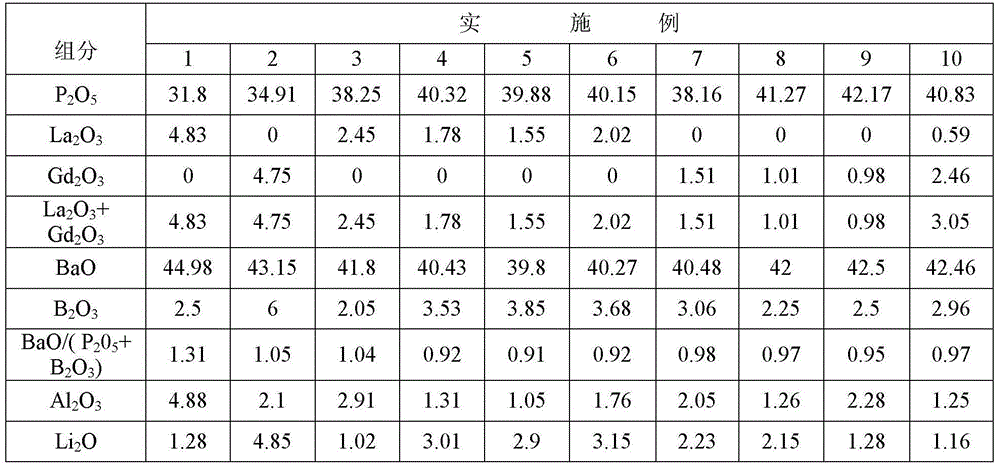

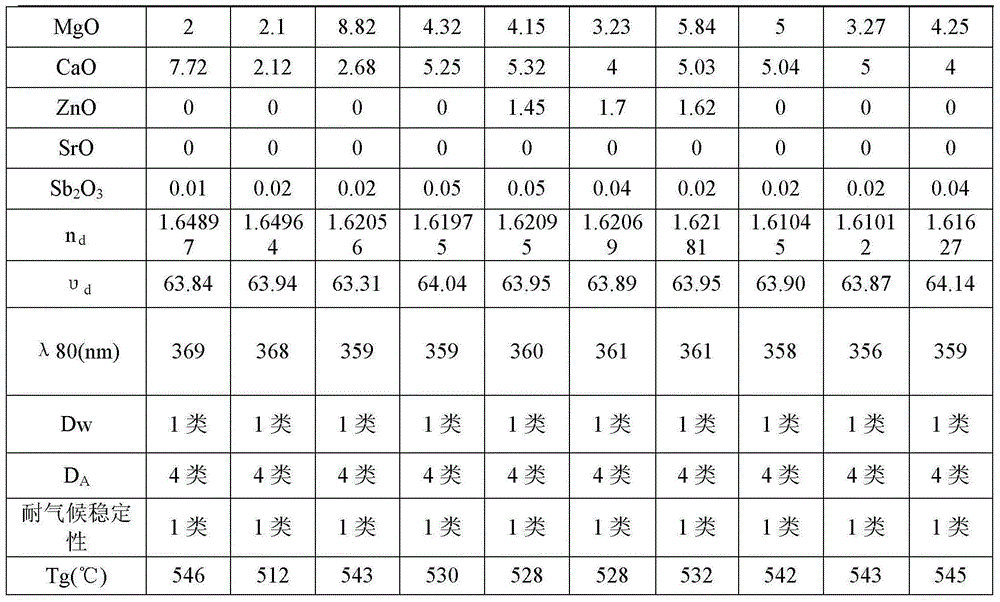

Optical glass and optical element

An optical glass having a low transition temperature, high transmissivity, and good chemical stability and devitrification resistance, the refractive index of the optical glass being 1.60-1.65, and the Abbe number thereof being 62-66; the optical glass comprises the following components by weight percentage: P2O5: 30%-50%, BaO: 35%-50%, B2O3: 2%-6%, La2O3: 0%-5%, Gd2O3: 0%-5%, Al2O3: 0.1%-5%, Li2O: 0.1%-5%, MgO: 2%-10%, and CaO: 2%-10%. The present invention utilizes P2O5 as the network former of the glass, increasing the transmissivity of the glass; in addition, a large amount of BaO is an important ingredient for improving the transmissivity of the glass, while also increasing the refractive index of the glass, and improving the weathering stability of the glass.

Owner:CDGM OPTICAL GLASS

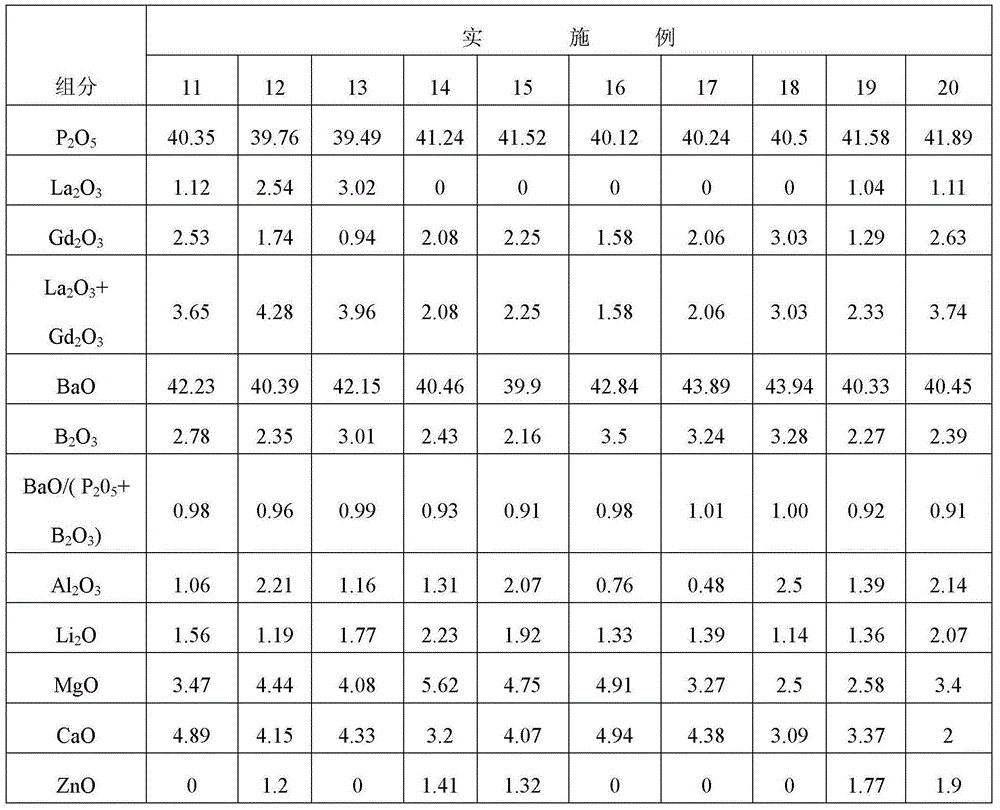

High-refraction high-dispersion optical glass

ActiveCN110342814ASmall coefficient of thermal expansionExcellent devitrification resistanceOptical elementsDevitrificationRefractive index

The invention provides high-refraction and high-dispersion optical glass. The optical glass comprises the following components in percentage by weight: 25-40% of SiO2, 20-38% of TiO2, 3-20% of Na2O, 3-20% of BaO and 5-20% of Nb2O5, wherein the ratio of SiO2 / (BaO+Nb2O5) is 0.75-3.0. Through reasonable component design and proportion, the optical glass provided by the invention has a low thermal expansion coefficient and excellent devitrification resistance and meets the requirements of the photoelectric field while meeting the expected refractive index and Abbe number.

Owner:CDGM OPTICAL GLASS

Optical glass

InactiveCN1187277CExcellent devitrification resistanceStable mass productionOptical elementsDevitrificationRefractive index

There is provided an optical glass suitable for precision mold pressing having optical constants of a refractive index (nd) within a range from 1.75 to 1.85 and an Abbe number ( nu d) within a range from 35 to 45, comprising in mass % on oxide basis: having a transition point (Tg) within a range from 500 DEG C to 590 DEG C and a yield point (At) within a range from 530 DEG C to 630 DEG C, and being free from devitrification in a devitrification test conducted under a condition of 950 DEG C / 2 hours.

Owner:OHARA

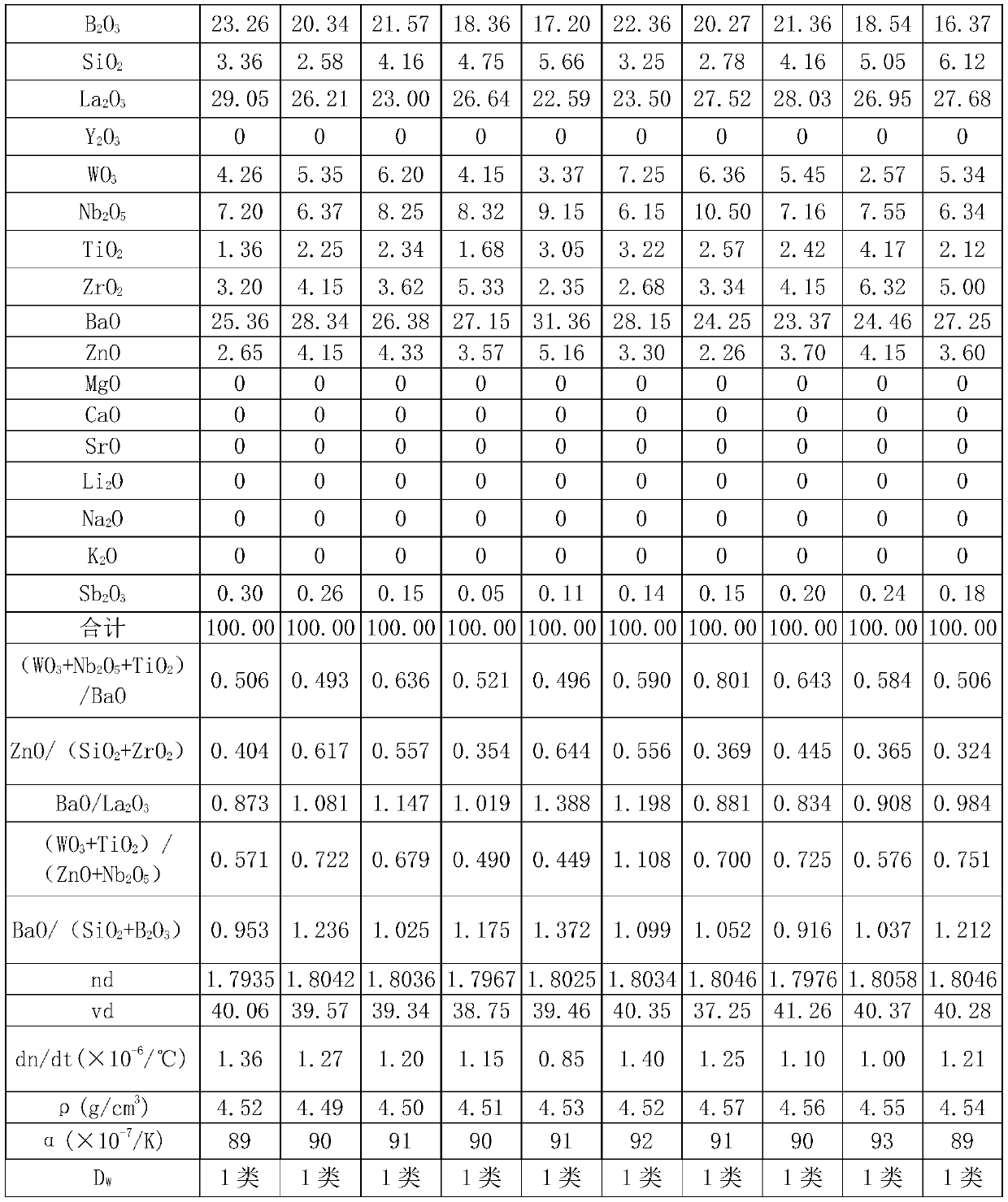

Optical glass

PendingCN110590154AExcellent devitrification resistanceOptical elementsDevitrificationAdditive ingredient

The invention provides optical glass. The optical glass contains the ingredients in percentage by weight: 10%-30% of B2O3, 0%-10% of SiO2, 20%-40% of La2O3, 1%-10% of WO3, 3%-15% of Nb2O5, 0%-8% of TiO2, 16%-35% of BaO, more than 0% but less than or equal to 10% of ZrO2 and more than 0% but less than or equal to 9.5% of ZnO, and is free of Gd2O3. Through reasonable ingredient design, the optical glass provided by the invention with expected index of refraction and Abbe number can be obtained by a relatively low cost; and the optical glass has excellent devitrification resistance.

Owner:CDGM OPTICAL GLASS

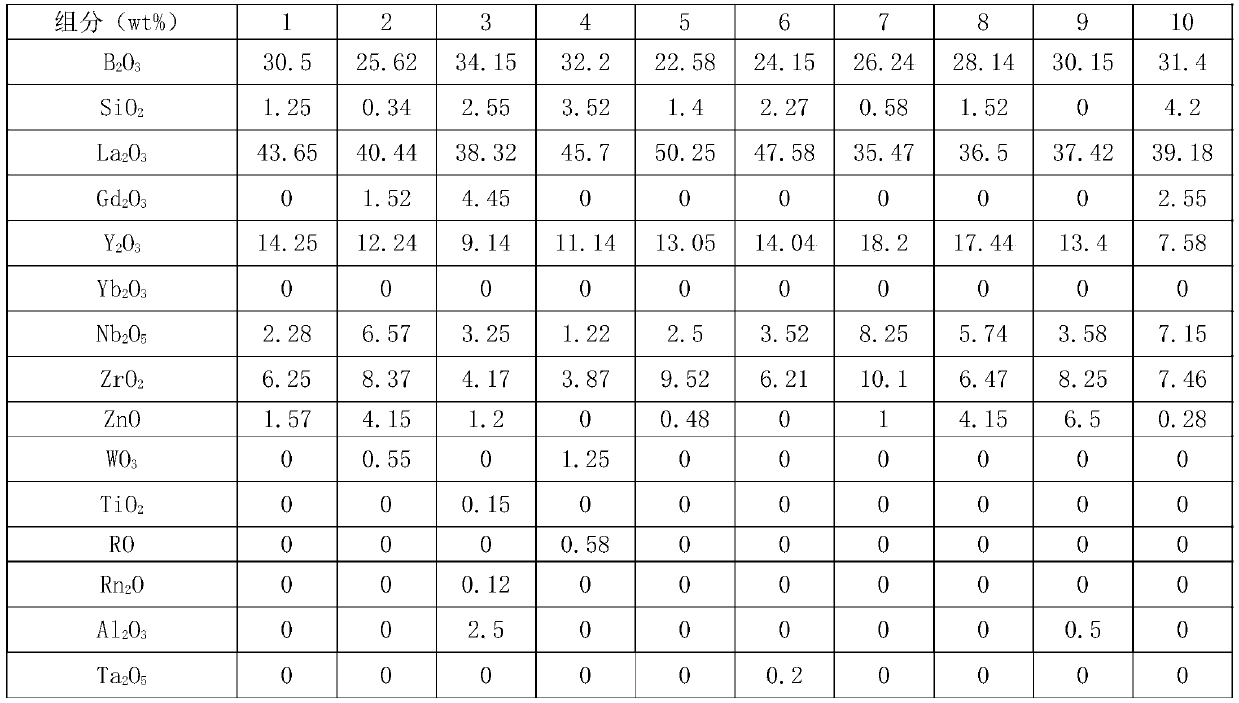

Optical glass, glass prefabricated part, optical element and optical instrument

ActiveCN109775981AHigh refractive indexLow dispersionOptical elementsDevitrificationRefractive index

The invention provides high-refractive-index low-chromatic-dispersion optical glass. The optical glass comprises, by weight, 20-35% of B2O3, 32-52% of La2O3, 6-20% of Y2O3, 0-15% of Gd2O3 and 1-12% ofZrO2, wherein Y2O3 / (Y2O3+Gd2O3) is 0.6-1.0. The Young modulus E of the optical glass is 10000*10<7> or above. Through reasonable component design, the obtained optical glass has high refractive indexand low chromatic dispersion, and is low in production cost, excellent in devitrification resistance and high in Young modulus.

Owner:CDGM OPTICAL GLASS

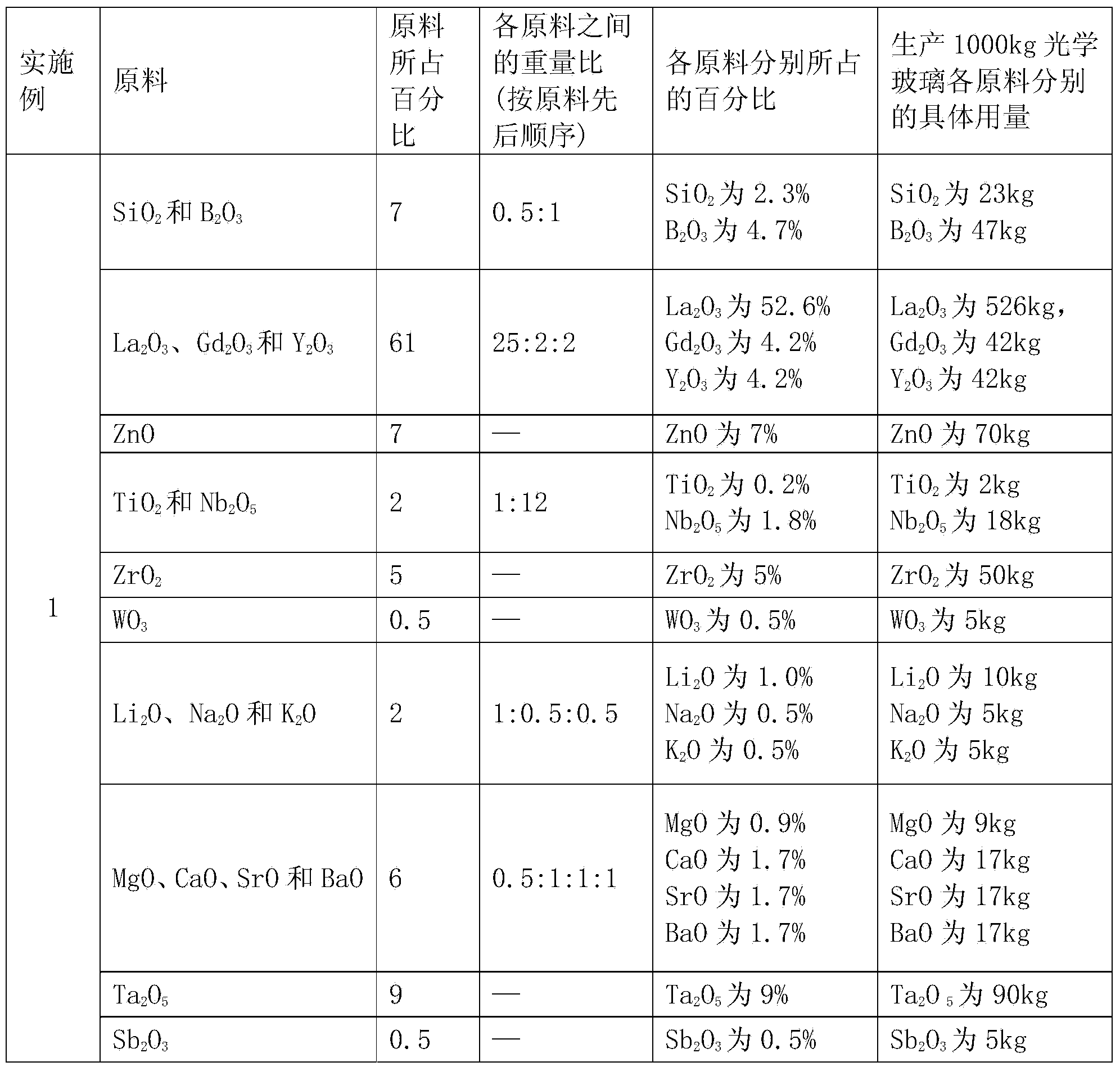

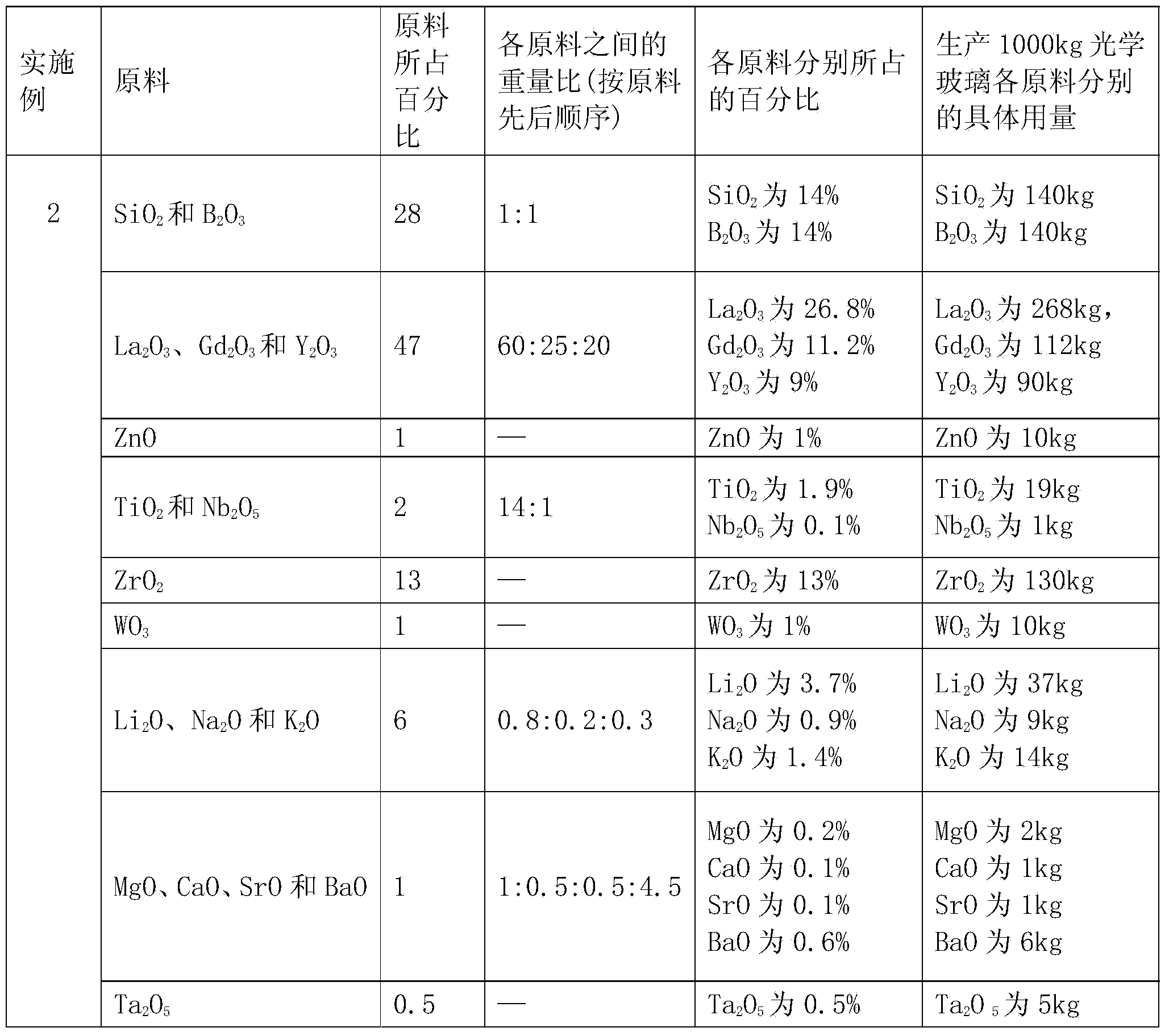

High-refractive-index and low-dispersion optical glass and preparation method thereof

The invention provides high-refractive-index and low-dispersion optical glass. The optical glass consists of the following raw materials in percentage by weight: 5-32 percent of SiO2 and B2O3, 45-65 percent of La2O3, Gd2O3 and Y2O3, 0.5-10 percent of ZnO, 1-20 percent of TiO2 and Nb2O5, 0-15 percent of ZrO2, 0-2 percent of WO3, 0-10 percent of Li2O, Na2O and K2O, 0-10 percent of MgO, CaO, SrO and BaO, 0-12 percent of Ta2O5 and 0-1 percent of Sb2O3. Compared with the prior art, the high-refractive-index and low-dispersion optical glass has the beneficial effects of higher internal color penetration degree, small specific weight, low smelting process temperature, smaller adding amounts of Ta2O5 and Gd2O3 and lowered cost.

Owner:SICHUAN RUITIAN OPTICAL

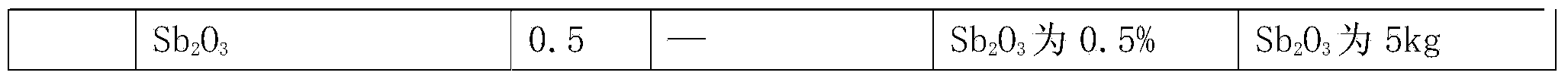

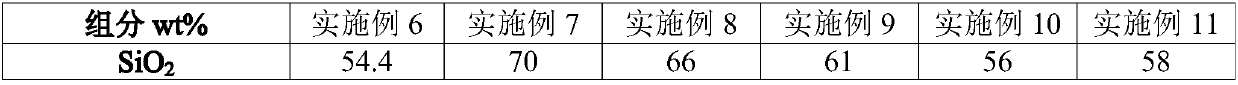

Chemical reinforced glass for electronic device and preparation method thereof

The invention provides chemical reinforced glass for an electronic device and a preparation method thereof. An ideal compression stress layer depth is obtained at relatively low reinforcing temperature and relatively short reinforcing time. The method comprises the following steps: 1) taking raw materials: greater than or equal to 50 percent and less than or equal to 70 percent of SiO2, greater than or equal to 0 percent and less than or equal to 2 percent of B2O3, greater than or equal to 12 percent and less than or equal to 25 percent of Al2O3, greater than or equal to 11 percent and less than or equal to 15 percent of Na2O, greater than or equal to 0 percent and less than or equal to 5 percent of ZnO, greater than or equal to 2 percent and less than or equal to 5 percent of Li2O, greater than or equal to 0 percent and less than or equal to 5 percent of MgO, greater than or equal to 0 percent and less than or equal to 1 percent of ZrO2, greater than or equal to 1 percent and less than or equal to 4 percent of SnO2 and greater than or equal to 0.67 and less than or equal to 0.97 of (Na2O+Li2O) / (Al2O3+ZrO2+MgO); 2) melting and clarifying and carrying out ion change. The surface compressive stress of the reinforced glass is 882.4MPa to 990.5MPa, the surface stress layer depth is 80.5mu m to 96.3mu m, the Vickers hardness is 658kg / mm<2> to 690kg / mm<2> and the strain point temperature is 550.5 DEG C to 572.2 DEG C.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

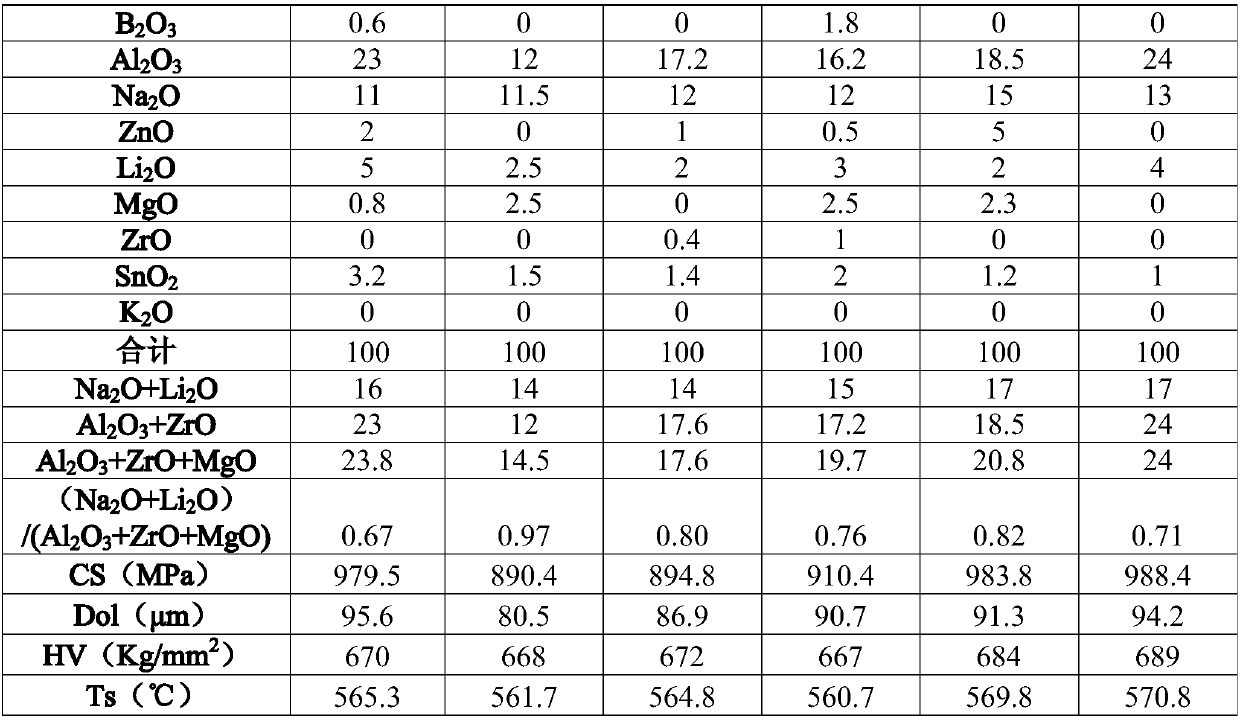

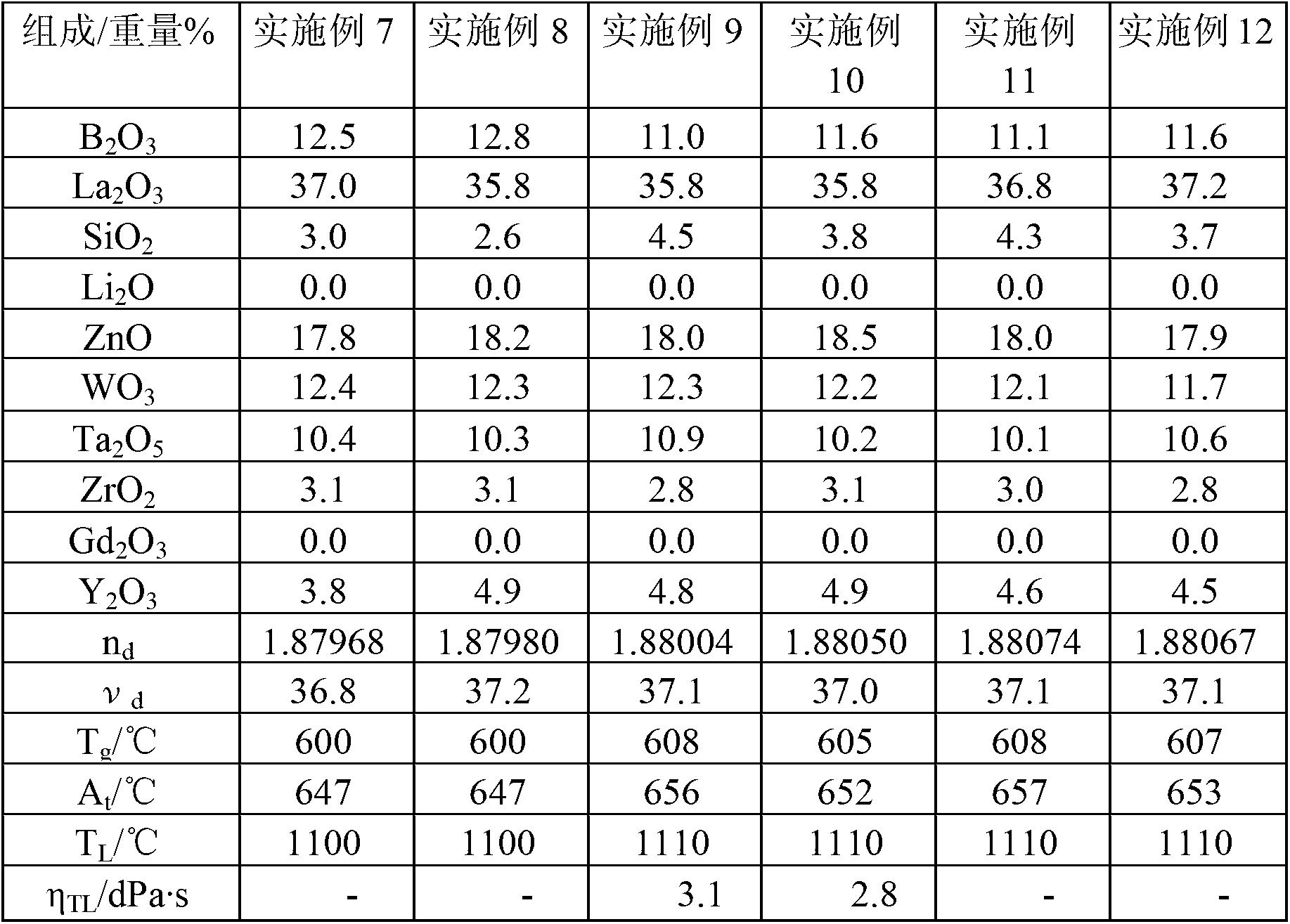

Optical glass, preform for precision press molding and optical element using the same

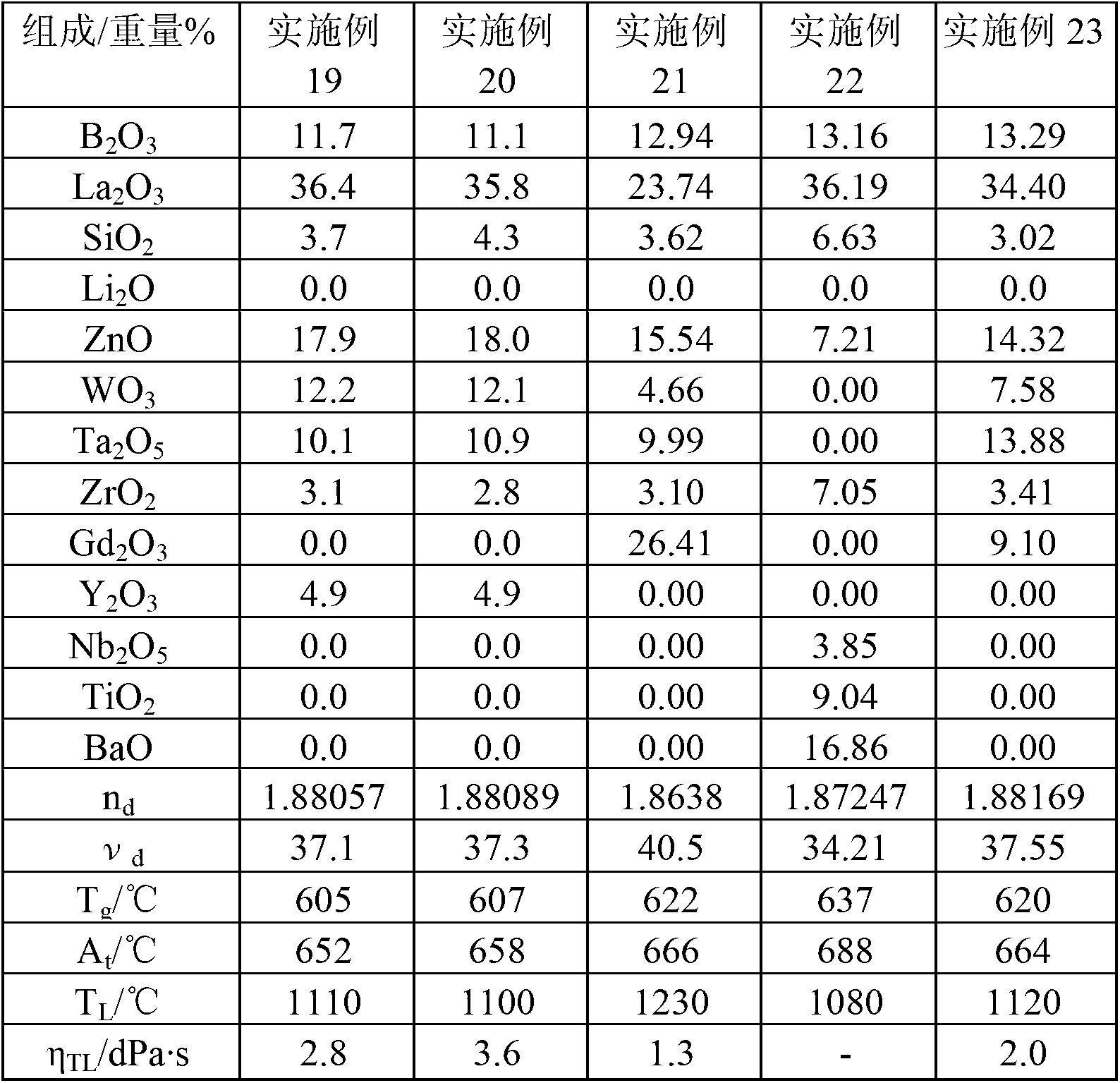

InactiveCN103288344AExcellent devitrification resistanceHigh viscosityOptical elementsRefractive indexOptical glass

The invention relates to an optical glass, a preform for precision press molding and an optical element using the same. The present invention relates to an optical glass containing, in terms of % by weight on the basis of oxides, B2O3: 8 to 15%, La2O3: 27 to 40%, SiO2: 1 to 10%, ZnO: 13 to 20%, WO3: 9 to 17%, Ta2O5: 7 to 15%, ZrO2: 1 to 6%, Y2O3: 2 to 8%, and Bi2O3: 0 to 5%, in which the optical glass contains substantially no Li2O and Gd2O3, and the optical glass has a refractive index nd of 1.86 to 1.90 and an Abbe number vd of 35 to 40.

Owner:ASAHI GLASS CO LTD

Optical glass with abnormal dispersity

InactiveCN1451620AIncreased durabilityGood light transmissionOptical elementsRefractive indexOptical glass

An optical glass having a positive anomalous dispersion comprises, in mass %, is free of PbO and As2O3 except for unavoidable mixing of these compounds as impurities, has optical constants of a refractive index (nd) within the range from 1.48 to less than 1.55 and an Abbe number ( nu d) within the range from 45 to 55, and has an anomalous dispersion ( DELTA &thetas; g,F) of + 0.0010 or over.

Owner:OHARA

Glass

ActiveUS20160368815A1Improve melting effectPrevent melt defectSolid-state devicesPhotovoltaic energy generationAnalytical chemistryLiquidus

A glass composition SiO2, Al2O3, B2O3, and RO, where RO represents one kind or two or more kinds selected from MgO, CaO, SrO, and BaO, and allows two or more kinds of crystals selected from a SiO2—Al2O3—RO-based crystal, a SiO2-based crystal, and a SiO2—Al2O3-based crystal to precipitate in a temperature range of from a liquidus line temperature to (the liquidus line temperature—50° C.)

Owner:NIPPON ELECTRIC GLASS CO LTD

Optical glass, optical glass blank, glass material for press molding, optical element, and methods for producing them

ActiveUS20150368151A1High refractive indexHigh dispersionGlass pressing apparatusGlass reforming apparatusOxideRefractive index

An aspect of the present invention relates to optical glass, wherein, in a glass composition based on oxides, a content of P2O5 is in the range of 20˜34 weight %; a content of B2O3 is over 0 weight % but 10 weight % or less; a weight ratio (B2O3 / P2O5) is over 0 but less than 0.39; a weight ratio [TiO2 / (TiO2+Nb2O5+WO3+Bi2O3+Ta2O5)] is in the range of 0.059˜0.180; and a weight ratio [(P2O5+B2O3+SiO2) / (Na2O+K2O+Li2O)] is in the range of 1.39˜1.80, the optical glass having a refractive index nd of 1.78˜1.83, and an Abbe's number vd of 20˜25.

Owner:HOYA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com