Flame-retardant anti-aging ABS and preparation thereof

An anti-aging and flame retardant technology, applied in the field of acrylonitrile-butadiene-styrene copolymer composition, can solve the problems of restricting the use of flame retardant ABS, yellowing, etc., and achieves improved processing temperature, stable performance, Reduce the effect of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

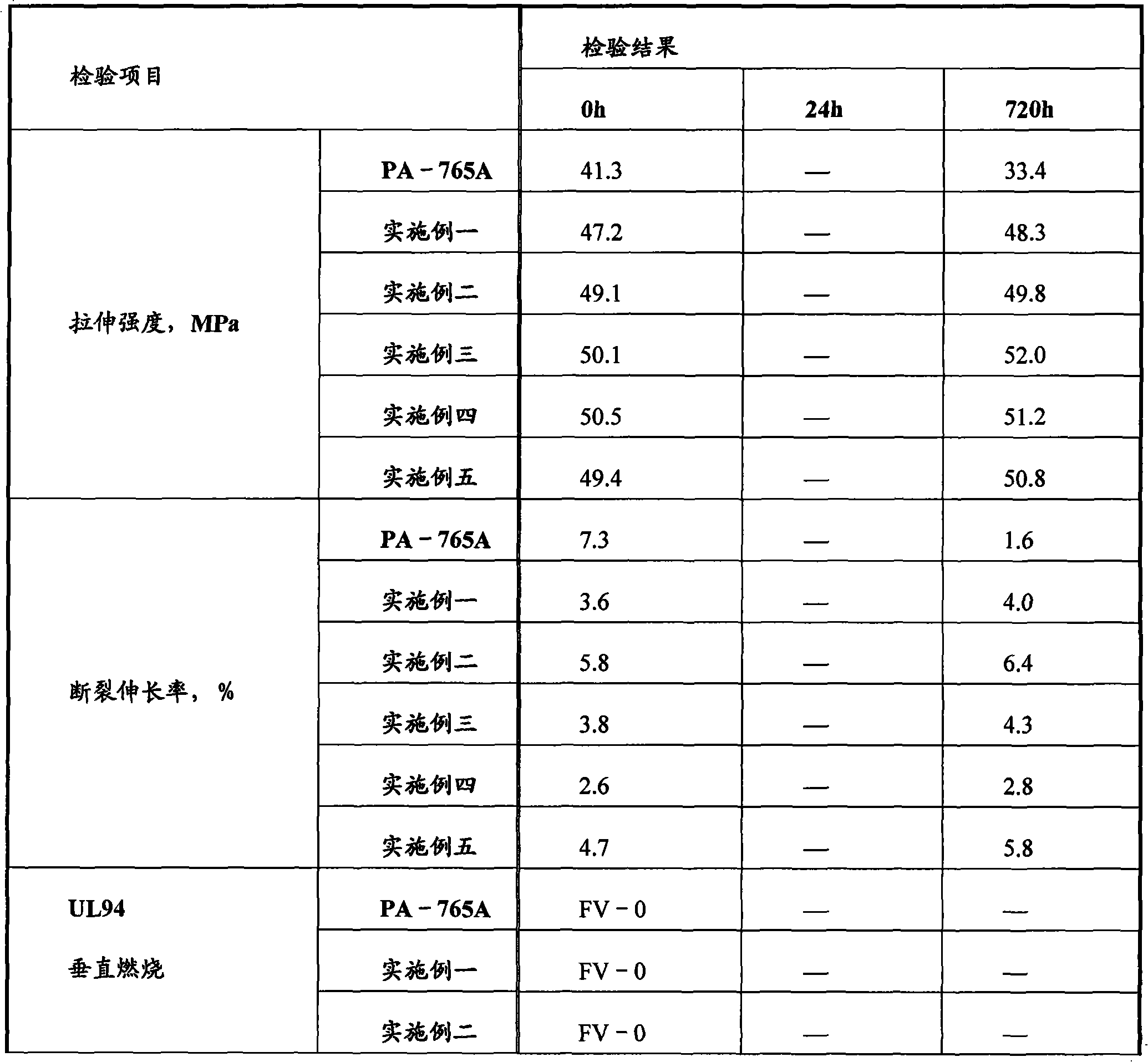

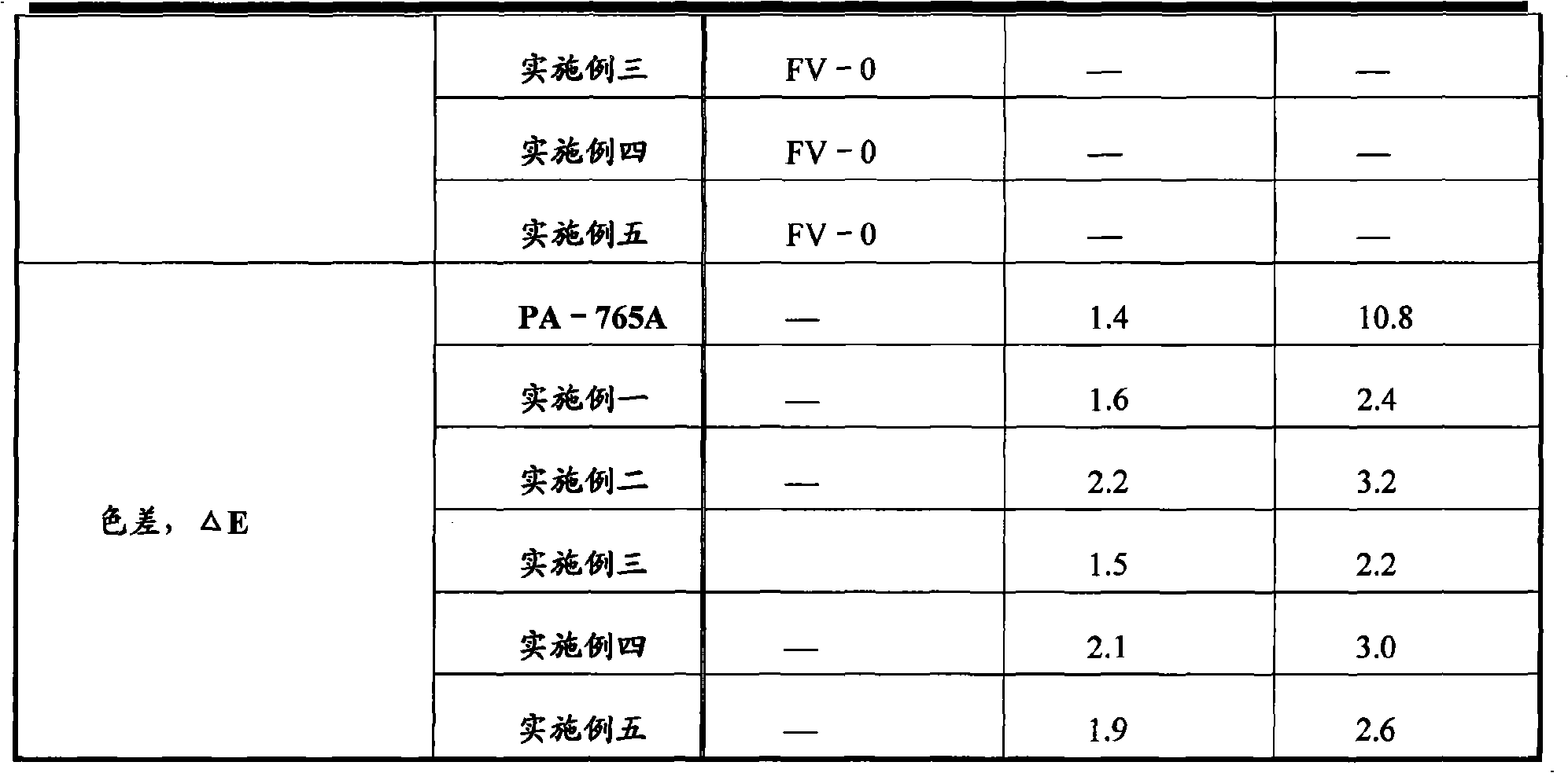

Examples

Embodiment 1

[0052] (1) 20kg of weather-resistant and environmentally friendly low-bromine flame retardant FR-245, 60kg of water, and 3kg of dispersant were added to the reactor, and emulsified and dispersed at high shear for 90min to obtain a flame retardant suspension. Next, adjust the pH value of the flame retardant suspension and 1 kg of melamine-formaldehyde prepolymer to 5 with 5% dilute hydrochloric acid, and then heat the mixed solution to 70° C. for 3 hours. The reacted product was washed with water, filtered, and vacuum-dried to obtain about 21 kg of microencapsulated environmental protection flame retardant.

[0053] (2) After mixing 70kg ABS and 0.4kg coupling agent KH550, stir on a high-speed mixer for 2min, then add 0.3kg antioxidant 168, 0.3kg antioxidant 1076, 0.5kg light stabilizer 327, 0.5kg light stabilizer in turn 770, 1kg of calcium stearate, and 2kg of titanium dioxide were mixed evenly, and finally 20kg of microencapsulated environmental protection flame retardant an...

Embodiment 2

[0056](1) 20kg of weather-resistant and environmentally friendly low-bromine flame retardant FR-245, 60kg of water, and 3kg of dispersant were added to the reactor, and emulsified and dispersed at high shear for 90min to obtain a flame retardant suspension. Next, adjust the pH value of the flame retardant suspension and 1 kg of melamine-formaldehyde prepolymer to 5 with 5% dilute hydrochloric acid, and then heat the mixed solution to 70° C. for 3 hours. The reacted product was washed with water, filtered, and vacuum-dried to obtain about 21 kg of microencapsulated environmental protection flame retardant.

[0057] (2) After mixing 75kg ABS and 0.4kg coupling agent KH550, stir on a high-speed mixer for 2min, then add 0.2kg antioxidant 168, 0.2kg antioxidant 1076, 0.3kg light stabilizer 327, 0.3kg light stabilizer in turn 770, 1kg of calcium stearate, and 1kg of titanium dioxide were mixed uniformly, and finally 18kg of microencapsulated environmental protection flame retardant ...

Embodiment 3

[0060] (1) 20kg of weather-resistant and environmentally friendly low-bromine flame retardant FR-245, 60kg of water, and 4kg of dispersant were added to the reactor, and emulsified and dispersed at high shear for 70min to obtain a flame retardant suspension. Next, adjust the pH of the flame retardant suspension and 1.5 kg of melamine-formaldehyde prepolymer to 6 with 5% dilute hydrochloric acid, and then heat the mixed solution to 80° C. and hold for 2.5 hours. The reacted product was washed with water, filtered, and vacuum-dried to obtain about 21.5 kg of microencapsulated environmental protection flame retardant.

[0061] (2) After mixing 72kg ABS and 0.4kg coupling agent KH550, stir on a high-speed mixer for 2min, then add 0.3kg antioxidant 168, 0.3kg antioxidant 1076, 0.5kg light stabilizer 327, 0.5kg light stabilizer in turn 770, 1kg of calcium stearate, and 1kg of titanium dioxide were mixed uniformly, and finally 20kg of microencapsulated environmental protection flame ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com