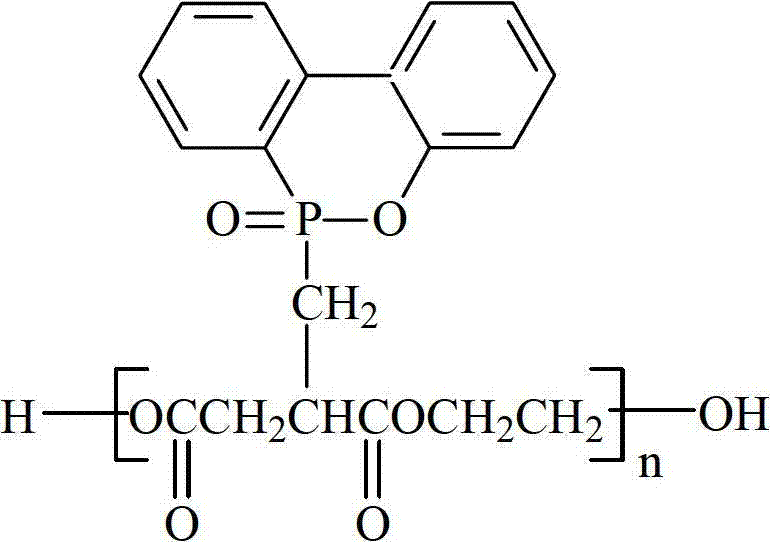

Additive type phosphorus phenanthrene oxa-flame retardant and preparation method thereof

An additive type, flame retardant technology, applied in the field of flame retardants, can solve problems such as narrow application scope, and achieve the effects of reducing production costs, simple operation process and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

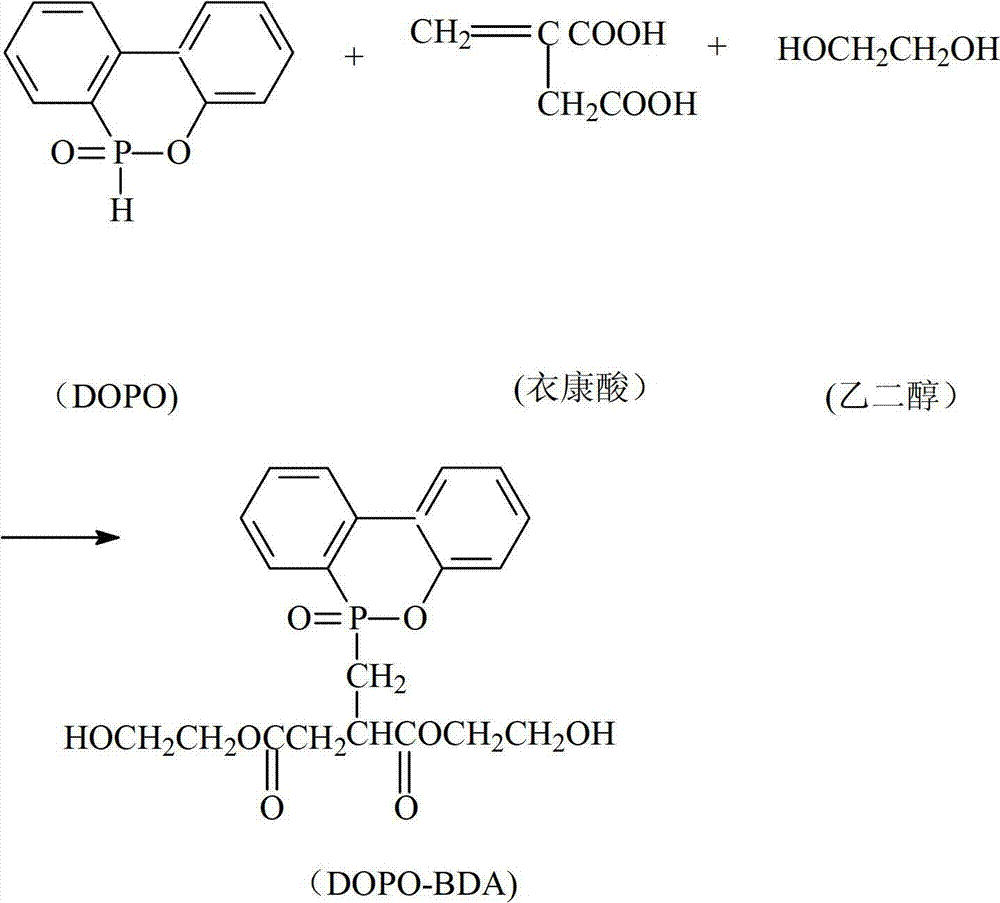

[0037] (1) Mix 0.4mol DOPO, 0.4mol itaconic acid and 0.42mol ethylene glycol into the reaction kettle, heat up to 120°C and dissolve. After the dissolution is complete, the transparent solution is stirred evenly, and then distilled under normal pressure at 180°C for 4 hours ~8h, remove the water generated in the reaction;

[0038] (2) Add 0.02mol butyl titanate as a catalyst to the solution of step (1) at one time, distill in a semi-vacuum at 210°C and a vacuum of -0.04MPa for 2 hours, and distill out the residue in the solution of step (1) water;

[0039] (3) Distill the solution of step (2) at 240°C and a vacuum degree of -0.095MPa for 4 hours in full vacuum to polymerize the monomer intermediate of the product, and obtain the product after the polymerization is completed;

[0040] After the reaction is completed, release the product while it is hot, make it solidify, slice the product and pack it.

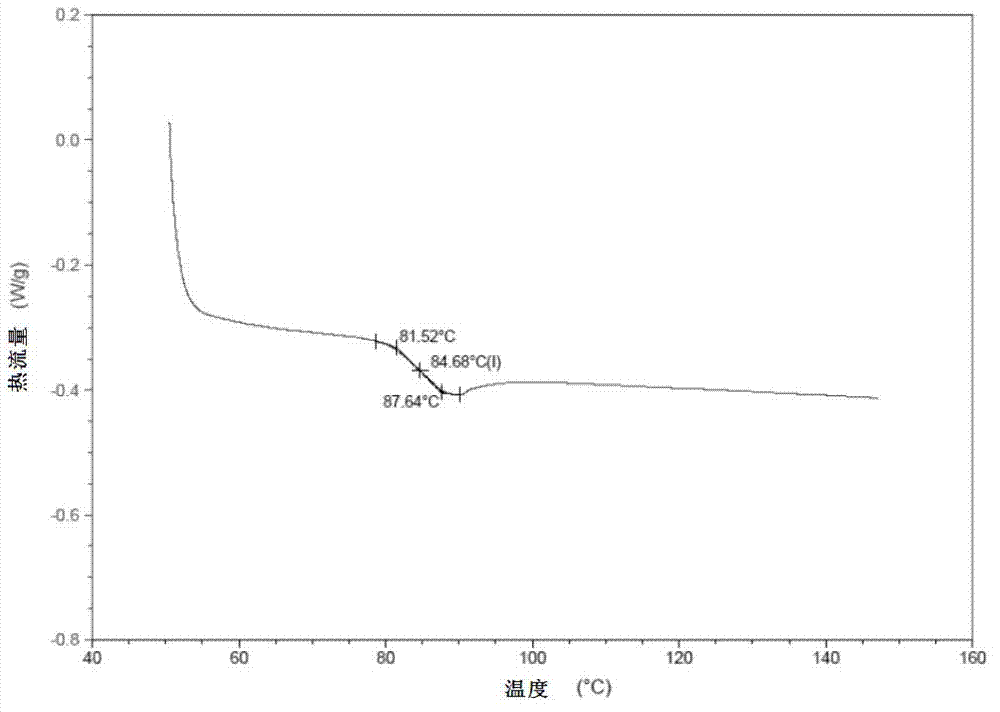

[0041] The DOPO derivatives prepared by the present invention have techni...

Embodiment 2

[0044] (1) Mix 0.4mol DOPO, 0.4mol itaconic acid and 0.6mol ethylene glycol into the reaction kettle, heat up to 160°C and dissolve. After the dissolution is complete, the transparent solution is stirred evenly, and then reflux distillation at 220°C for 8 hours , to remove the water generated in the reaction;

[0045] (2) Use 0.4 mol of antimony trioxide and butyl titanate mixture as a catalyst, add it to the solution of step (1) at one time, distill in a semi-vacuum at 230°C and a vacuum of -0.05MPa for 3 hours, and distill out the step ( 1) residual water in the solution;

[0046] (3) Distill the solution of step (2) under full vacuum at 280°C and vacuum degree of -0.096MPa for 12 hours to polymerize the monomer intermediate of the product, and obtain the product after the polymerization is completed;

[0047] After the reaction is completed, release the product while it is hot, make it solidify, slice the product and pack it.

[0048] The DOPO derivatives prepared by the ...

Embodiment 3

[0051] (1) Mix 0.4mol DOPO, 0.4mol itaconic acid and 0.44mol ethylene glycol into the reaction kettle, heat up to 140°C to dissolve, and stir to obtain a transparent solution after complete dissolution, then distill at 200°C under normal pressure for 5 hours , to remove the water generated in the reaction;

[0052] (2) Use 0.3mol triethylbenzyl ammonium chloride as a catalyst, add it to the solution of step (1) at one time, distill in a semi-vacuum at 220°C and a vacuum of -0.045MPa for 2h to 3h, and distill out the step ( 1) residual water in the solution;

[0053] (3) Fully vacuum distill the solution of step (2) at 260°C and a vacuum of -0.096MPa for 8 hours to polymerize the monomer intermediate of the product, and obtain the product after the polymerization is completed;

[0054] After the reaction is completed, release the product while it is hot, make it solidify, slice the product and pack it.

[0055] The DOPO derivatives prepared by the present invention have technic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com